Printed circuit board and manufacturing methods of printed circuit board and plate hole of printed circuit board

A technology of printed circuit board and manufacturing method, which is applied in printed circuit manufacturing, printed circuit, printed circuit and other directions, can solve the problems of decreased hole position accuracy, large copper thickness, poor uniformity of surface copper thickness, etc., and achieves convenient and fast manufacturing. The effect of thin surface copper thickness and high hole position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

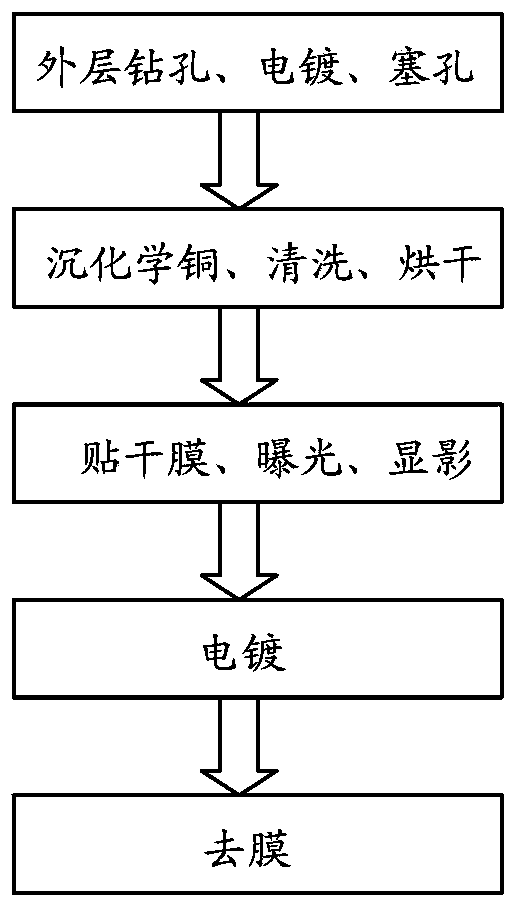

[0037] The manufacturing method of the holes in the PCB in this embodiment is applicable to the manufacturing of PCBs with isolated holes in the board without connection. After plugging all the holes, carry out copper sinking, and then use dry film to cover the places that do not need to be made into the hole in the plate and need to control the thickness of the copper on the surface, and then remove the dry film after electroplating, and the partial hole in the plate can be completed. .

[0038] The specific process is as follows:

[0039] (1) Drill, electroplate, and plug all the holes on the outer layer of the PCB;

[0040] It should be noted that in this process, the thickness of thin copper plating can be controlled between 18um and 25um;

[0041] figure 2 It is the effect diagram of using resin plug holes for all the hole diameters that need to be plugged in the first implementation of the present invention; it is best to polish the slightly convex part of the hole a...

Embodiment 2

[0057] The manufacturing method of the PCB hole in this embodiment is applicable to the manufacture of a PCB in which the hole in the board is not isolated but connected (that is, the hole in the board is connected to other circuit PAD (soldering point)). For local electroplating, it is necessary to make holes in the plate. After the copper thickness is sufficient, this part of the hole is plugged, and then copper plating is performed to plug the remaining holes, and the partial hole in the plate can be completed. The specific process is as follows:

[0058] (1) Drill out all the holes on the outer layer of the printed board, and electroplate thin copper (5-8um);

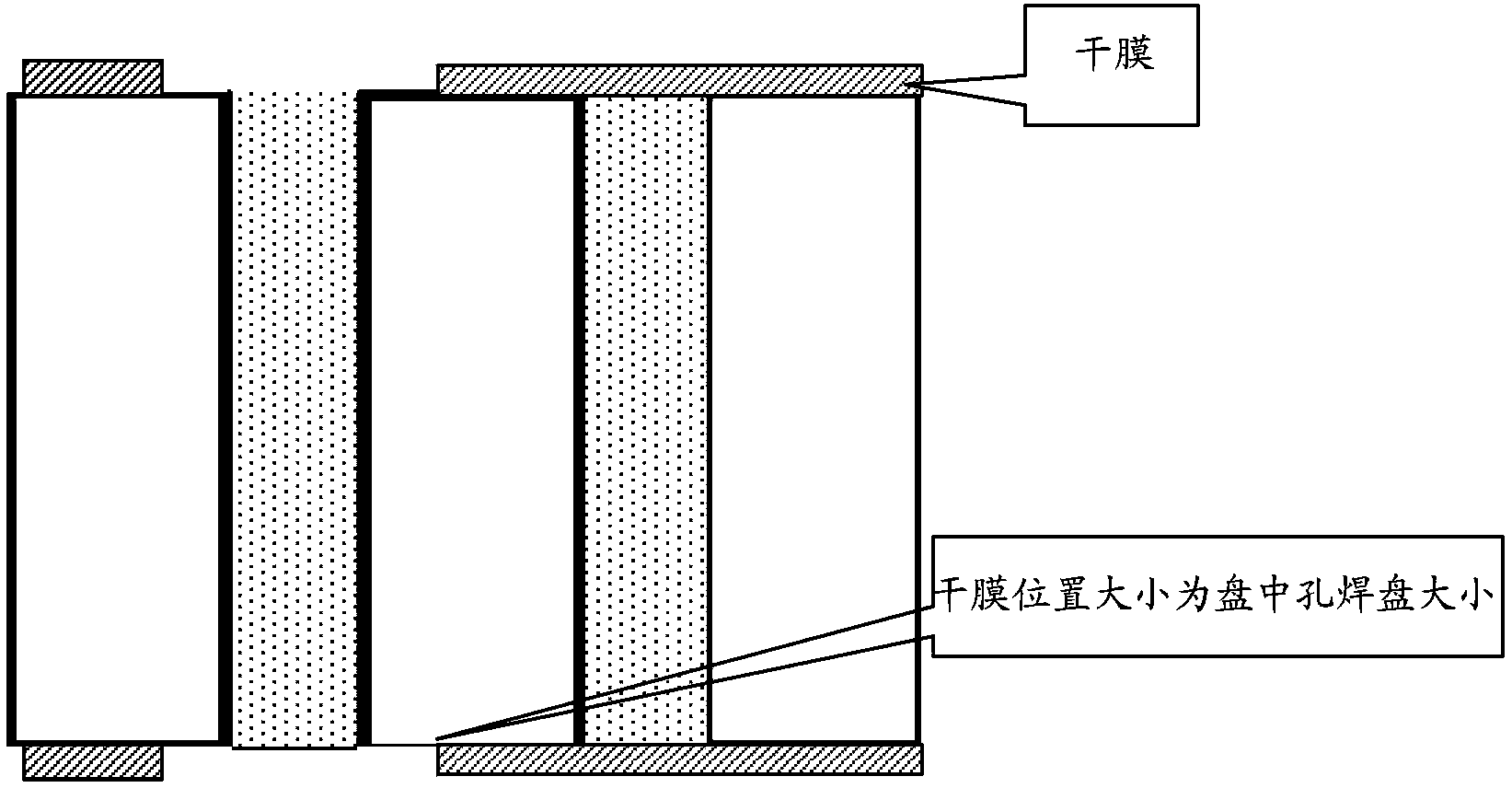

[0059] (2) Applying dry film, exposure, and development;

[0060] Only the locations where holes in the disc need to be made are developed. Preferably, the exposed size of the development is slightly smaller than the size of the holes in the disk, for example, 50um smaller on one side, so as to ensure the alignmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com