Preparation method of super-amphiphobic coating

A super-amphiphobic and coating technology, applied in coatings and other directions, can solve the problems of difficult preparation of oleophobic materials, less research on super-oleophobic materials, and low surface tension, so as to improve hydrophobic and oleophobic properties and operability Strong, surface energy-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The embodiment of the present invention provides a method for preparing a super-amphiphobic coating, comprising the following steps:

[0015] Step S1: preparing a fluorine-containing silane polymer solution;

[0016] Step S2: Then, hydrolyze the prepared fluorine-containing silane polymer by adding tetraethyl orthosilicate (TEOS), water, and hydrochloric acid to obtain a transparent solution; the mass fraction of the hydrochloric acid is 38%; the fluorine-containing silane polymer, The mass ratio of ethyl orthosilicate, water, and hydrochloric acid is (2-8): (1-5): (0.5-3): (0.2-1).

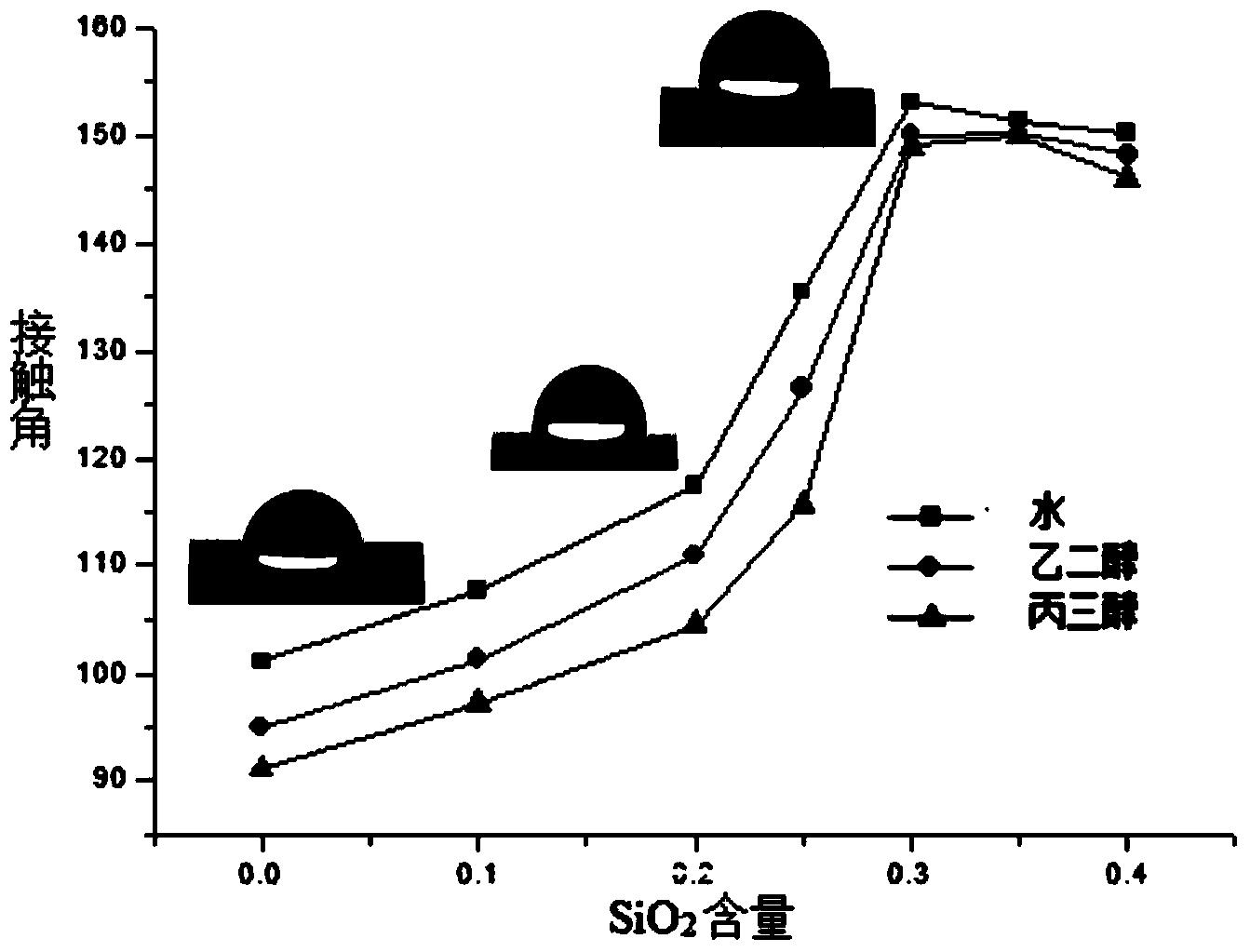

[0017] Step S3: add a certain amount of nano silicon dioxide (SiO2) to the transparent solution again 2 ), mixed uniformly to obtain composite sol;

[0018] Step S4: coating the composite sol on the substrate, curing and drying.

[0019] Wherein, in step S1, a free radical polymerization method is used to prepare the fluorine-containing silane polymer. Dissolve organic fluorine monomer...

Embodiment 1

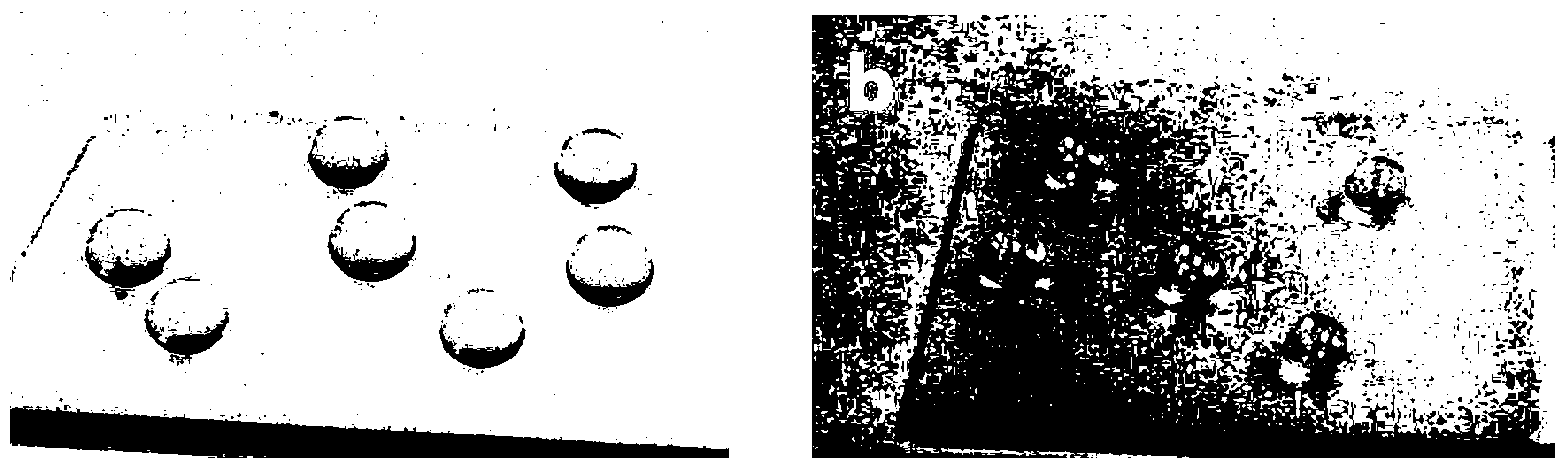

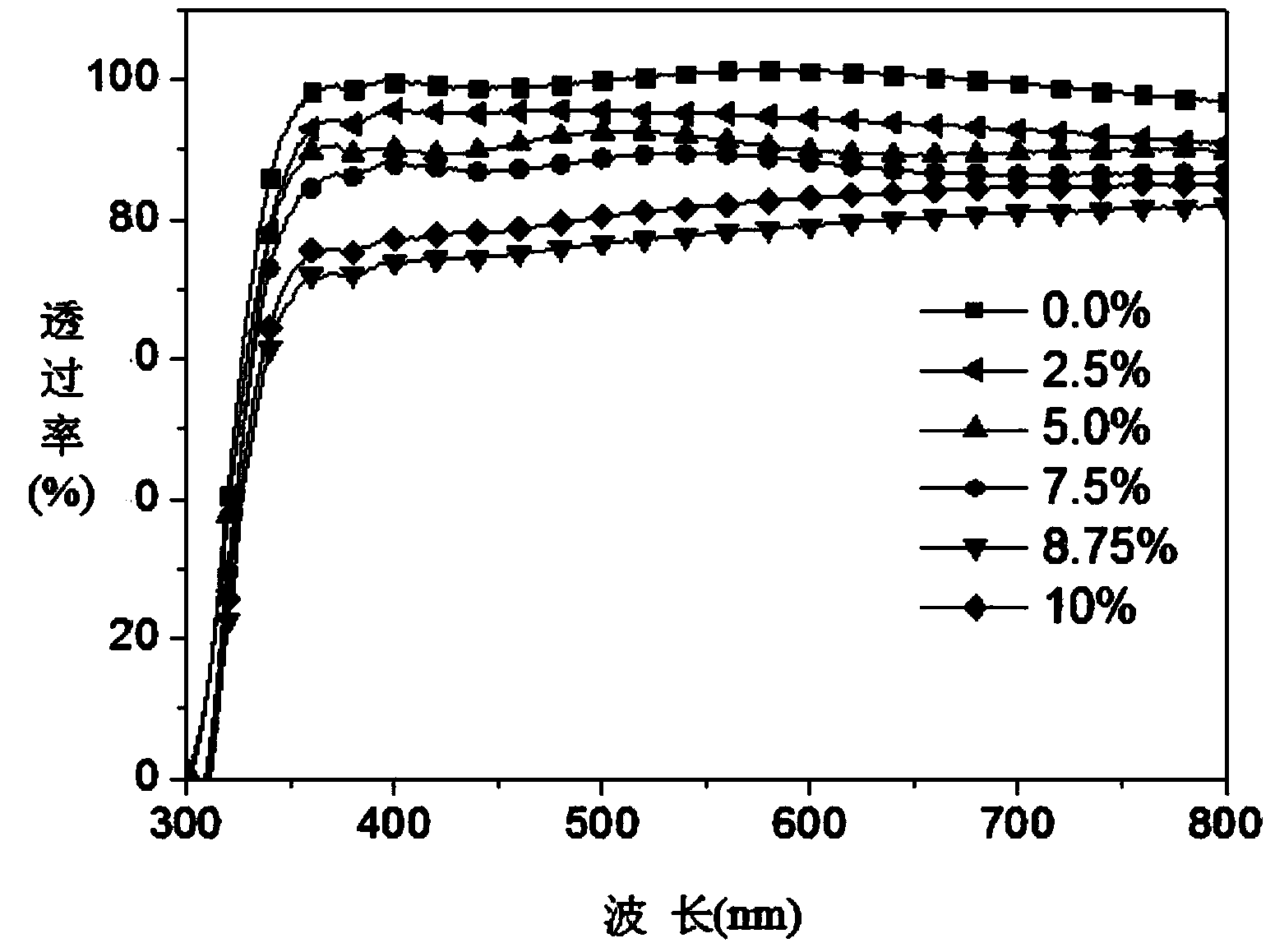

[0024] First, dissolve 6g of organic fluorine monomer (DFMA), 3.72g of silane coupling agent (KH-570), and 0.32g of initiator (BPO) in 43.2g of organic solvent (THF) solvent, pour it into a cooling reflux device and stir In the three-necked flask of the device, control the temperature at 60-65°C for polymerization reaction for 6 hours to form a fluorine-containing silane polymer solution. Add 3.12gTEOS, 2gH to the fluorosilane polymerization solution 2 O and an appropriate amount of hydrochloric acid to adjust the pH to 3-4, and continue stirring for 5 hours for hydrolysis to obtain a transparent fluorine-containing silane polymer solution. Take a certain amount of nano-SiO 2 Particles were added to the transparent fluorosilicone solution, stirred for 5 minutes, ultrasonicated for 10 minutes, and stirred for another 5 minutes to obtain a composite sol, in which nano-SiO 2 The mass of the particles is 7.5% of the mass of the composite sol. The treated glass slide is dipped i...

Embodiment 2

[0026] Other conditions are the same as embodiment 1, only change nanometer SiO 2 The mass of the particles is 0% of the mass of the composite sol, that is, no nano-SiO is added 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com