Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

A composite adhesive and flexible packaging technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of poor water resistance, inability to high-speed coating, high cross-linking temperature, and achieve high peel strength and adhesion. The effect of improving the bonding strength of the substrate and improving the adhesion of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

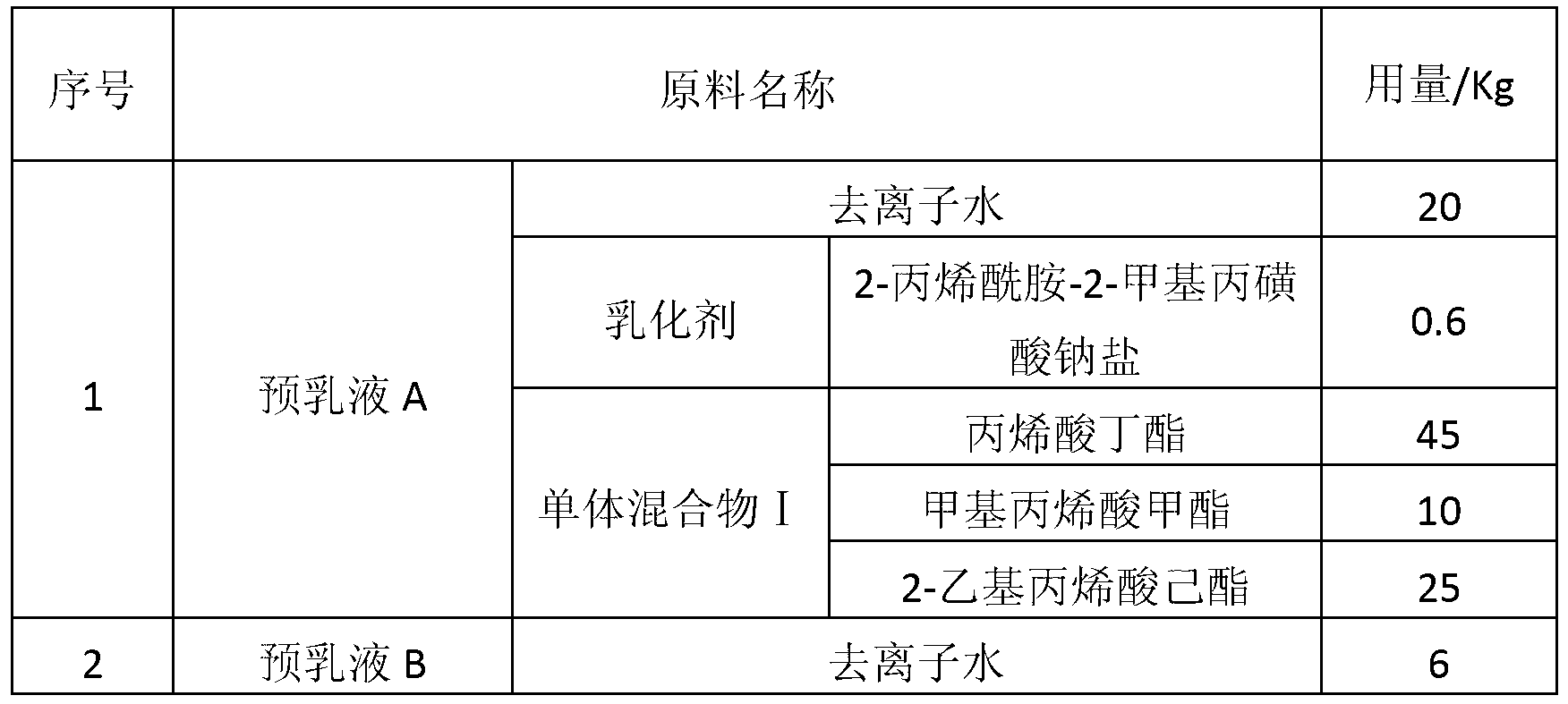

[0027] Synthesis method: according to the formula composition and dosage of Example 1 listed in Table 1, the water-based plastic-plastic composite adhesive for food and drug flexible packaging is synthesized according to the following steps:

[0028] (1) Take 20Kg deionized water, 0.6Kg 2-acrylamide-2-methylpropanesulfonic acid sodium salt, 45Kg butyl acrylate, 10Kg methyl methacrylate and 25Kg 2-hexyl ethacrylate for pre-emulsion to obtain a pre-emulsion A; Then take 6Kg deionized water, 0.2Kg 2-acrylamide-2-methylpropanesulfonic acid sodium salt, 2Kg methacrylic acid, 3Kg acrylate-β-hydroxyethyl ester and 1Kg diacetone acrylamide for pre-emulsification to obtain a pre-emulsion b. Get 1Kg deionized water and 0.3Kg ammonium persulfate to prepare initiator aqueous solution C;

[0029] (2) Add 70Kg of deionized water, 0.1Kg of 2-acrylamide-2-methylpropanesulfonic acid sodium salt, and 0.02Kg of ammonium persulfate to a four-neck flask to prepare the base material, raise the tem...

Embodiment 2

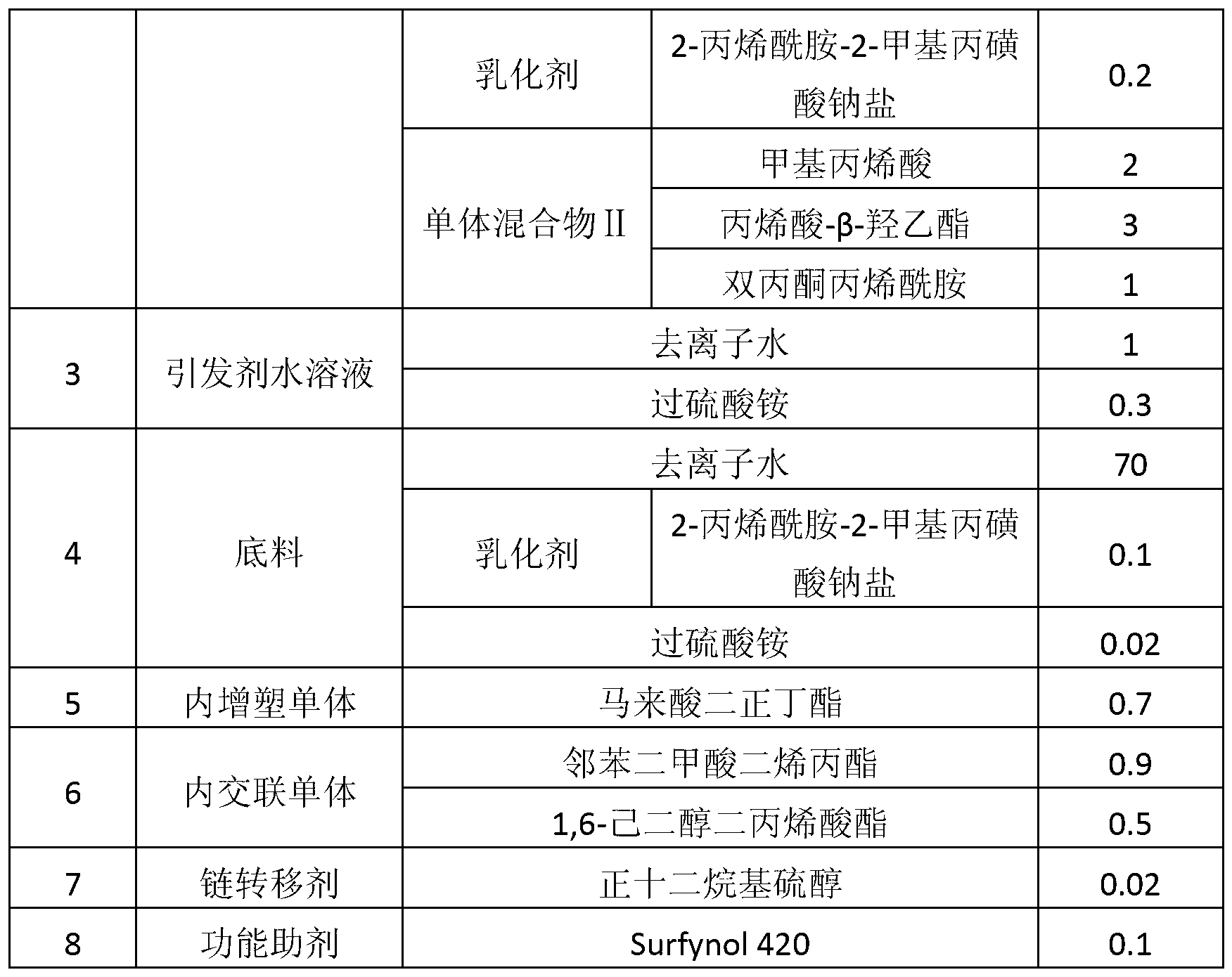

[0039] The synthetic formula is shown in Table 2:

[0040] Table 2. Synthetic formulation of water-based plastic-plastic composite adhesive for food and drug flexible packaging in Example 2

[0041]

[0042]

[0043] Synthetic method: according to the formula composition and dosage of the embodiment 2 listed in table 2, the water-based plastic-plastic composite adhesive for food and drug flexible packaging is synthesized according to the following steps:

[0044] (1) Take 25Kg of deionized water, 0.8Kg of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 65Kg of butyl acrylate, and 10Kg of methyl methacrylate for pre-emulsification to obtain pre-emulsion A; then take 5Kg of deionized water , 0.25Kg allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 2Kg methacrylic acid, 8Kg acrylate-β-hydroxyethyl ester and 1.5Kg diacetone acrylamide were pre-emulsified to obtain pre-emulsion B. Get 2Kg deionized water and 0.5Kg ammonium persulfate to prepare initia...

Embodiment 3

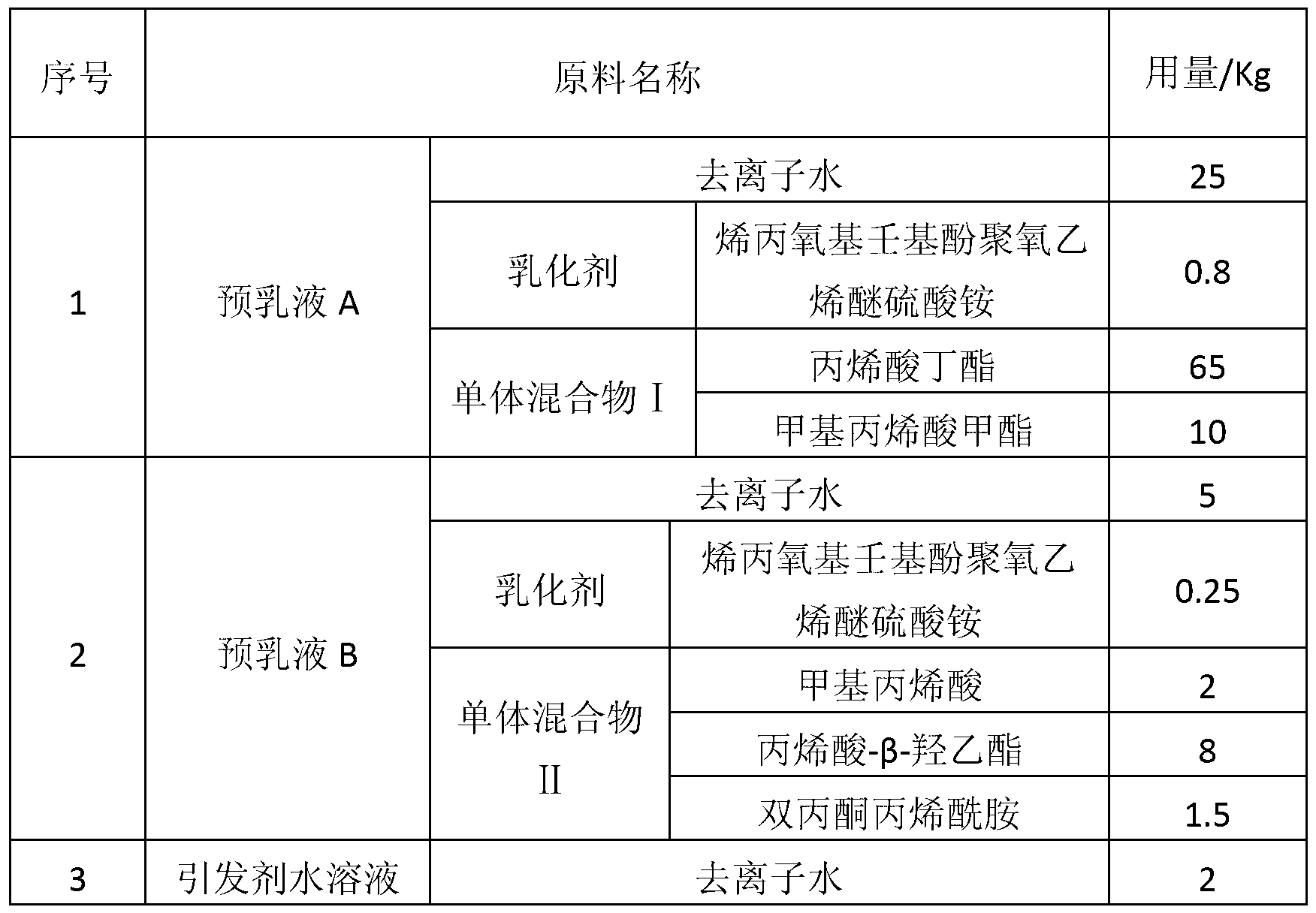

[0052] The synthetic formula is shown in Table 3:

[0053] Table 3. Synthetic formulation of water-based plastic-plastic composite adhesive for food and drug flexible packaging in Example 3

[0054]

[0055] Synthesis method: according to the formula composition and dosage of Example 3 listed in Table 3, the water-based plastic-plastic composite adhesive for food and drug flexible packaging is synthesized according to the following steps:

[0056] (1) Take 30Kg deionized water, 1.0Kg sodium vinyl sulfonate, 55Kg ethyl acrylate, 20Kg styrene and 10Kg 2-hexyl acrylate for pre-emulsion to obtain pre-emulsion A; then take 6Kg deionized water, 0.2Kg Sodium vinyl sulfonate, 1Kg acrylic acid, 5Kg acrylate-β-hydroxypropyl acrylate and 2Kg acetoacetyl ethyl methacrylate were pre-emulsified to obtain pre-emulsion B. Get 1.5Kg deionized water and 0.2Kg2,2'-azobisisobutylamidine dihydrochloride to prepare initiator aqueous solution C;

[0057] (2) Add 90Kg of deionized water, 0.1Kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com