Preparation method for power NCM523 material capable of improving high-and-low-temperature performance

A high-low temperature, high-performance technology, applied in the field of power NCM523 material preparation, can solve the high-temperature cycle performance of nickel-cobalt-lithium manganese oxide, poor high-temperature storage performance, no description of the improvement of the low-temperature performance of the material, and failure to achieve the high-low temperature performance of the material, etc. , to achieve excellent high and low temperature performance, improve the surface condition, and achieve the effect of large market promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

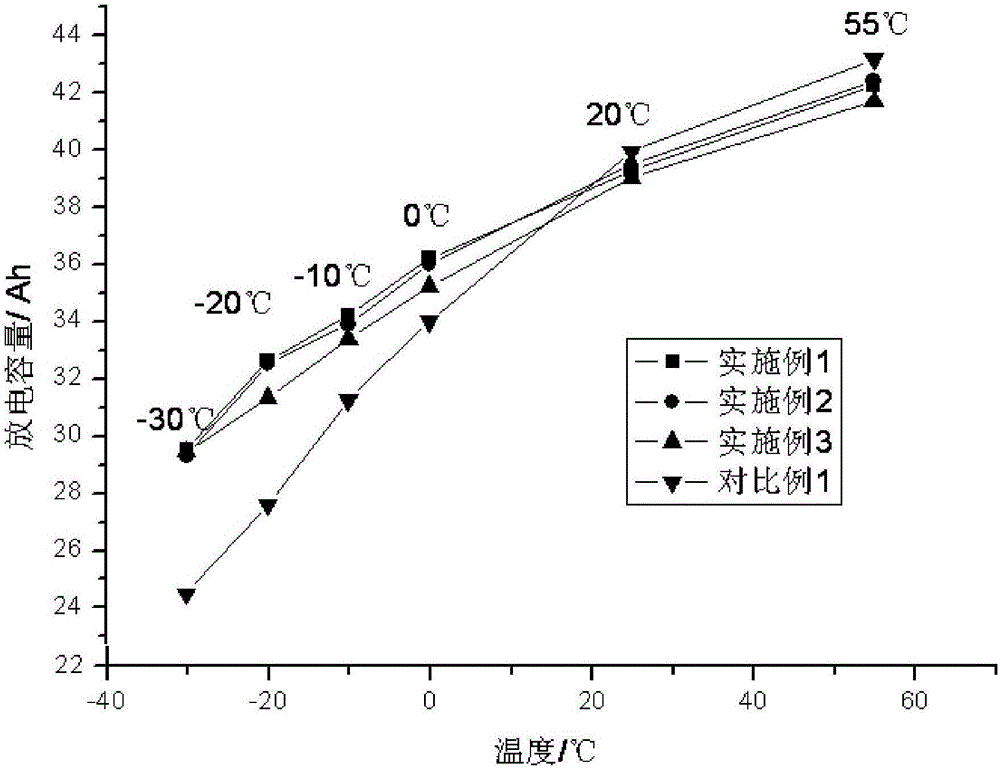

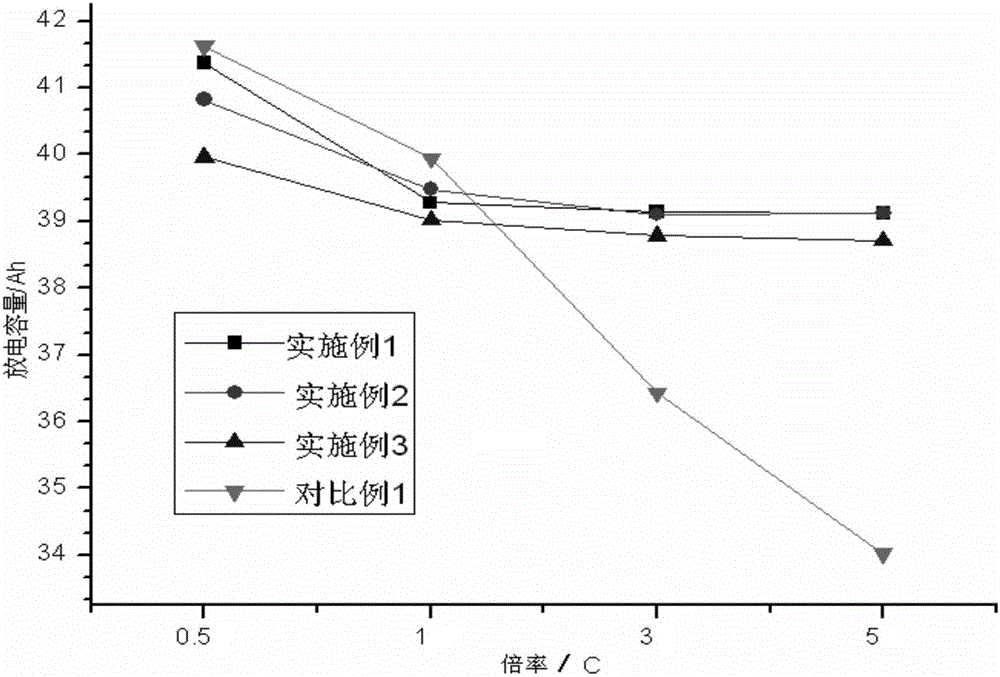

Embodiment 1

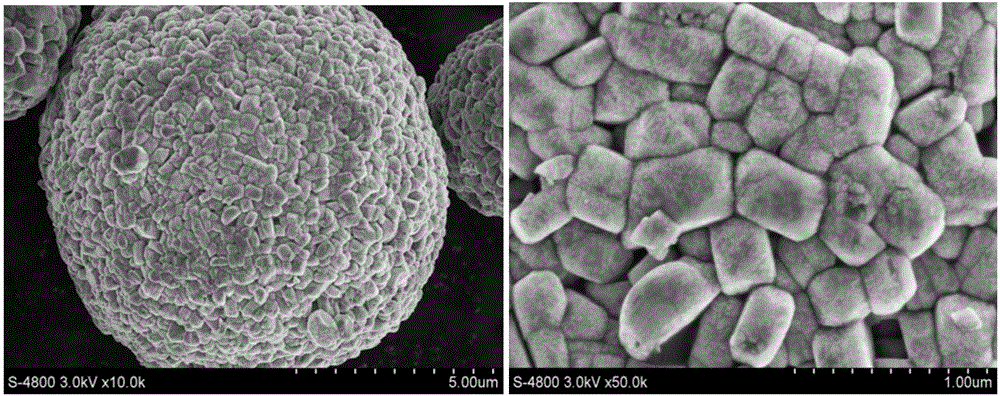

[0046] A preparation method of power NCM523 material with improved high and low temperature performance, using LiNi 0.5 co 0.2 mn 0.25 AL 0.03 Y 0.02 o 2 The preparation of is an example, including the following preparation process:

[0047] Step 1: β-Ni 0..5 co 0.2 mn 0.25 AL 0.03 Y 0.02 (OH) 2 preparation of

[0048] (1) Prepare the solution

[0049] Weigh NiSO according to the ratio of stoichiometric ratio 0.5:0.2:0.25:0.02 (Ni:Co:Mn:Y) 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, Y (NO 3 ) 3 ·6H 2 O, prepared into a sulfate solution containing Y, the total metal ion molar content is 1.94mol / L, which is recorded as solution a; NaOH was weighed, prepared into a 10mol / L alkali solution, and then added to the alkali solution in accordance with the chemical dosage ratio Al(NO 3 ) 3 9H 2 O, where Al:OH=0.03 (molar ratio), stir evenly to form NaAlO 2 After cooling down to below 35°C, add a certain volume of ammonia water and mix evenly. The molar ratio of am...

Embodiment 2

[0067] A preparation method of power NCM523 material with improved high and low temperature performance, using LiNi 0.5 co 0.2 mn 0.25 AL 0.04 Y 0.01 o 2 The preparation of is an example, including the following preparation process:

[0068] Step 1: β-Ni 0..5 co 0.2 mn 0.25 AL 0.03 Y 0.02 (OH) 2 preparation of

[0069] (1) Prepare the solution

[0070] Weigh NiSO according to the ratio of stoichiometric ratio 0.5:0.2:0.25:0.01 (Ni:Co:Mn:Y) 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, Y (NO 3 ) 3 ·6H 2 O, prepared into a sulfate solution containing Y, the total molar content of metal ions is 1.92mol / L, which is recorded as solution a; NaOH is weighed, prepared into a 10mol / L alkali solution, and then added to the alkali solution in accordance with the chemical dosage ratio Al(NO 3 ) 3 9H 2 O, where Al:OH=0.04 (molar ratio), stir evenly to form NaAlO 2 After cooling down to below 35°C, add a certain volume of ammonia water, the molar ratio of ammonia to alk...

Embodiment 3

[0087] A preparation method of power NCM523 material with improved high and low temperature performance, using LiNi 0.5 co 0.2 mn 0.25 AL 0.05 o 2 The preparation of is an example, including the following preparation process:

[0088] Step 1: β-Ni 0..5 co 0.2 mn 0.25 AL 0.05 (OH) 2 preparation of

[0089] (1) Prepare the solution

[0090]Weigh NiSO according to the ratio of stoichiometric ratio 0.5:0.2:0.25 (Ni:Co:Mn) 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 0, be mixed with mixed sulfate solution, total metal ion molar content 1.9mol / L, be recorded as solution a; Take NaOH, be mixed with the alkali solution of 10mol / L, then add the Al( NO 3 ) 3 9H 2 O, where Al:OH=0.05 (molar ratio), stir evenly to form NaAlO 2 After cooling down to below 35°C, add a certain volume of ammonia water and mix evenly. The molar ratio of ammonia to alkali is 0.38, which is solution b;

[0091] (2) The reaction process of the two solutions

[0092] The two solutions of a and b a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com