Two-phase stainless steel and manufacturing method therefor

A technology of duplex stainless steel and manufacturing method, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of expensive stainless steel, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

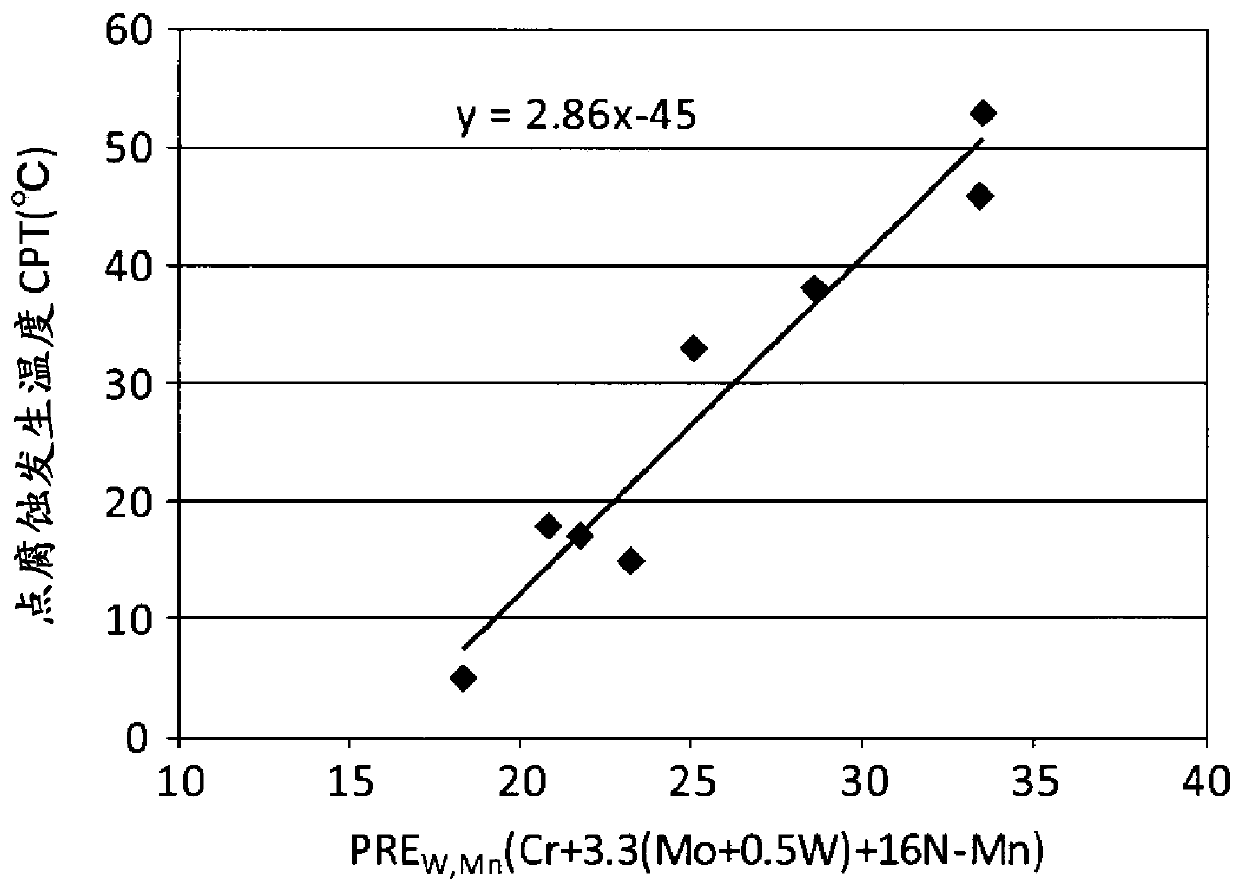

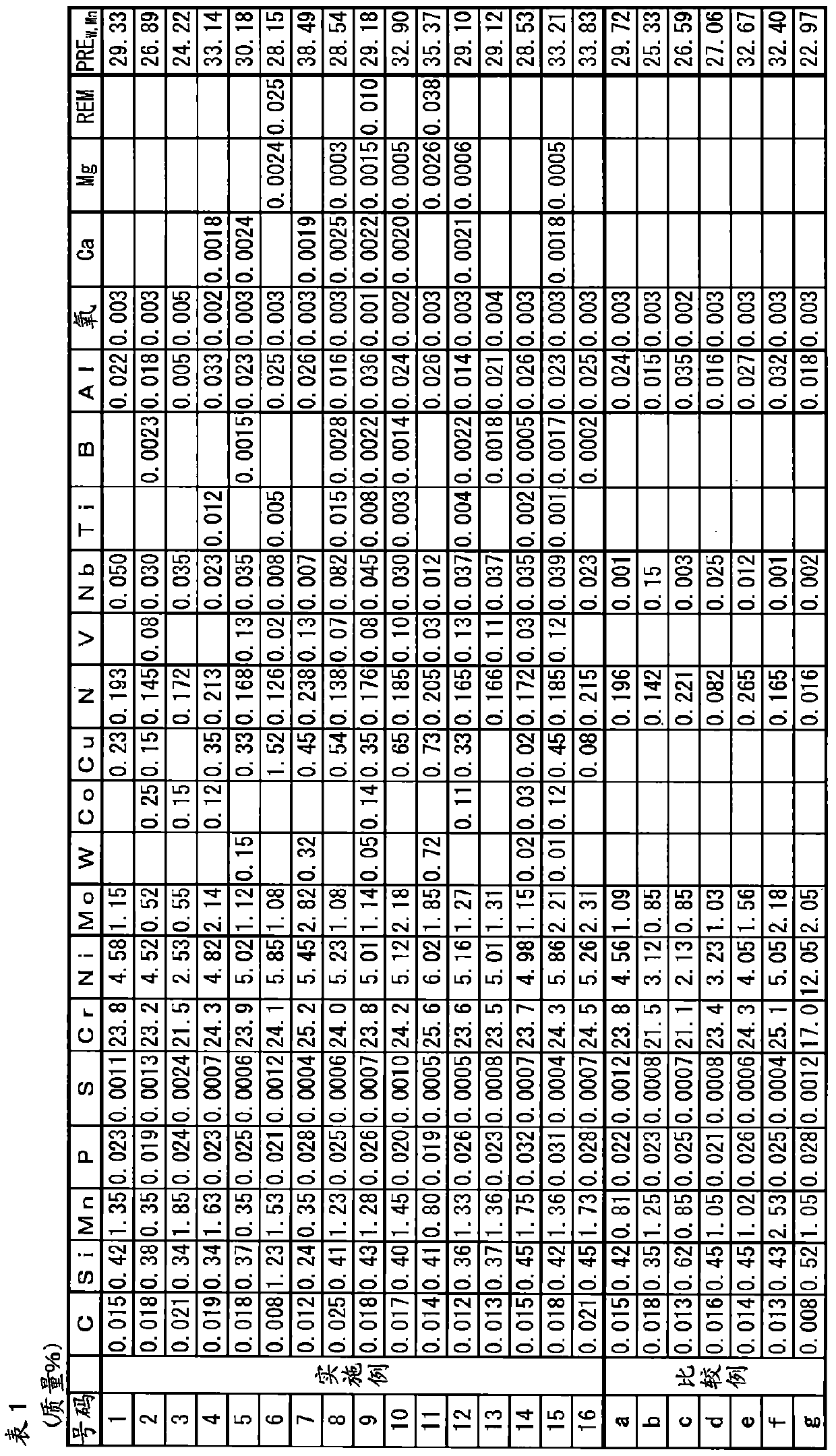

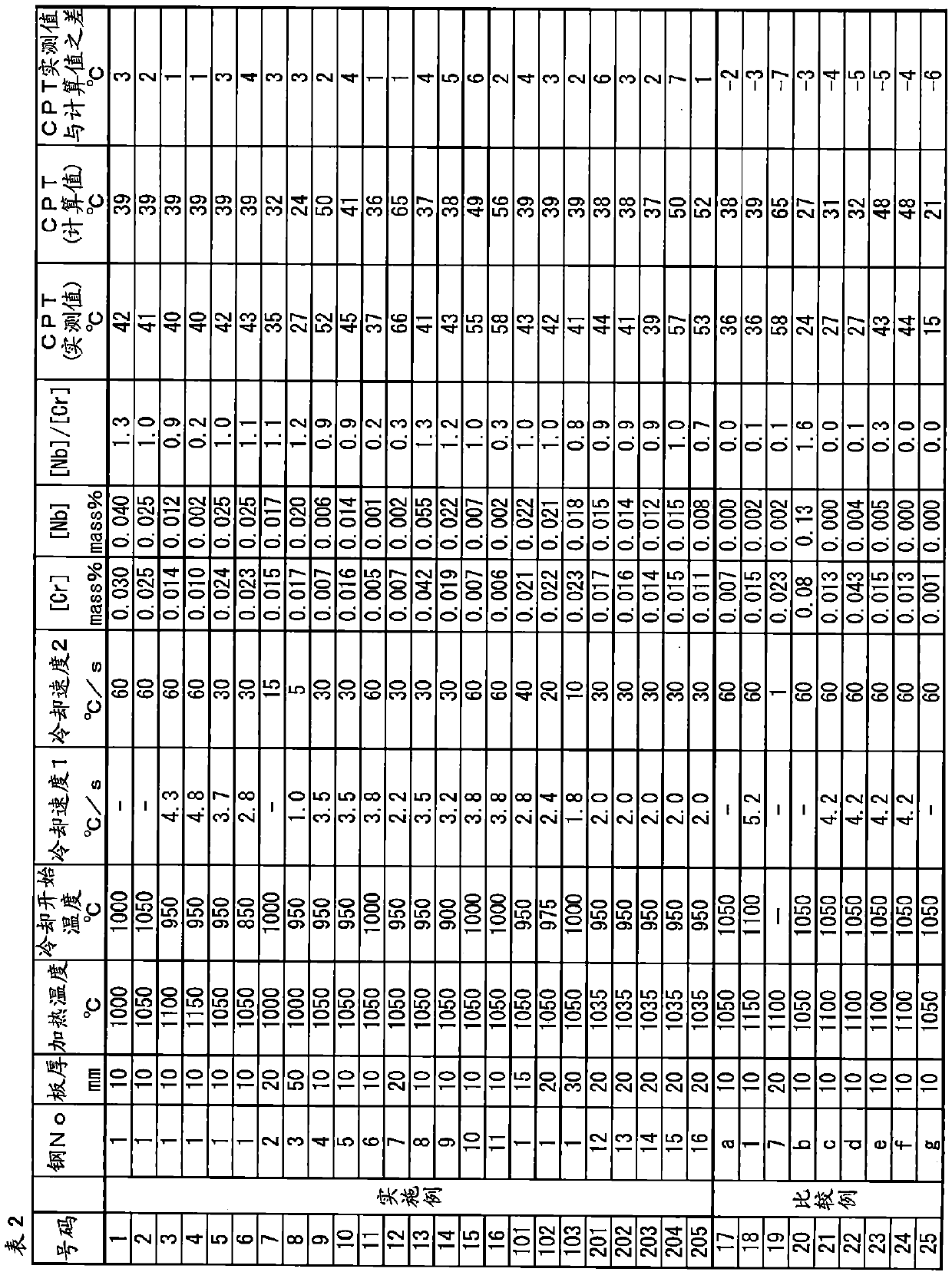

[0105] Examples are described below. Table 1 shows the chemical compositions of the test steels. These steels are obtained by hot-rolling molten materials in a laboratory, or by cutting out a part of actual manufacturing materials. For the components shown in Table 1, the parts without content are indicated as unavoidable impurity levels. REM means lanthanide rare earth elements, and the content indicates the total of those elements. Various heat treatments were applied to steel plates (thickness×100 mm width×300 mm length) obtained from these steels. A thermocouple was placed in the center of the thickness of the steel sheet to measure the temperature during the heat treatment, and the surface temperature of the steel sheet after it was extracted from the heat treatment furnace was measured with a radiation thermometer. The cooling of the steel plate is mainly performed by immersing it in a water tank.

[0106] First, put the steel plate into a heat treatment furnace for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com