Electrical discharge machining method of three-dimensional space hole

A three-dimensional space, processing method technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of reducing the effective processing time of the equipment, poor positioning accuracy of small holes, and low equipment utilization, and achieve improved processing efficiency and The effect of machining quality, improving hole position accuracy and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Refer to Figure 1-4 , An EDM method for machining small holes in three-dimensional space, which is characterized in that it comprises the steps:

[0025] (1) Making the positioning fixture: The positioning fixture must be able to clamp and locate the workpiece, and be able to be connected to the machine tool turntable stably and reliably, and the fixture must not interfere with the processing position.

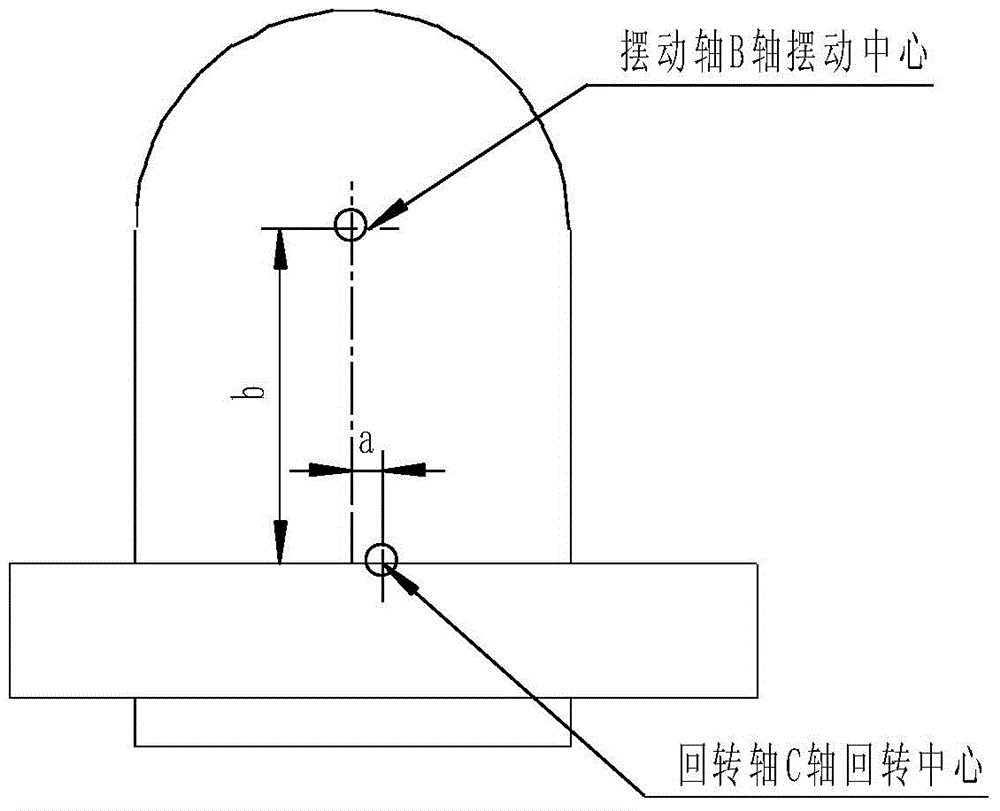

[0026] (2) Define the coordinate zero position of each axis of the machine tool: refer to figure 1 , When the turntable plane is parallel to the XY plane, it is the zero state of the swing axis B axis, the position of the swing axis B at this time is the zero point, and the machine tool X, Y, Z axis coordinate zero point is the swing axis B axis in the zero state, the rotary axis C The intersection position of the axis rotation center and the turntable plane, the zero point of the rotation axis C axis is a fixed position.

[0027] (3) Transform the mathematical model of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com