Hot extrusion die and hot extrusion overall forming method of special-shaped square pipe

A hot extrusion die and integral forming technology, applied in metal extrusion dies, forming tools, metal extrusion and other directions, can solve the problem of inability to prepare special-shaped square tubes, solve the problem of metal filling and avoid high temperature ferrite. The effect of the formation and surface quality of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

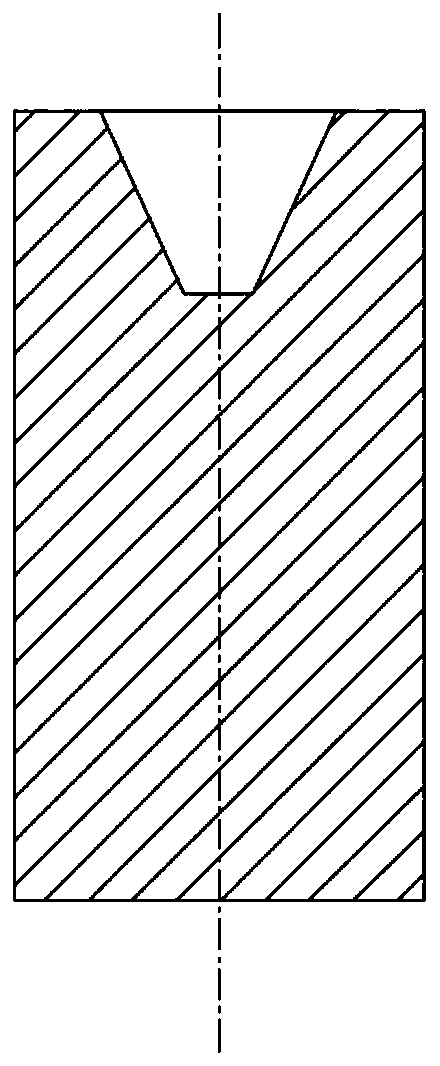

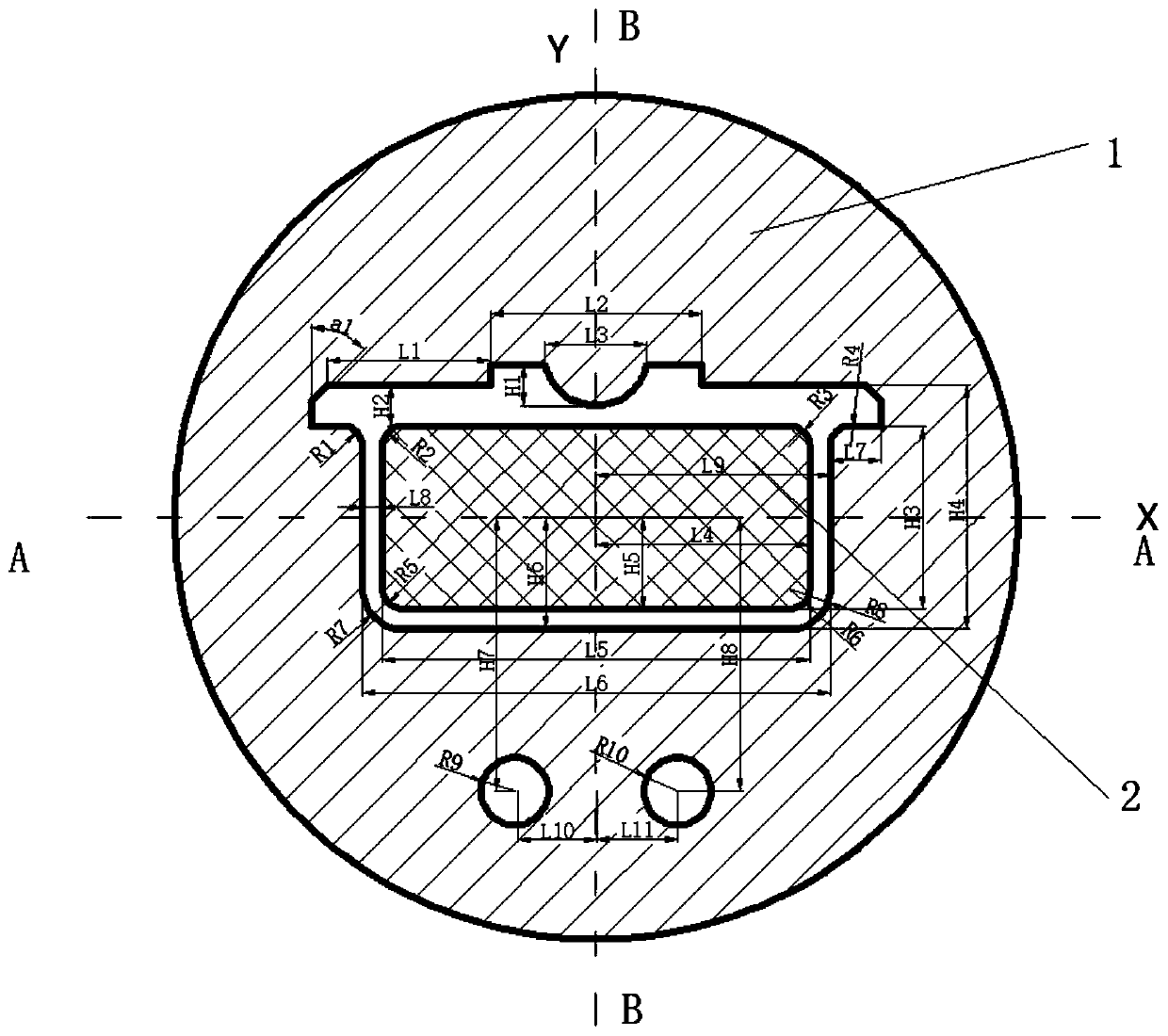

[0042] This embodiment provides a hot extrusion die for special-shaped square tubes, such as figure 1 , Figure 3-5 As shown, it includes a mold cavity cover 1 with a special-shaped cavity, and a hot-extruded mandrel 2 is arranged inside the mold cavity cover 1, and the area between the mold cavity cover 1 and the hot-extruded mandrel 2 forms a mold cavity hole of a special-shaped square tube ; There is a first extrusion diversion hole and a second low-pressure diversion hole below the mold cavity hole of the special-shaped square tube; The location of the center of the truncated face.

[0043] Specifically, the hot extrusion die provided by the present invention is used to extrude a special-shaped square tube. The hot extrusion die includes a mold cavity cover 1 with a special-shaped cavity inside, and the shape of the special-shaped cavity constitutes the external shape of the special-shaped square tube; The mandrel 2 is fixed inside the cavity cover 1, and the shape of th...

Embodiment 2

[0062] This embodiment provides a method for integral forming of a special-shaped square tube by hot extrusion, which includes the following steps:

[0063] Step 1, heating the blank and expanding the hole;

[0064] Step 2. Carry out a second heat treatment to the blank after the hole is expanded;

[0065] Step 3, using a special-shaped square tube hot extrusion die to hot extrude the billet;

[0066] Step 4. Air-cool the hot-extruded special-shaped square tube to room temperature, and inspect the surface quality and mechanical properties of the special-shaped square tube.

[0067] It should be noted that the step 1 of the hot extrusion integral forming method for special-shaped square tubes of the present invention also includes blank preparation, and the specific process of blank preparation is as follows:

[0068] Surface turning, sawing, grinding, and prefabricated holes are carried out on the forged round steel. The process requirements: after turning the outer surface ...

Embodiment 3

[0084] This example uses the special-shaped square tube hot extrusion die provided in Example 1 and the special-shaped square tube hot extrusion integral molding method provided in Example 2 to prepare a special-shaped square tube. The specific steps are as follows:

[0085] Step 1, heating the blank and expanding the hole;

[0086] Firstly, the billet is machined, the process is: surface turning, sawing, turning and grinding, and prefabricated holes on the forged round steel with the grade S45000. The process requirements: after turning the outer surface of the round steel, the surface is smooth and free of defects. Roughness ≤ 3.2μm, the end surface of the blank after sawing is turned and ground, the cutting slope of the two end surfaces is ≤ 2mm, the outer diameter of the blank after processing The length is 900-1000mm, and a prefabricated hole is made on one of the end faces. The hole is located at the center of the end face circle. The diameter of the bell mouth is 235mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com