Coating prepared from particles with ultrahigh roughness

A roughness and particle technology, applied in the field of coating technology preparation, can solve the problems of short life, difficult preparation and low mechanical strength of the coating, and achieve the effect of long life, moderate cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0084] Example 2 Hydrophobic and oleophobic

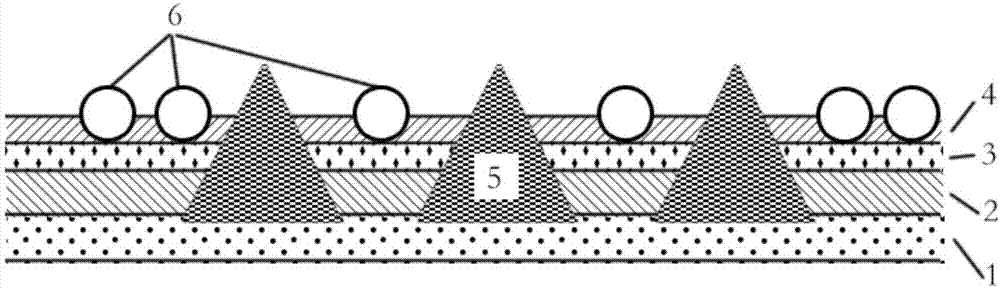

[0085] refer to Figure 4 , the schematic diagram indicates that the coating is mainly composed of a protective layer primer 1 , a protective layer overcoat 2 , protective particles 5 , ultra-high roughness particles 6 , and an ultra-thin layer adhesive 7 .

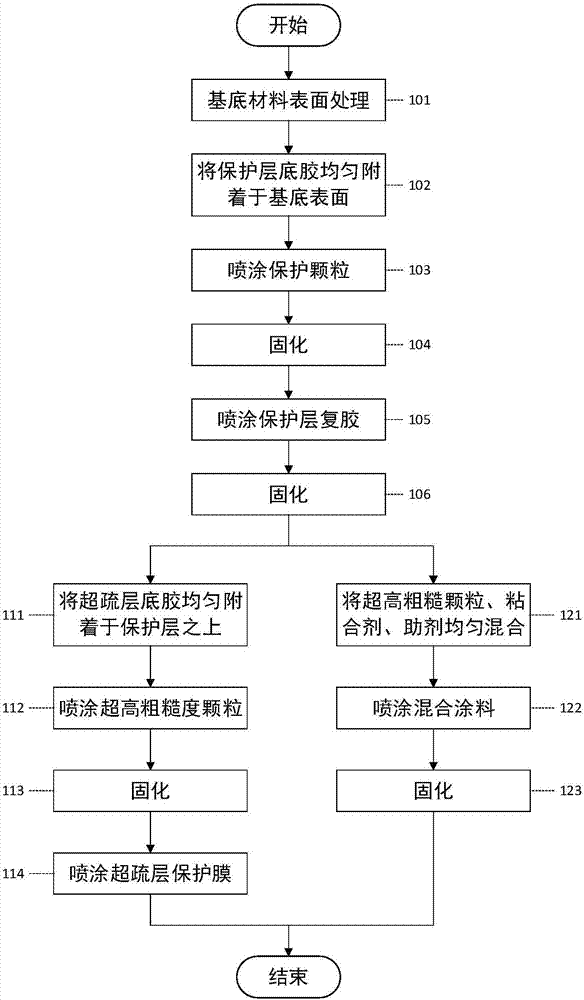

[0086] refer to figure 1 , in step 101, the surface treatment of the base material can be carried out by conventional methods such as surface sandblasting, phosphating, attaching a primer, and scrubbing with a paint thinner.

[0087]In step 102, firstly, the polyurethane resin and its curing agent are respectively diluted to 1-50wt% by organic solvent. Secondly, after mixing the diluted epoxy resin and curing agent, it is evenly sprayed on the base material by a pneumatic spray gun, with a solid content thickness of 3-5 μm to form a protective layer of primer.

[0088] In step 103, 3000-mesh corundum particles (5 protective particles) are uniformly sprayed on the base mater...

Embodiment 3

[0096] Example 3 Hydrophobic and lipophilic

[0097] refer to Figure 5 , the schematic diagram indicates that the coating is mainly composed of protective particles 5 , ultra-high roughness particles 6 and mixed layer binder 8 .

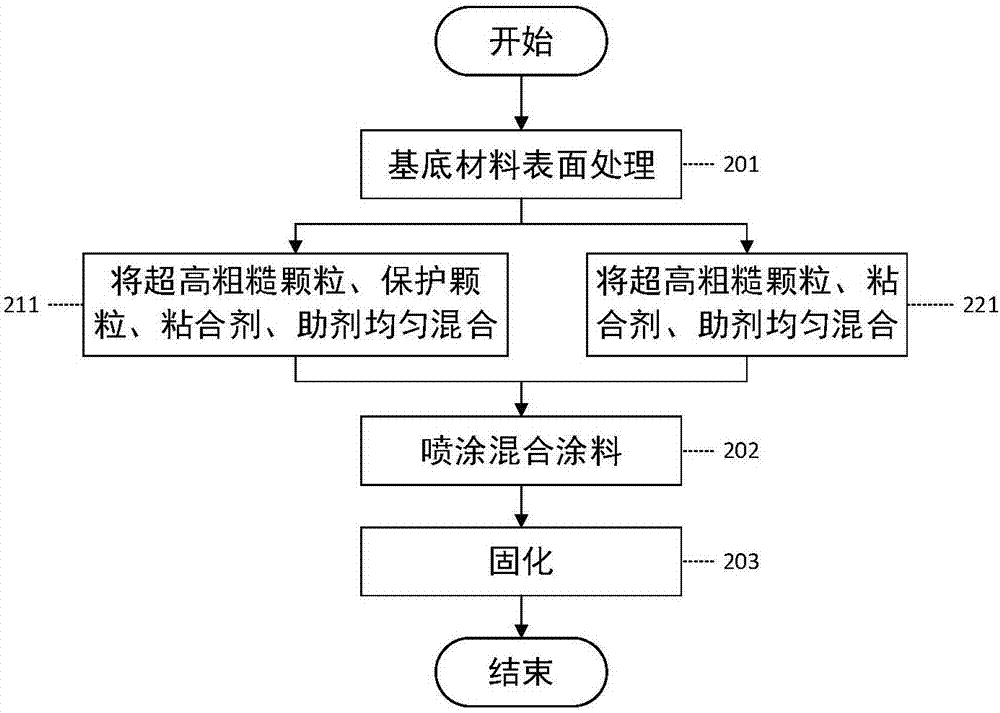

[0098] refer to figure 2 , in step 201, the surface treatment of the base material can be carried out by conventional methods such as surface sandblasting, phosphating, attaching a primer, and scrubbing with a paint thinner.

[0099] In step 211, the airgel particles surface-modified by hexamethyldisilazane are first ground to D 90 Particles smaller than 5 μm. Then 0.1-15wt% of airgel particles, 0.01-60wt% of 2000 mesh corundum particles, 0.1-20wt% of hydroxyl-terminated silicone resin and 0.01-1wt% of KH550 are dispersed in the organic solvent to form a mixed solution.

[0100] In step 202, the mixed solution is uniformly sprayed on the base material through a pneumatic spray gun.

[0101] In step 203, the substrate that has been sprayed with...

Embodiment 4

[0103] Example 4 superhydrophilic, underwater superoleophobic

[0104] refer to Image 6 , the schematic diagram indicates that the coating is mainly composed of protective particles 5 , ultra-high roughness particles 6 and super-thin layer binder 7 .

[0105] refer to figure 2 , in step 201, the surface treatment of the base material can be carried out by conventional methods such as surface sandblasting, phosphating, attaching a primer, and scrubbing with a paint thinner.

[0106] In step 221, the unmodified airgel particles are first heated to above 350°C in air for 1 hour, and then ground to D 90 Particles smaller than 5 μm. Then 0.1-15wt% of airgel particles, 0.1-20wt% of hydroxyl-terminated silicone resin and 0.01-1wt% of KH550 are dispersed in the organic solvent to form a mixed solution.

[0107] In step 202, the mixed solution is uniformly sprayed on the base material through a pneumatic spray gun.

[0108] In step 203, the substrate that has been sprayed with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com