Epoxy resin composition for prepreg, prepreg, and multilayer printed circuit board

A technology of epoxy resin and reactive epoxy resin, which is applied in multilayer circuit manufacturing, printed circuit, printed circuit and other directions, can solve the problems of large hole position deviation, difficult to have both hole position accuracy, heat resistance, thermal rigidity, etc. , to achieve the effect of excellent hole position accuracy, good hole position accuracy, and excellent thermal rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0140] Hereinafter, the present invention will be specifically described based on examples.

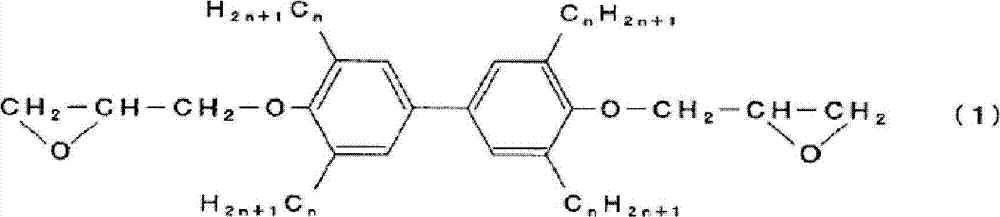

[0141] Hereinafter, the phosphorus compound, epoxy resin, curing agent, inorganic filler, molybdenum compound, curing accelerator, and solvent used are shown in order.

[0142]

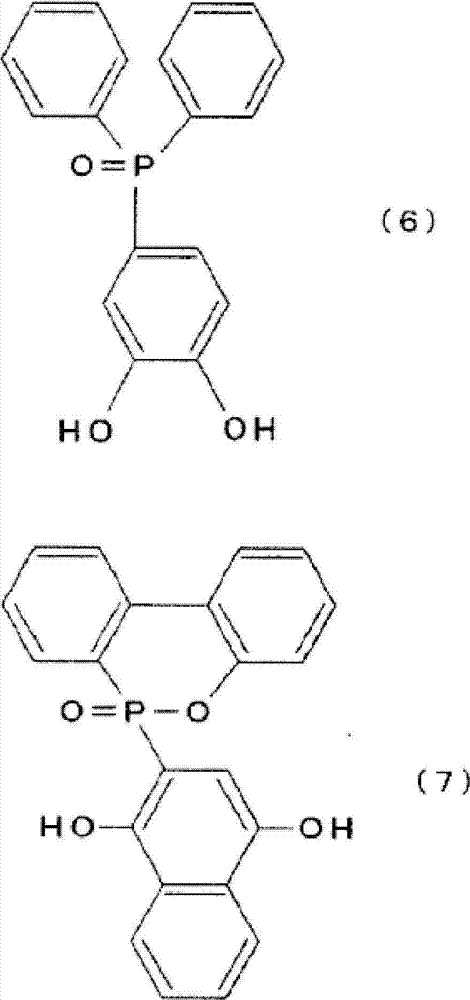

[0143] As the phosphorus compound, the following three compounds were used.

[0144] Phosphorus compound 1: a compound of chemical formula (8) having an average of 2.0 phenolic hydroxyl groups, "HCA-HQ" manufactured by Sanko Co., Ltd. (phosphorus content about 9.6% by mass, hydroxyl equivalent weight about 162)

[0145] Phosphorus compound 2: a compound of chemical formula (7) having an average of 2.0 phenolic hydroxyl groups; Sanko Co., Ltd. "HCA-NQ" (phosphorus content of about 8.2% by mass, hydroxyl equivalent of about 188)

[0146] Phosphorus compound 3: a compound of chemical formula (6) having an average of 2.0 phenolic hydroxyl groups (diphenylanthraquinone phosphine oxide); Hokko Chemical Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com