Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about "Fuel injection with sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow meter

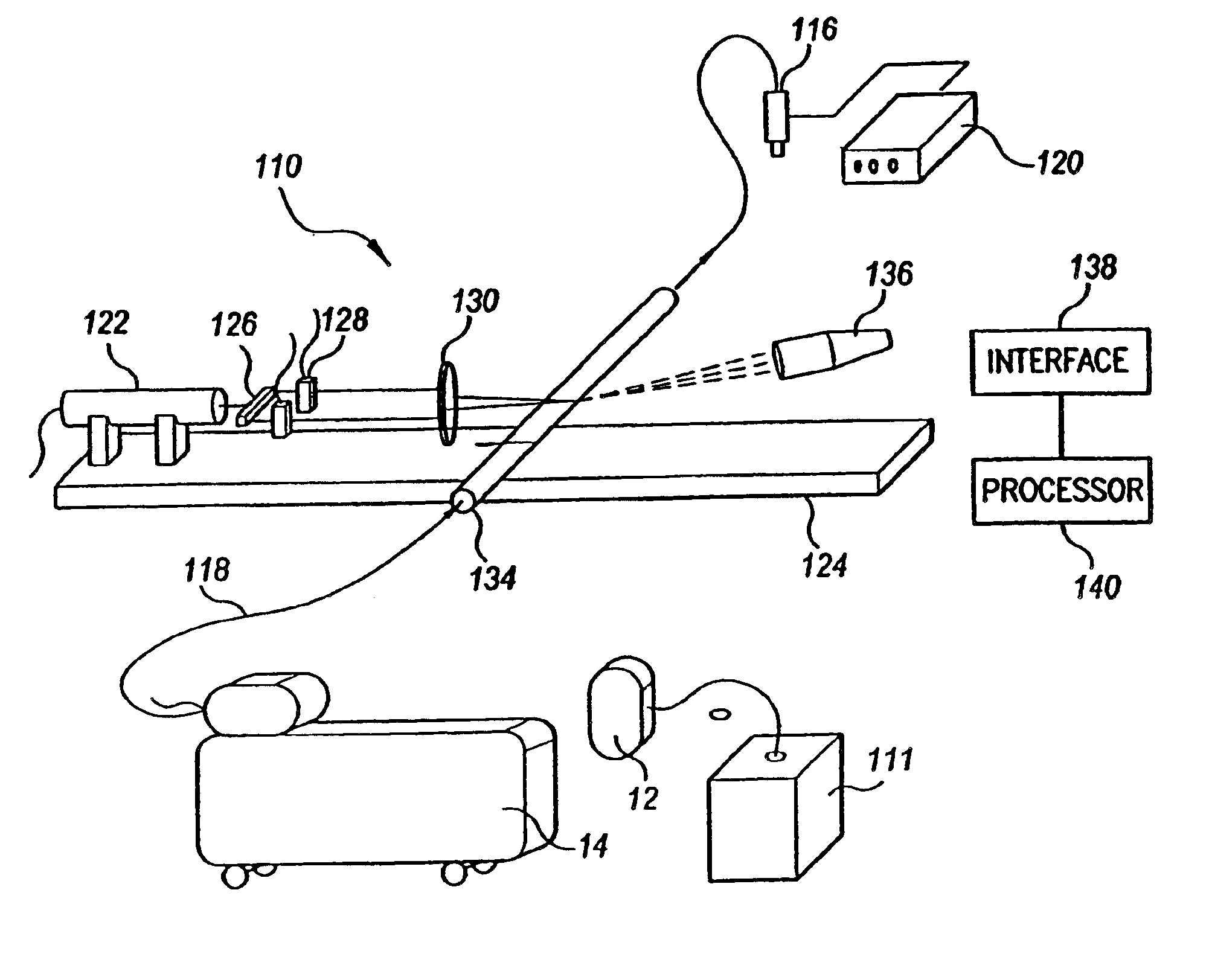

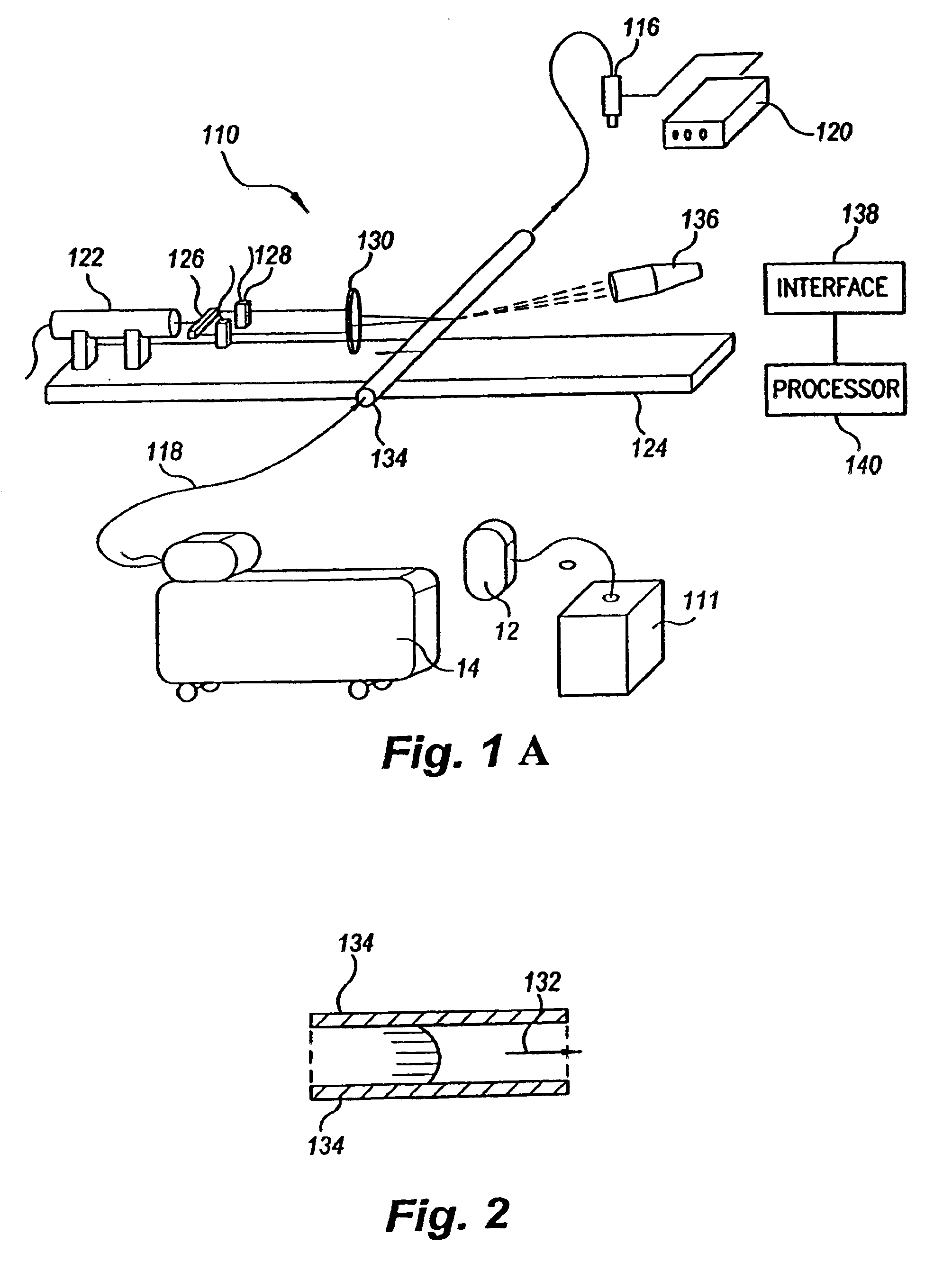

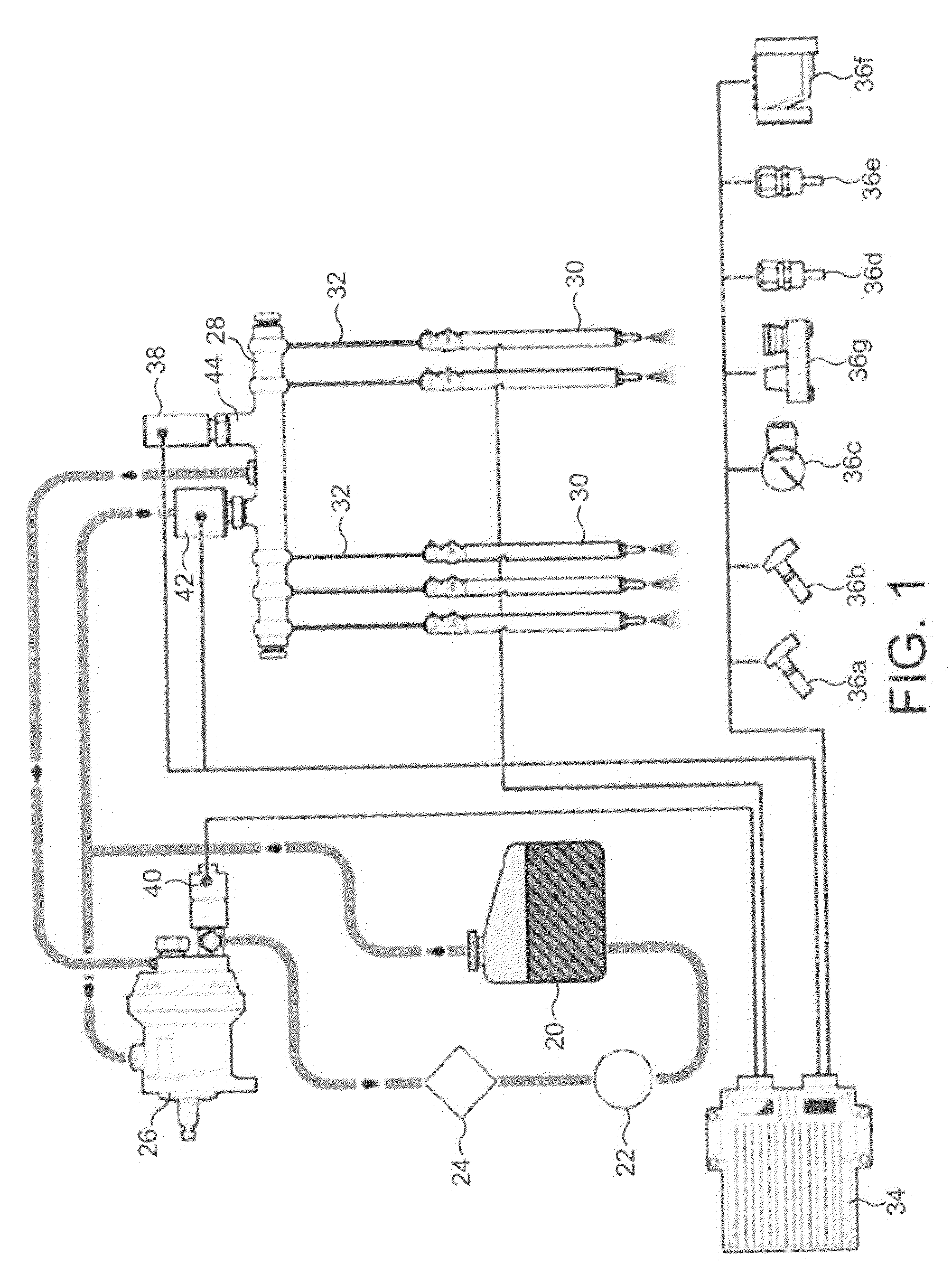

Various embodiments of the present invention provide a flow meter device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe. The flow meter may process the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and / or other flow characteristics (e.g., as instantaneous quantities and / or integrated over a time interval) The flow meter may use an electronic processing method. The electronic processing method may provide essentially an exact solution to the Navier-Stokes equations for any periodically oscillating flow.

Owner:COMBUSTION DYNAMICS

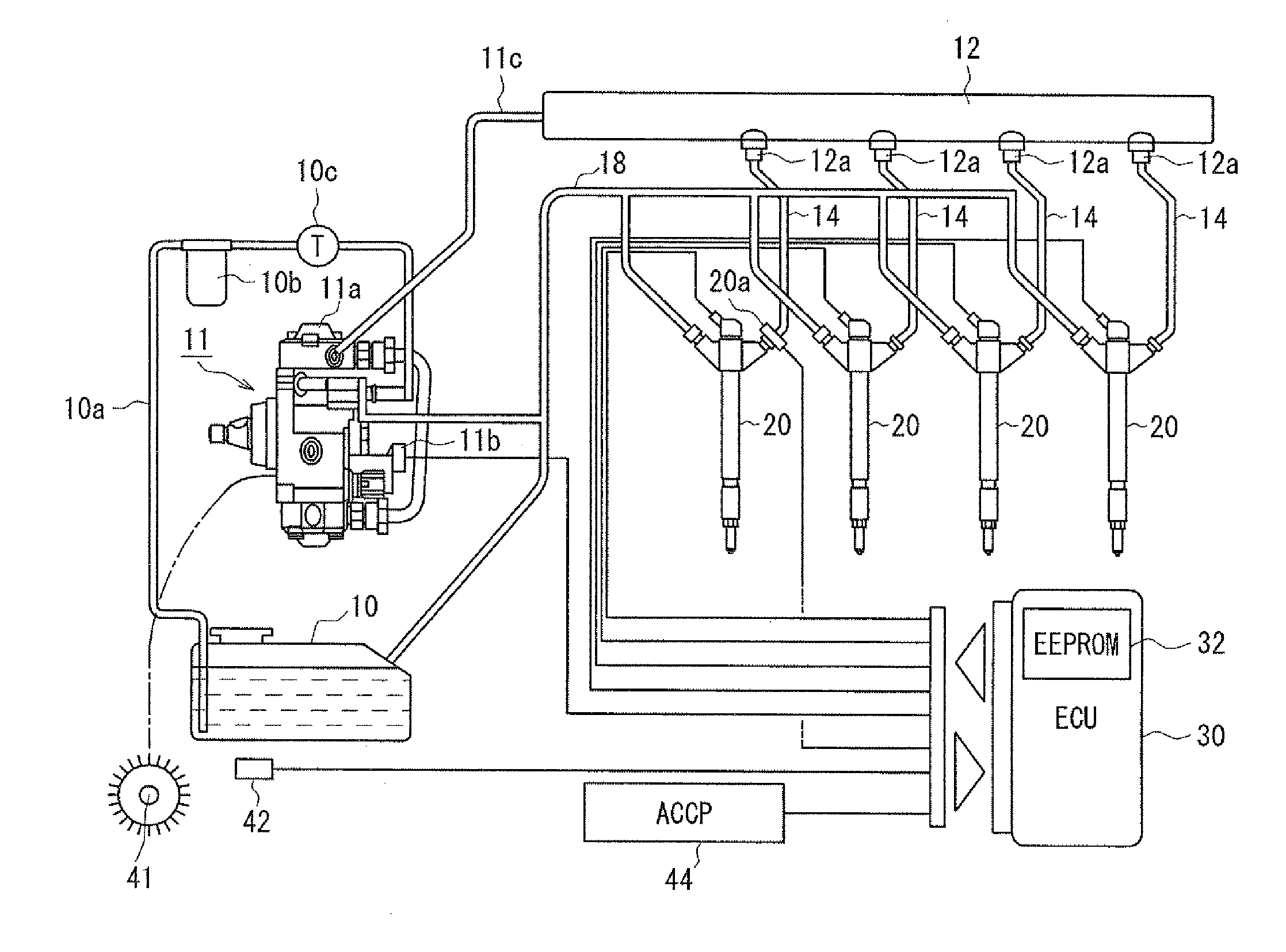

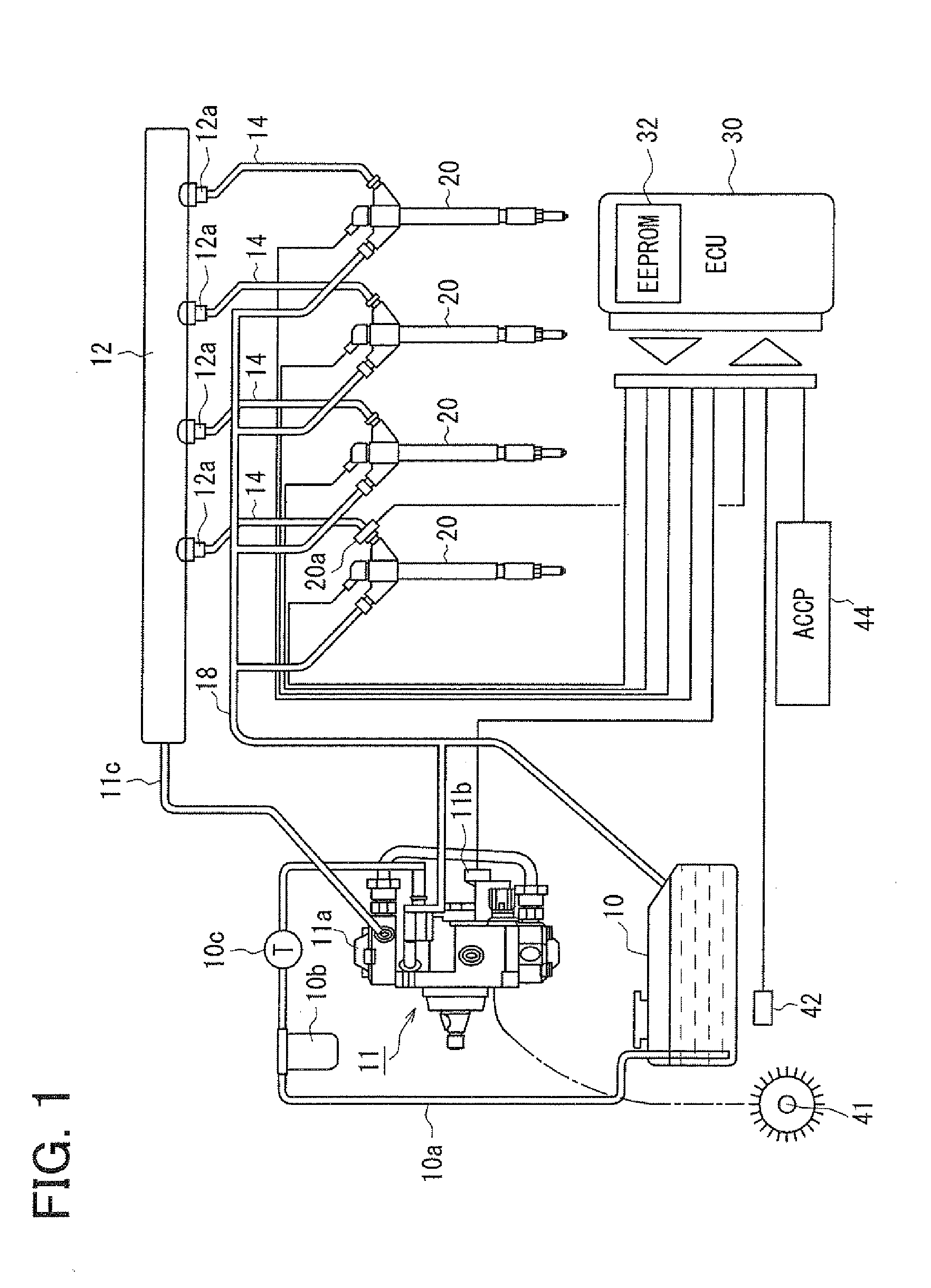

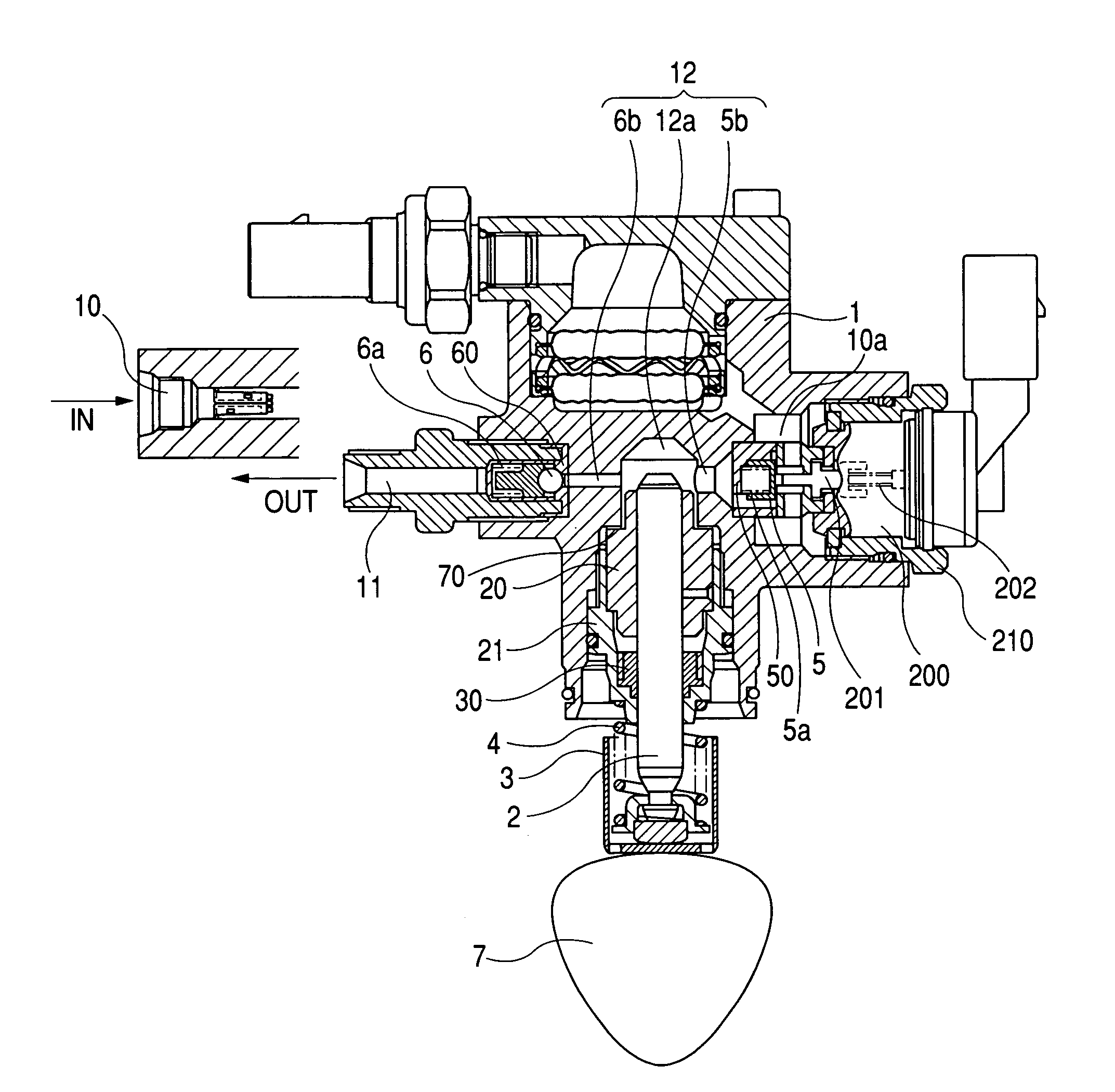

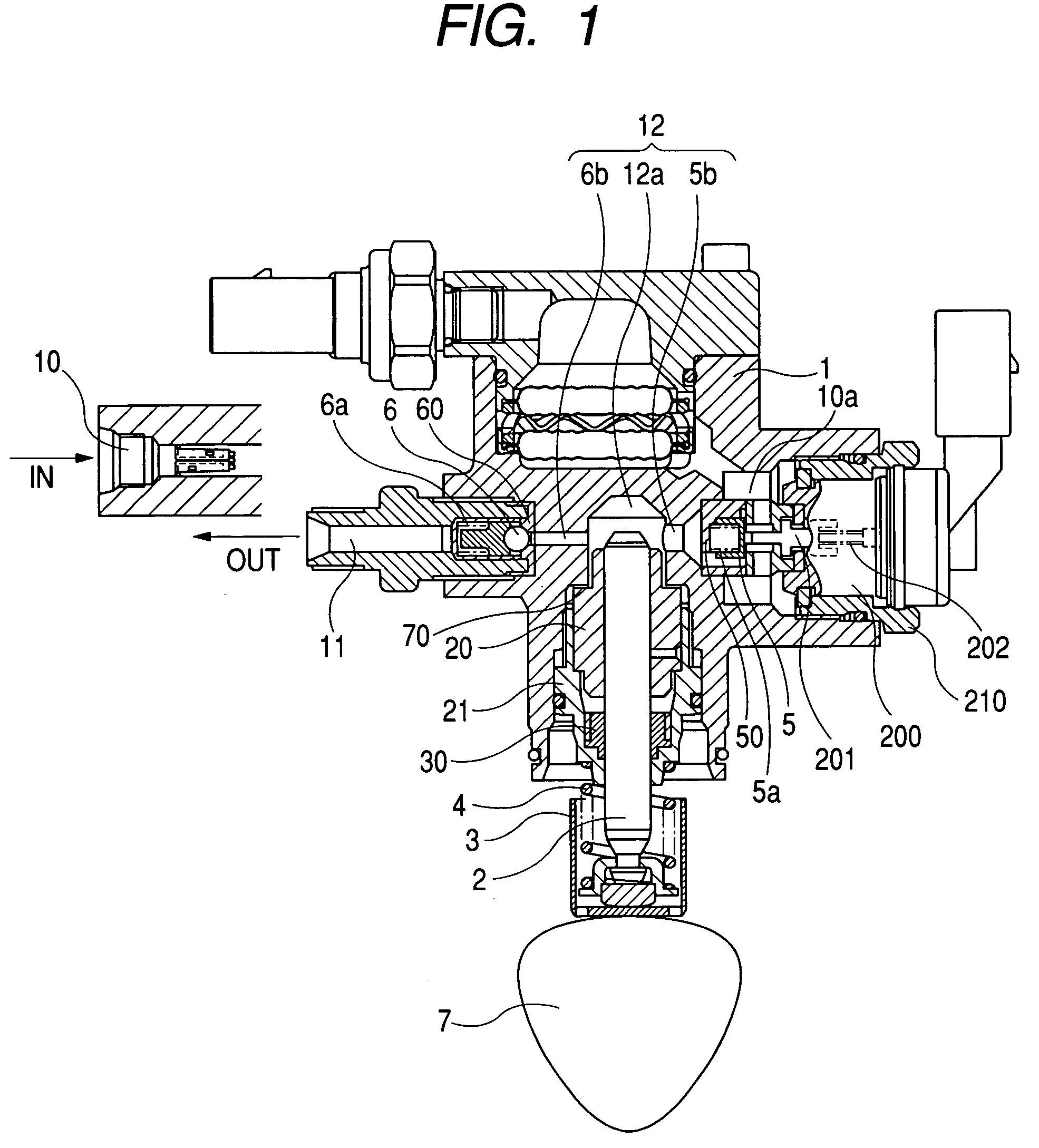

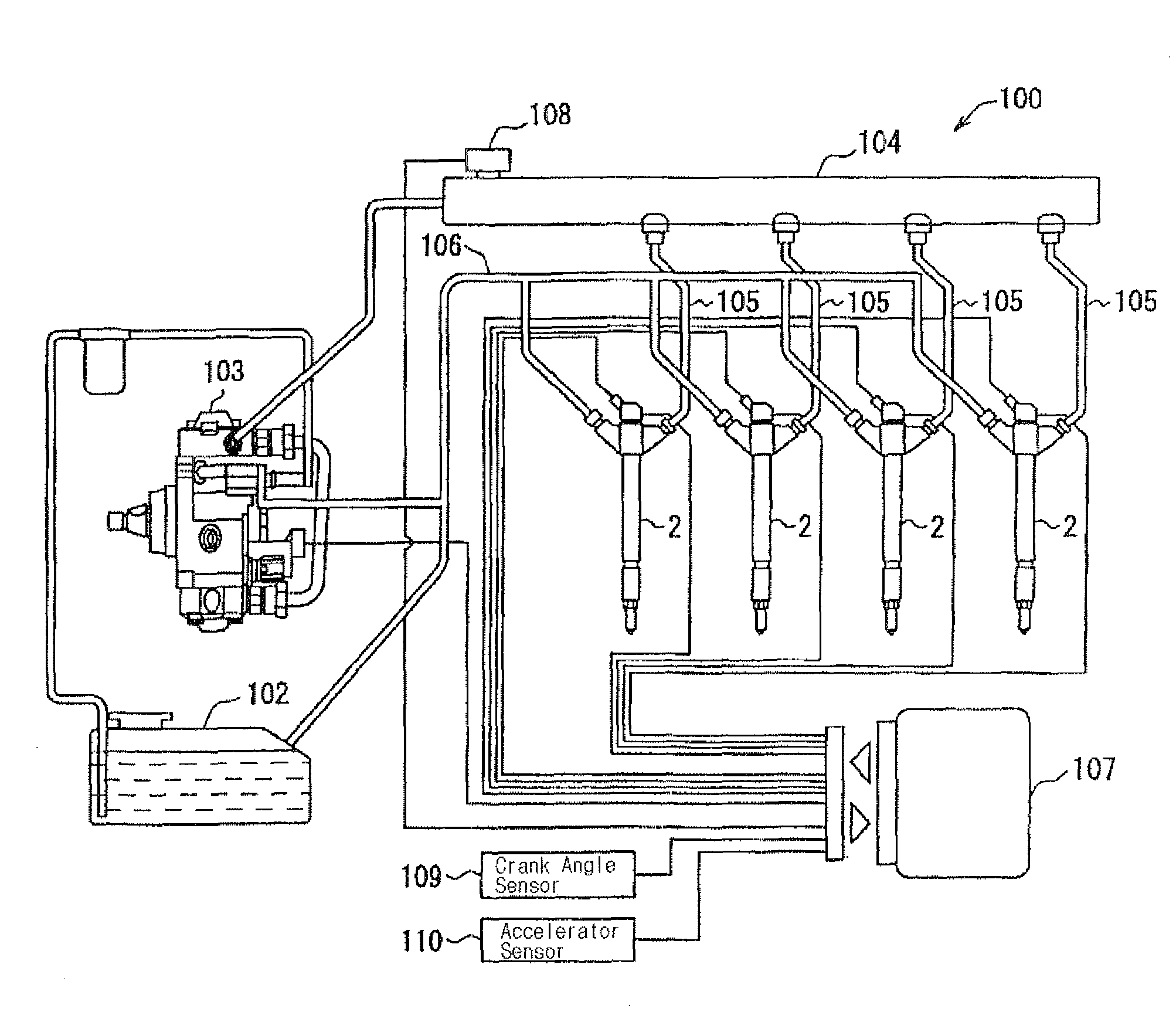

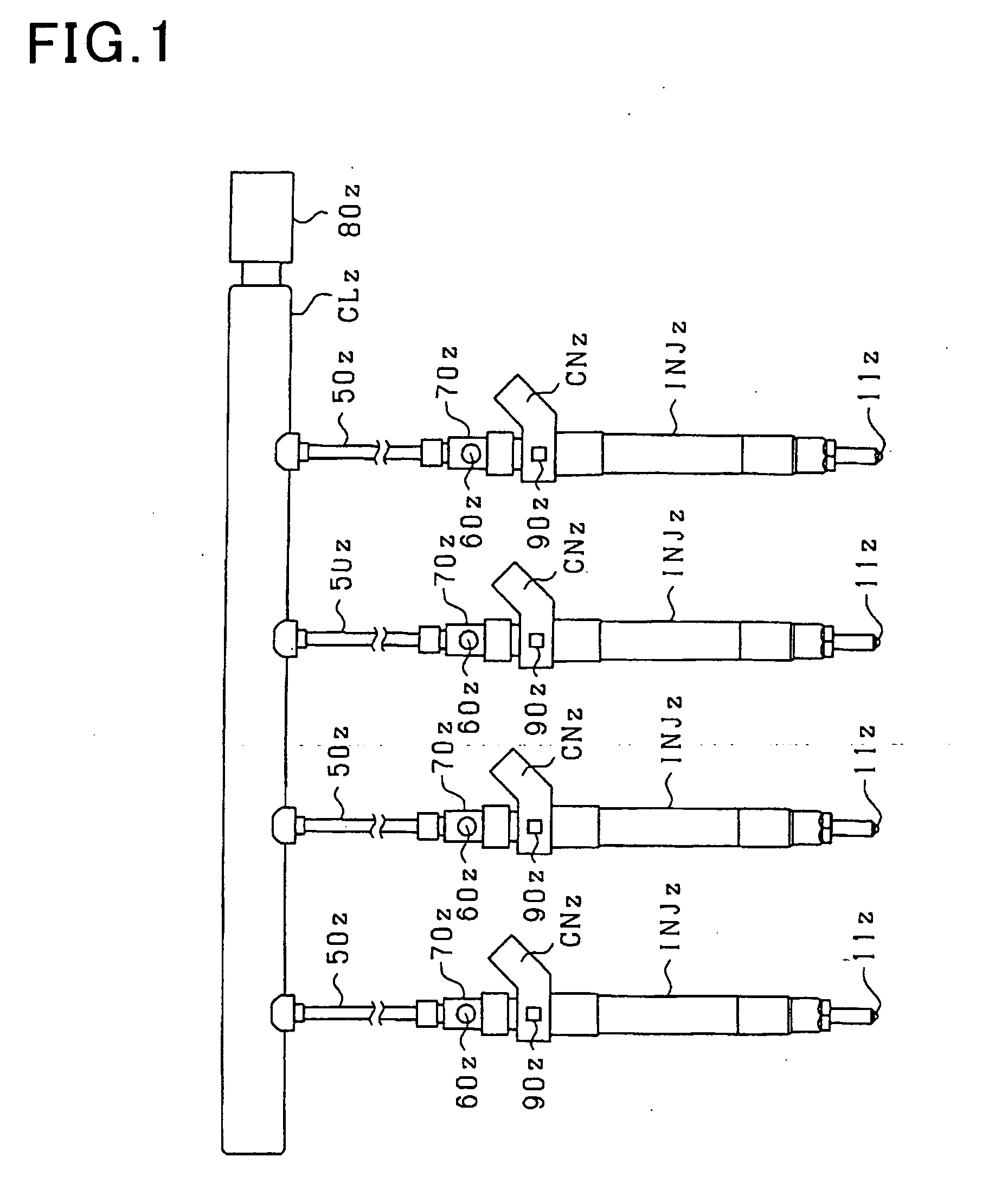

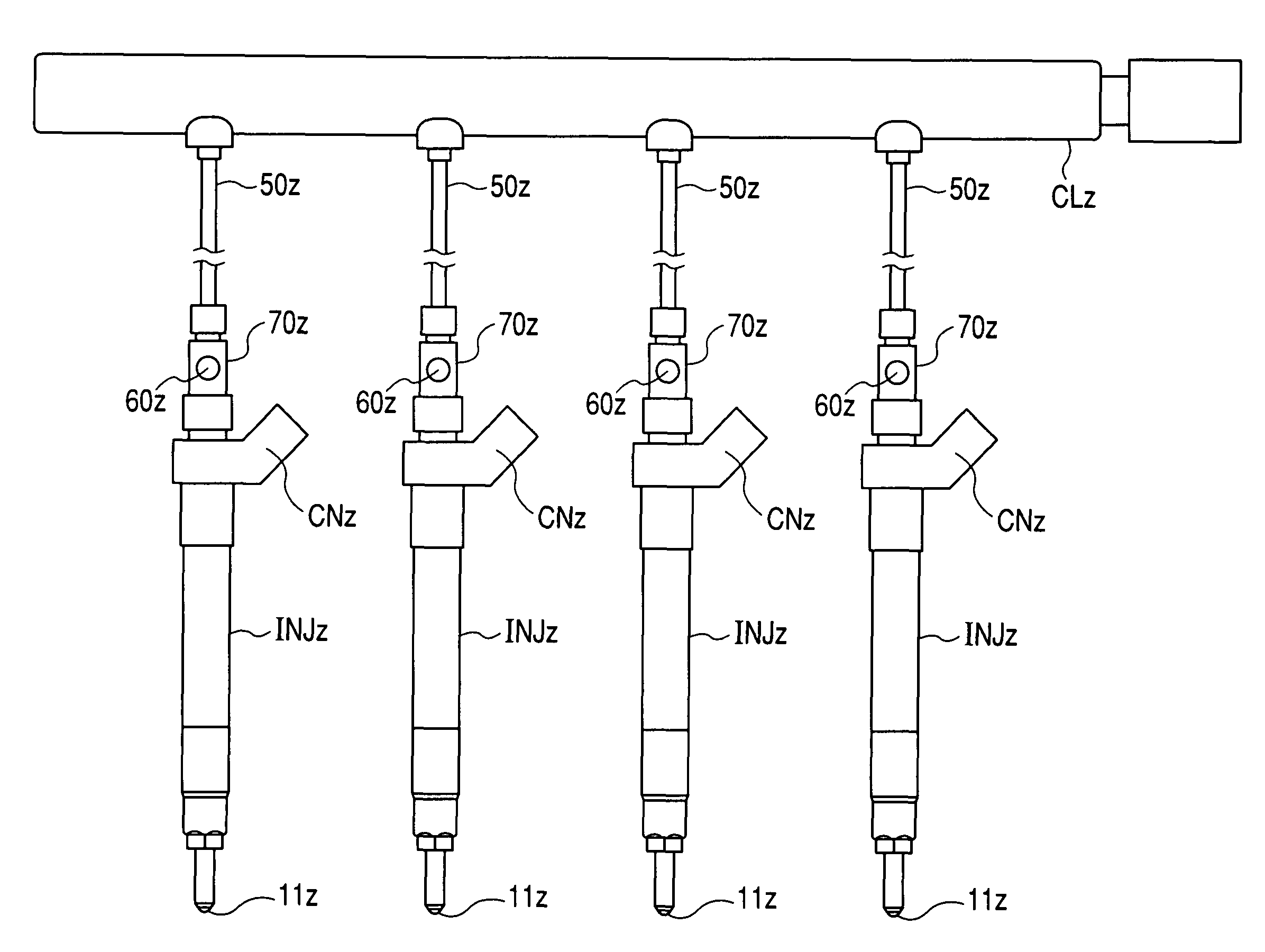

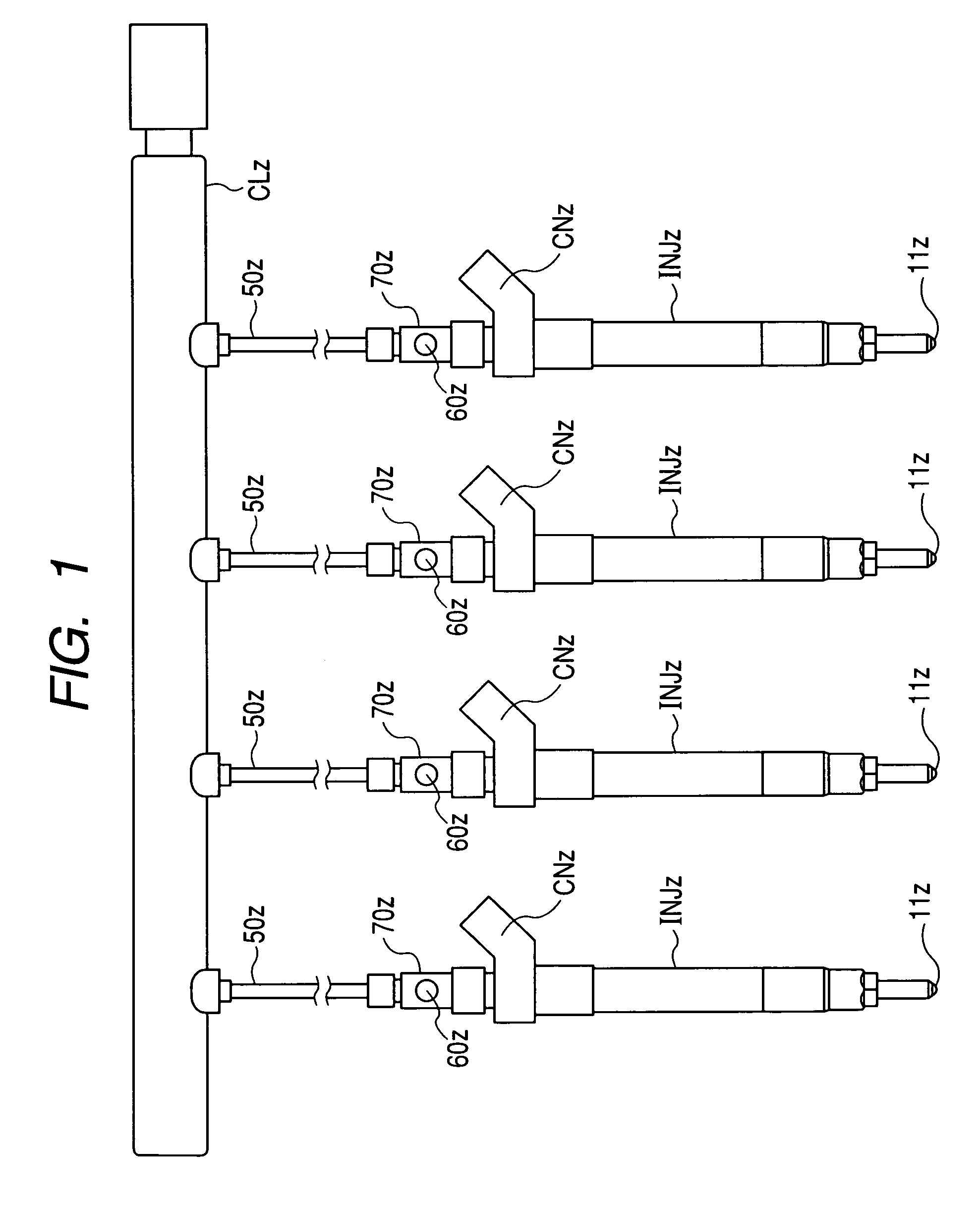

Fuel injection device and adjustment method thereof

ActiveUS20080228374A1Improve accuracyAccurate inductionInternal-combustion engine testingElectrical controlCommon railForce sensor

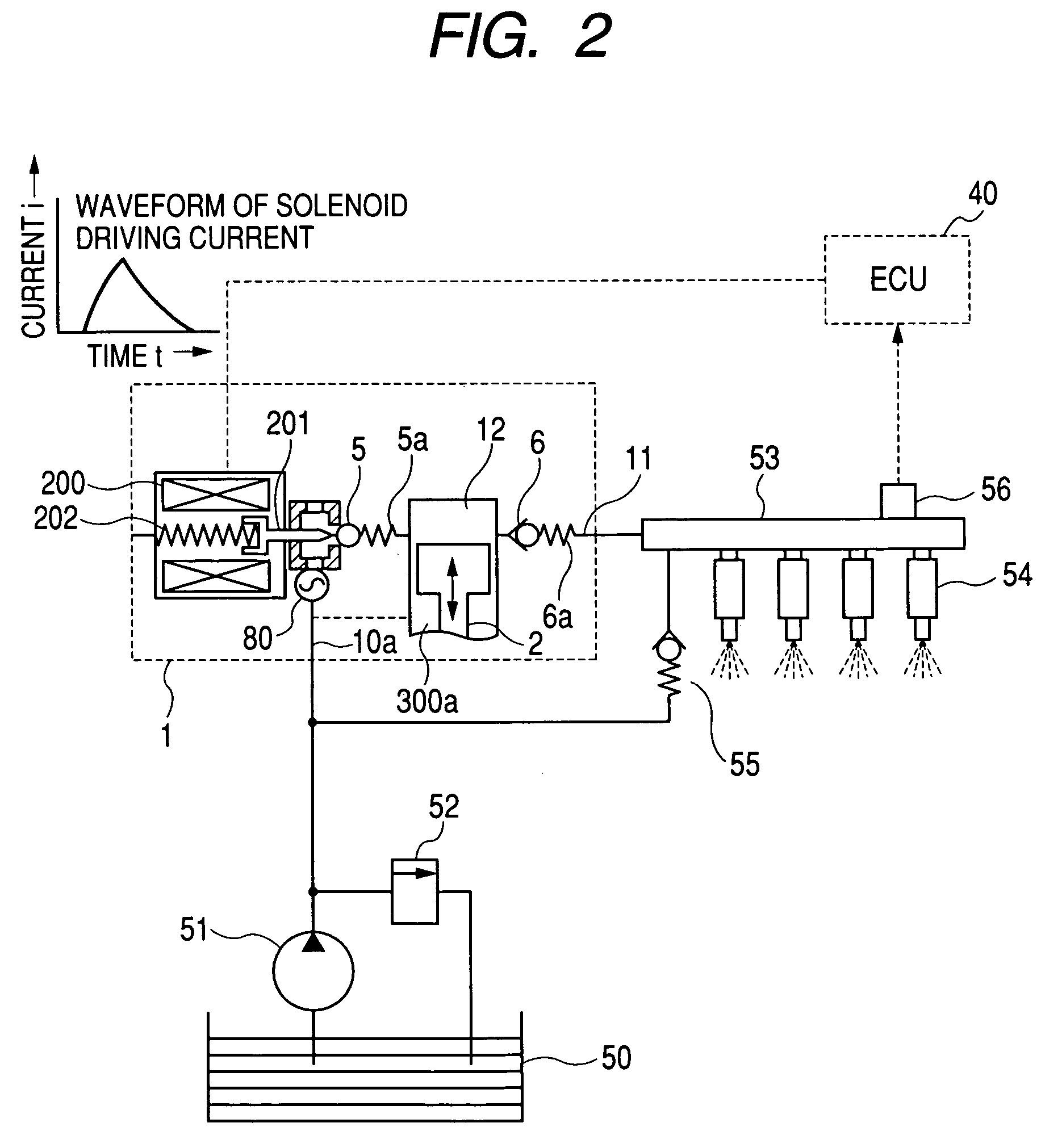

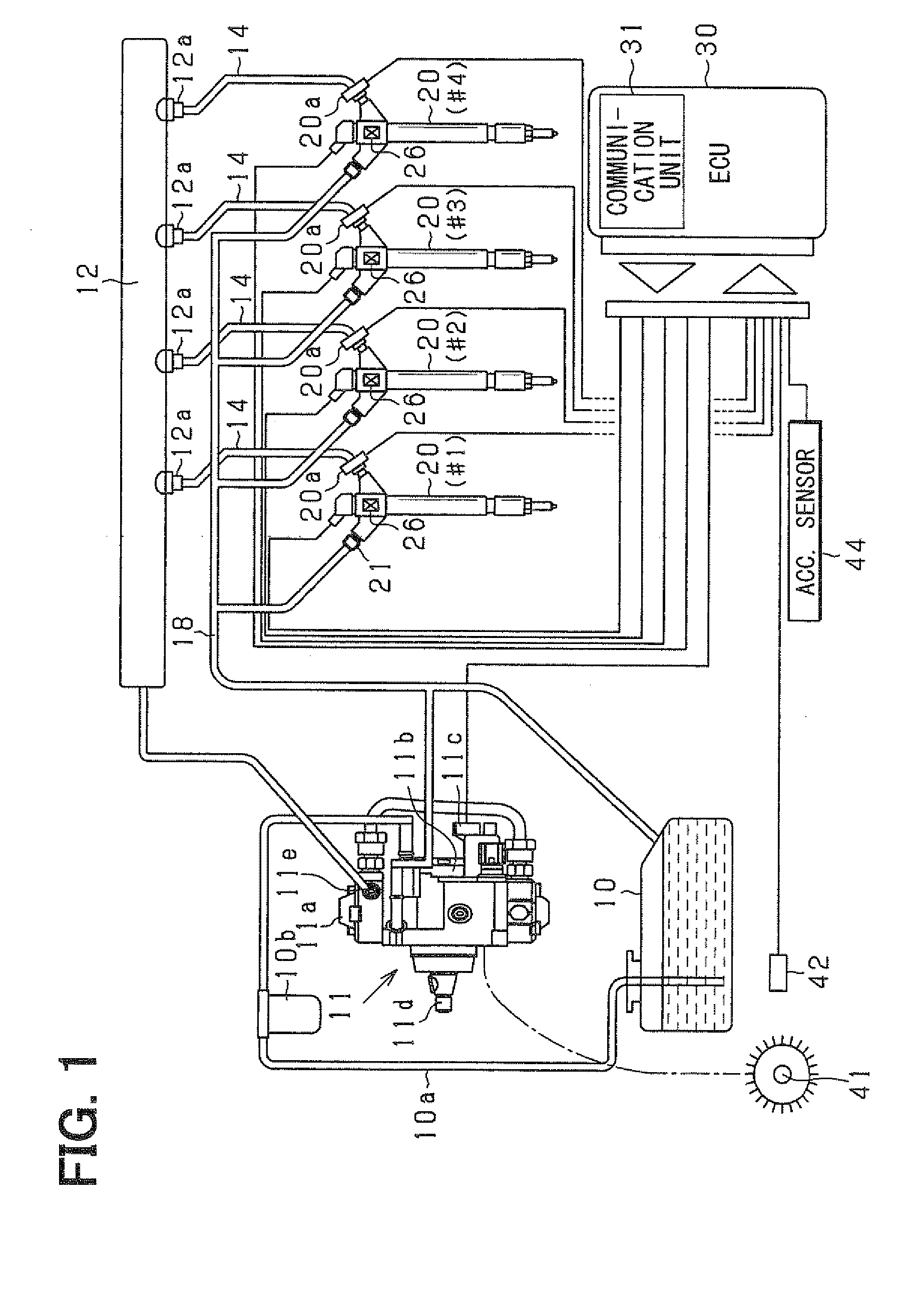

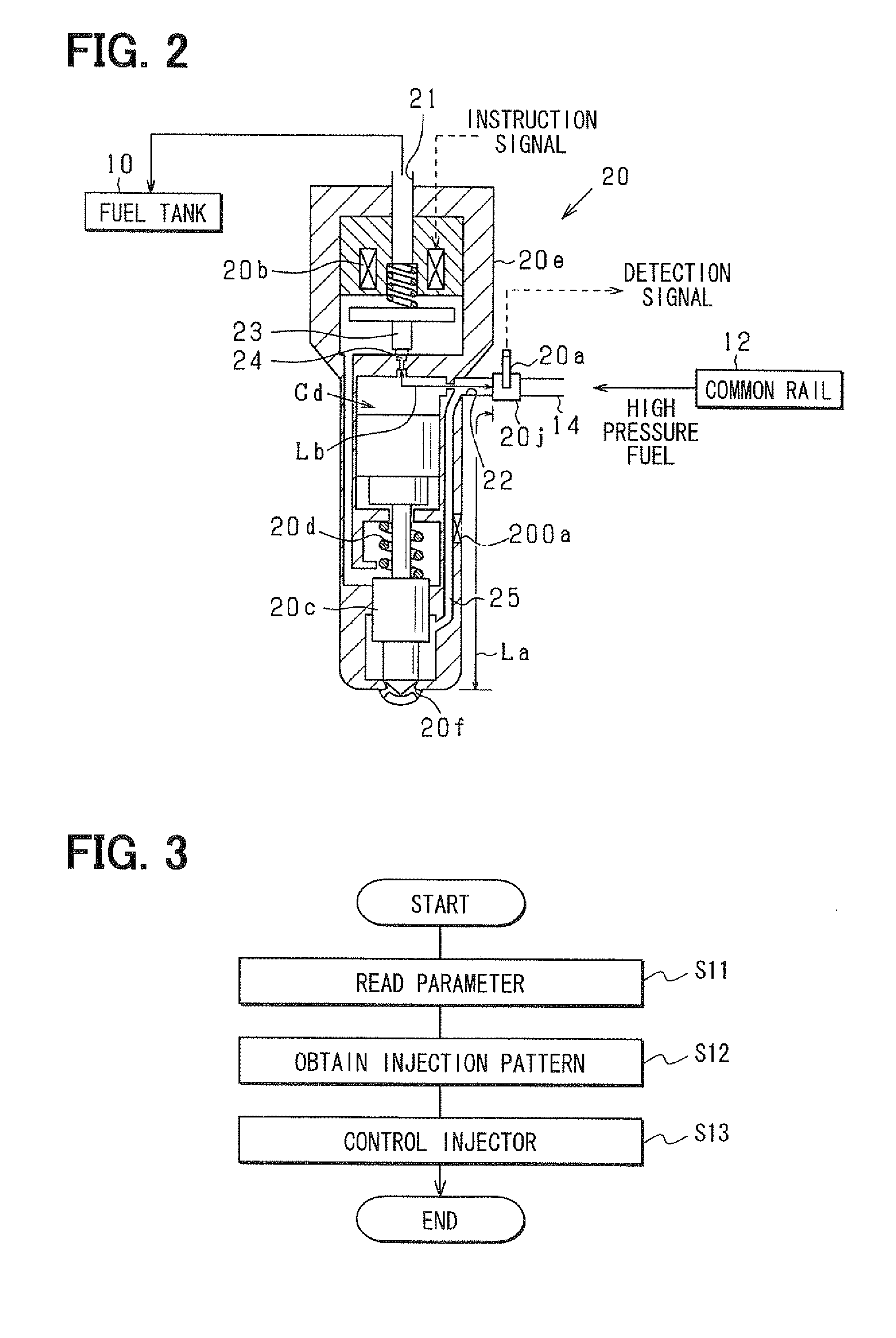

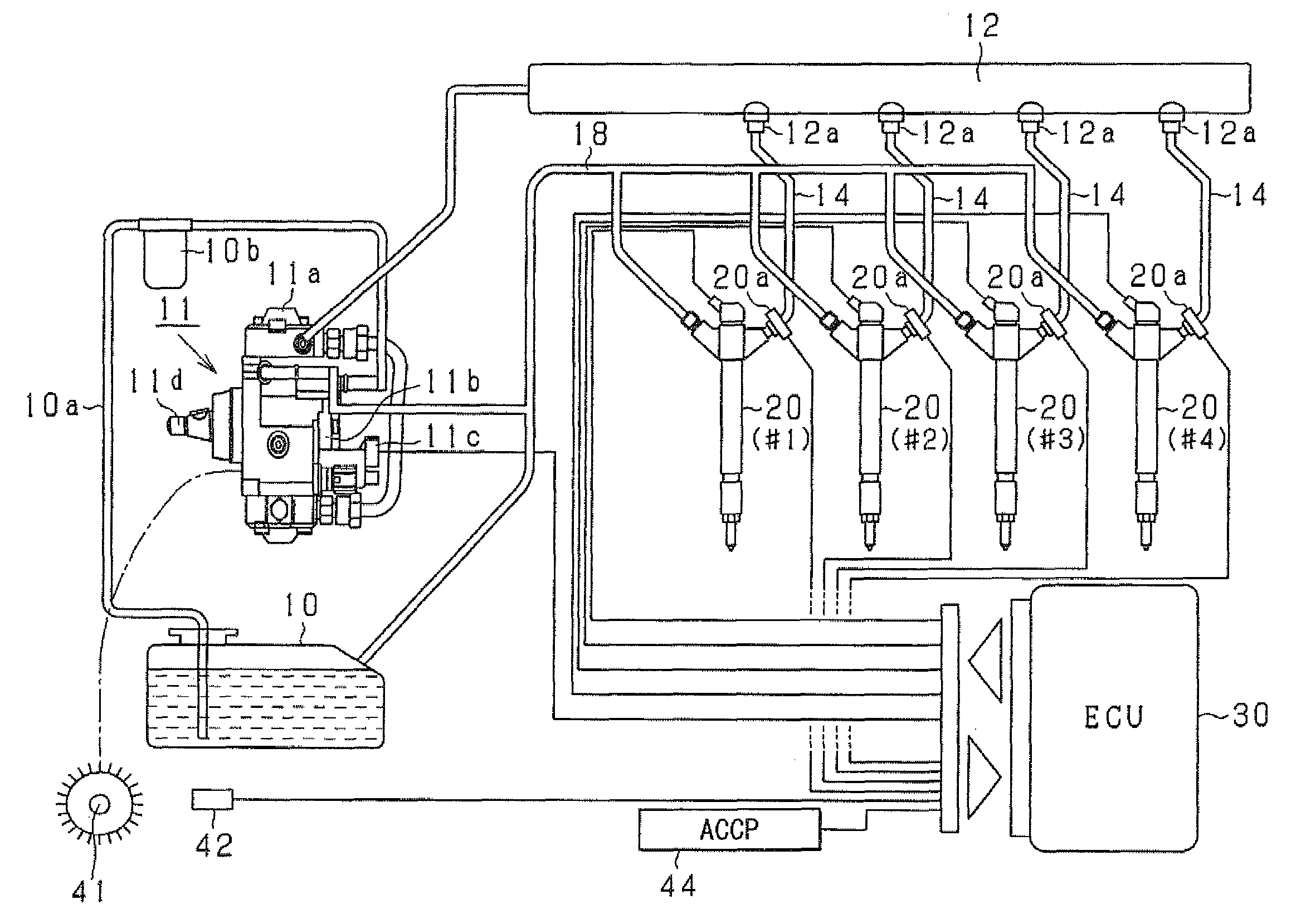

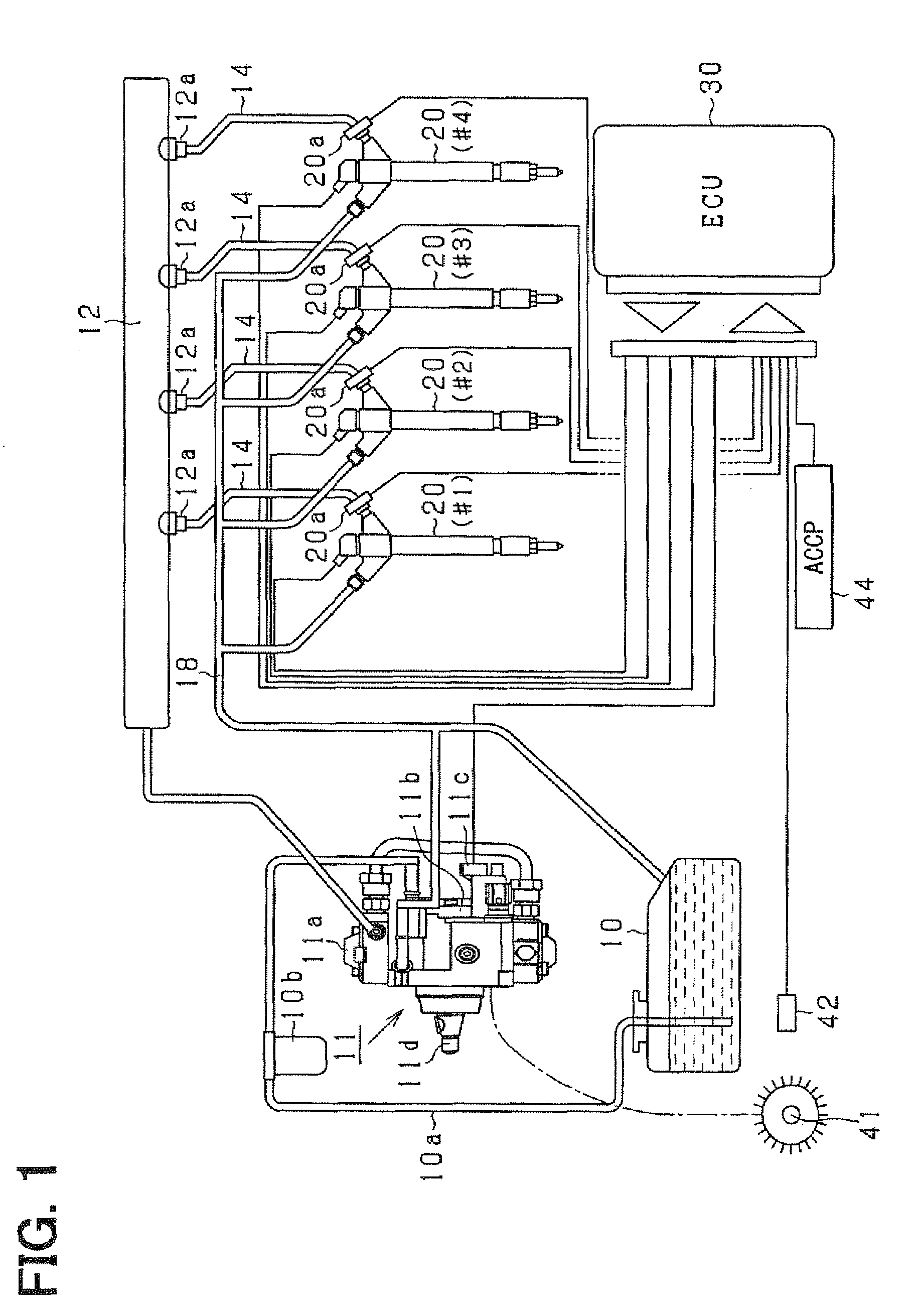

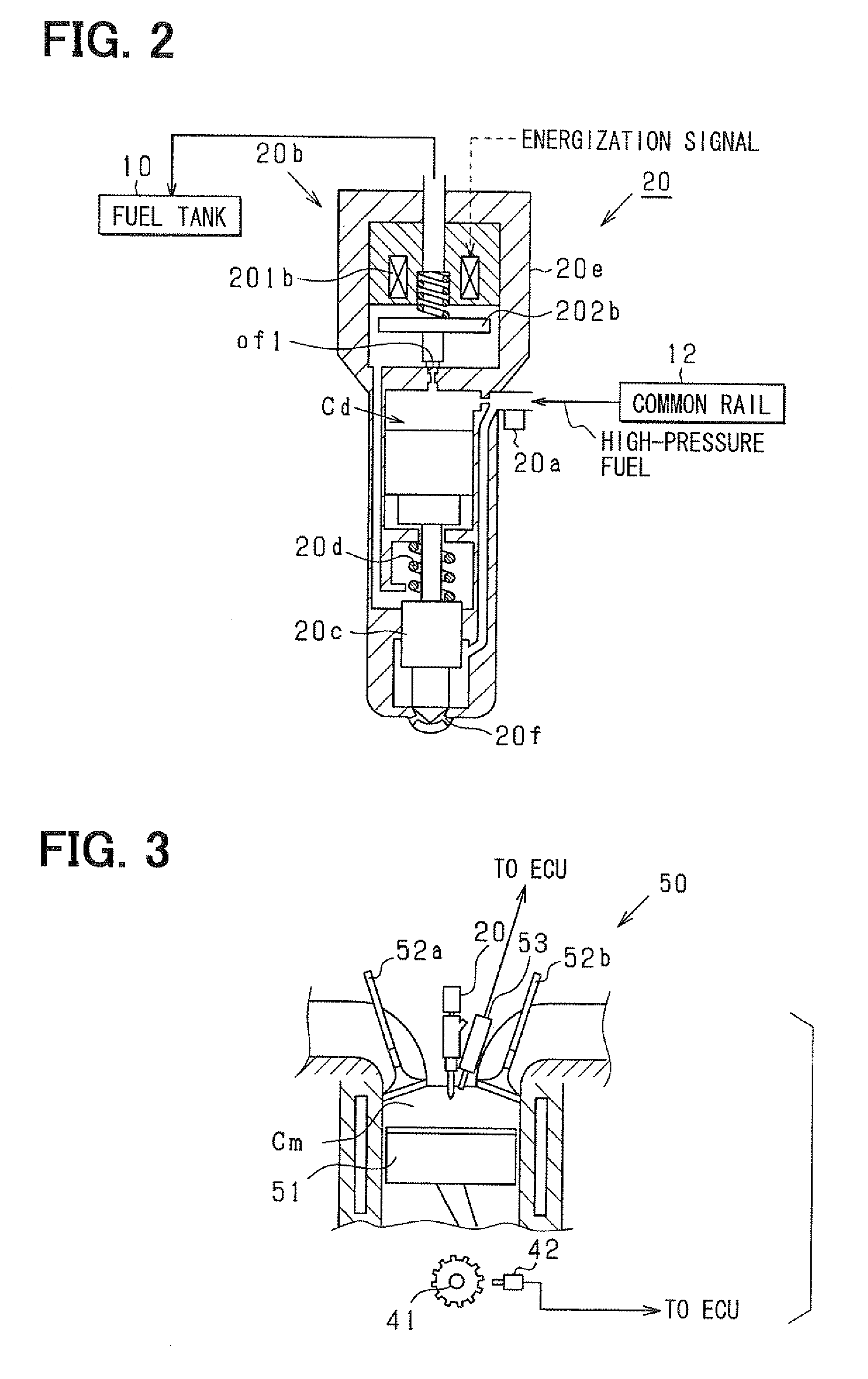

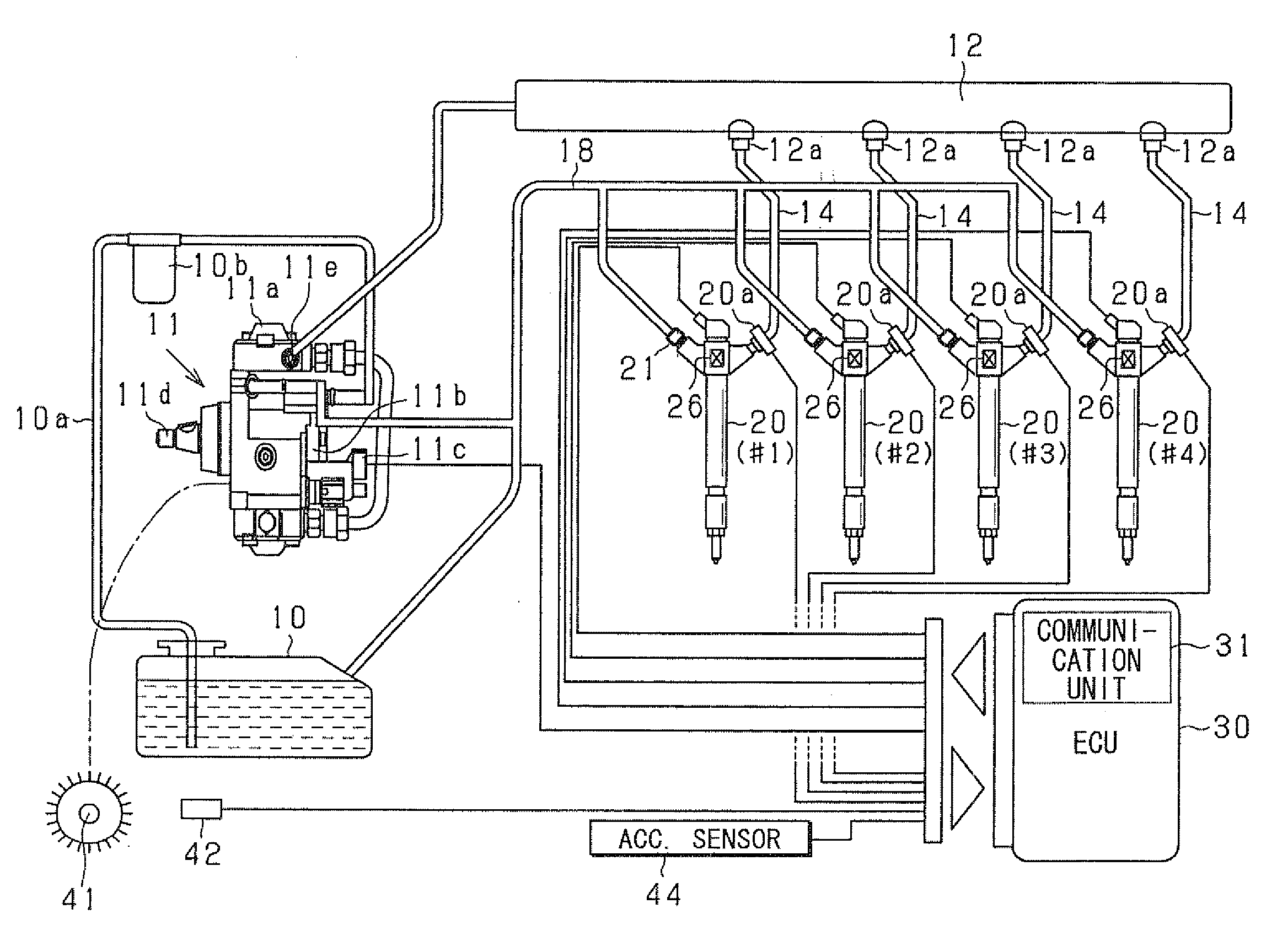

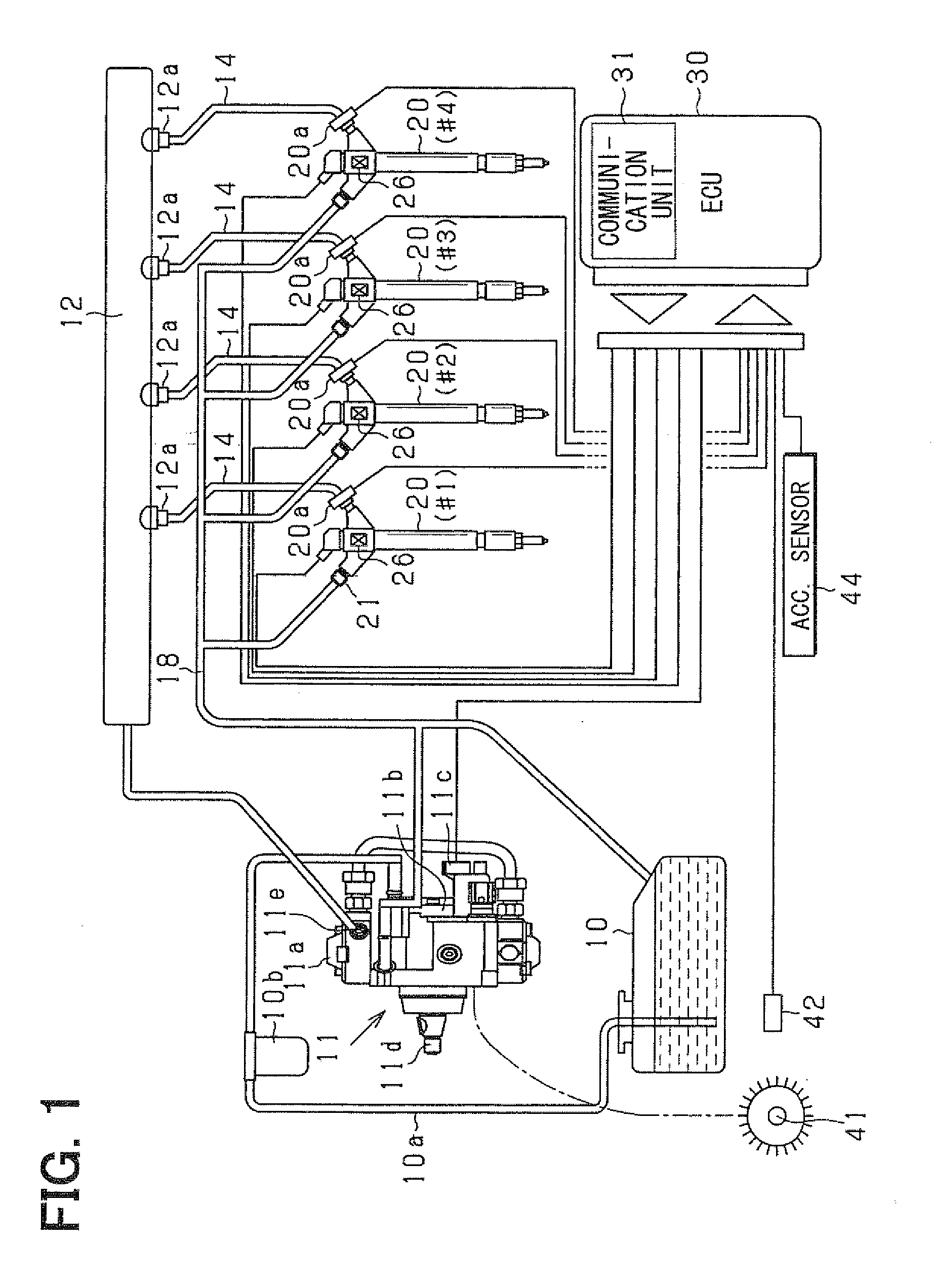

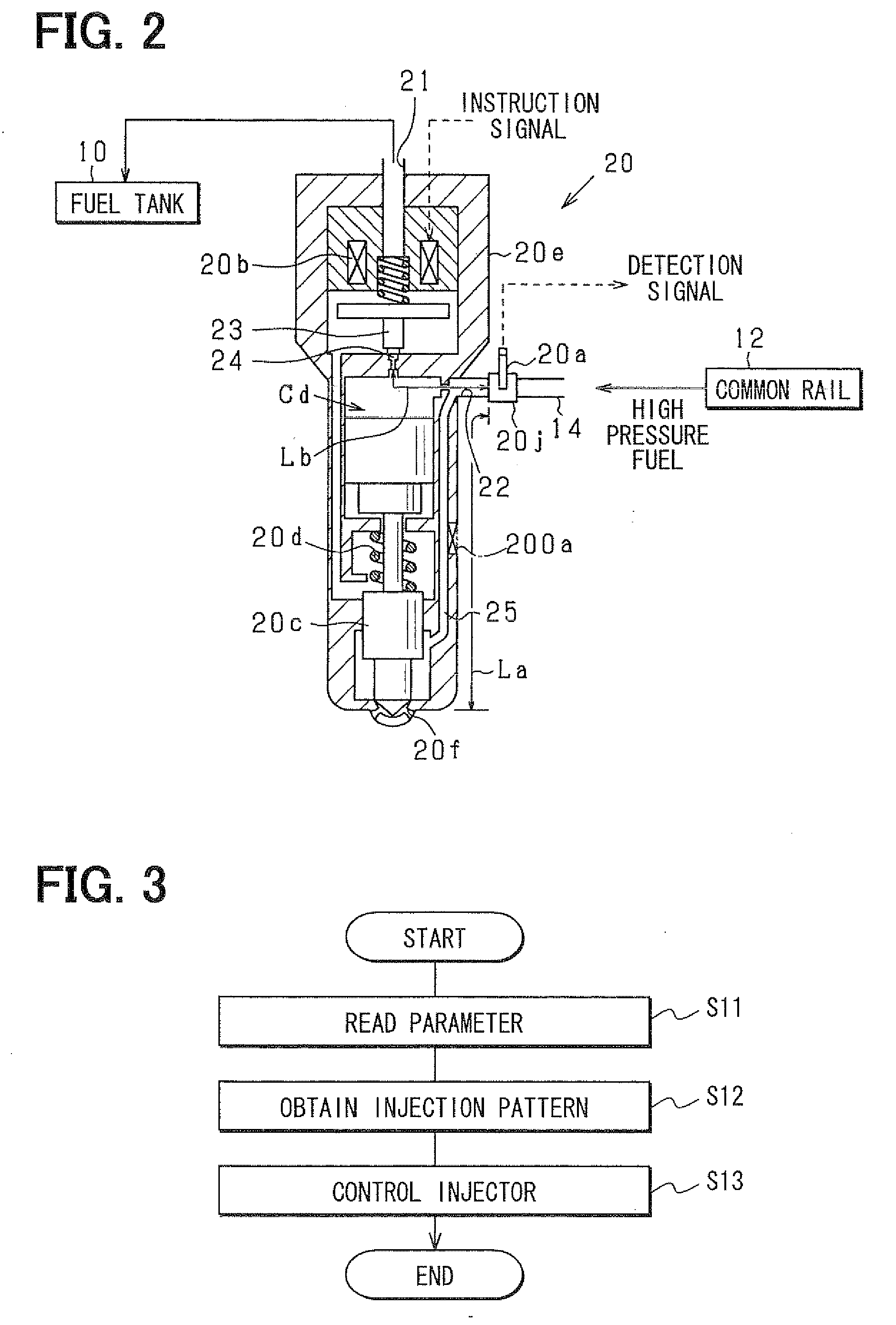

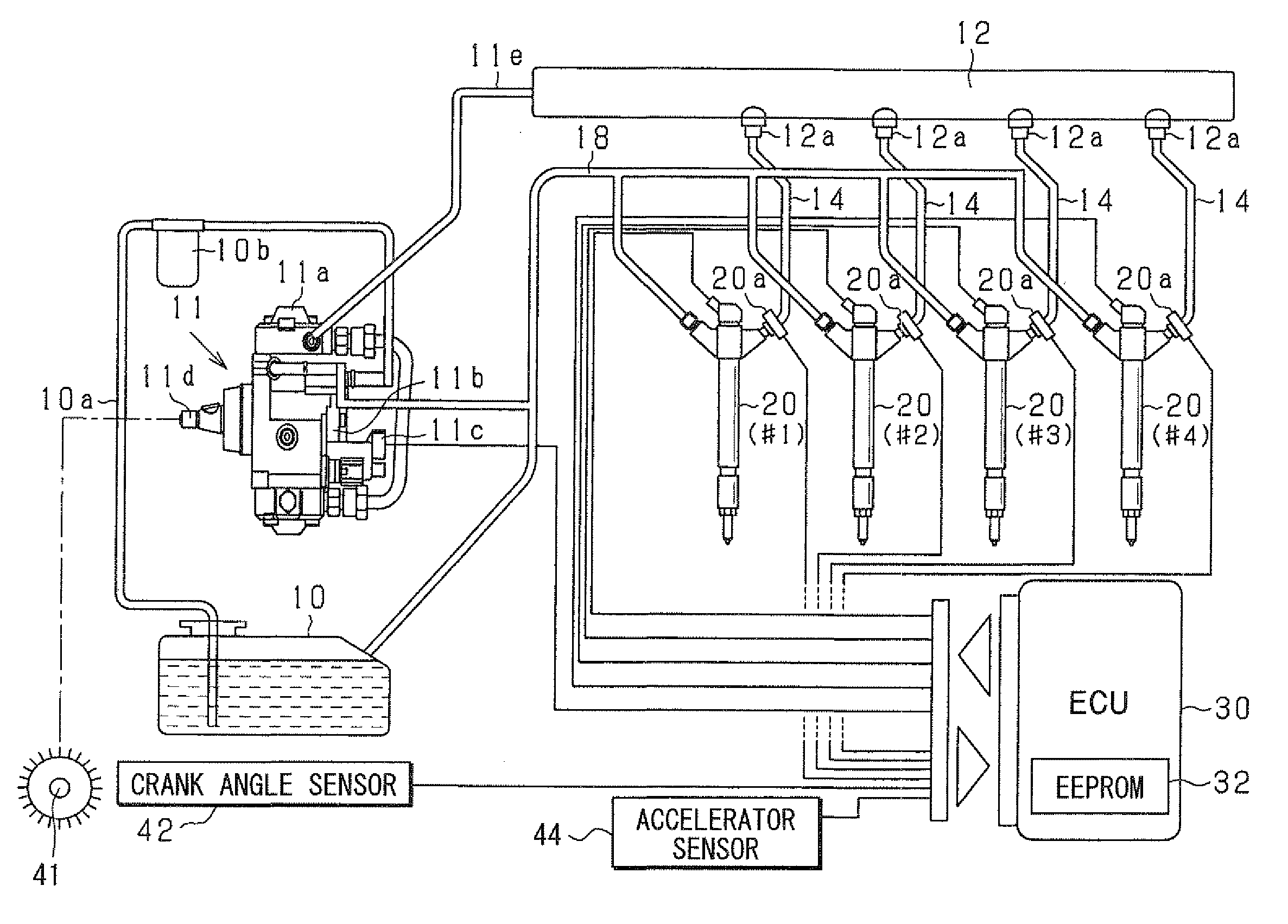

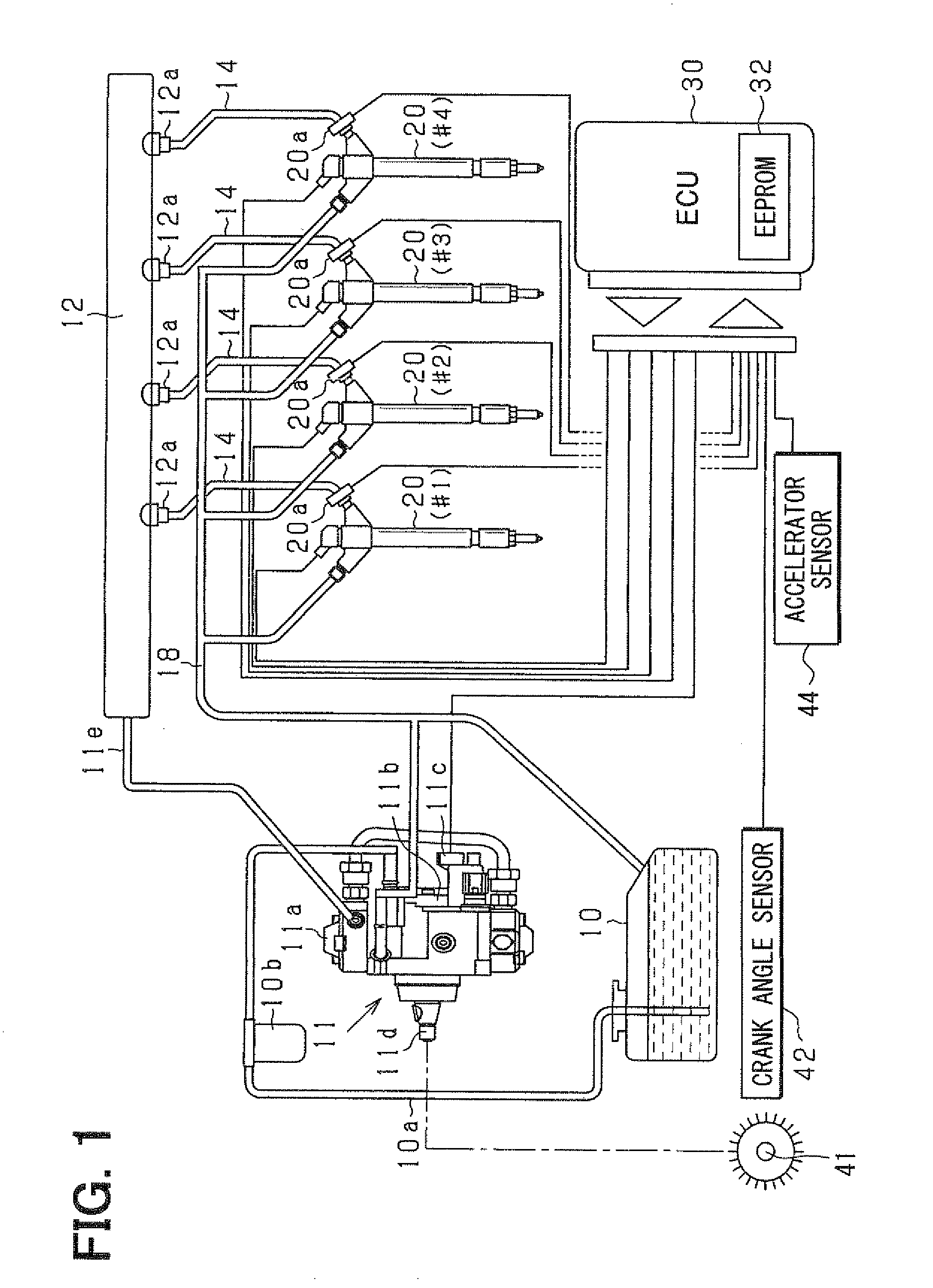

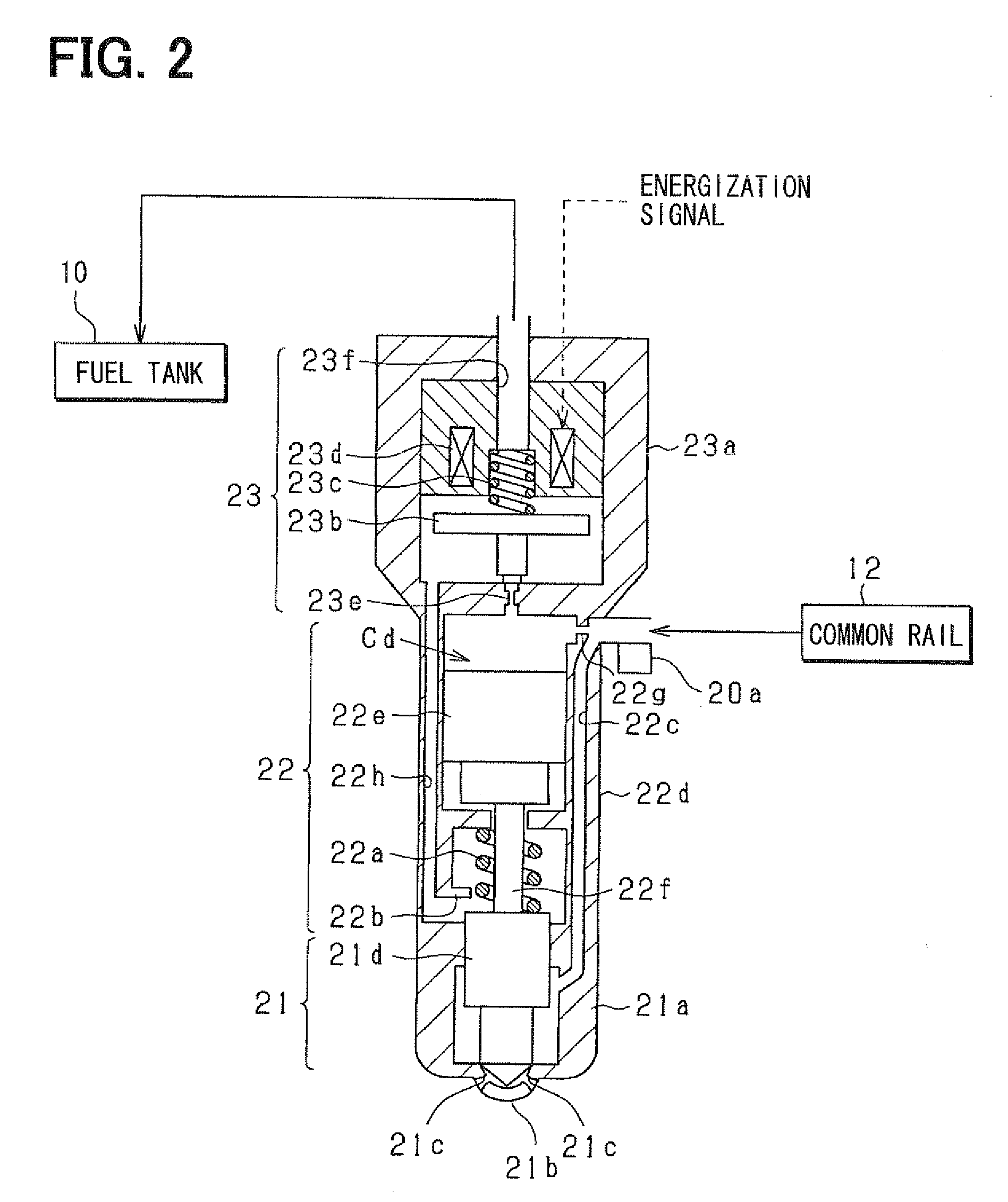

A fuel injection device (fuel supply system) of a common rail type fuel injection system for an engine includes a pressure sensor disposed in a fuel inlet of an injector for measuring a fuel pressure at a position where the sensor is disposed and an ECU for sensing various kinds of pressure fluctuations associated with the injection including a pressure leak due to an injection operation of the injector and waving characteristics due to actual injection thereof based on sensor outputs from the pressure sensor. The ECU serially obtains the sensor outputs from the pressure sensor at intervals of 20 μsec.

Owner:DENSO CORP

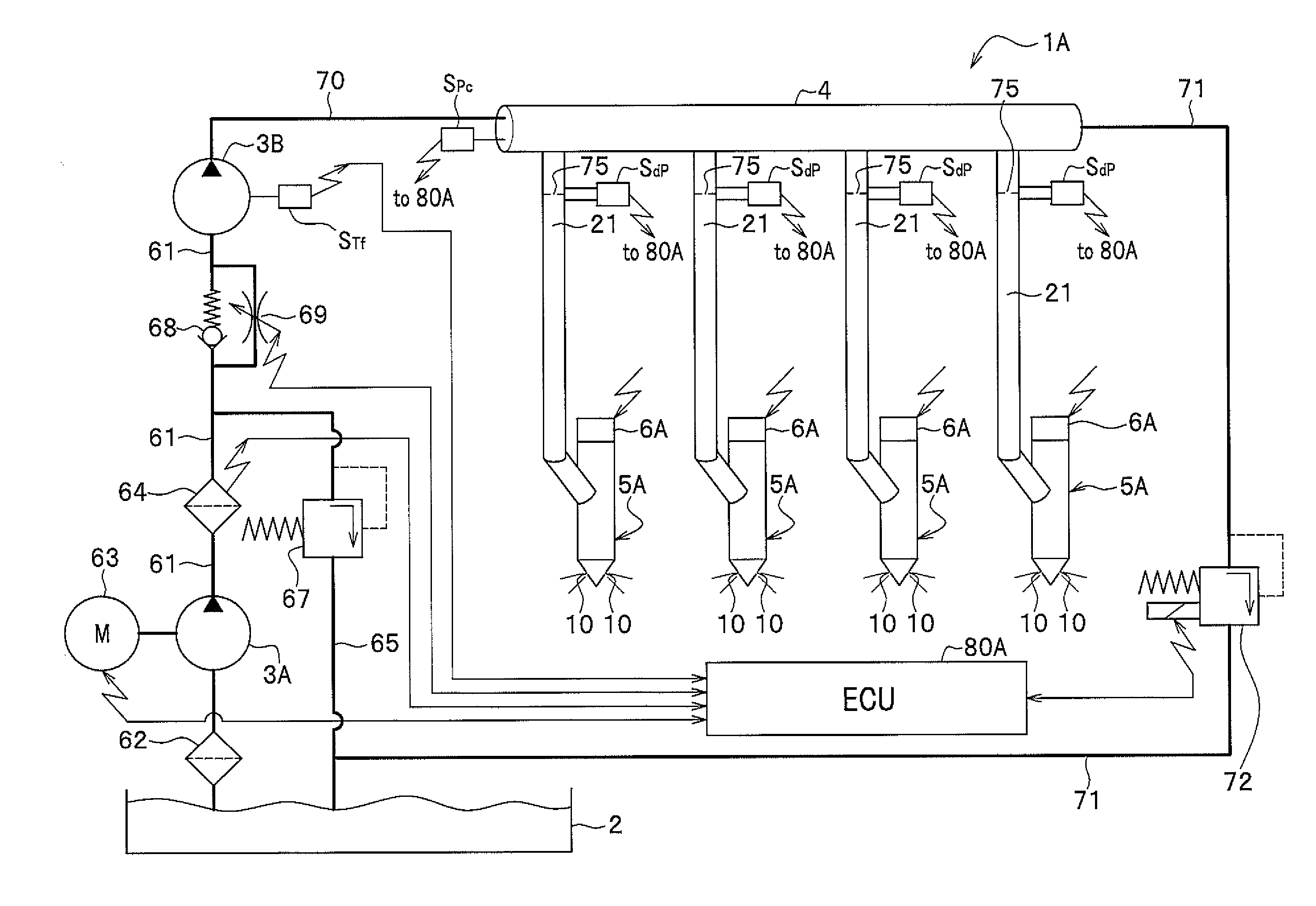

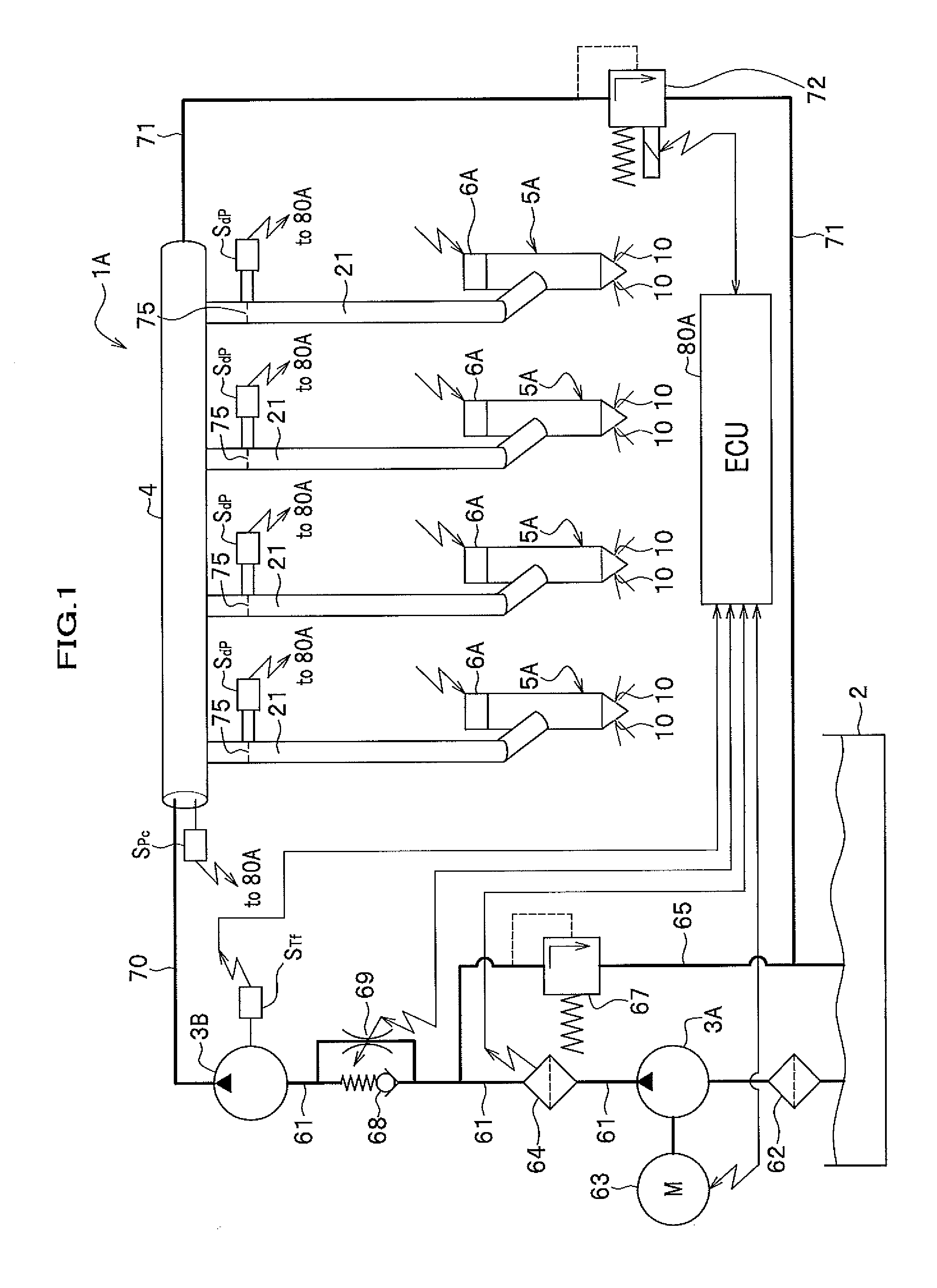

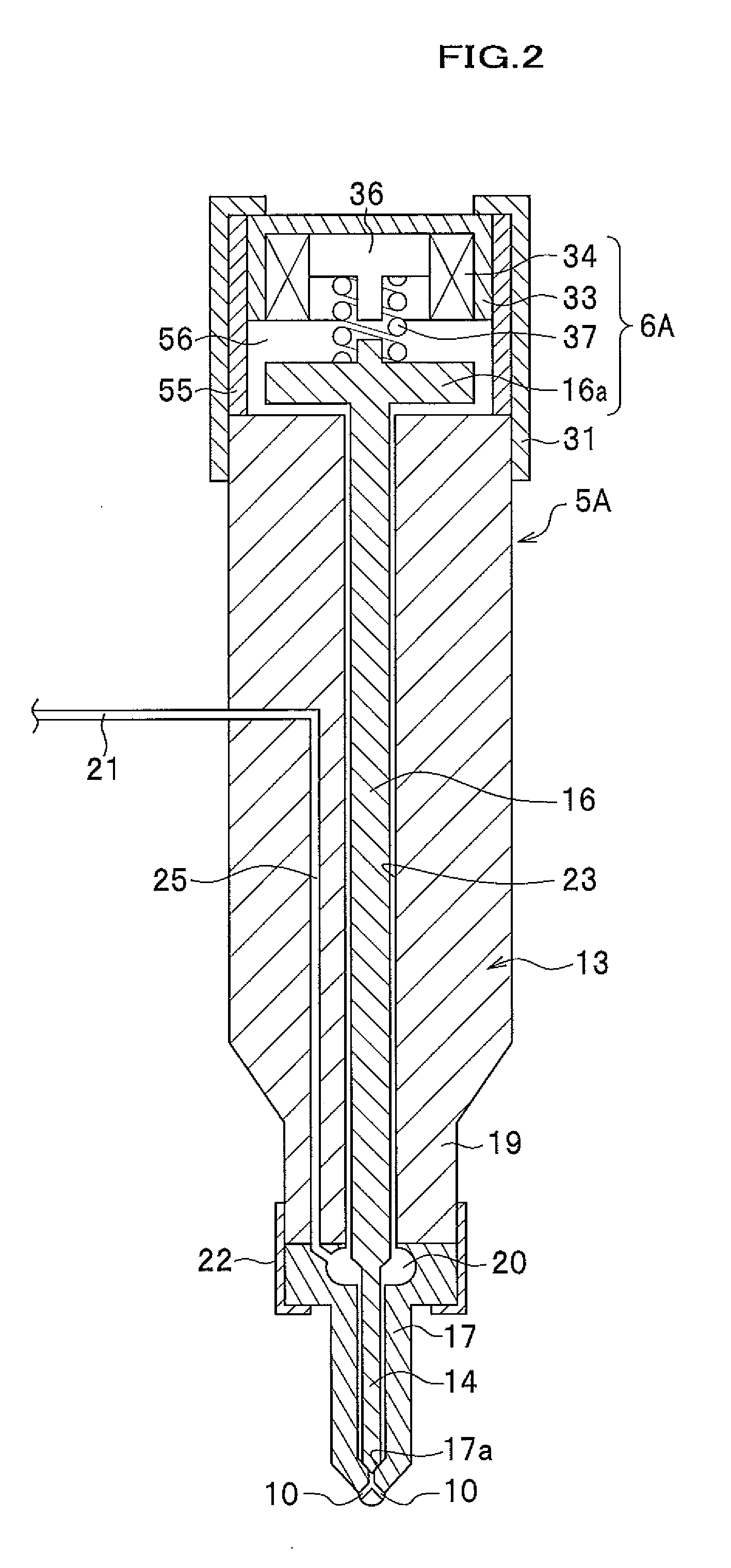

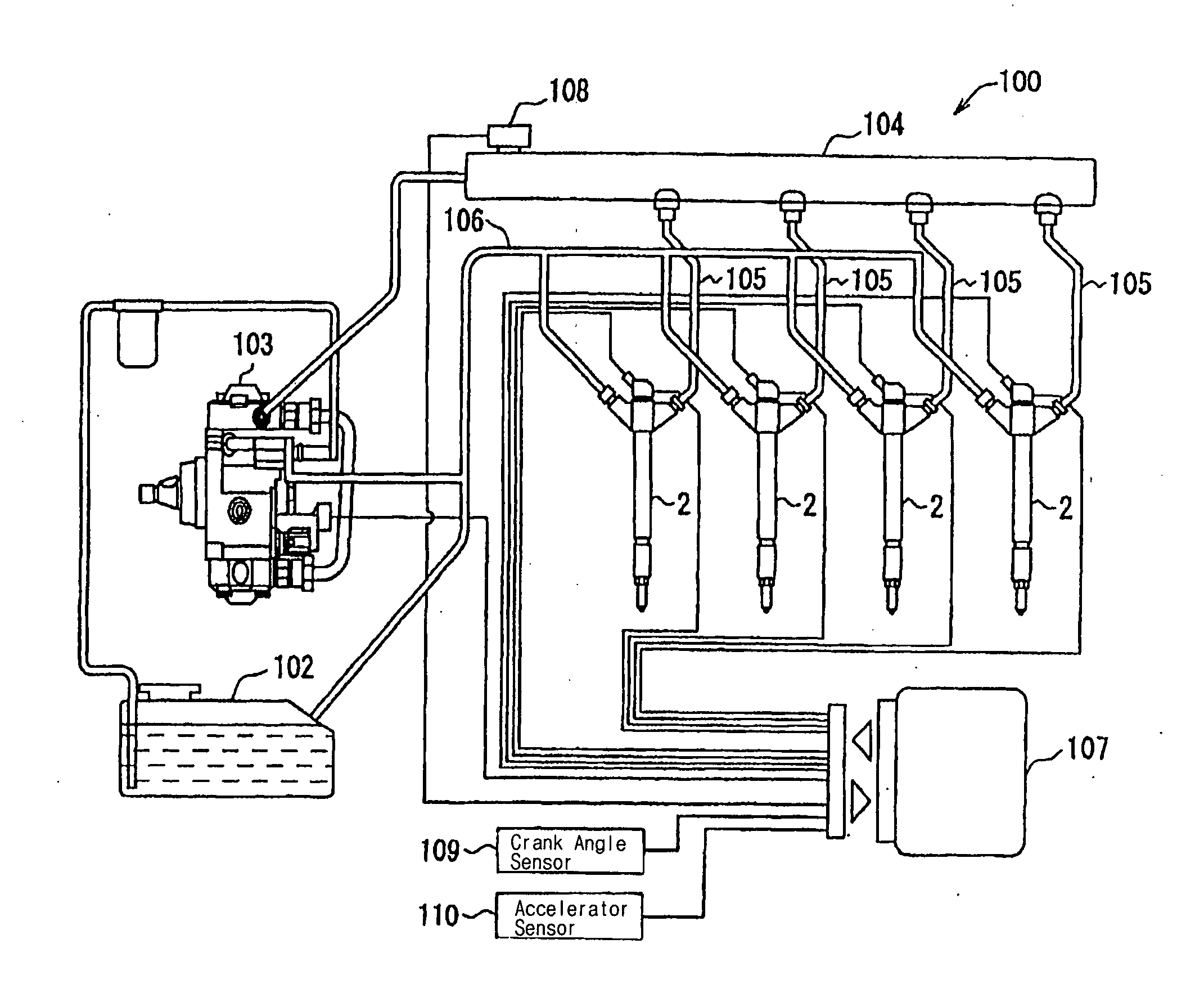

Fuel injection device

InactiveUS20090326788A1Accurate calculationPrecision injectionElectrical controlDigital data processing detailsDifferential pressureCommon rail

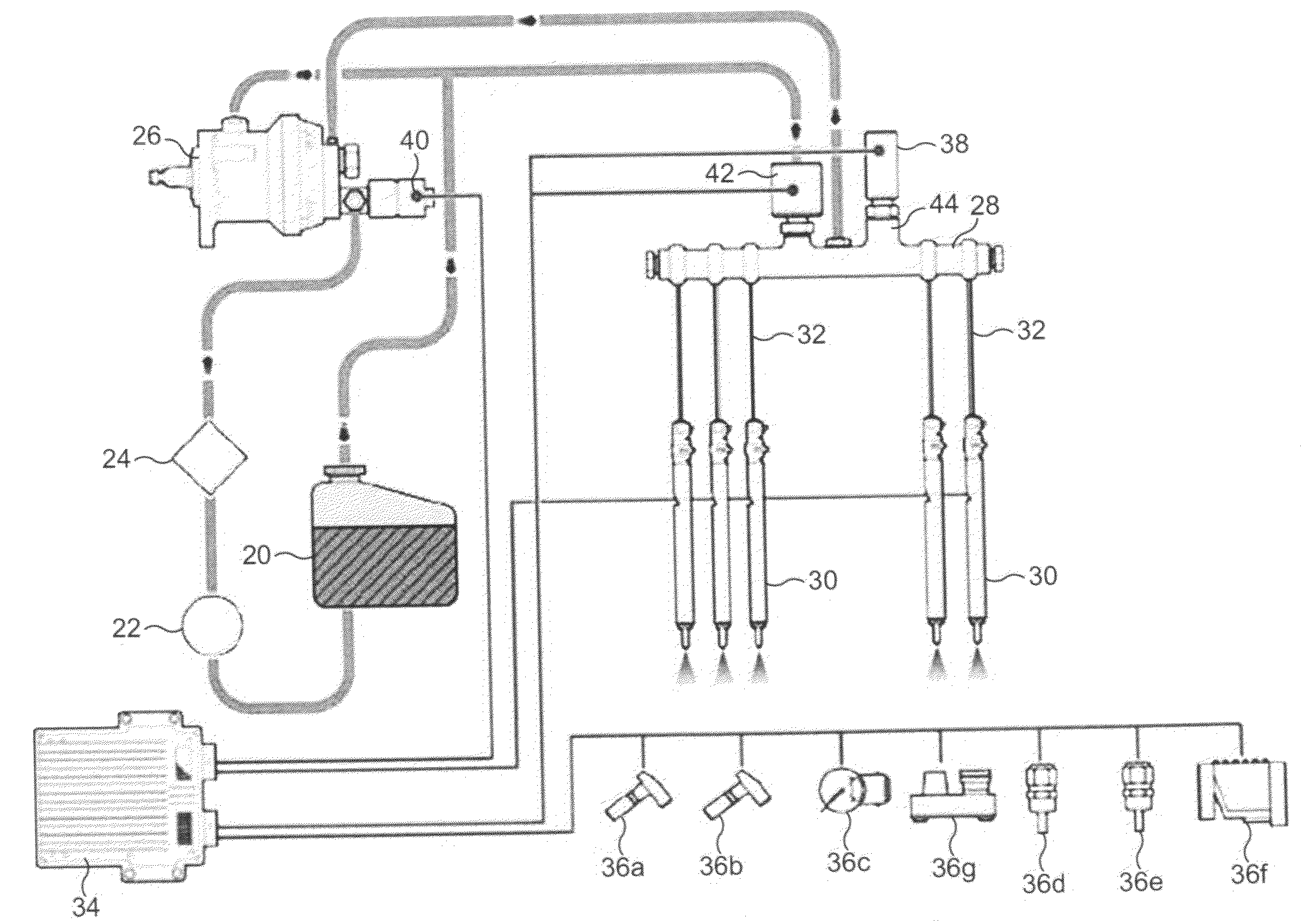

A fuel injection device 1A which includes a common rail 4 for accumulating fuel delivered by a high pressure pump 3B in a pressure-accumulated state, an injector for injecting in a cylinder of the diesel engine fuel supplied through a high pressure fuel supply passage 21 branched from the common rail 4, and an ECU 80A for outputting an injection command signal for injecting the fuel from the injector 5A. The fuel injection device 1A further includes an orifice 75 in the high pressure fuel supply passage 21 on the side of the common rail 4, and a differential pressure sensor SdP for detecting the pressure difference of the pressures on the upstream and downstream sides of the orifice 75. The ECU 80A calculates an actual fuel supply amount that passes the orifice 75 based on a signal from the differential pressure sensor SdP.

Owner:HONDA MOTOR CO LTD

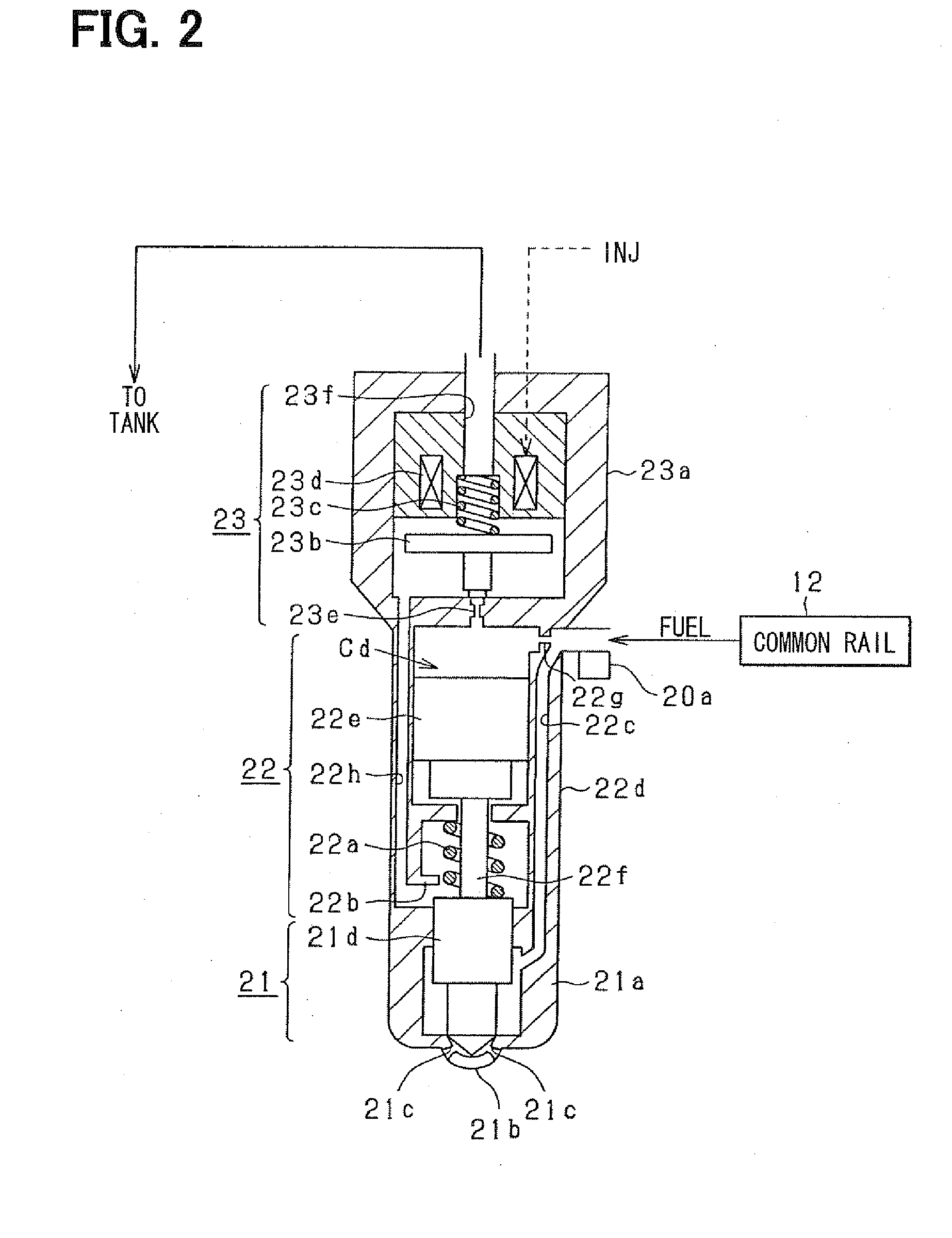

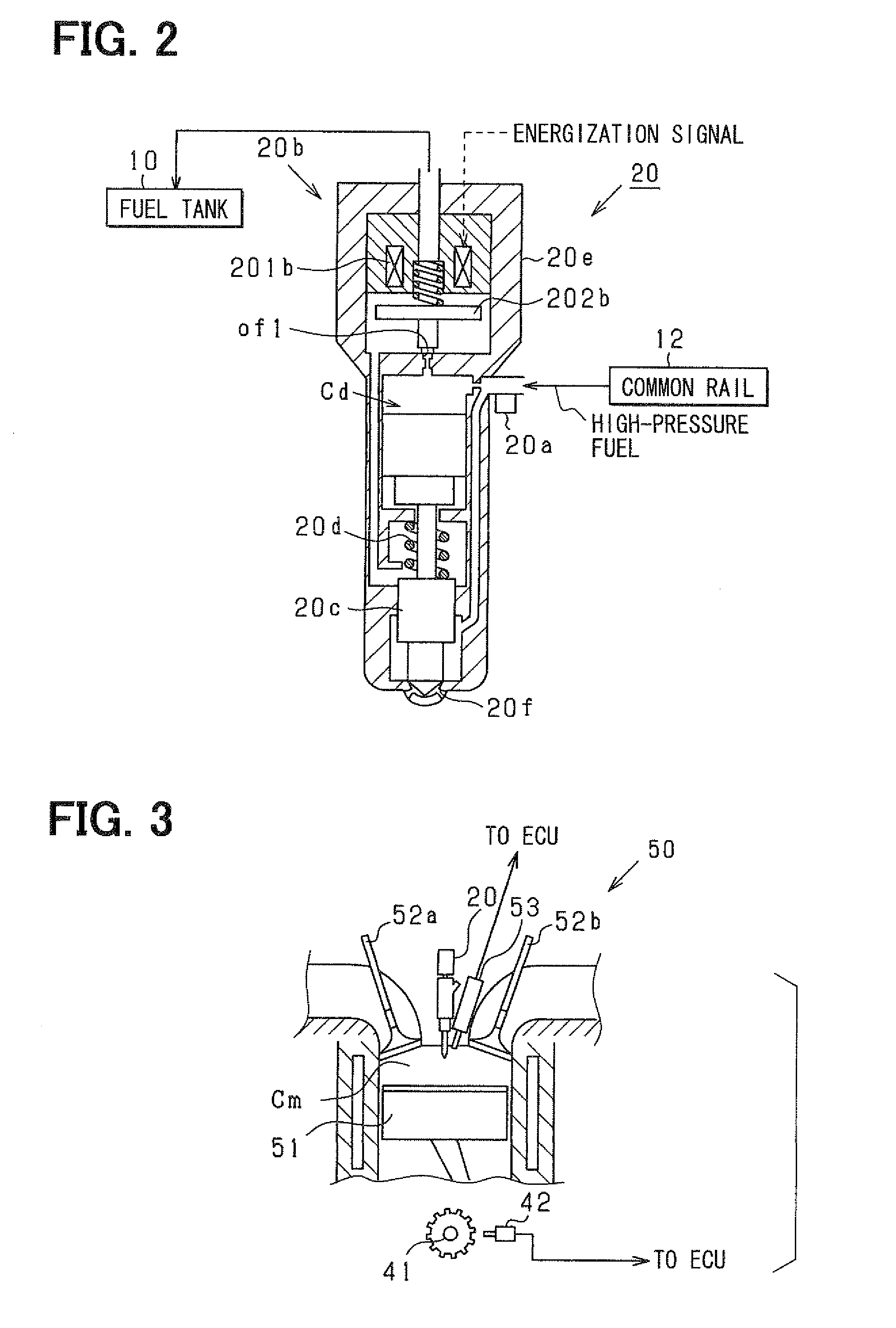

Fuel injection characteristic sensing device and fuel injection command correcting device

ActiveUS20090063013A1Compensating for such errorPrecision injectionElectrical controlInternal combustion piston enginesEngineeringPressure sensor

A fuel injection characteristic sensing device obtains an injection characteristic of a target injector (an injector of each cylinder of a multi-cylinder engine) at each time. The device has a program for sequentially sensing fuel pressure at a sensing point corresponding to a fuel pressure sensor, which is provided at a fuel inlet of each injector, based on an output of the fuel pressure sensor. The device has a program for detecting predetermined timings (injection timings such as an injection start timing and an injection end timing) in a series of operations concerning fuel injection of the injector of each cylinder based on the sequentially sensed fuel pressure. Thus, the injection characteristic at each time including a temporal characteristic change can be obtained.

Owner:DENSO CORP

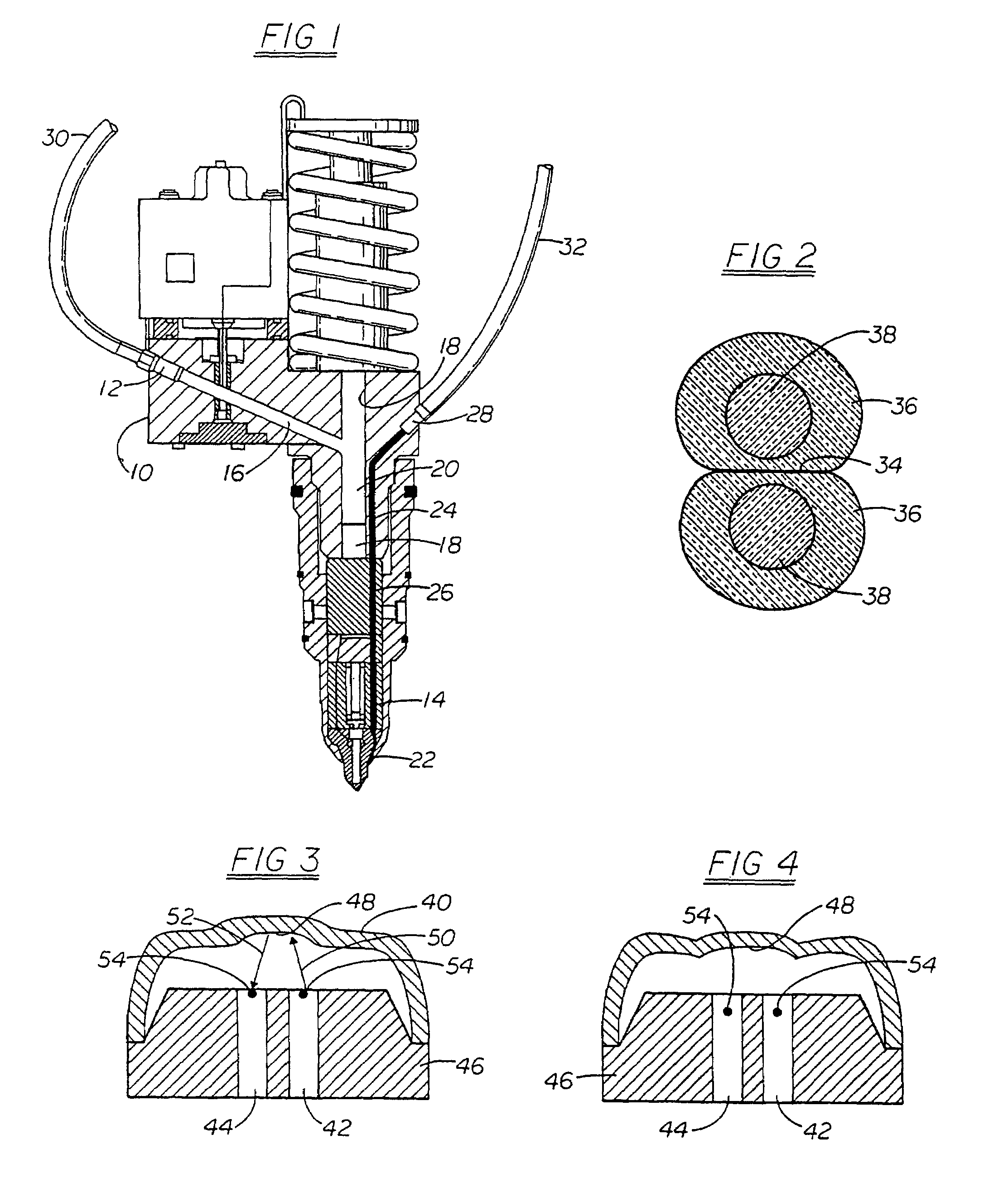

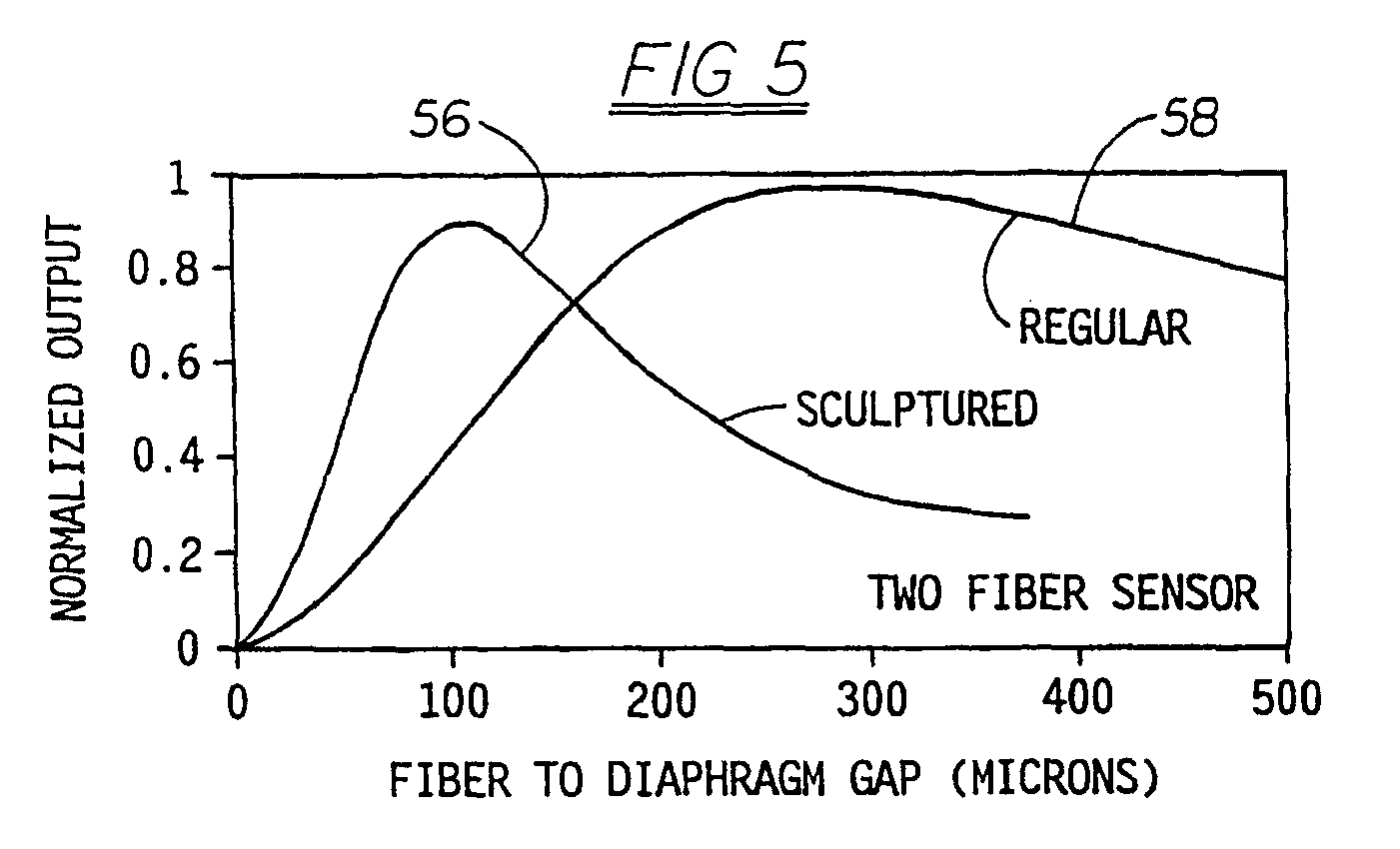

Fuel injectors with integral fiber optic pressure sensors and associated compensation and status monitoring devices

InactiveUS7340118B2Cost-effective and accurateAccurate and repeatable spray patternsTemperature measurement in motorsElectrical controlFiberCombustion chamber

Owner:WLODARCZYK MAREK T +1

Damper mechanism and high pressure fuel pump

ActiveUS7124738B2Increase in sizeReduce pressure pulsationFuel injecting pumpsFuel injection with sensorsEngineeringHigh pressure

To obtain a small and high performance damper mechanism which reduces pressure pulsation in low pressure-side fuel in the high pressure fuel pump in a high pressure fuel supply system or a high pressure fuel pump provided with the small and high performance damper mechanism.Two metal diaphragms are welded together over the entire circumference to obtain a metal diaphragm assembly (also referred to as “double metal diaphragm damper”). The whole or part of the portion of the metal diaphragm assembly other than the weld (for example, the portion inside the weld) is clamped by a pressing member and thereby the assembly is secured in a housing enclosure. The housing enclosure may be formed integrally with the body of a high pressure pump.

Owner:HITACHI ASTEMO LTD

Fuel Injector Having an Integrated Ignition Device

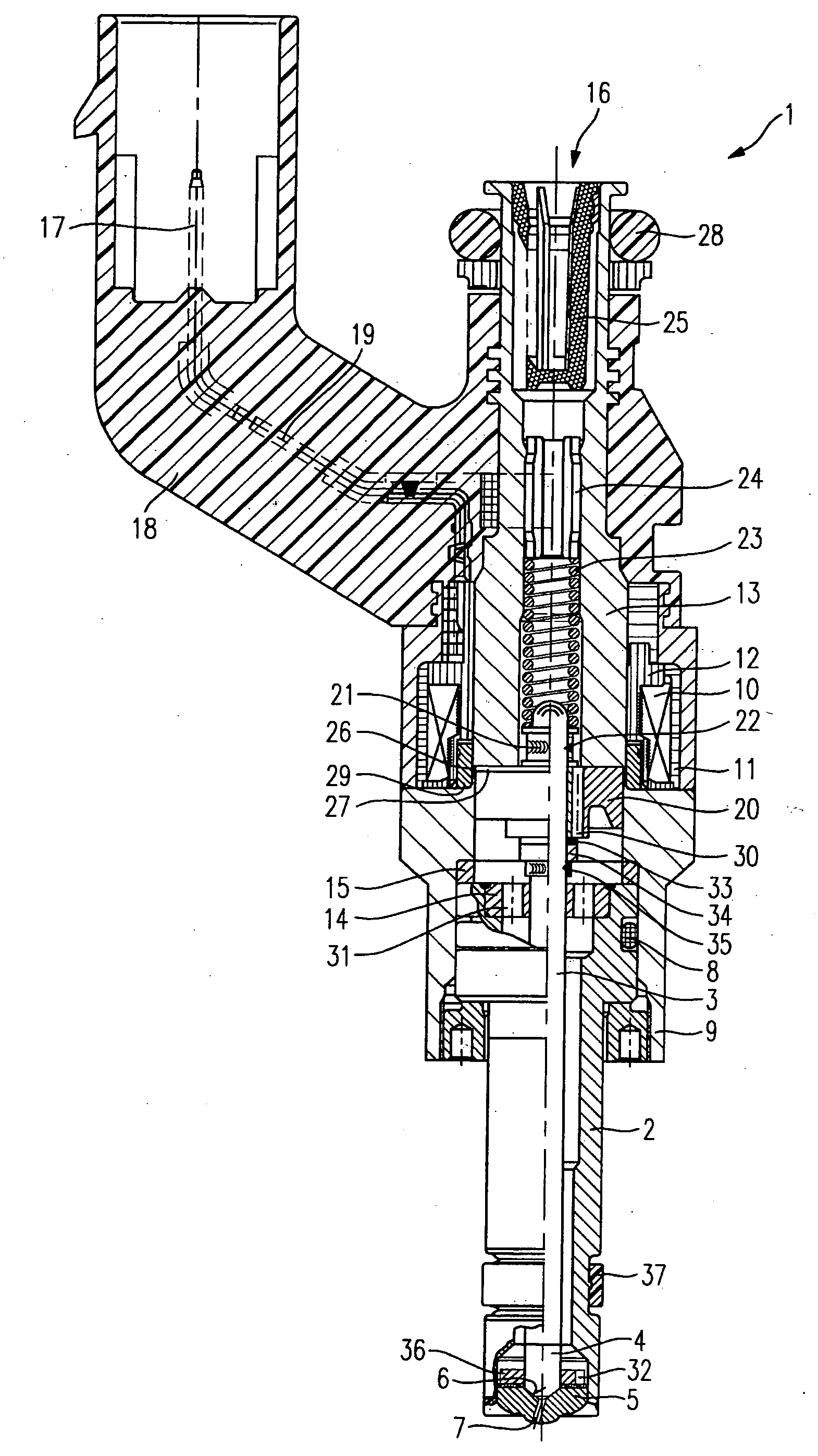

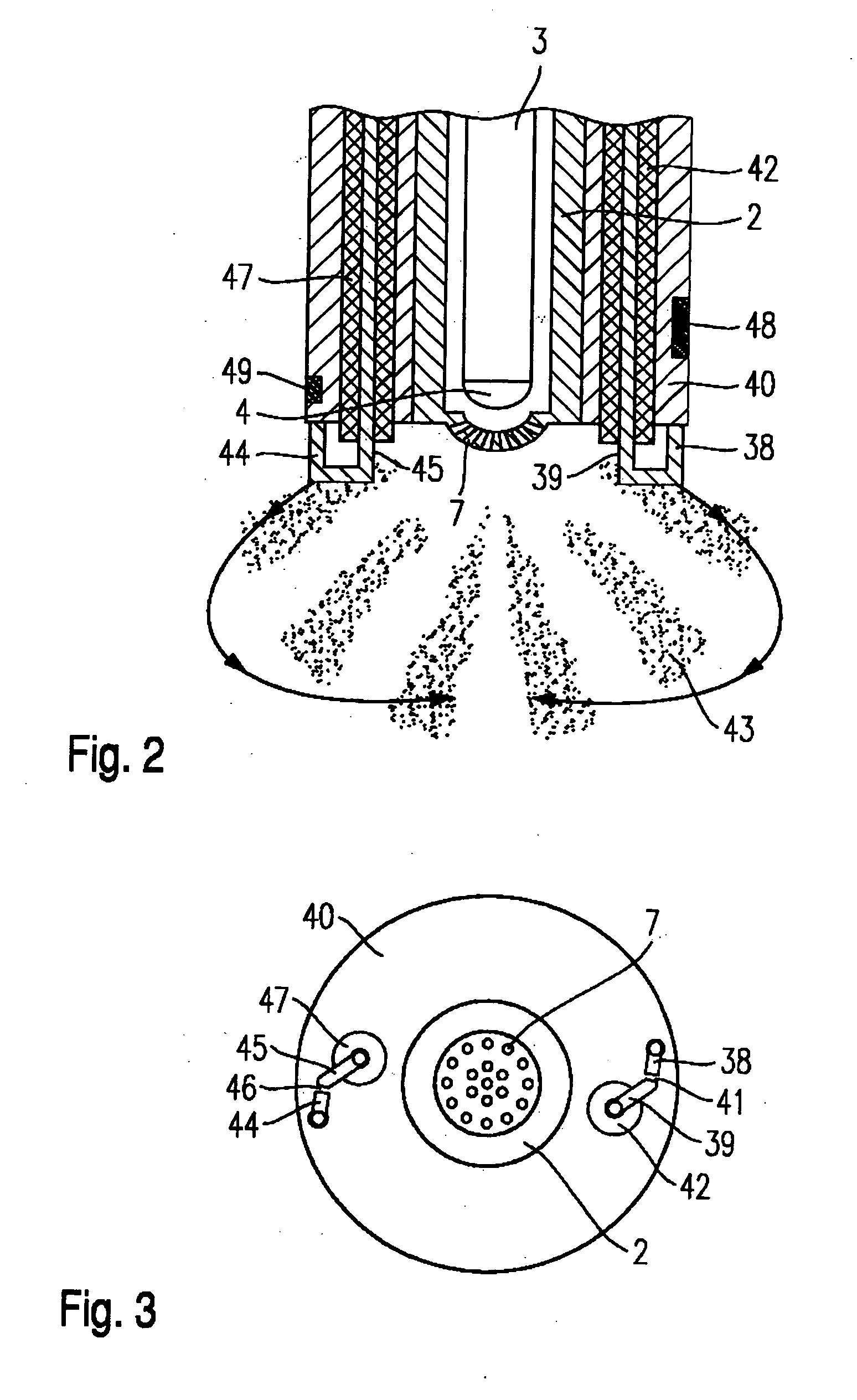

InactiveUS20080072871A1Reduce thicknessEasy to monitorMachines/enginesFuel injection with sensorsCombustion chamberElectrode pair

A fuel injector having an integrated ignition device includes a first electrode pair for igniting fuel which is injected directly into a combustion chamber of an internal combustion chamber through spray-discharge orifices of the fuel injector. The first electrode pair is made up of a ground electrode and a center electrode which are set apart by a spark gap. The fuel injector and the ignition device are situated in a shared housing. The ignition device has at least one additional spark gap and / or an additional electrode pair.

Owner:ROBERT BOSCH GMBH

Fuel injector and method for controlling fuel injectors

InactiveUS20090038589A1Low costAccurate predictionElectrical controlInternal combustion piston enginesControl signalInternal combustion engine

A fuel injector for an internal combustion engine, the fuel injector comprising an injector body, a fuel supply passage defined in the injector body, the fuel supply passage containing fuel under high pressure in use of the injector, a pressure sensor for measuring the pressure of fuel in the passage in use, wherein the pressure sensor is situated within the injector body and is separated from fuel in the passage in use, and a method of fuel injection, comprising constructing an hydraulic behaviour profile by fuel pressure measurement, using the hydraulic behaviour profile to predict fuel pressure that will prevail in a fuel injector during an injection event, and supplying a control signal to the fuel injector to control the amount of fuel injected during the injection event in accordance with the predicted fuel pressure. By predicting the fuel pressure that will prevail during an injection event, the fuel delivered during the injection event can be accurately controlled.

Owner:DELPHI TECH IP LTD

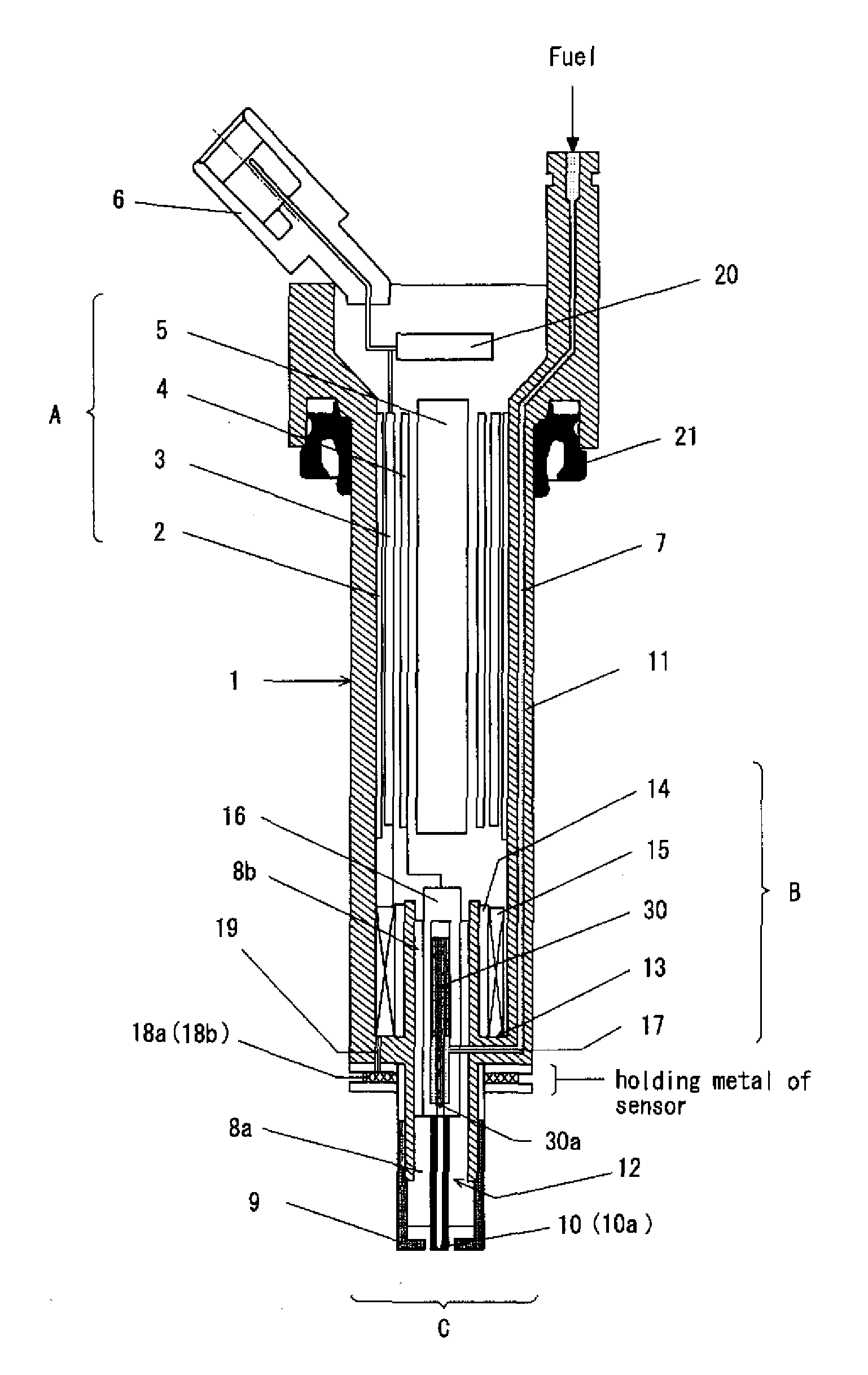

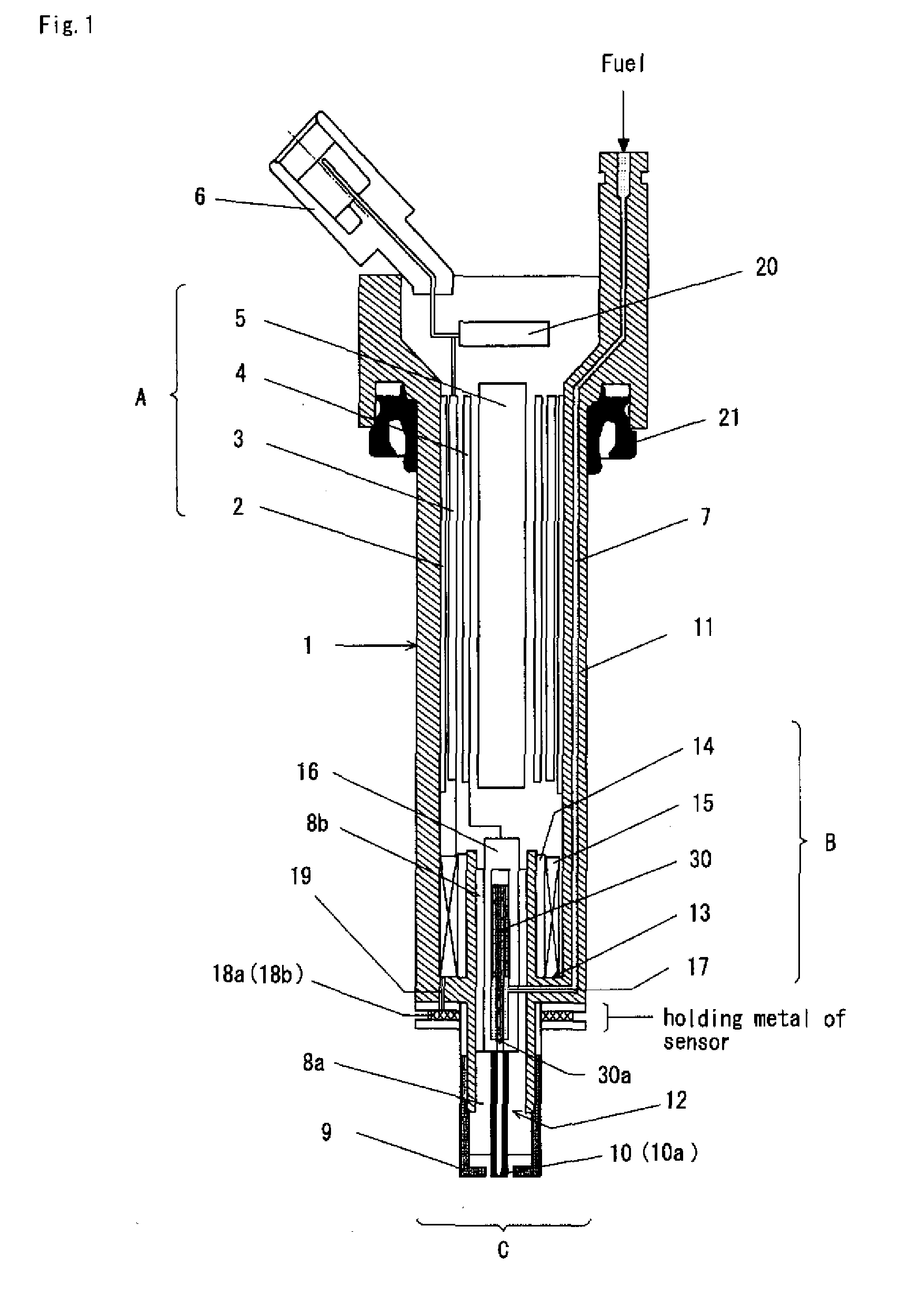

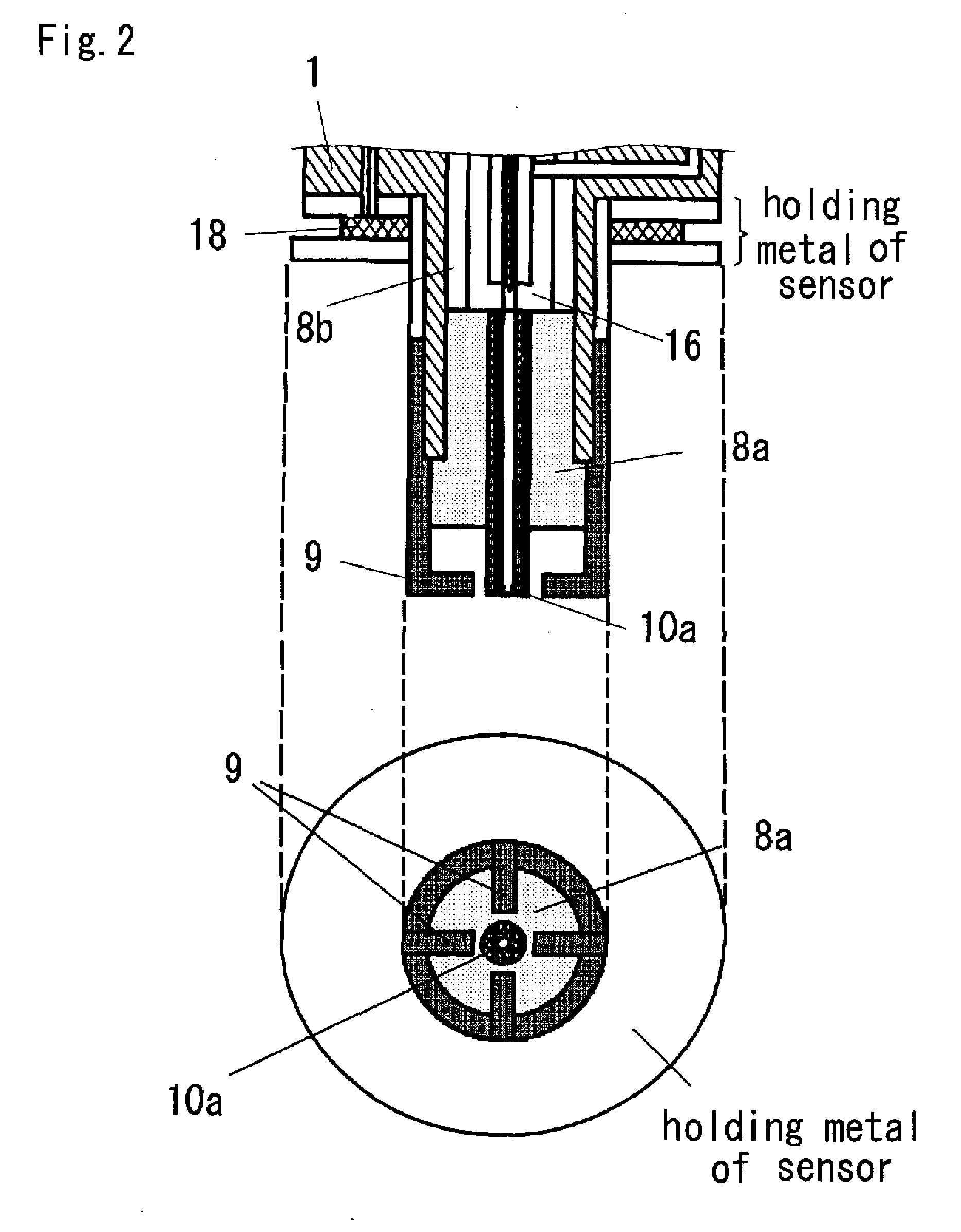

Multifunction ignition device integrated with spark plug

InactiveUS20080098984A1Improve ignition reliabilityIgnition is simplifiedTransformersMachines/enginesIgnition coilFuel efficiency

The object of the present invention is to provide a multifunction ignition device integrated with a spark plug for conserving space by integrating a spark plug, ignition coil, and fuel injection device in a single enclosure and for making a high fuel efficiency engine design possible and allowing spark plug electrode replacement, thereby reducing waste during plug maintenance. The multifunction ignition device of the present invention includes an ignition coil directly connected to a plug top of an internal combustion engine; the ignition coil, a fuel injection valve, and a fuel injection nozzle are housed in a single enclosure; and a center electrode and a ground electrode of the spark plug are removably mounted at the bottom end of the enclosure.

Owner:TOYO DENSO

High pressure fuel pump provided with damper

InactiveUS7513240B2Improve stabilityHigh capacity of absorbing pulsationFluid parameterPipe elementsWave shapeInlet valve

A fuel feed system capable of feeding a fuel to fuel injection valves at a fuel pressure with improved stability is provided. A fuel feed system for an internal combustion engine including a fuel tank and a low-pressure pump for feeding the fuel in the fuel tank to fuel injection valves, is provided with a diaphragm type damper having a wave-shape cross section at a position in contact with the fuel. Also, in a high-pressure fuel feed pump including a pressurizing chamber for pressurizing the fuel, a plunger for pumping the fuel within the pressurizing chamber, an intake valve provided at a fuel inlet of the pressurizing chamber, a discharge valve provided at a fuel outlet of the pressurizing chamber, and a low-pressure chamber provided in an upstream of the intake valve, a mechanism for reducing fuel pressure pulsation is disposed in a space of the low-pressure chamber provided in the upstream of the intake valve, and a fuel pressure sensor for measuring the fuel pressure is mounted near the mechanism for reducing fuel pressure pulsation.

Owner:HITACHI AUTOMATIVE SYST ENG +1

Damper mechanism and high pressure fuel pump

ActiveUS20050019188A1Reduce pressure pulsationDiameterFuel injecting pumpsFuel injection with sensorsEngineeringHigh pressure

To obtain a small and high performance damper mechanism which reduces pressure pulsation in low pressure-side fuel in the high pressure fuel pump in a high pressure fuel supply system or a high pressure fuel pump provided with the small and high performance damper mechanism. Two metal diaphragms are welded together over the entire circumference to obtain a metal diaphragm assembly (also referred to as “double metal diaphragm damper”). The whole or part of the portion of the metal diaphragm assembly other than the weld (for example, the portion inside the weld) is clamped by a pressing member and thereby the assembly is secured in a housing enclosure. The housing enclosure may be formed integrally with the body of a high pressure pump.

Owner:HITACHI ASTEMO LTD

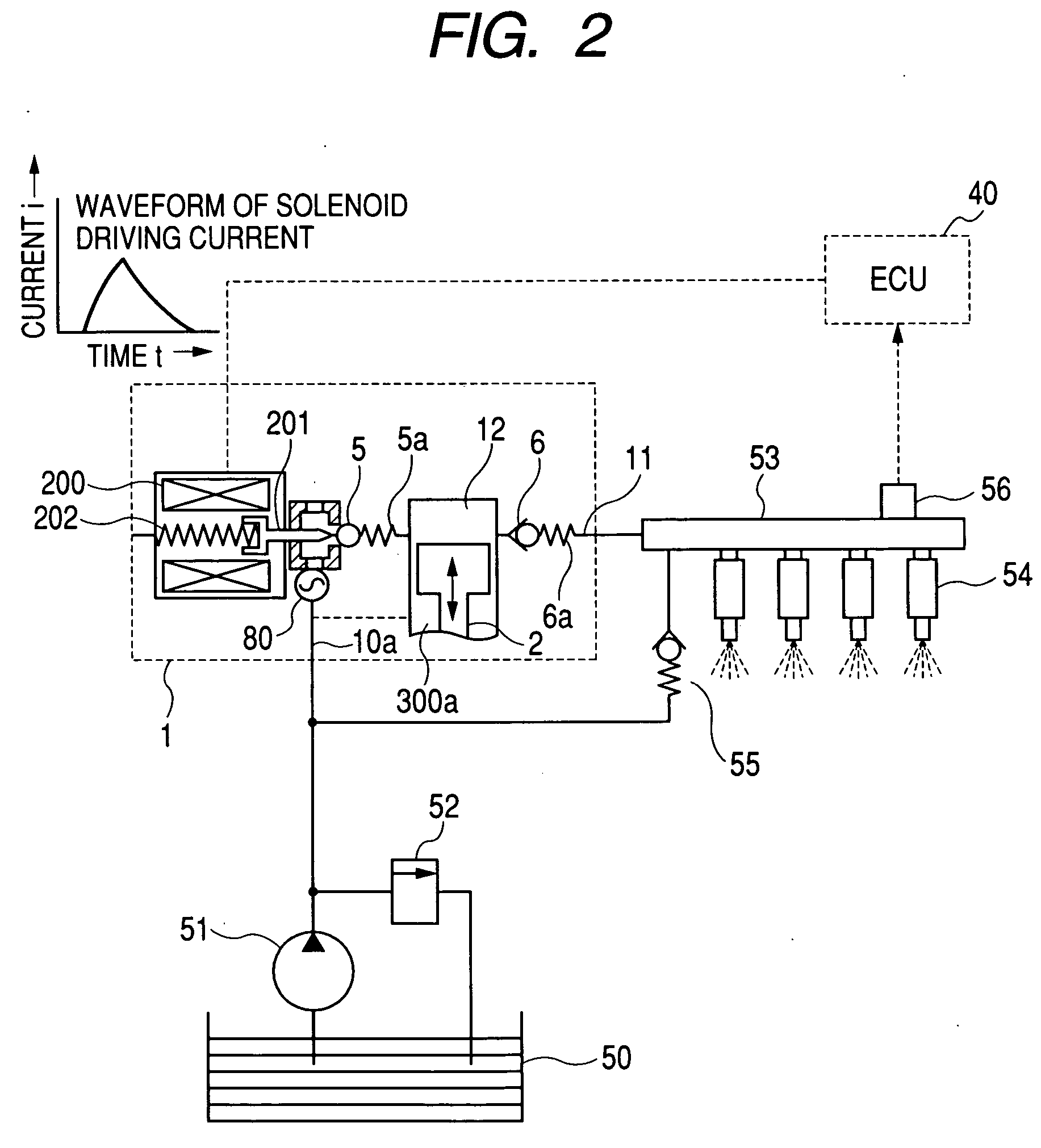

Fuel injection device and fuel injection system

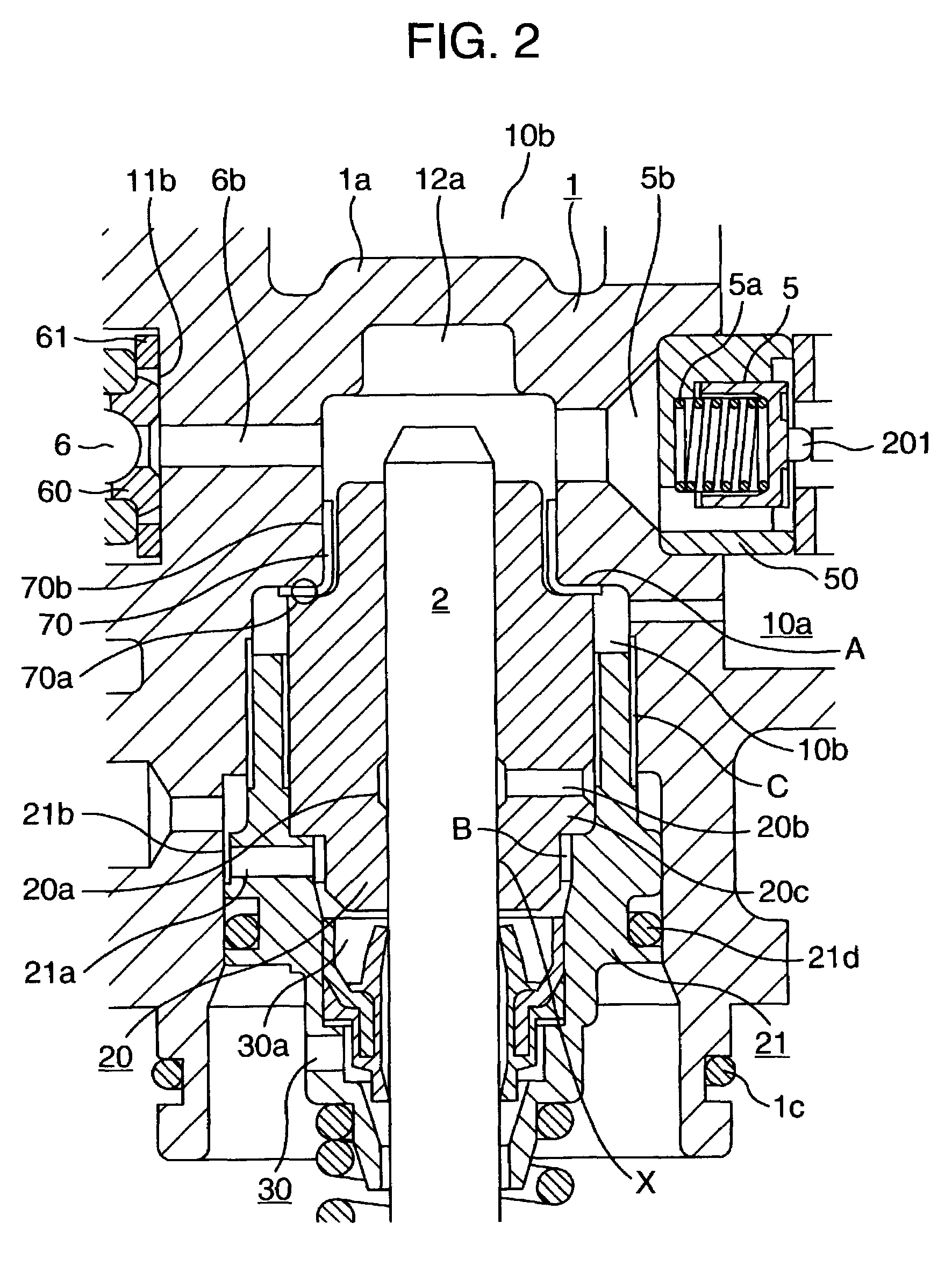

ActiveUS20090056676A1Improve accuracyLimiting fuel injectionElectrical controlInternal combustion piston enginesPressure sensorFuel injection

A fuel injection device includes a fuel injection valve for injecting fuel, which is distributed from a pressure-accumulation vessel. A pressure sensor is located in a fuel passage, which extends from the pressure-accumulation vessel to a nozzle hole, and configured to detect pressure of the fuel. The pressure sensor is located closer to the nozzle hole than the pressure-accumulation vessel. A storage unit stores individual difference information, which indicates an injection characteristic of the fuel injection valve, the injection characteristic being obtained by an examination. The individual difference information is related to a fluctuation pattern of a portion of the fluctuation in detected pressure waveform of the pressure sensor. The fluctuation is attributed to one fuel injection through the nozzle hole. The portion of the fluctuation is subsequent to an end of the fuel injection.

Owner:DENSO CORP

Fuel injection control device

ActiveUS20090063010A1Improve accuracyEasy maintenanceElectrical controlInternal combustion piston enginesEngineeringInjection rate

A fuel injection control device (ECU) for controlling injection supply of fuel to a target engine has a program for sequentially sensing fuel pressure fluctuating with injection of a predetermined injector a program for detecting an injection centroid of a diagram as a profile of a transition of an injection rate of the injector at a present time based on a transition of the sequentially sensed fuel pressure, and a program for varying an injection command (injection timing) of the injector based on the detected injection centroid and an injection centroid of a predetermined basic diagram such that a relative positional relationship between the injection centroids of the diagram as the actual profile of the injection rate transition and the basic diagram becomes a relationship, in which timings of the injection centroids are close to each other.

Owner:DENSO CORP

Fuel feed system

InactiveUS7165534B2Improve stabilityHigh capacity of absorbing pulsationFluid parameterLow-pressure fuel injectionWave shapeInlet valve

A fuel feed system capable of feeding a fuel to fuel injection valves at a fuel pressure with improved stability is provided. A fuel feed system for an internal combustion engine including a fuel tank and a low-pressure pump for feeding the fuel in the fuel tank to fuel injection valves, is provided with a diaphragm type damper having a wave-shape cross section at a position in contact with the fuel. Also, in a high-pressure fuel feed pump including a pressurizing chamber for pressurizing the fuel, a plunger for pumping the fuel within the pressurizing chamber, an intake valve provided at a fuel inlet of the pressurizing chamber, a discharge valve provided at a fuel outlet of the pressurizing chamber, and a low-pressure chamber provided in an upstream of the intake valve, a mechanism for reducing fuel pressure pulsation is disposed in a space of the low-pressure chamber provided in the upstream of the intake valve, and a fuel pressure sensor for measuring the fuel pressure is mounted near the mechanism for reducing fuel pressure pulsation.

Owner:HITACHI AUTOMATIVE SYST ENG +1

Fuel injector and method for controlling fuel injectors

InactiveUS7552717B2Expensive to fabricateReduced risk of mechanical failureElectrical controlInternal combustion piston enginesControl signalInternal combustion engine

A fuel injector for an internal combustion engine, the fuel injector comprising an injector body, a fuel supply passage defined in the injector body, the fuel supply passage containing fuel under high pressure in use of the injector, a pressure sensor for measuring the pressure of fuel in the passage in use, wherein the pressure sensor is situated within the injector body and is separated from fuel in the passage in use, and a method of fuel injection, comprising constructing an hydraulic behavior profile by fuel pressure measurement, using the hydraulic behavior profile to predict fuel pressure that will prevail in a fuel injector during an injection event, and supplying a control signal to the fuel injector to control the amount of fuel injected during the injection event in accordance with the predicted fuel pressure. By predicting the fuel pressure that will prevail during an injection event, the fuel delivered during the injection event can be accurately controlled.

Owner:DELPHI TECH IP LTD

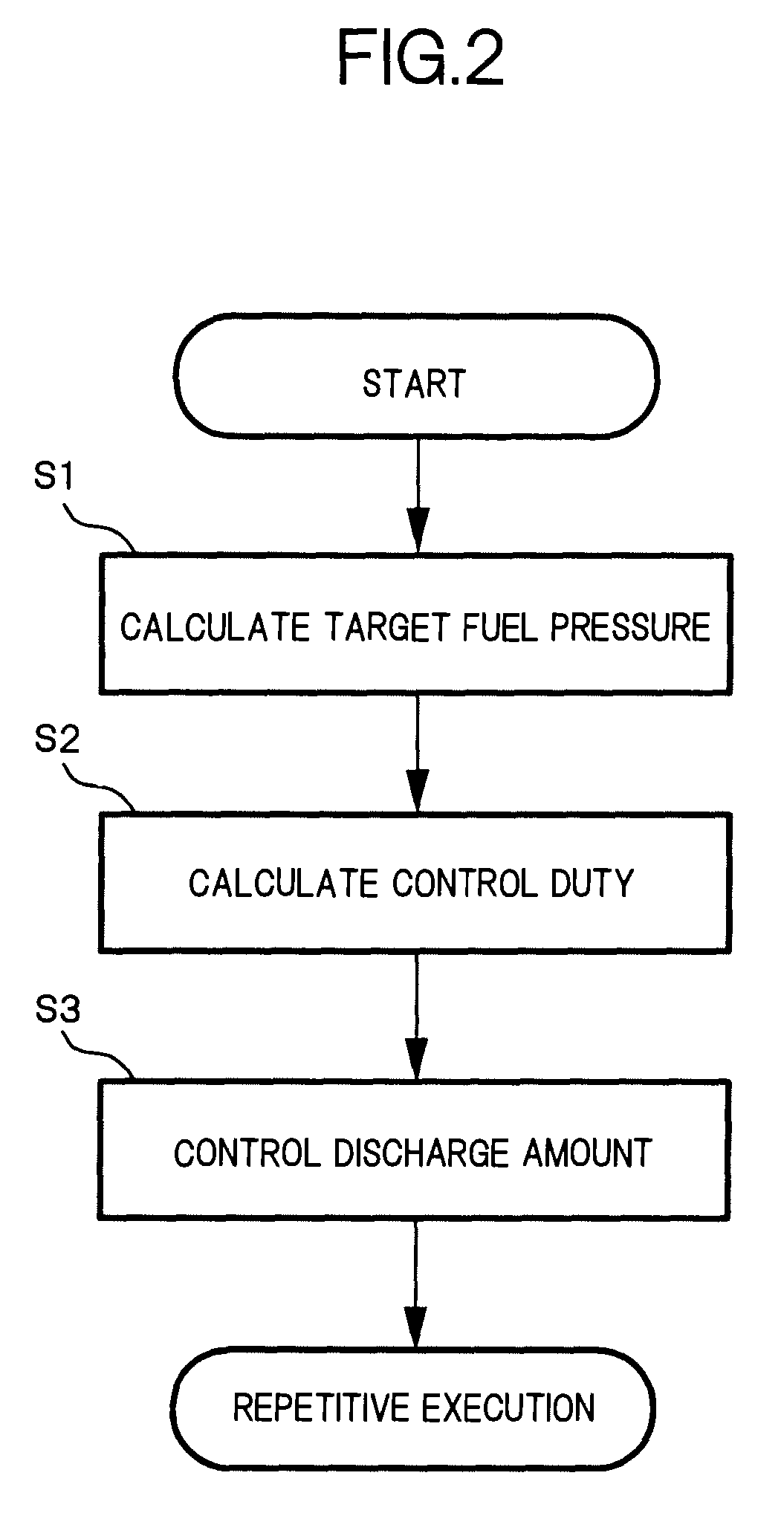

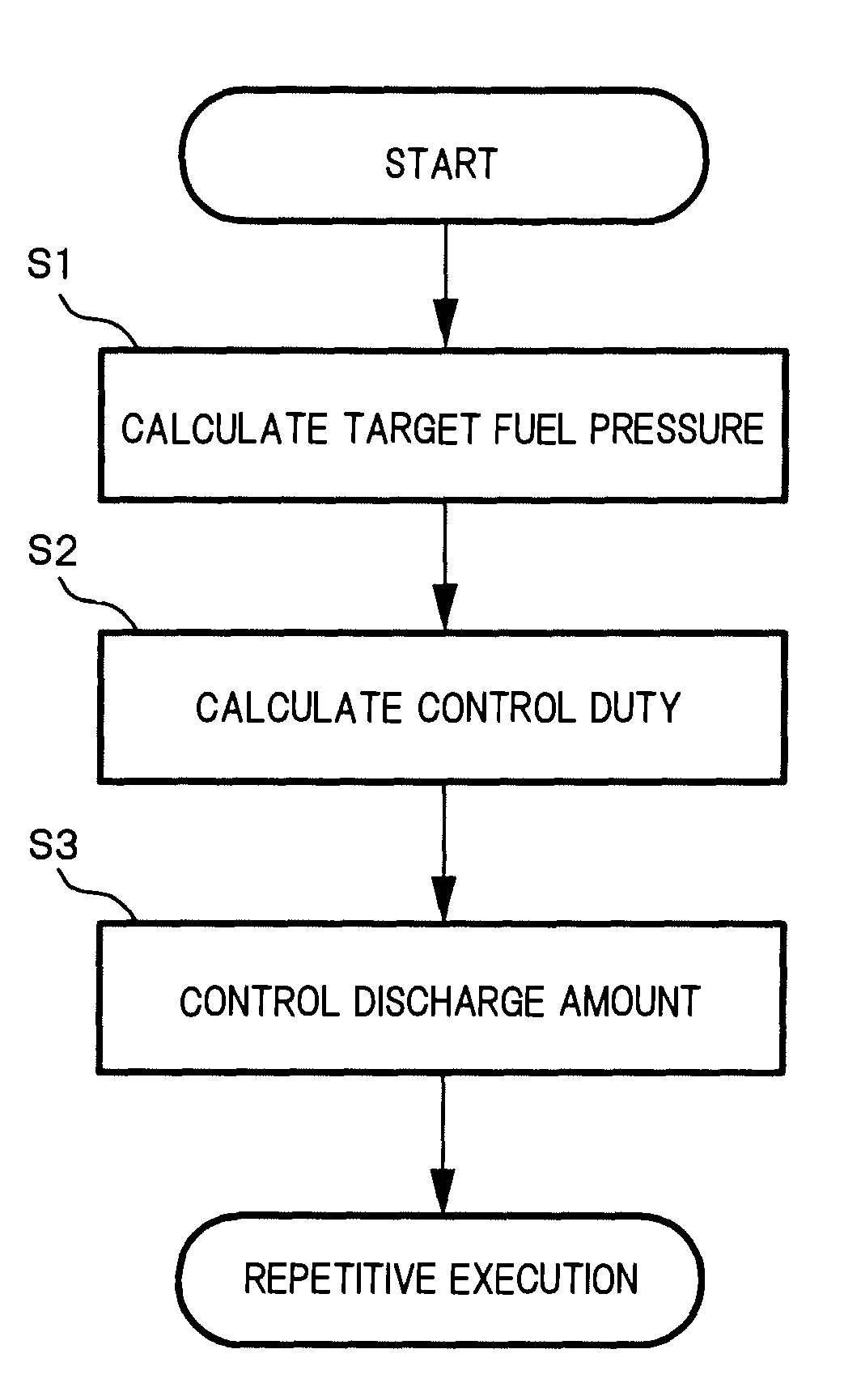

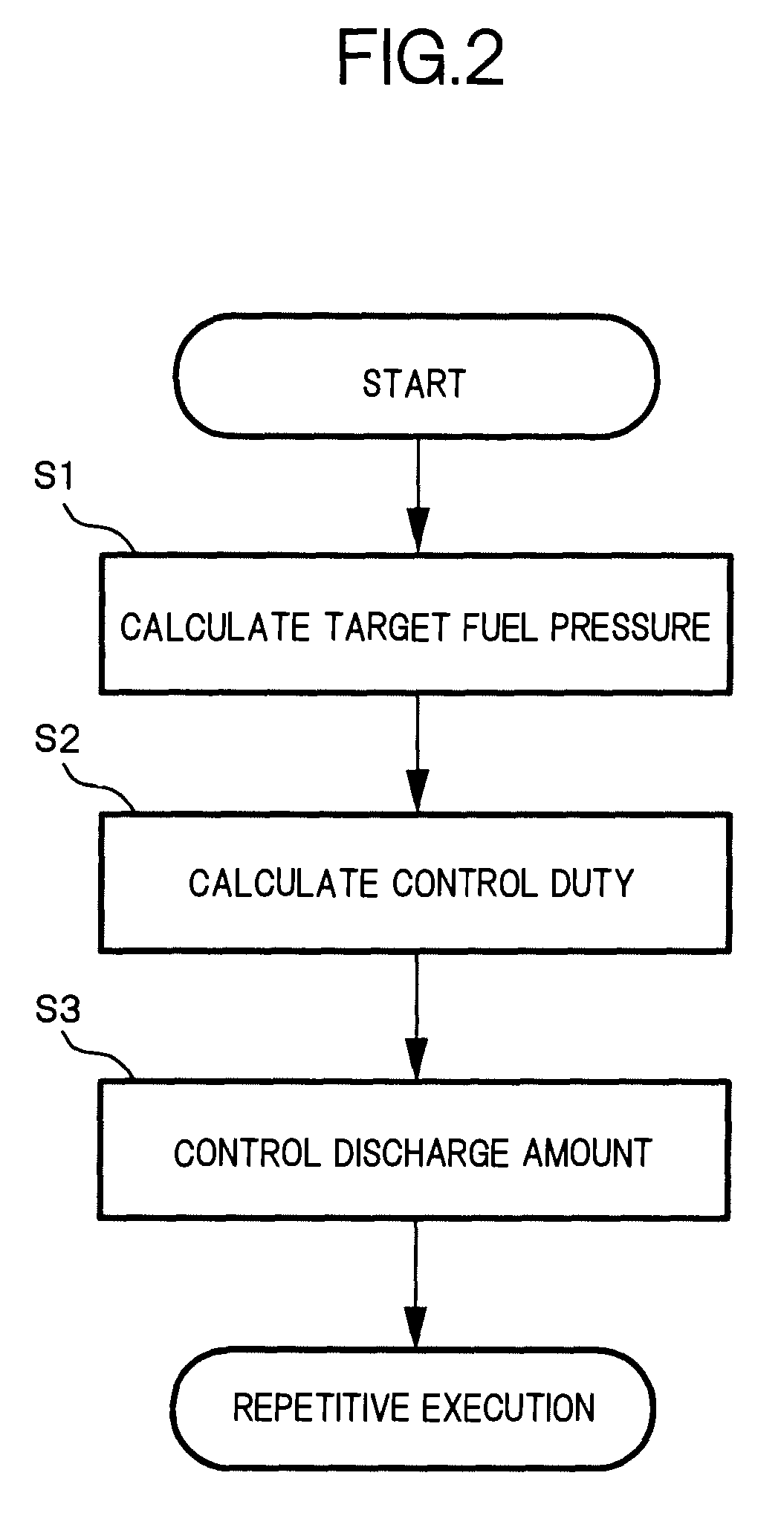

Fuel supply apparatus for engine and control method of same

A fuel supply apparatus for an engine in which calculation of a manipulated variable of a fuel pump in response to a deviation between a fuel pressure detected by a fuel pressure sensor and a target value is carried out, is configured in a manner such that when the fuel pressure sensor is failed, a change in the fuel pressure is estimated based on a required fuel flow amount of an engine, a discharge amount of the fuel pump and a fuel pressure detected immediately before the fuel pressure sensor is failed, so that deciding of the manipulated variable of the fuel pump is made, based on the estimation value. A method of controlling the fuel supply apparatus to realize the controlling of the fuel pump based on the manipulated variable is also disclosed.

Owner:HITACHI LTD

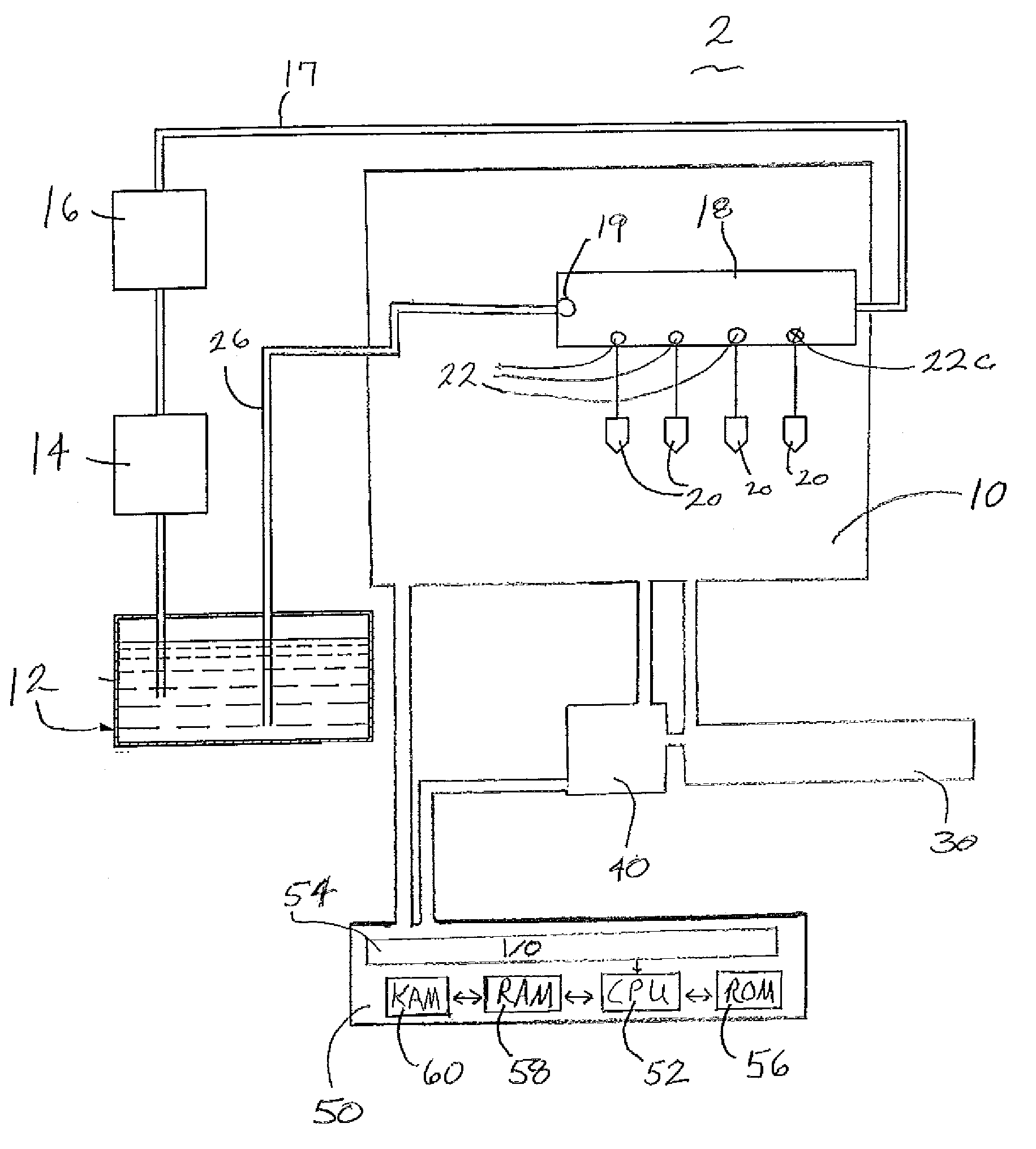

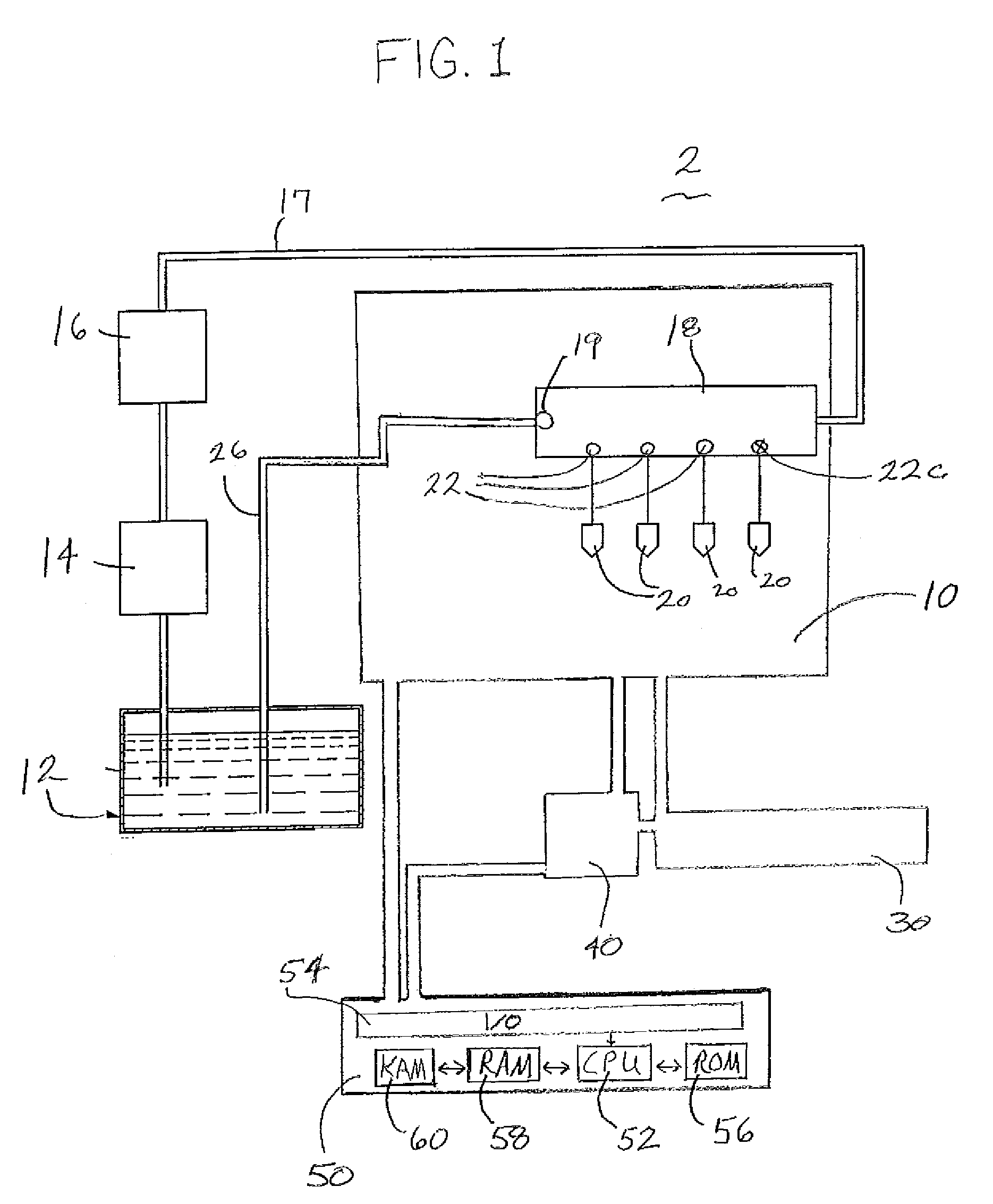

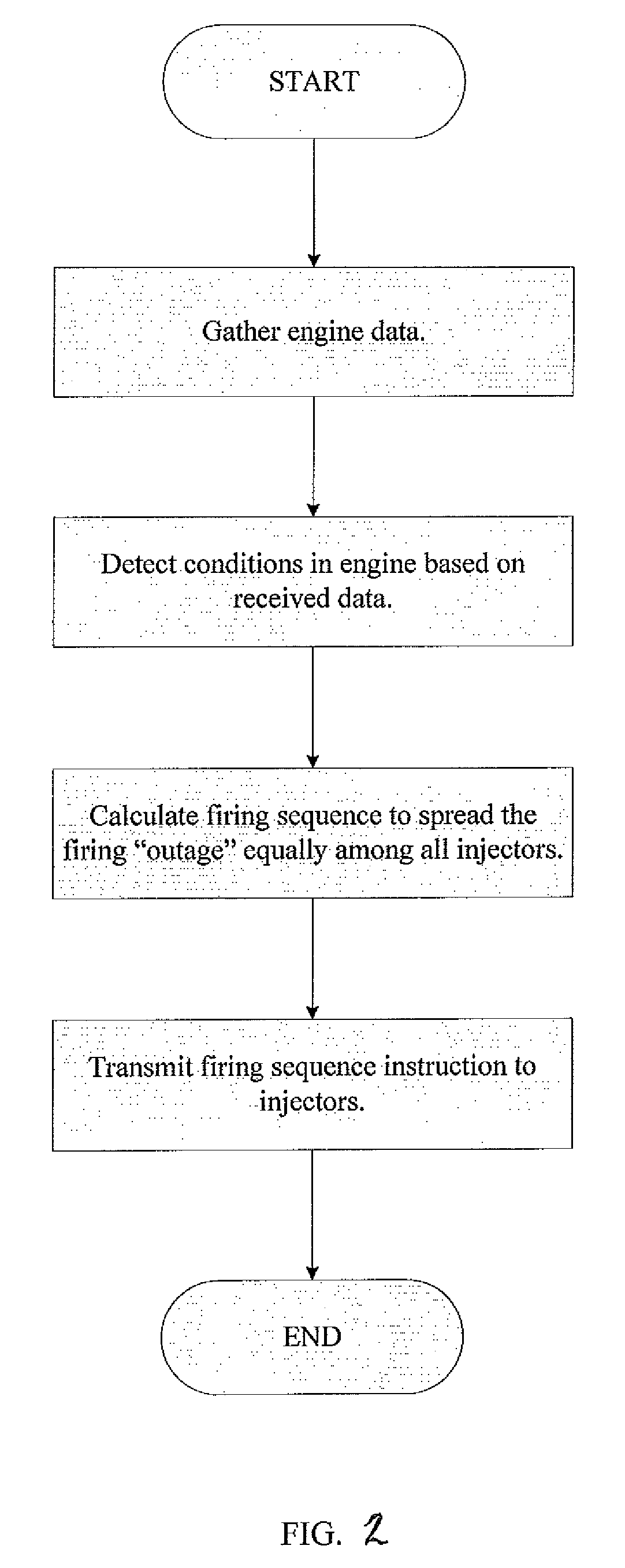

Method and system for conserving fuel in a diesel engine

A diesel engine coupled to a transmission and having a fuel injector control system which among other things monitors the load on the engine by measuring the transmission line pressure, a higher pressure being indicative of a greater load. When the pressure is below a preset value and the engine is sufficiently warm, the normal injector firing sequence is altered by not actuating injectors at spaced intervals in the firing sequence. As the pressure and therefore the load decreases, the intervals between which injectors are not actuated are decreased so that in a given number of engine rotations there are fewer injector actuations and as a result of corresponding cylinders being idle, less fuel is supplied to the engine at lighter loads.

Owner:WILLIAM SHERRY

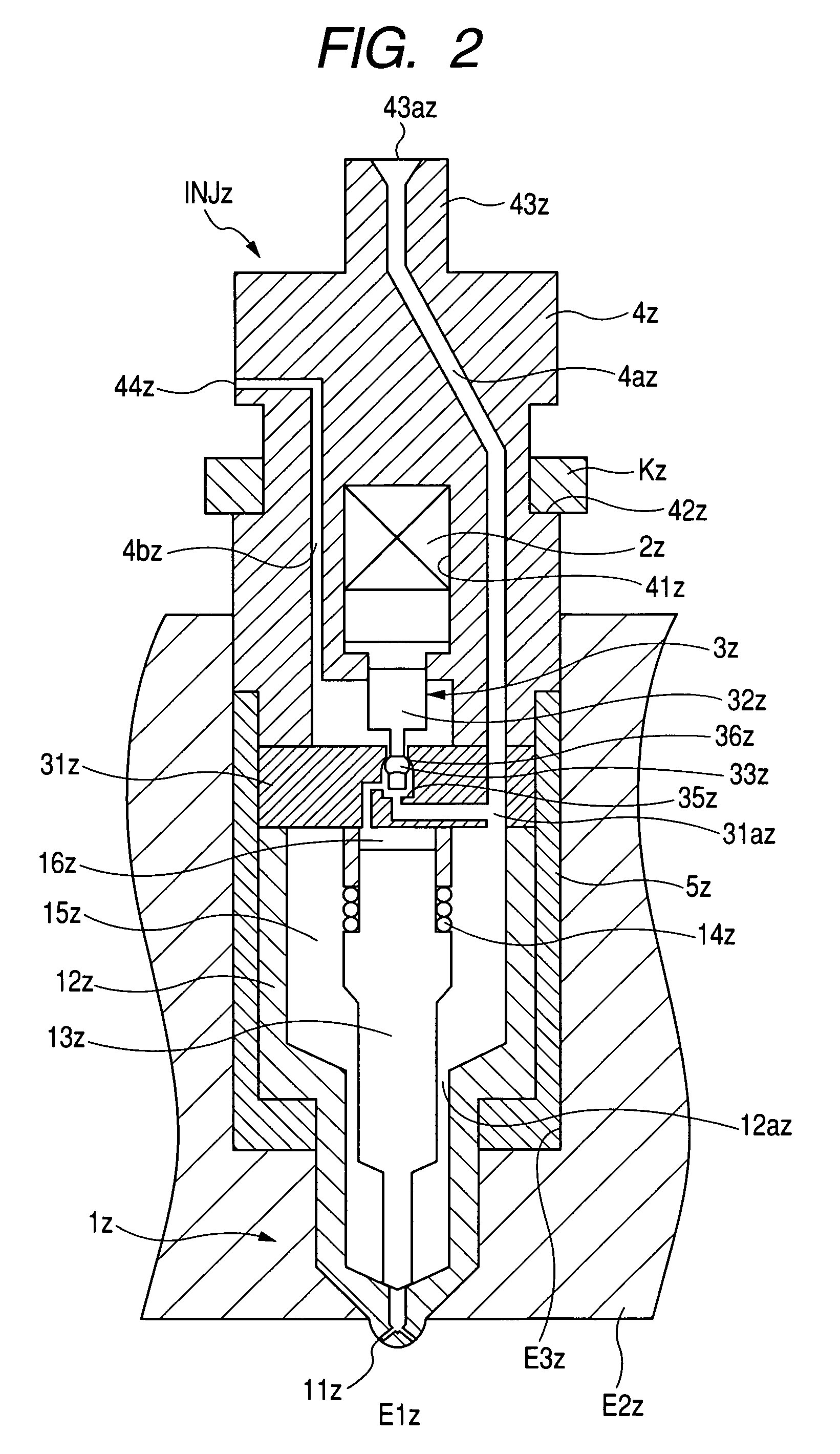

Fuel injection valve and fuel injection apparatus

InactiveUS20100263633A1Complicated layout of the harnessesIncreased amount of effort to join the connectorsElectrical controlMachines/enginesPiezoelectric actuatorsHigh pressure

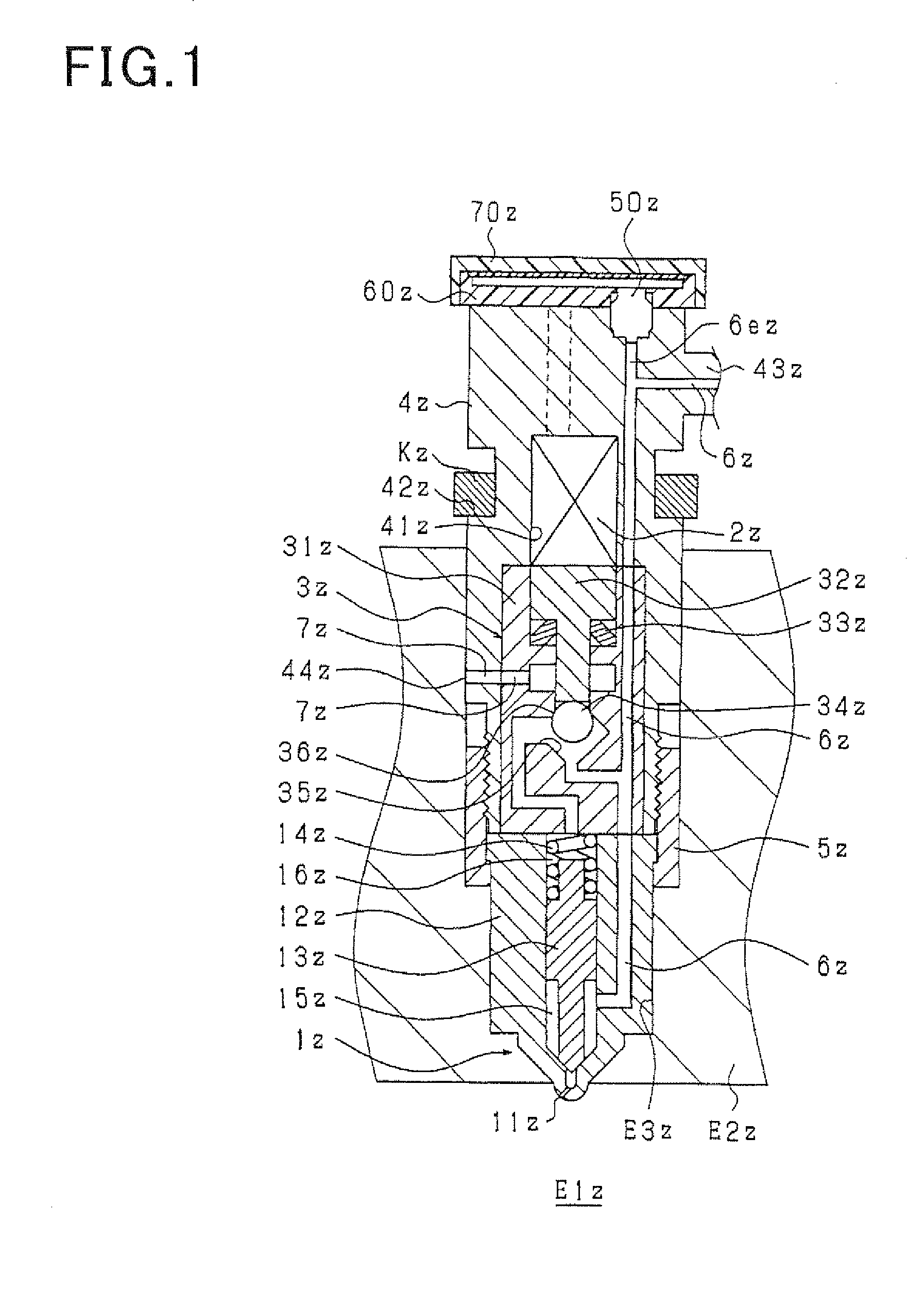

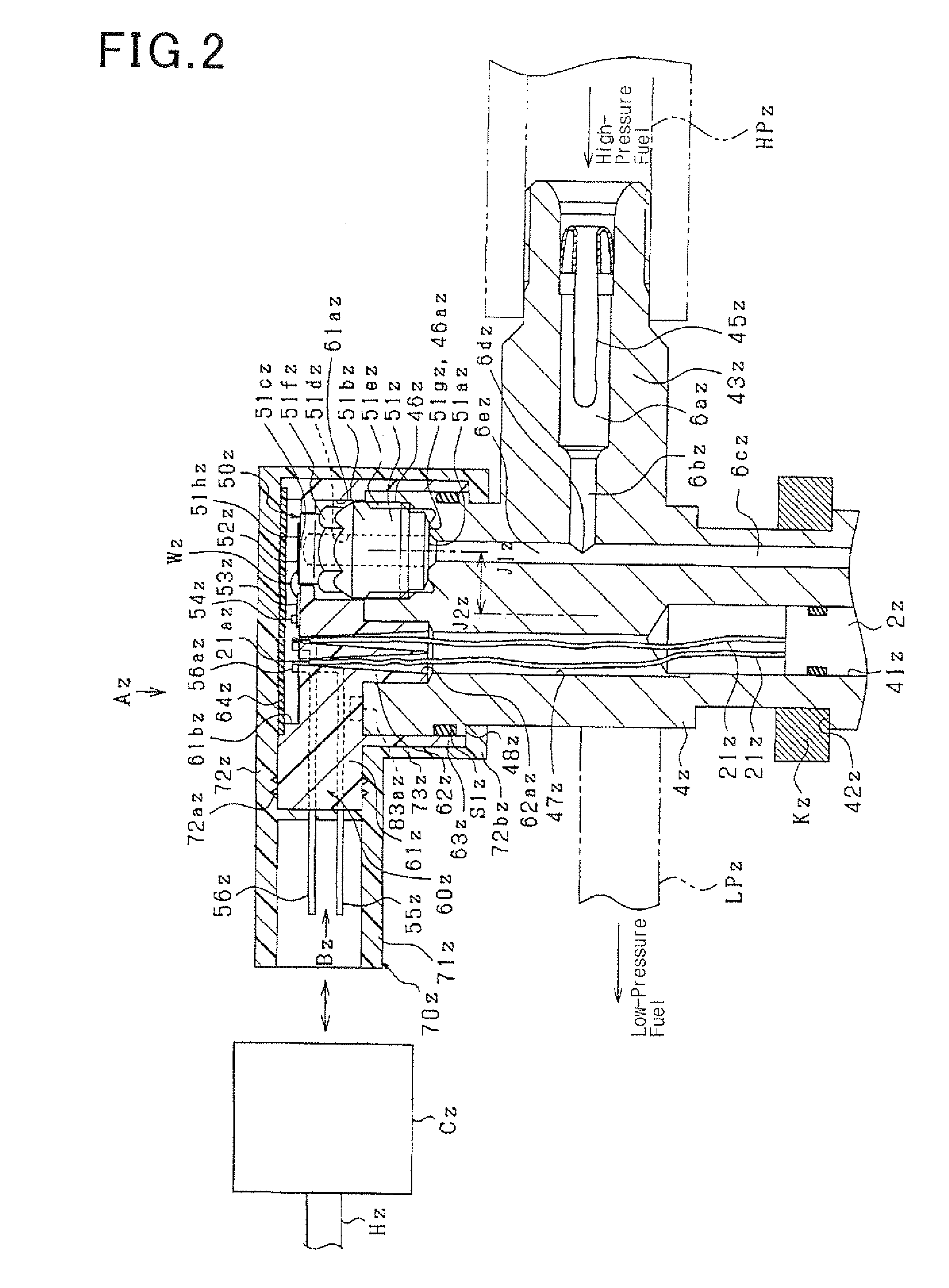

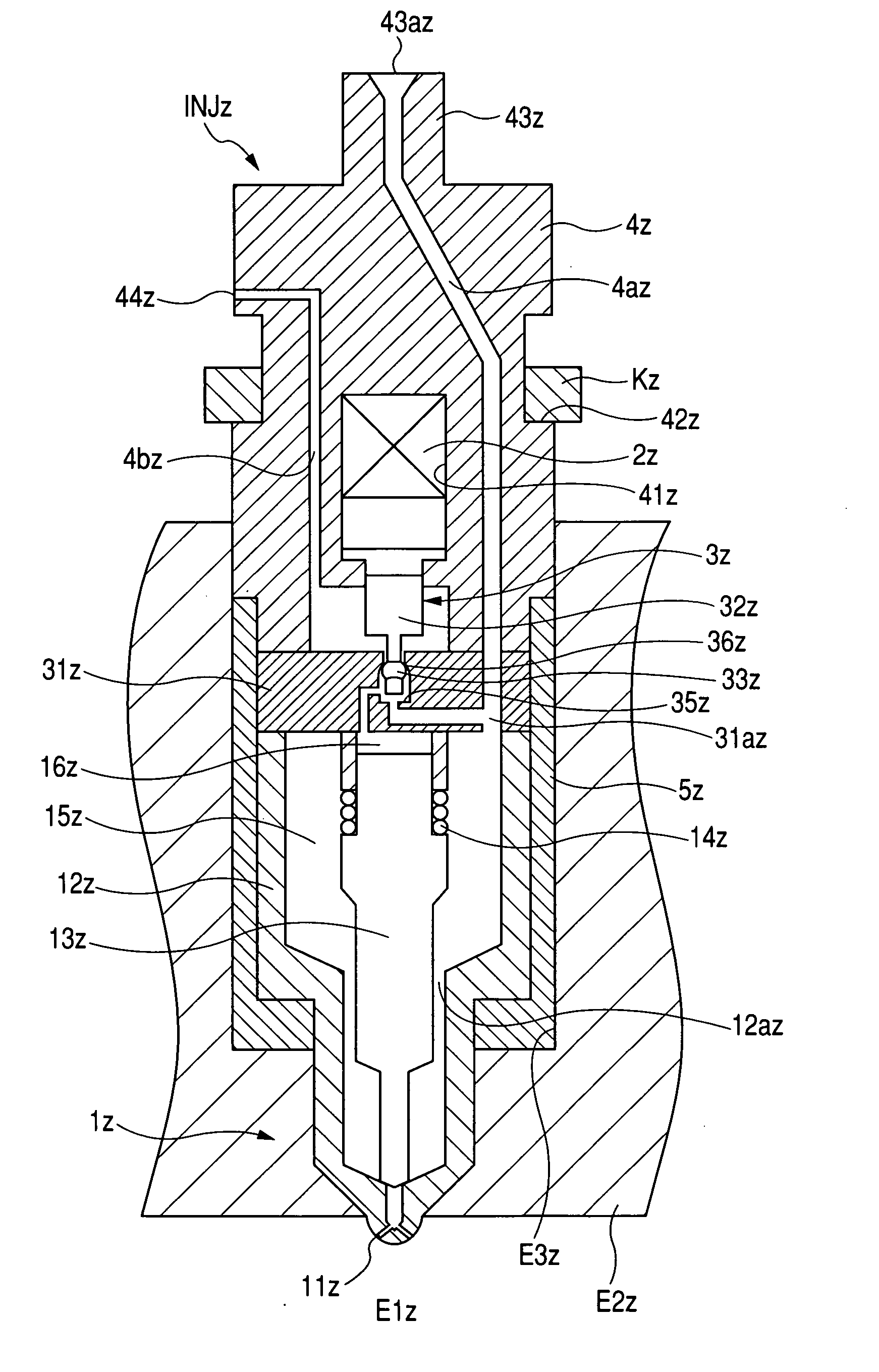

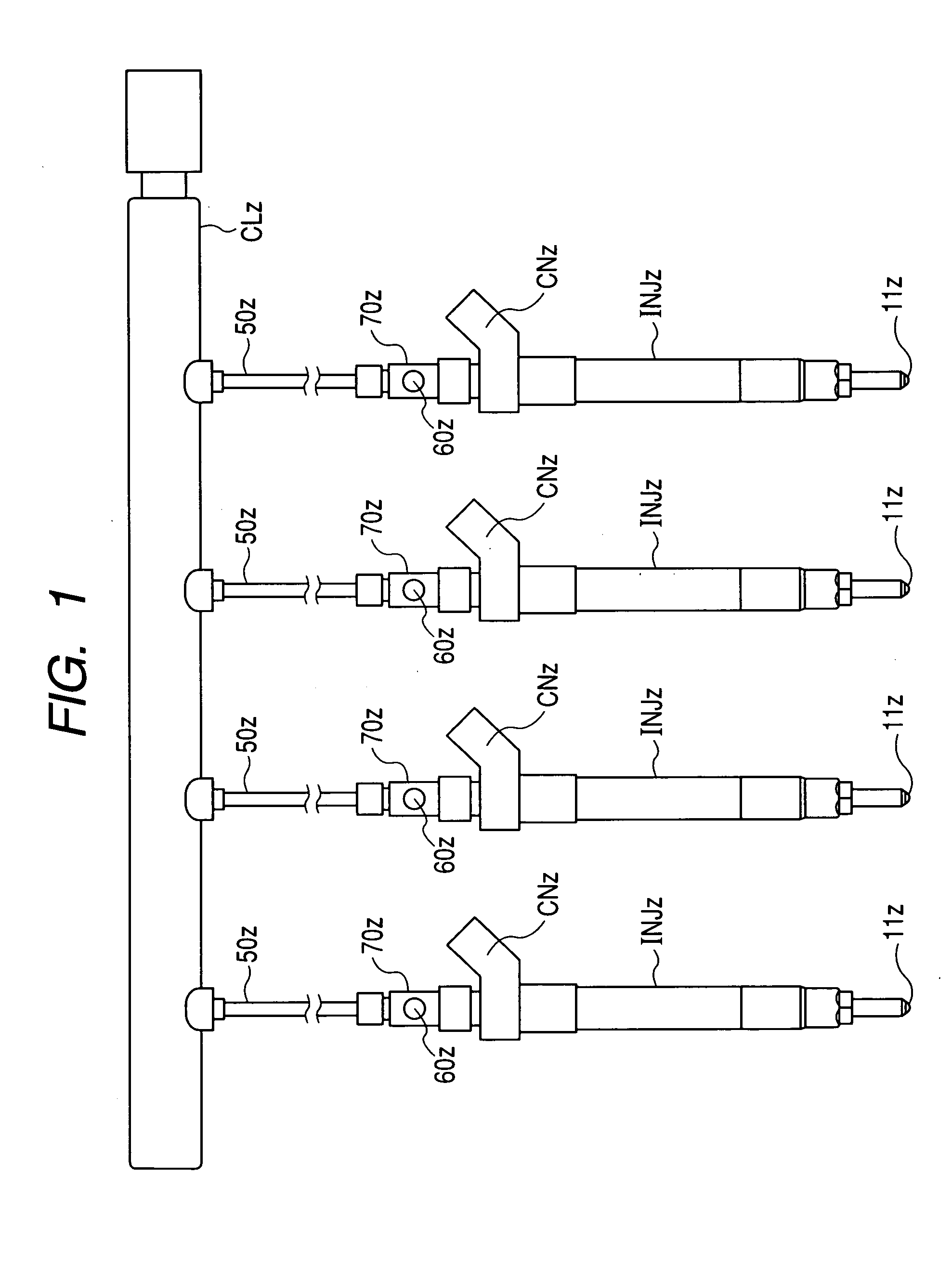

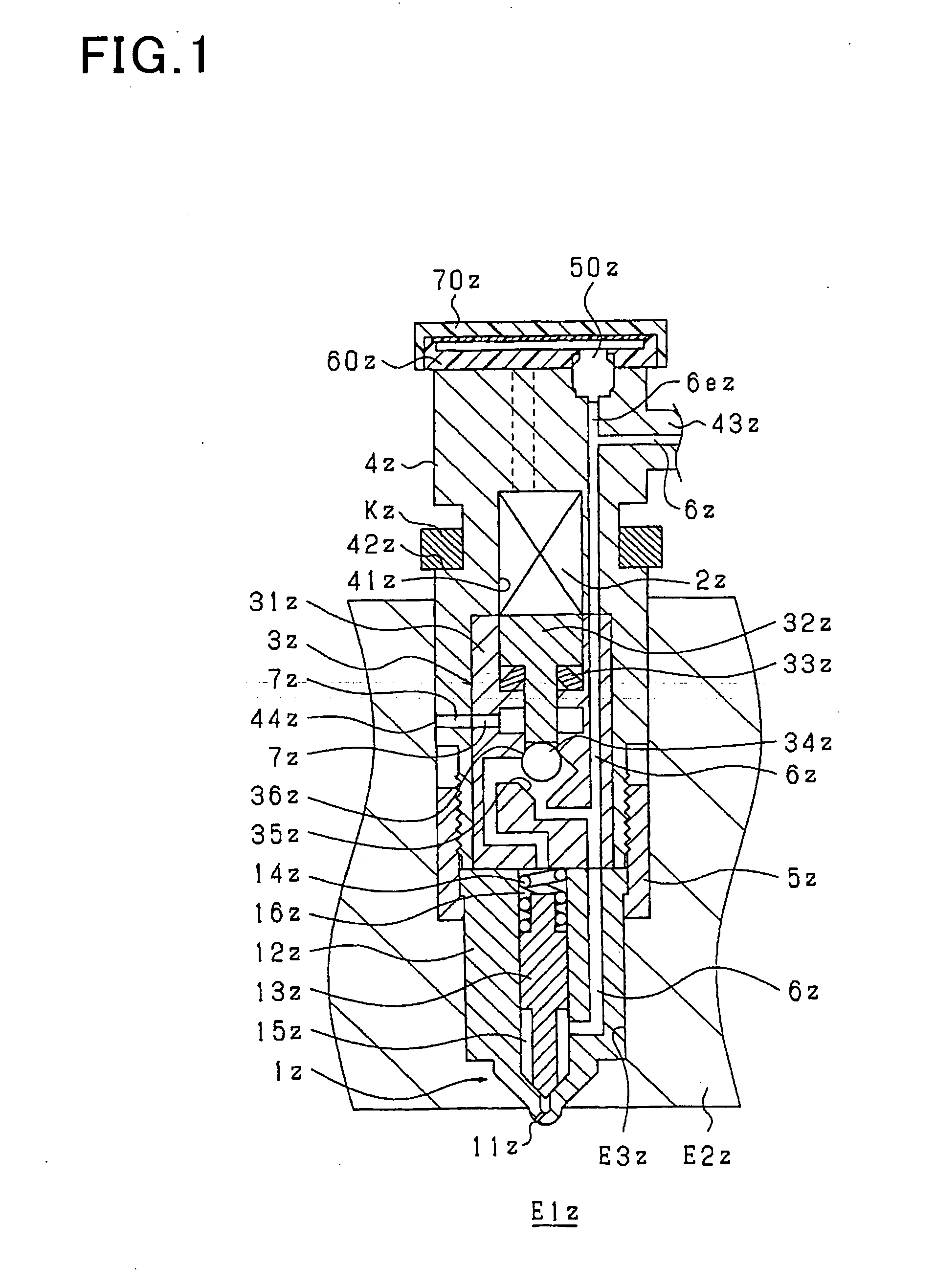

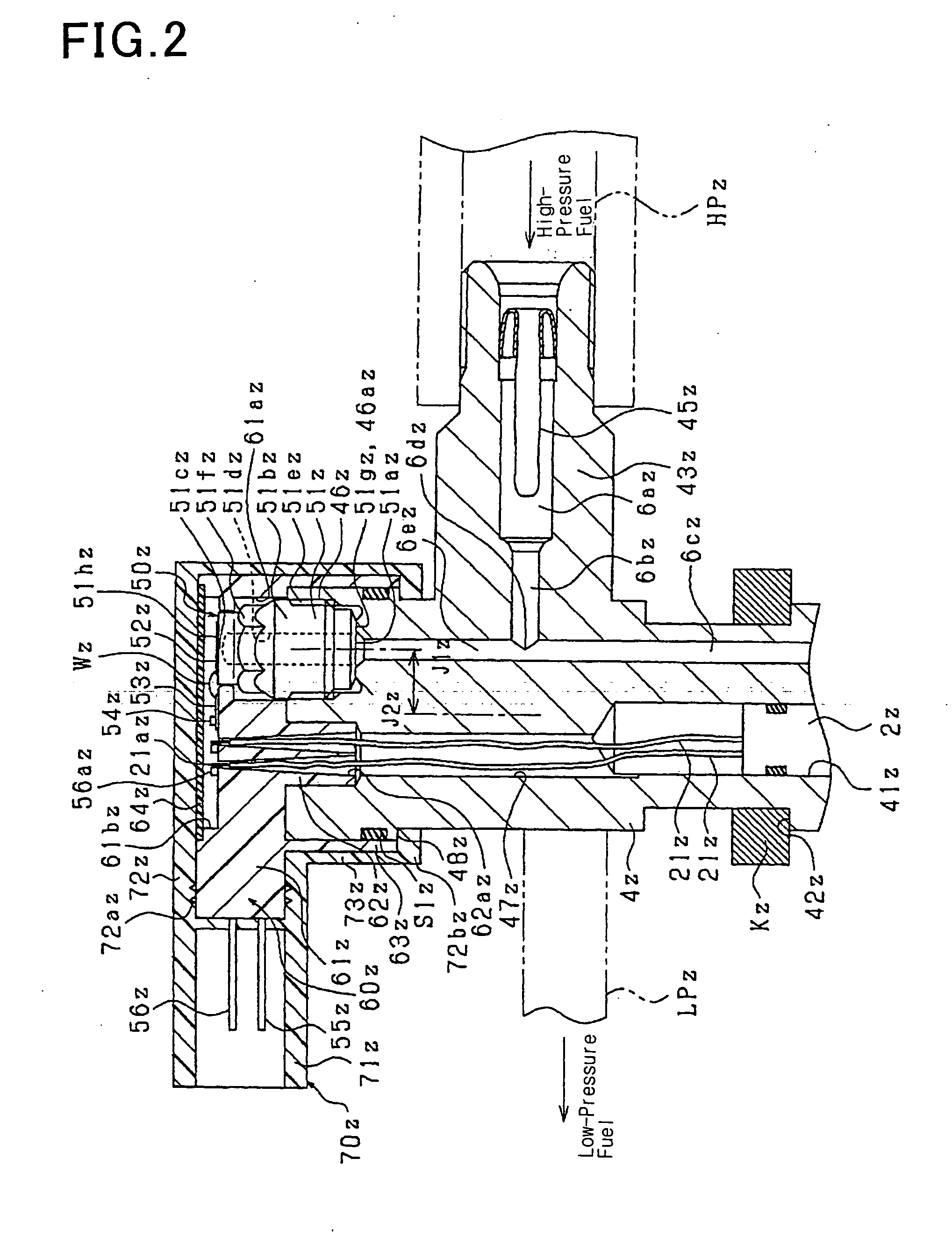

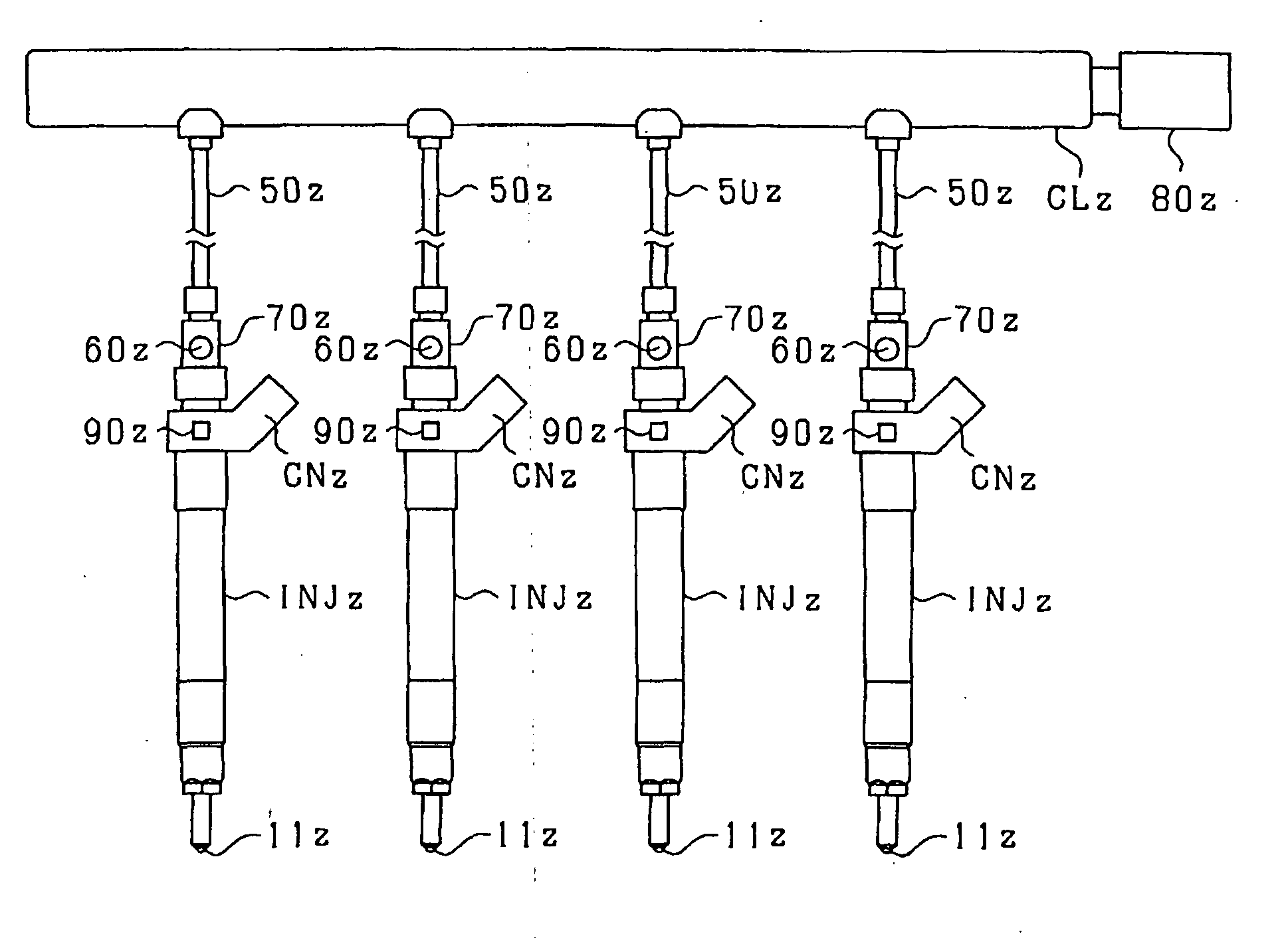

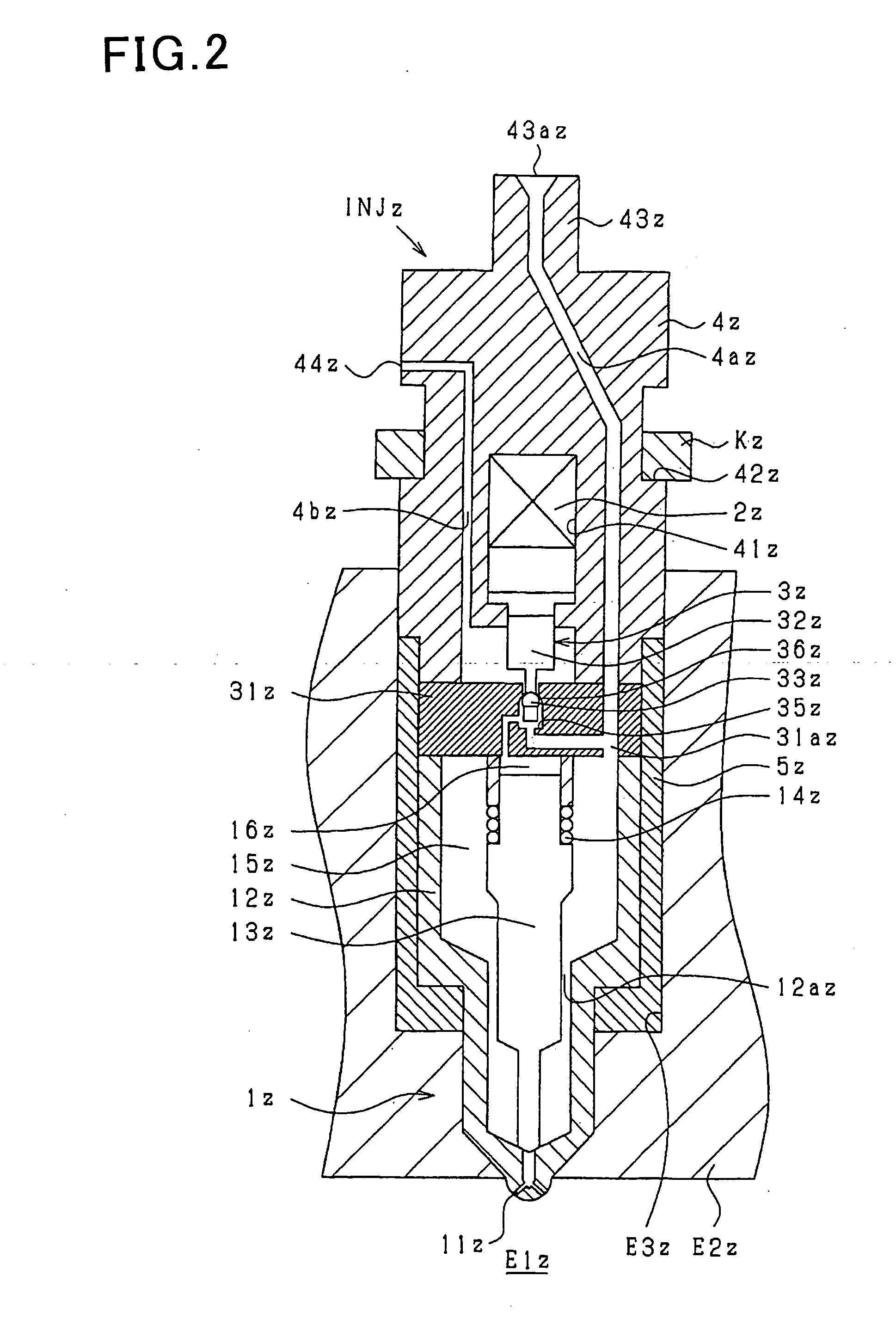

The injector body 4z which forms therein the high-pressure paths 6az, 6hz, and 6cz through which high-pressure fuel flows to a spray hole and has disposed therein the piezo-actuator 2z (drive means) to drive a needle (valve) to open or close the spray hole, the fuel pressure sensor 50z which is installed in the body 4z to measure the pressure of the high-pressure fuel, the sensor terminals 55z to output a measured pressure value from the fuel pressure sensor 50z externally, the drive terminals 56z to which the electric power for the piezo-actuator 2z is supplied, and the connector housing 70z retaining the sensor terminals 55z and the drive terminals 56z are provided. The sensor terminals 55z, the drive terminals 56z, and the connector housing 70z constitute a single connector.

Owner:DENSO CORP +1

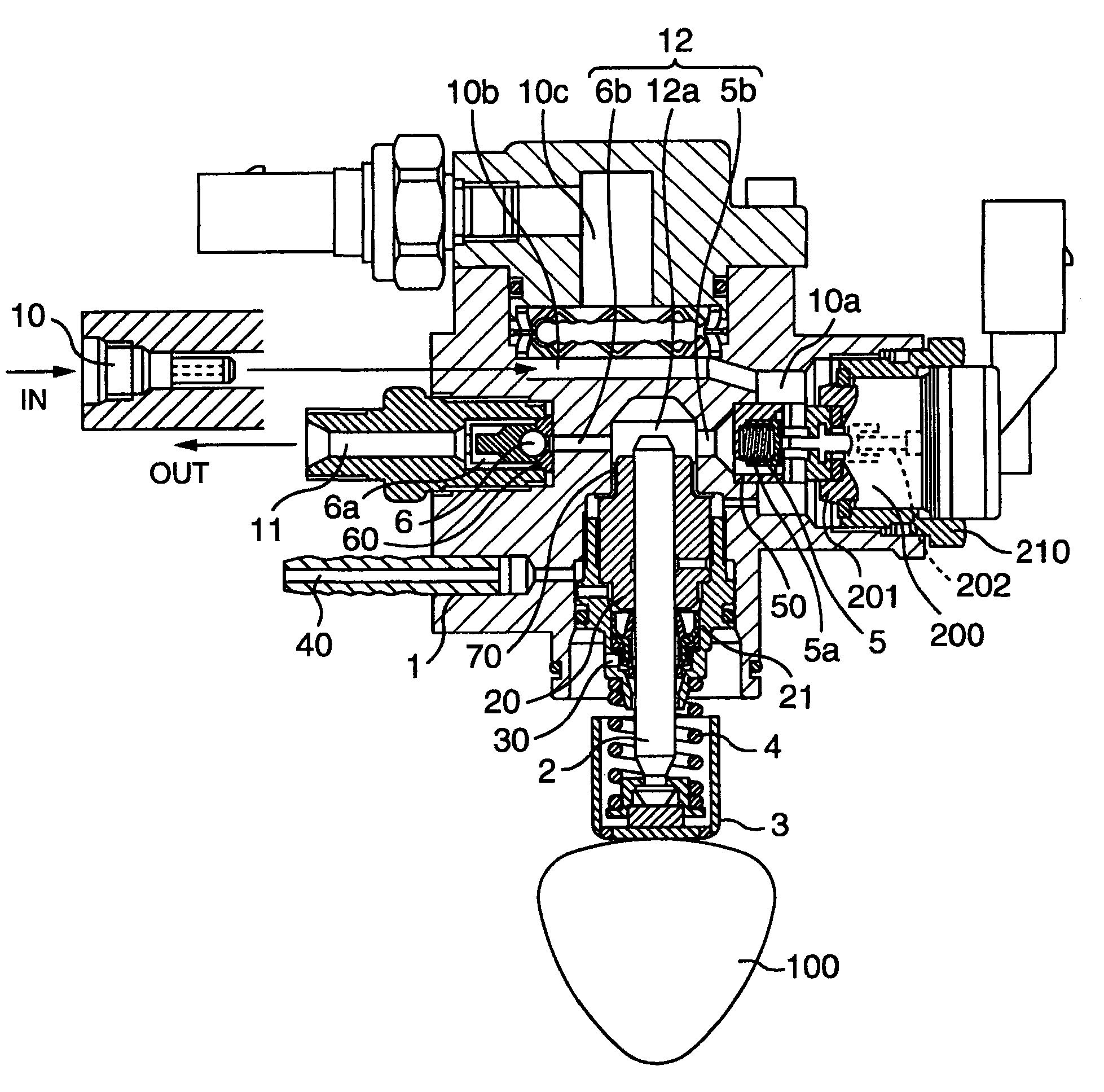

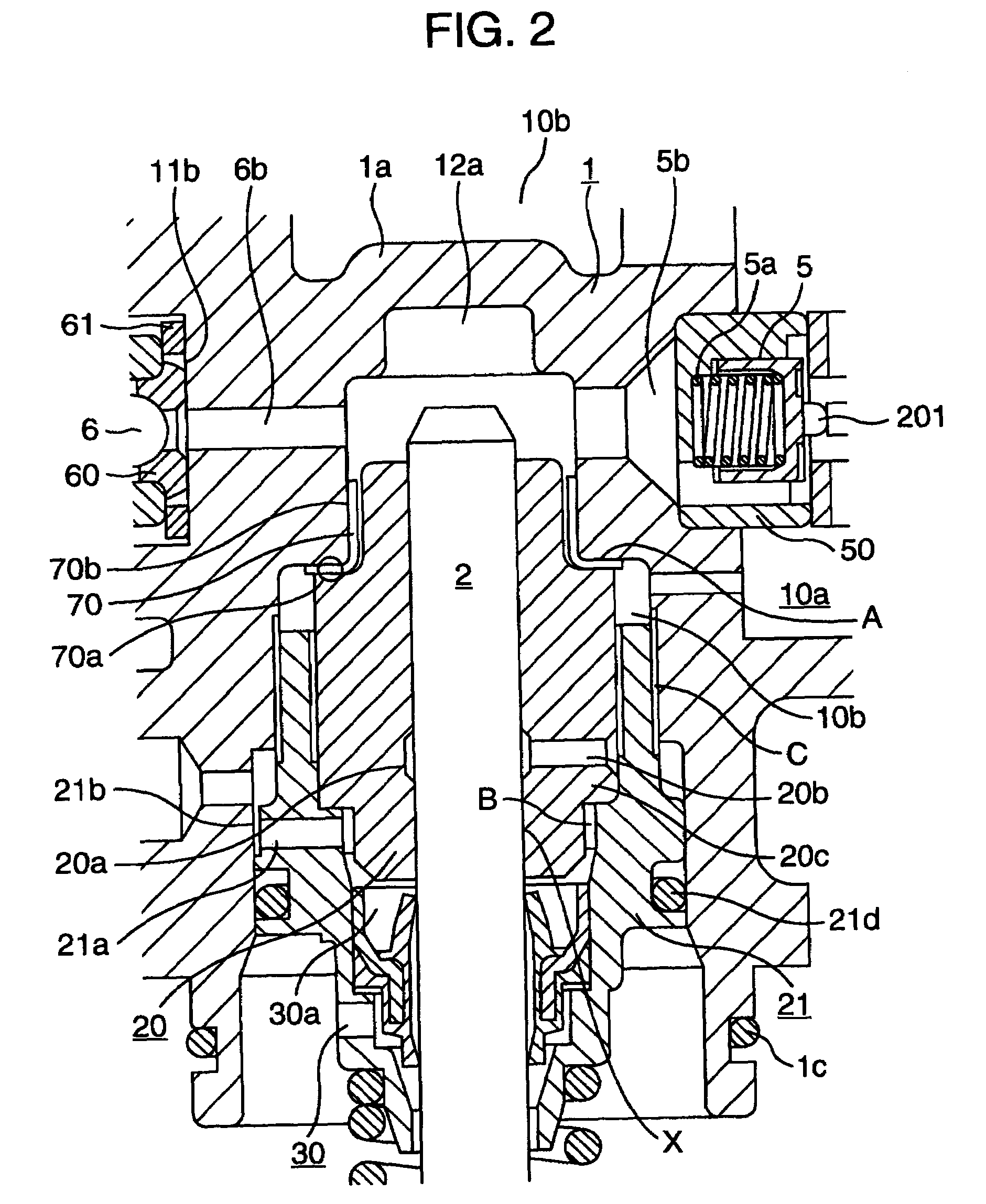

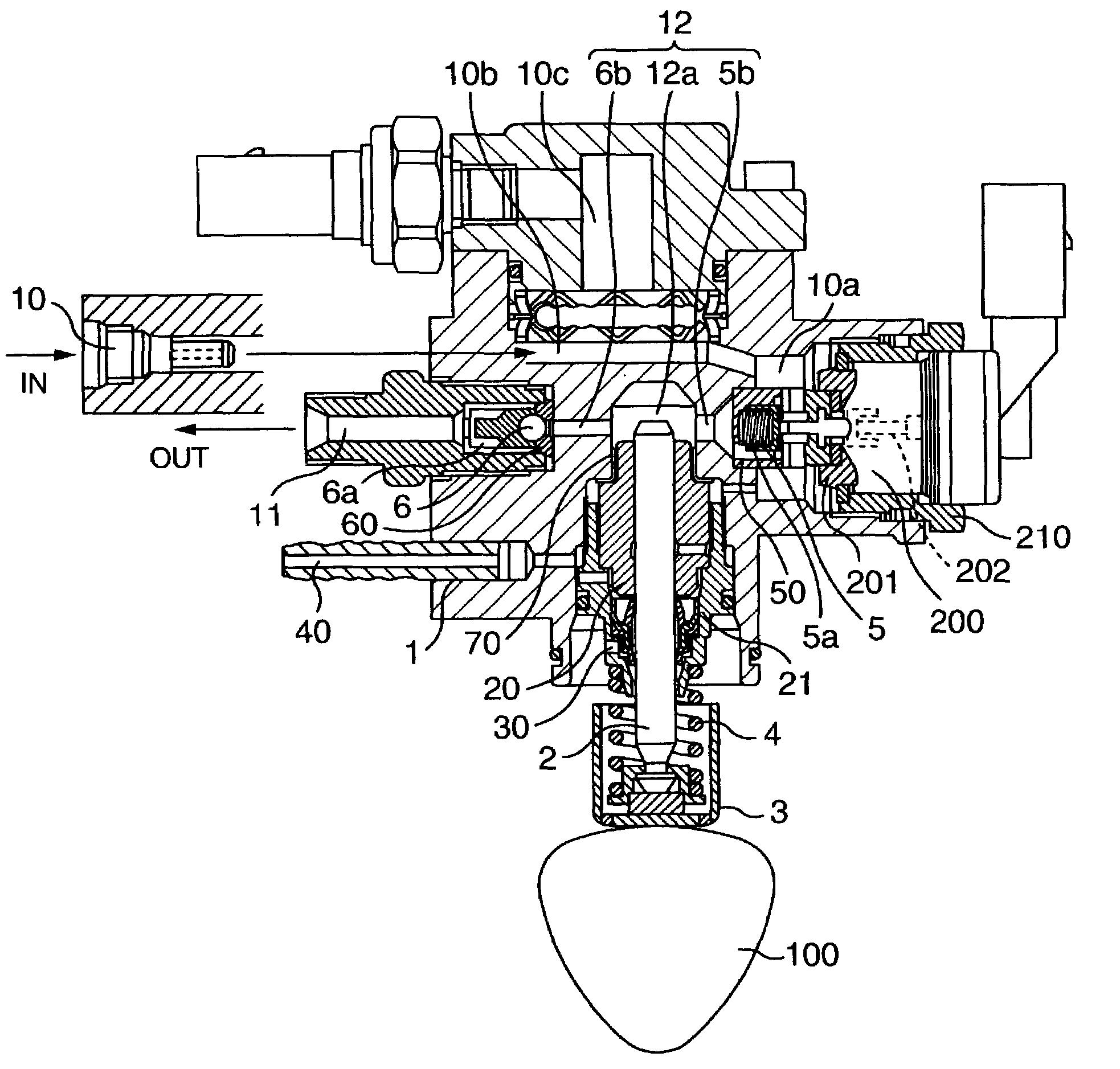

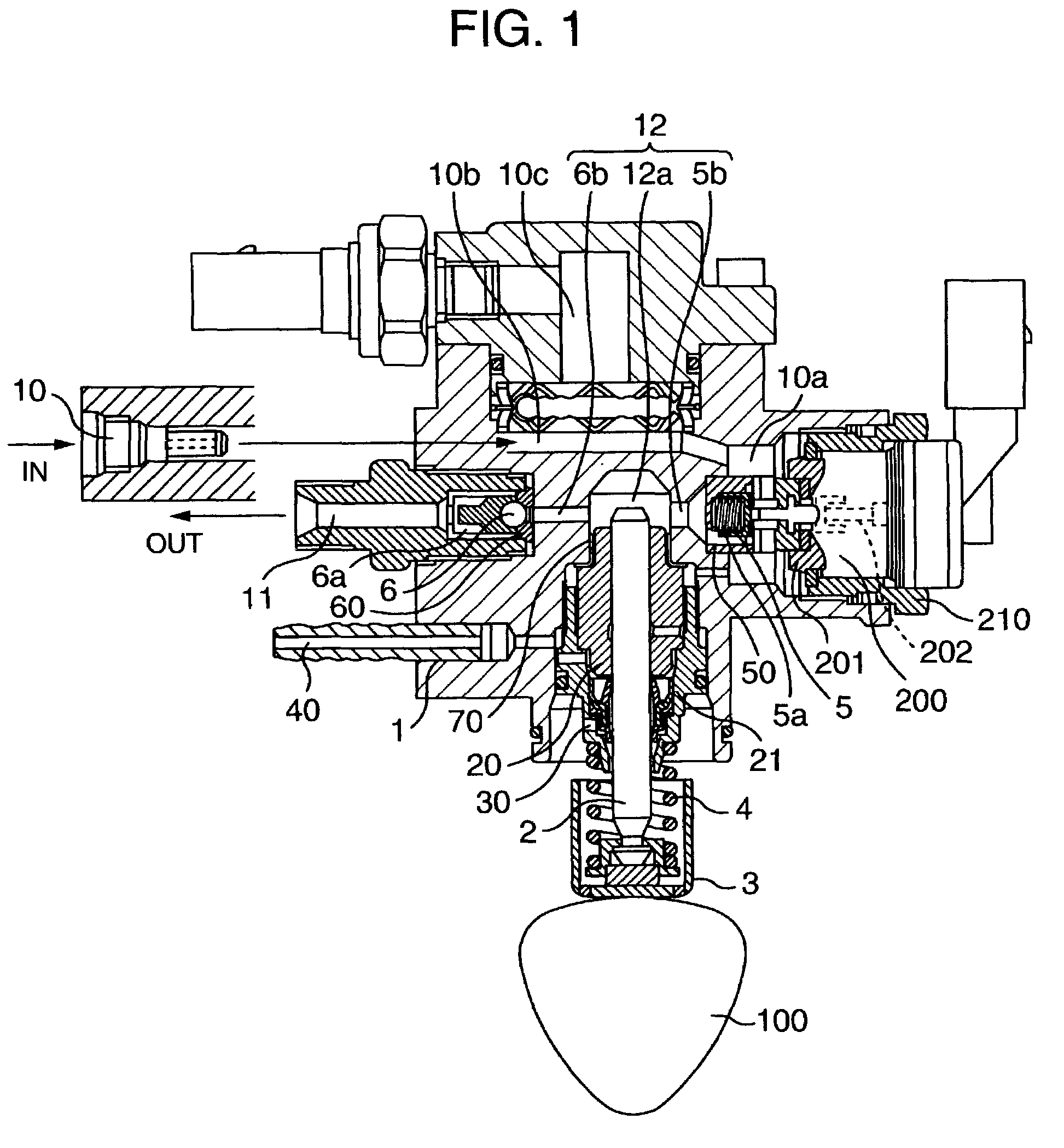

Fuel pressure sensor/sensor mount assembly, fuel injection apparatus, and pressure sensing apparatus

InactiveUS20090241650A1Easy to solveReduce vibrationInternal-combustion engine testingMachines/enginesControl theoryStress sensors

A fuel pressure sensor / sensor mount assembly in which a fuel pressure sensor is so mounted as to exposed to a high-pressure fuel path through which fuel is supplied to a fuel injector, a fuel injection apparatus equipped with a built-in fuel pressure sensor, and a pressure sensing apparatus working to measure the pressure of fuel in a fuel injector are provided. The fuel pressure sensor / sensor mount assembly is disposed between the high-pressure fuel path and the fuel injector, thus permitting the size of the fuel injector to be minimized without sacrificing the accuracy in measuring the pressure of the fuel. The fuel injection apparatus and the a pressure sensing apparatus are designed to ensure desired accuracy in measuring the pressure of the fuel.

Owner:DENSO CORP

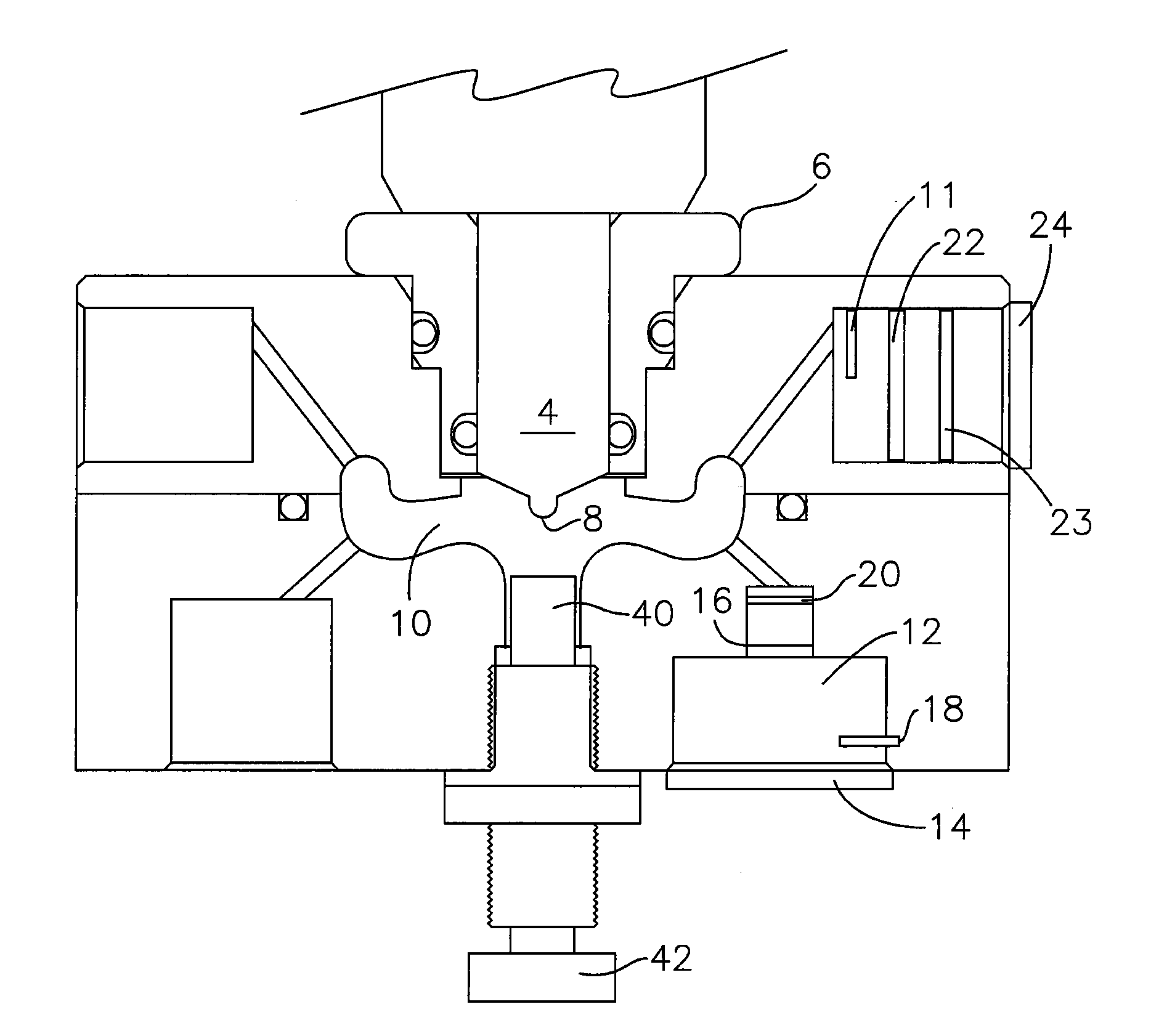

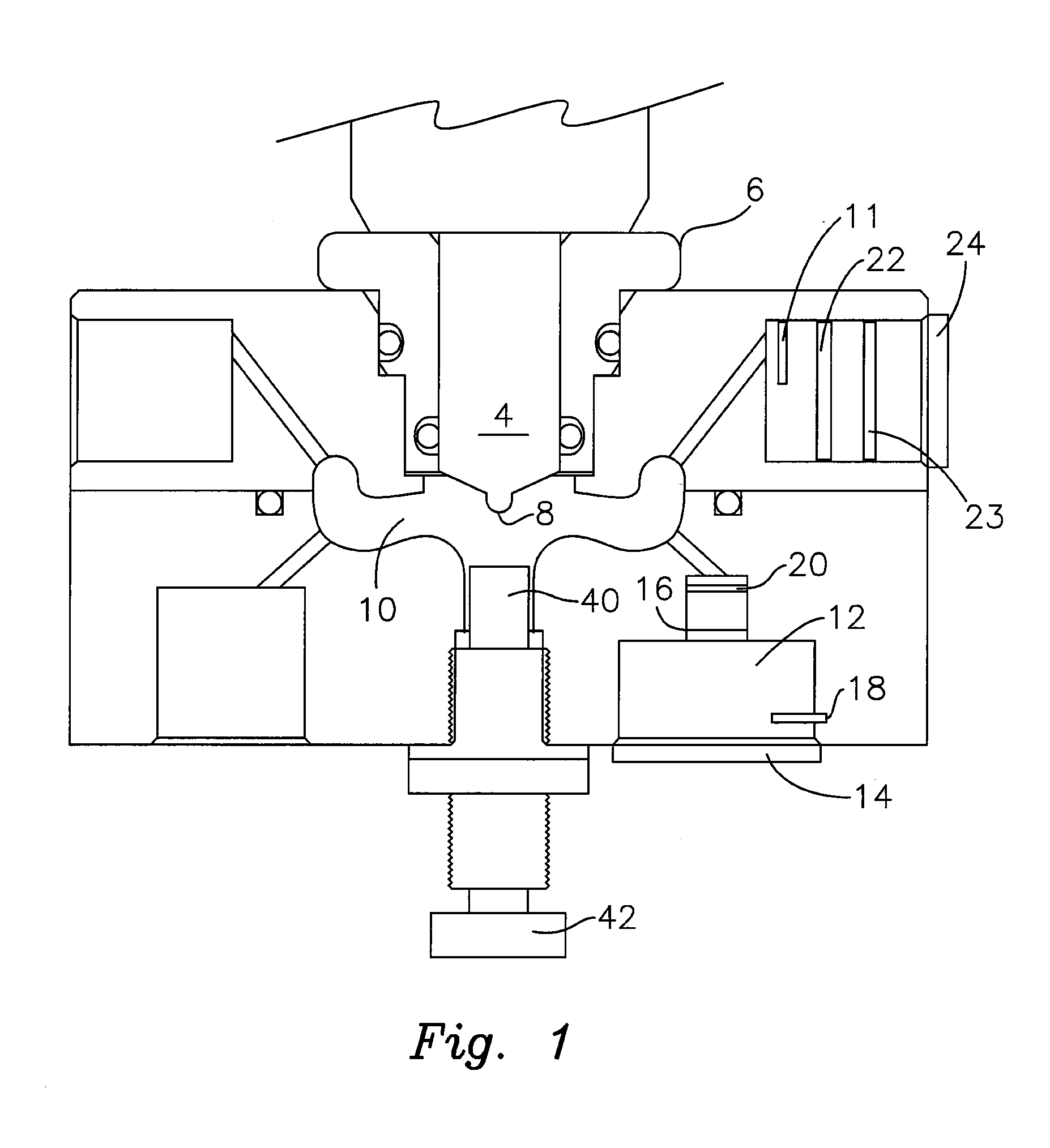

Fuel injector with real-time feedback control

InactiveUS20090206184A1Easy to controlMovable spraying apparatusSpray nozzlesCombustion chamberEngineering

A fuel injection apparatus with a piston device that includes a channel and a piston in the channel. A position sensor is used to detect the piston movement inside the channel when the fuel injection apparatus is energized and de-energized, and the sensing value is used for controlling fuel injection rate in real-time and diagnosing failures in the apparatus. With an actuator installed, the piston can also be used for independently modulating fuel pressure during fuel injection. Thereby the shape of fuel injection pulses is controlled. The fuel injection apparatus has three injection states, and flexible fuel injection timing and multi-pulse injection are allowed. Furthermore, in all injection states, fuel supply has no direct contact to combustion chamber. As a result, when a malfunction sticks the apparatus open, no fuel is supplied. This feature provides a safety nature to the fuel injection apparatus.

Owner:YAN MI

Fuel supply apparatus for engine and control method of same

A fuel supply apparatus for an engine in which calculation of a manipulated variable of a fuel pump in response to a deviation between a fuel pressure detected by a fuel pressure sensor and a target value is carried out, is configured in a manner such that when the fuel pressure sensor is failed, a change in the fuel pressure is estimated based on a required fuel flow amount of an engine, a discharge amount of the fuel pump and a fuel pressure detected immediately before the fuel pressure sensor is failed, so that deciding of the manipulated variable of the fuel pump is made, based on the estimation value. A method of controlling the fuel supply apparatus to realize the controlling of the fuel pump based on the manipulated variable is also disclosed.

Owner:HITACHI LTD

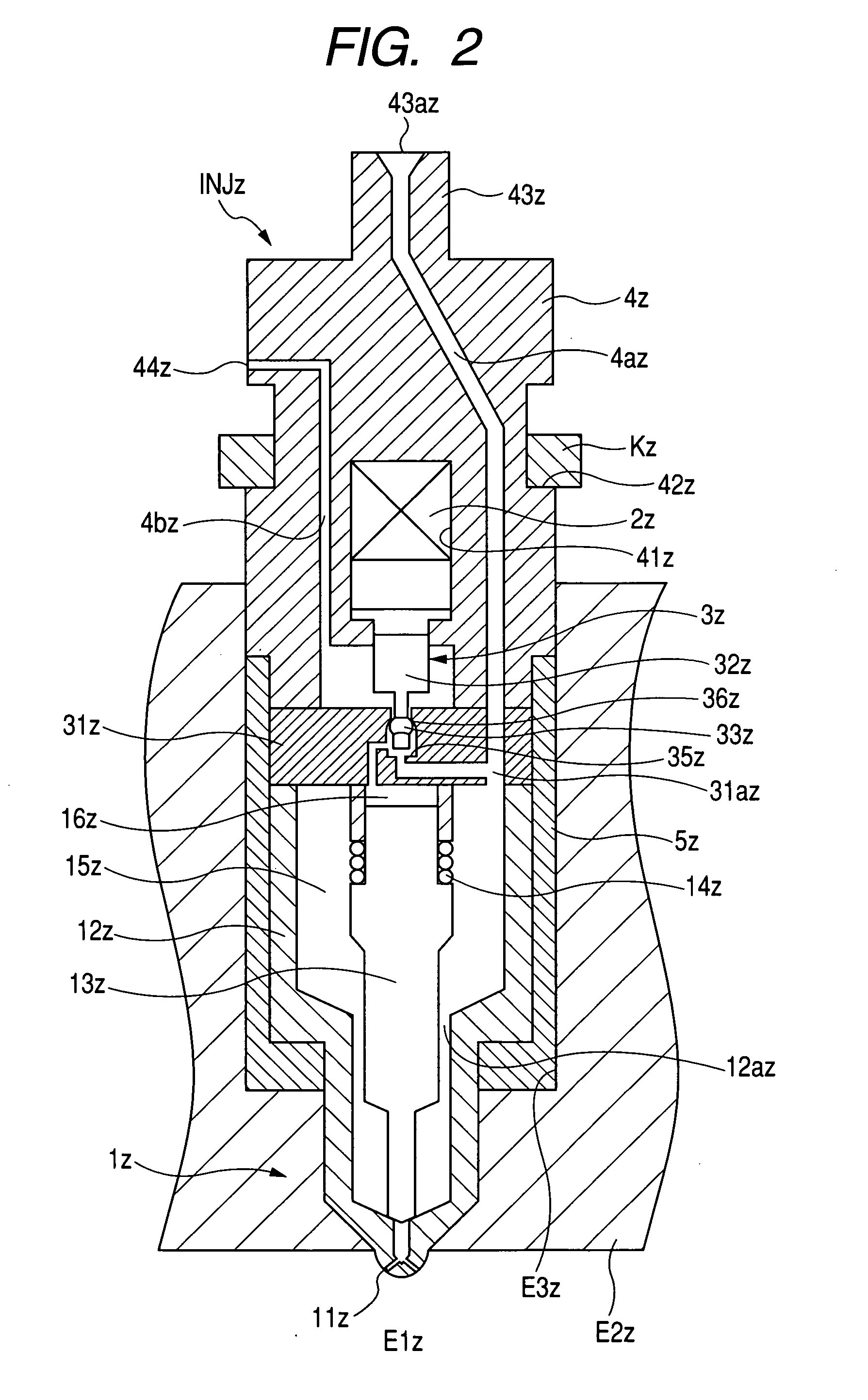

Fuel injection valve and fuel injection device

ActiveUS20100294242A1Promote formationImproved pressure sensing accuracyEngine testingEngine controllersEngineeringActuator

It is equipped with an injector body 4z which has formed therein high-pressure paths 6az, 6bz, and 6cz through which high-pressure fuel flows to a spray hole and stores therein a piezo-actuator 2z (i.e., an opening / closing mechanism) and a back-pressure control mechanism 3z (i.e., an opening / closing mechanism) which open or close the spray hole, a stem 51z (i.e., an elastic body) which is installed in said body 4z and elastically deformed when subjected to pressure of the high-pressure fluid, and a strain gauge 52z (i.e., a sensing device) which converts the degree of strain occurring at the stem 51z into an electric signal and outputs it as a measured-pressure signal. Specifically, the stain gauge 52z is installed on the stem 51z that is constructed as being separate from the body 4z.

Owner:DENSO CORP +1

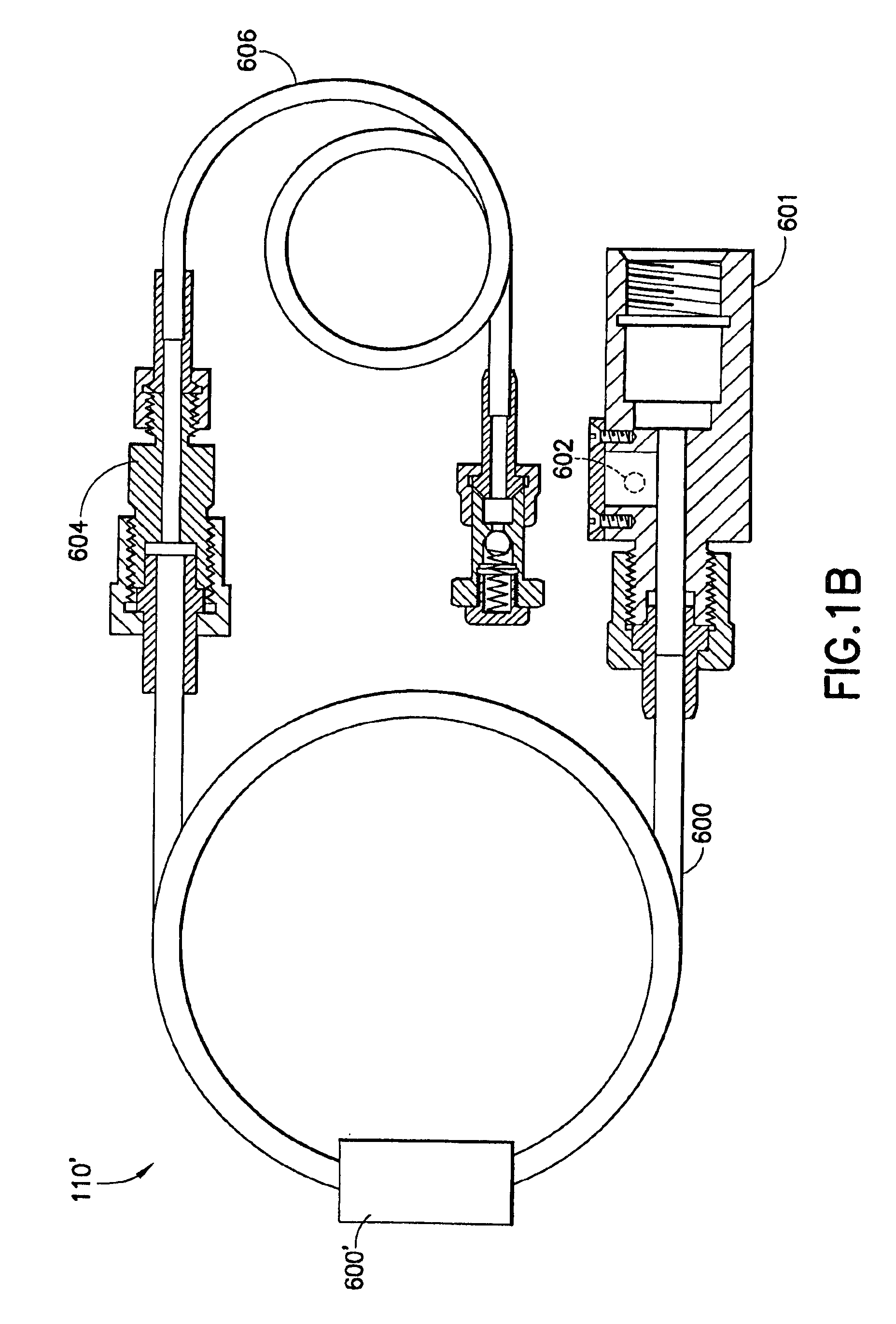

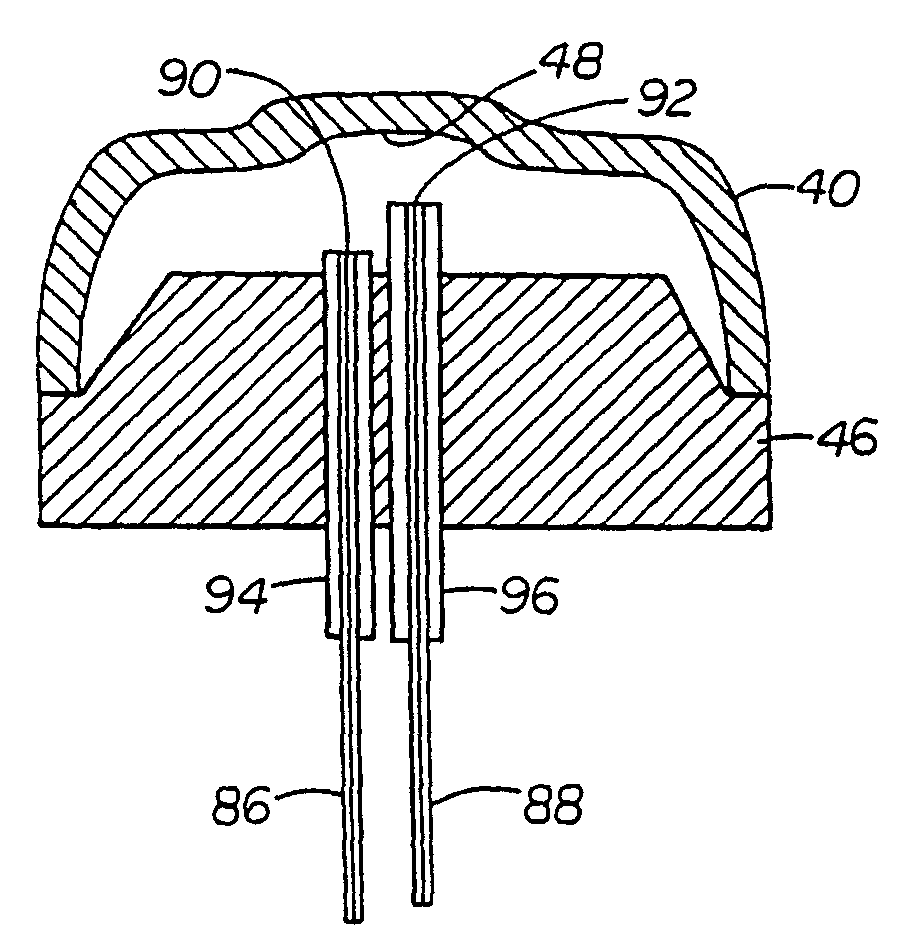

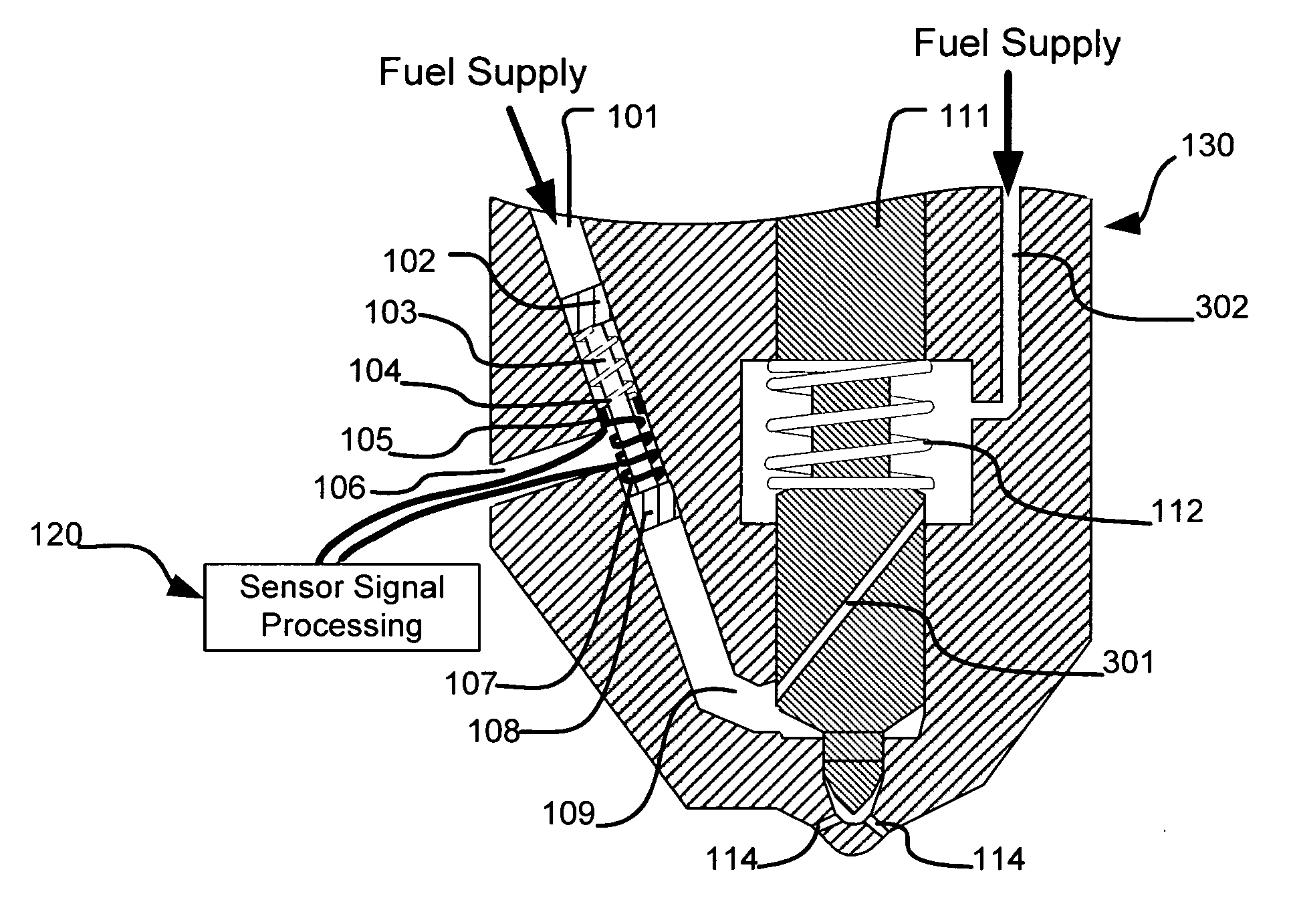

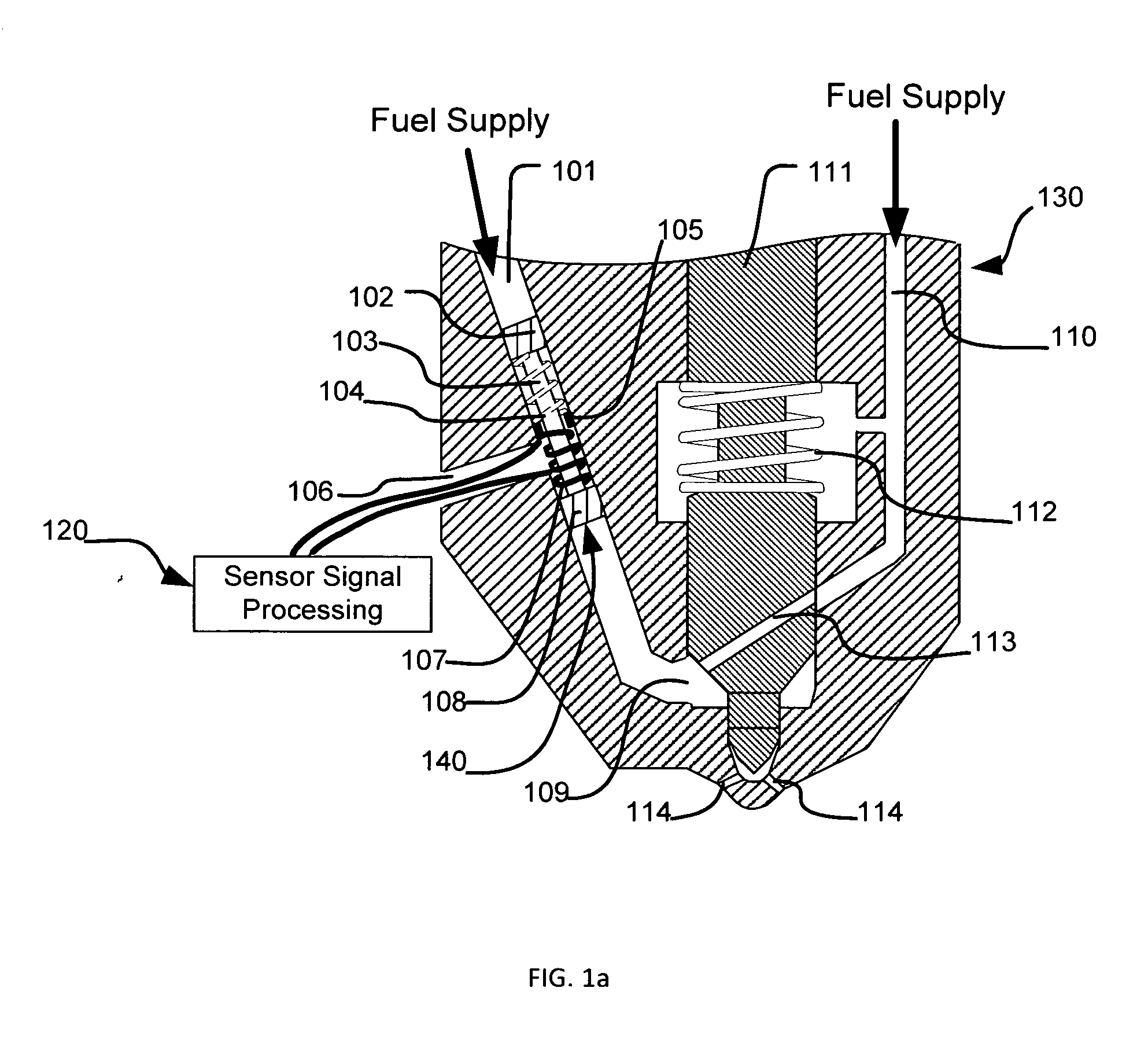

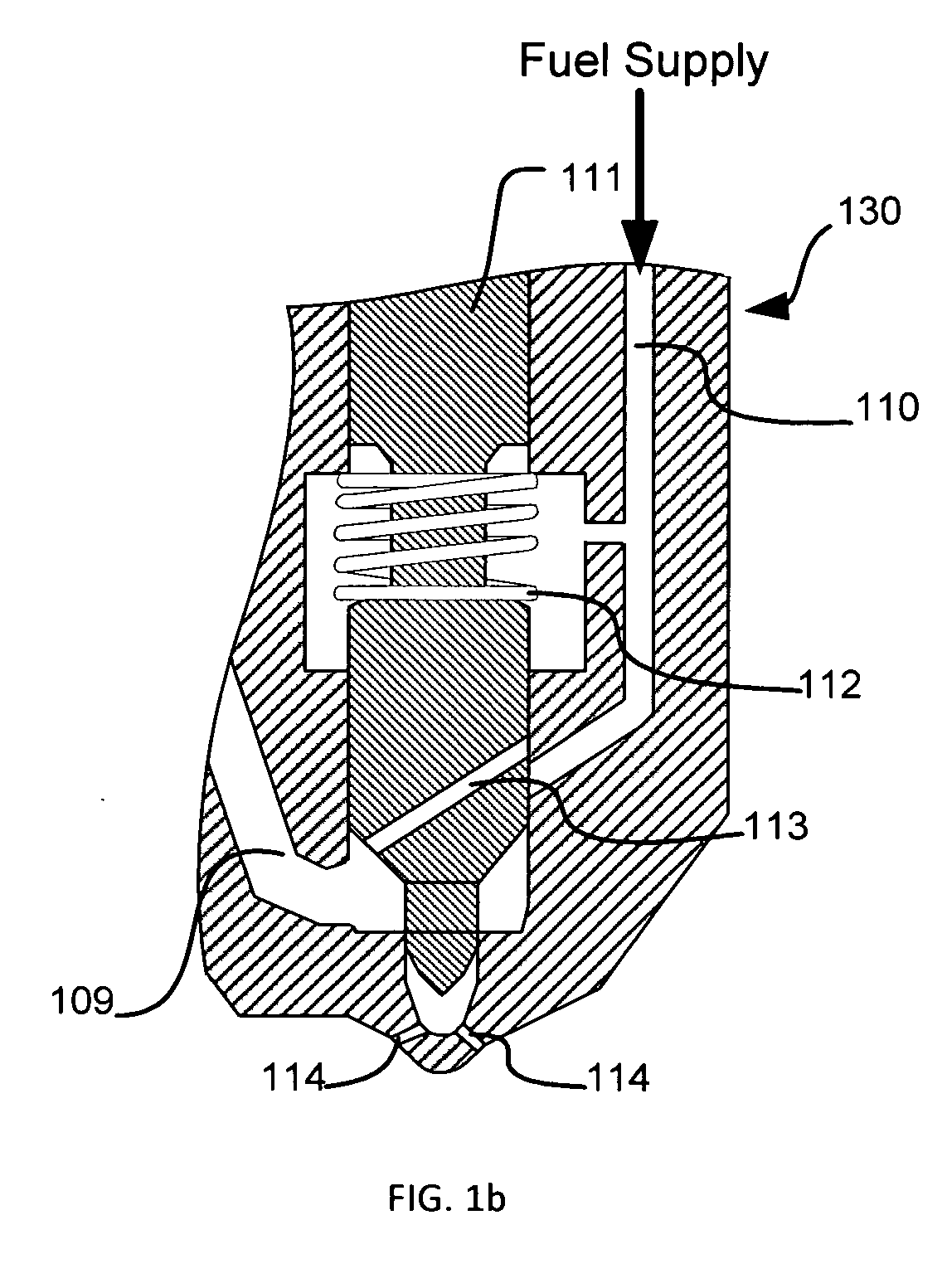

Fuel injectors with integral fiber optic pressure sensors and associated compensation and status monitoring devices

InactiveUS20060170909A1Cost-effective and accurateAccurate and repeatable spray patternTemperature measurement in motorsElectrical controlFiberCombustion chamber

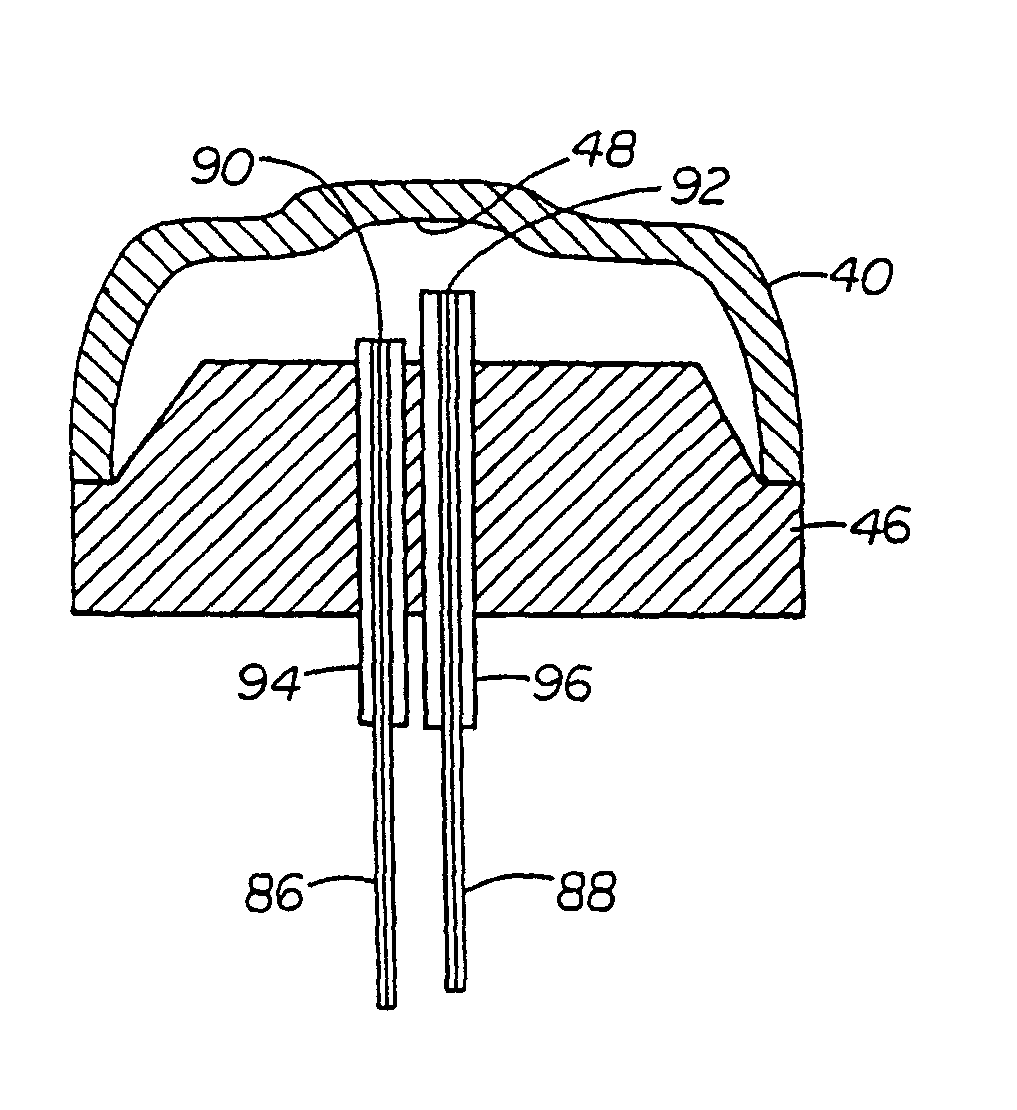

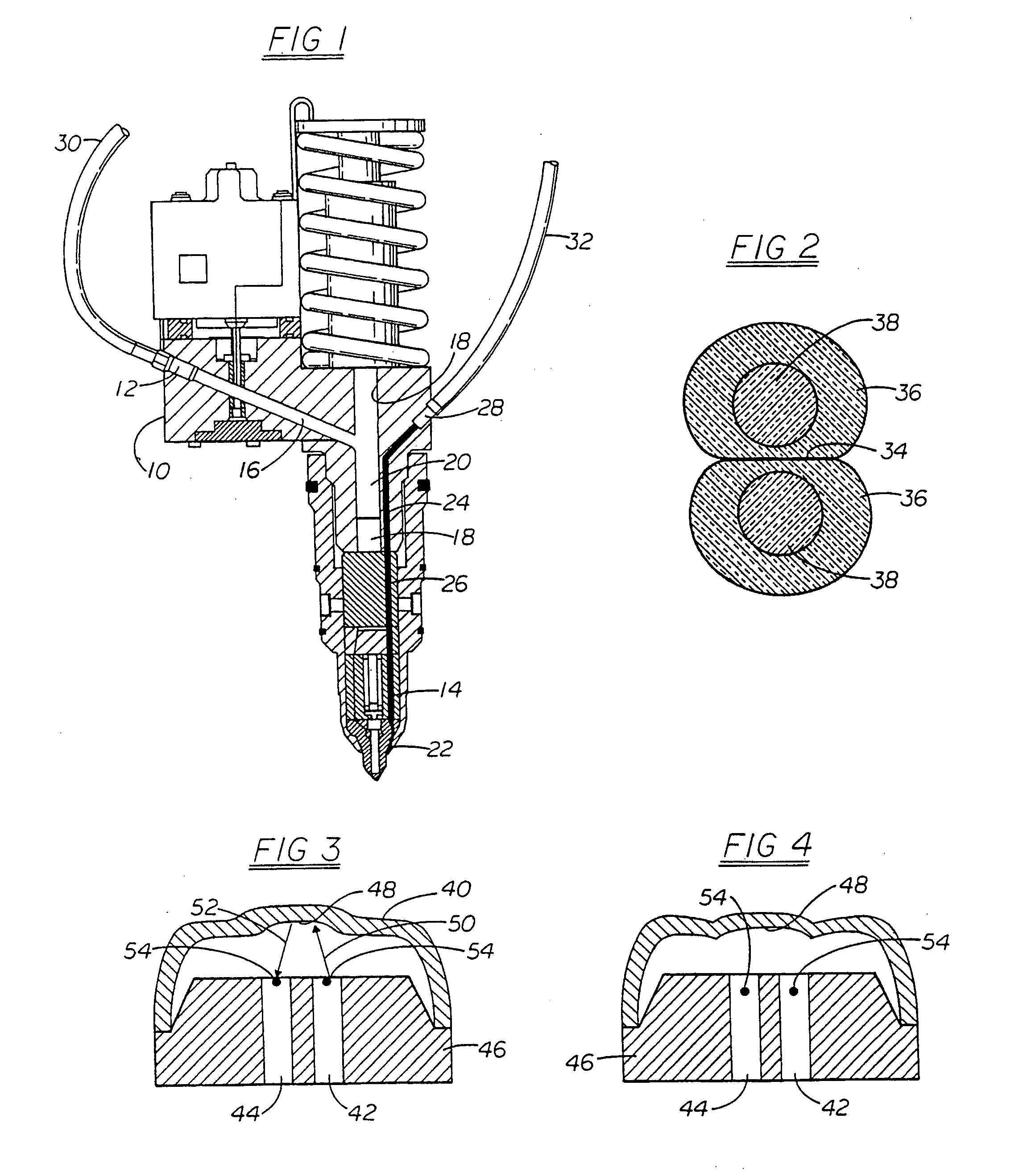

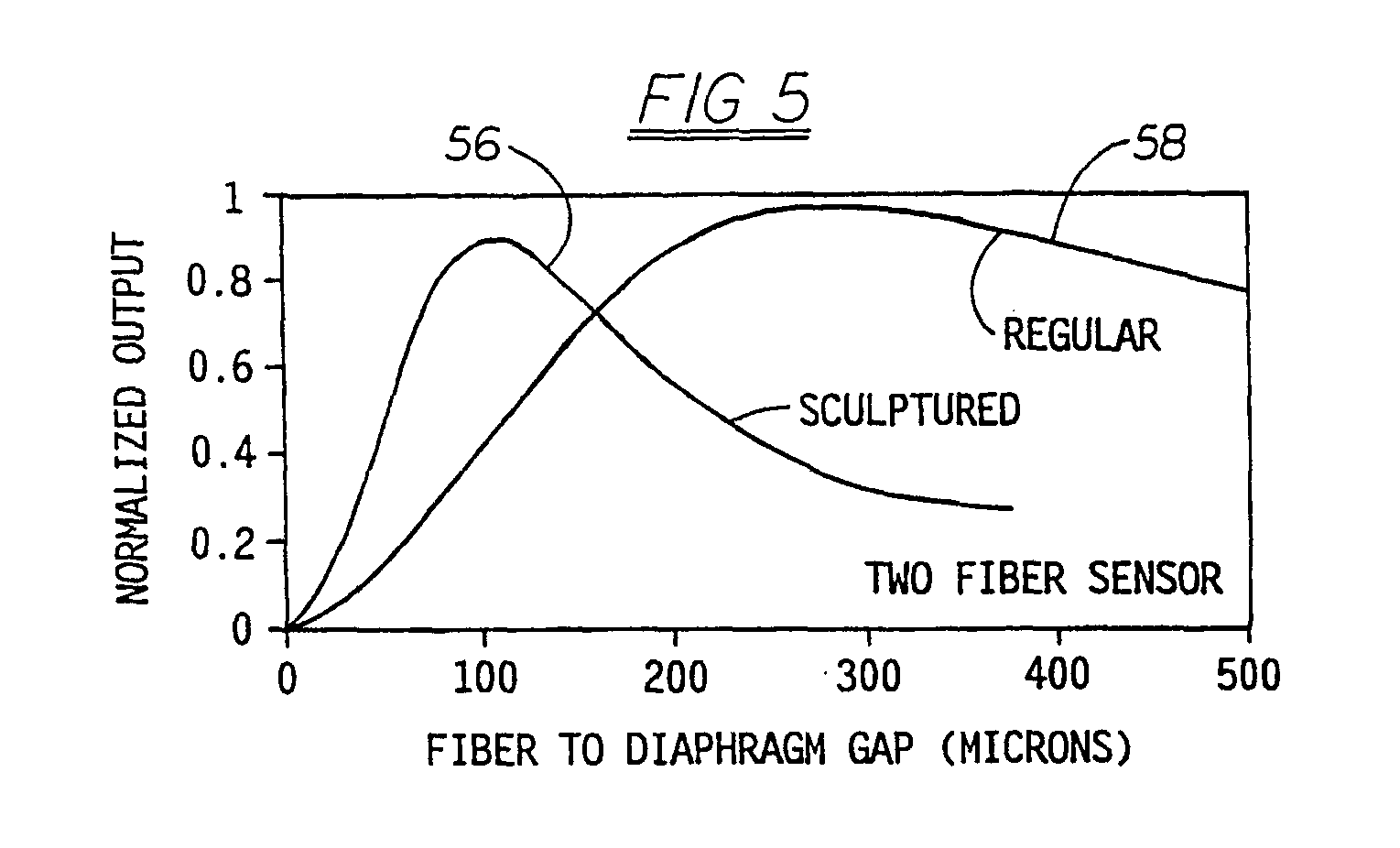

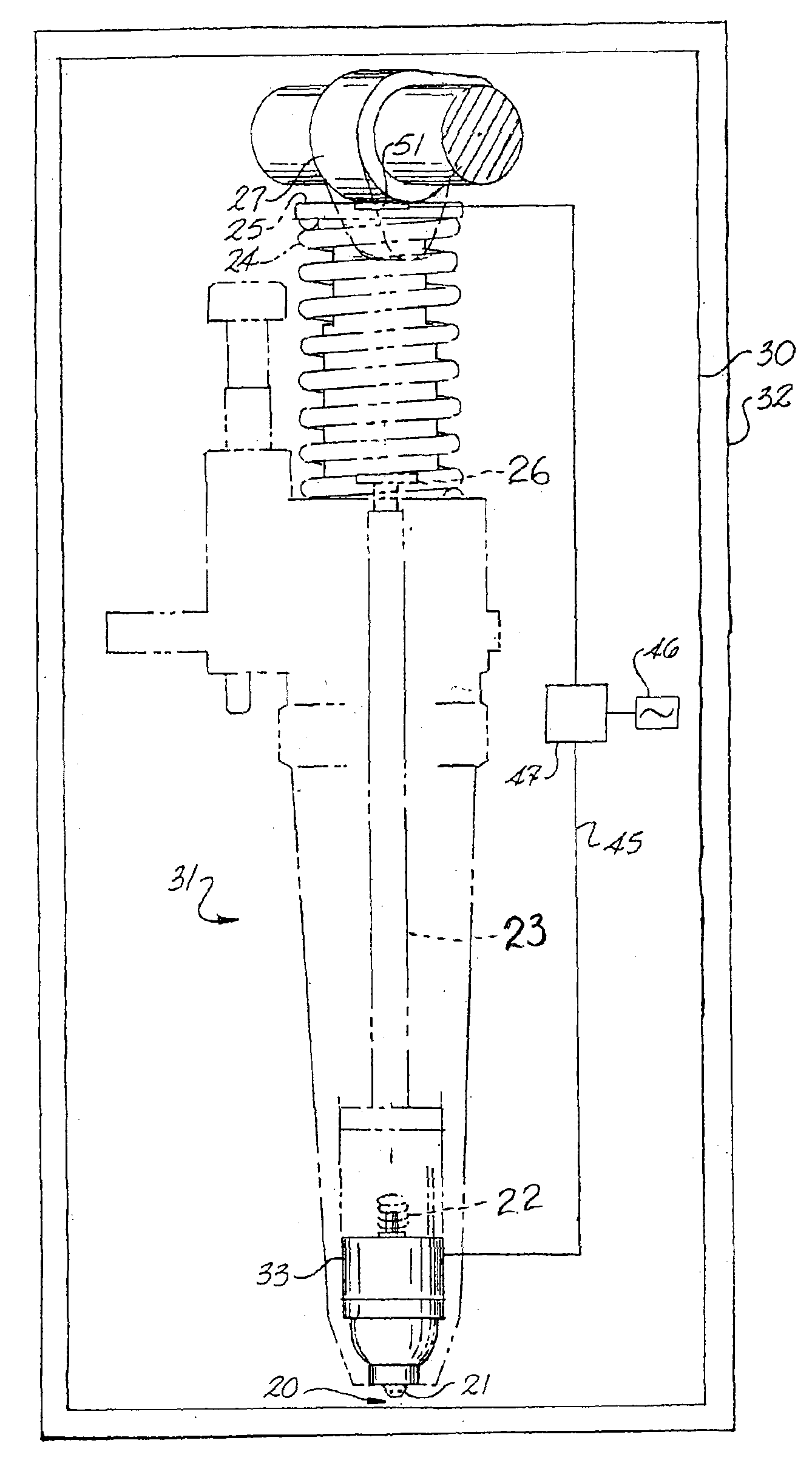

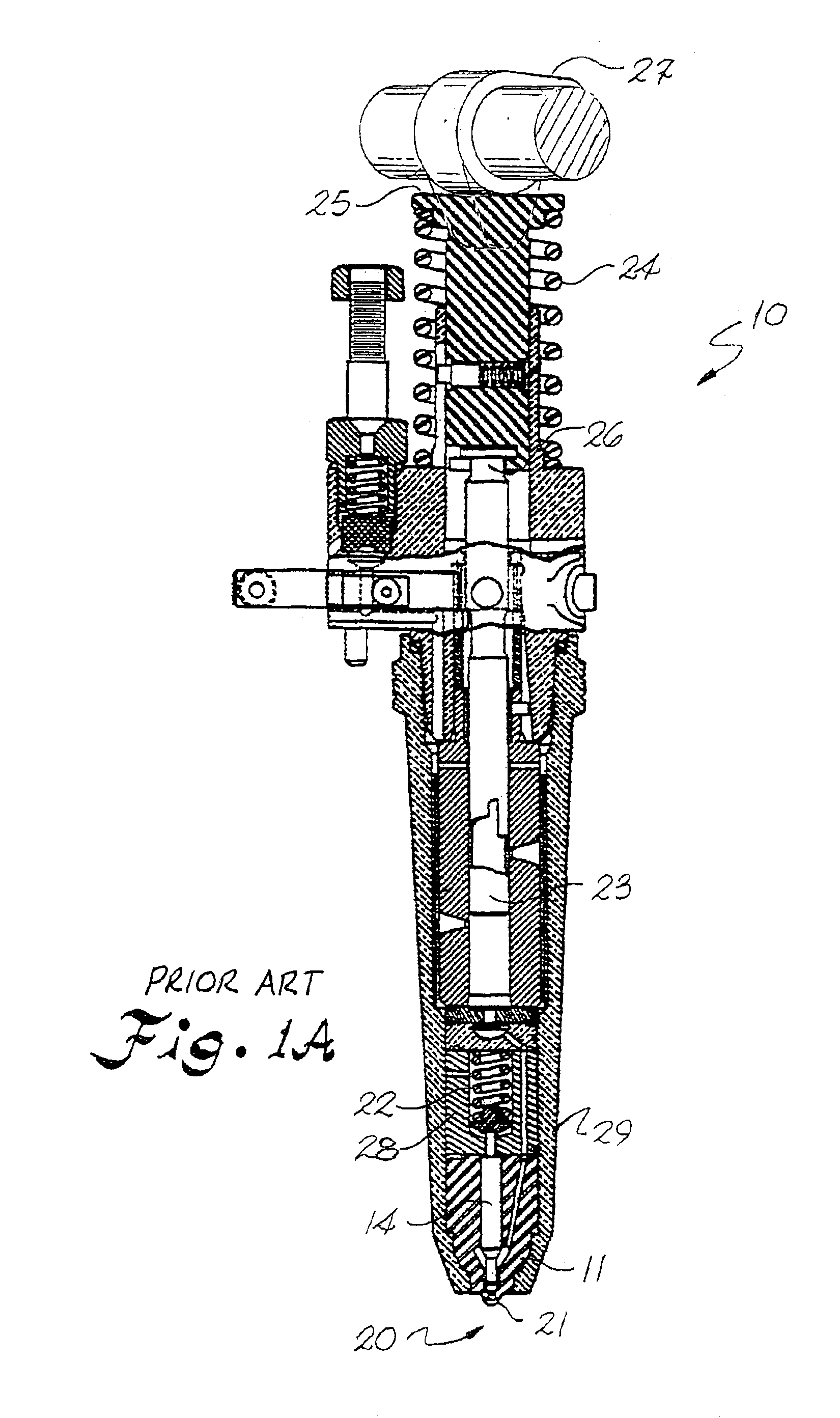

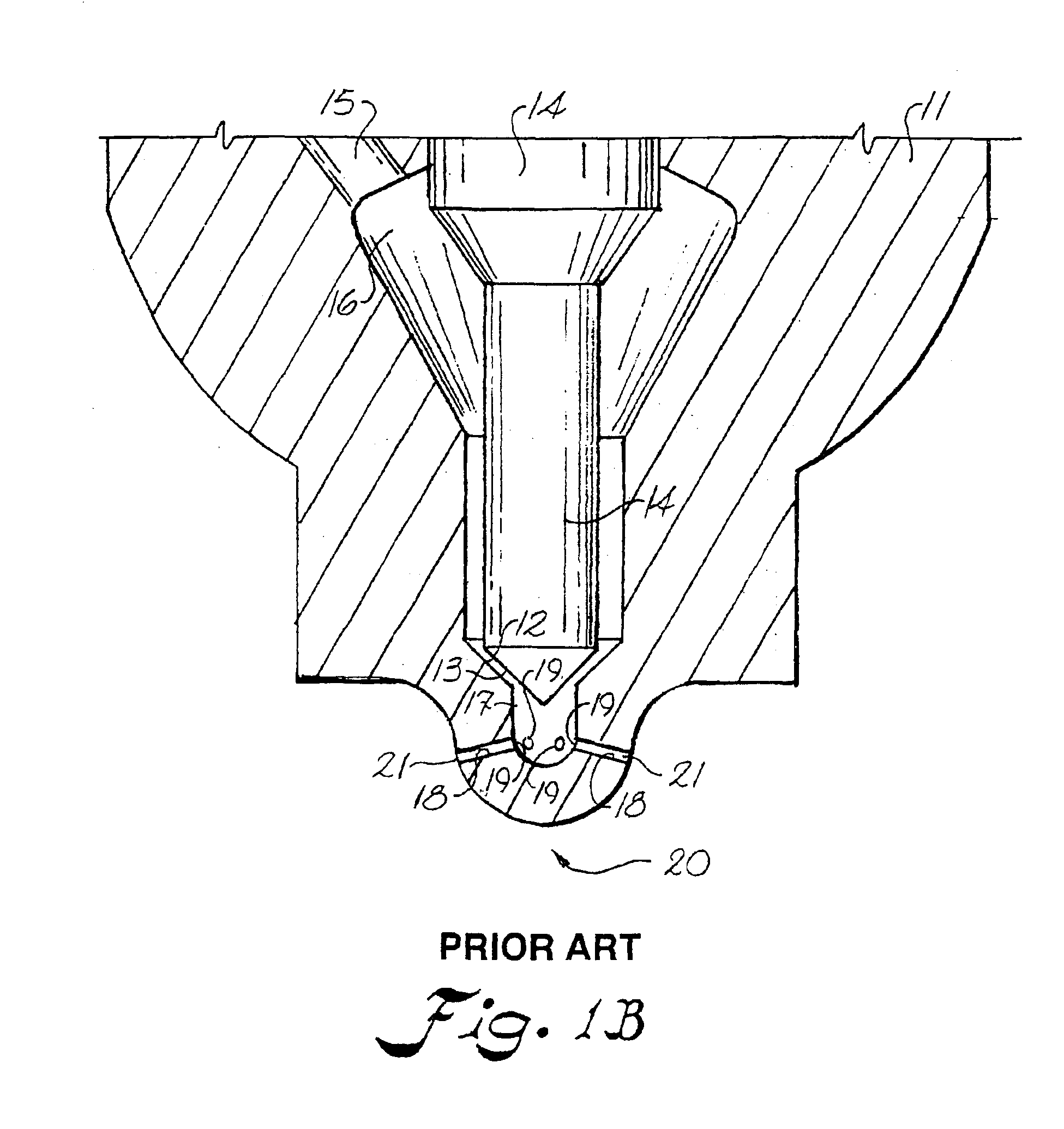

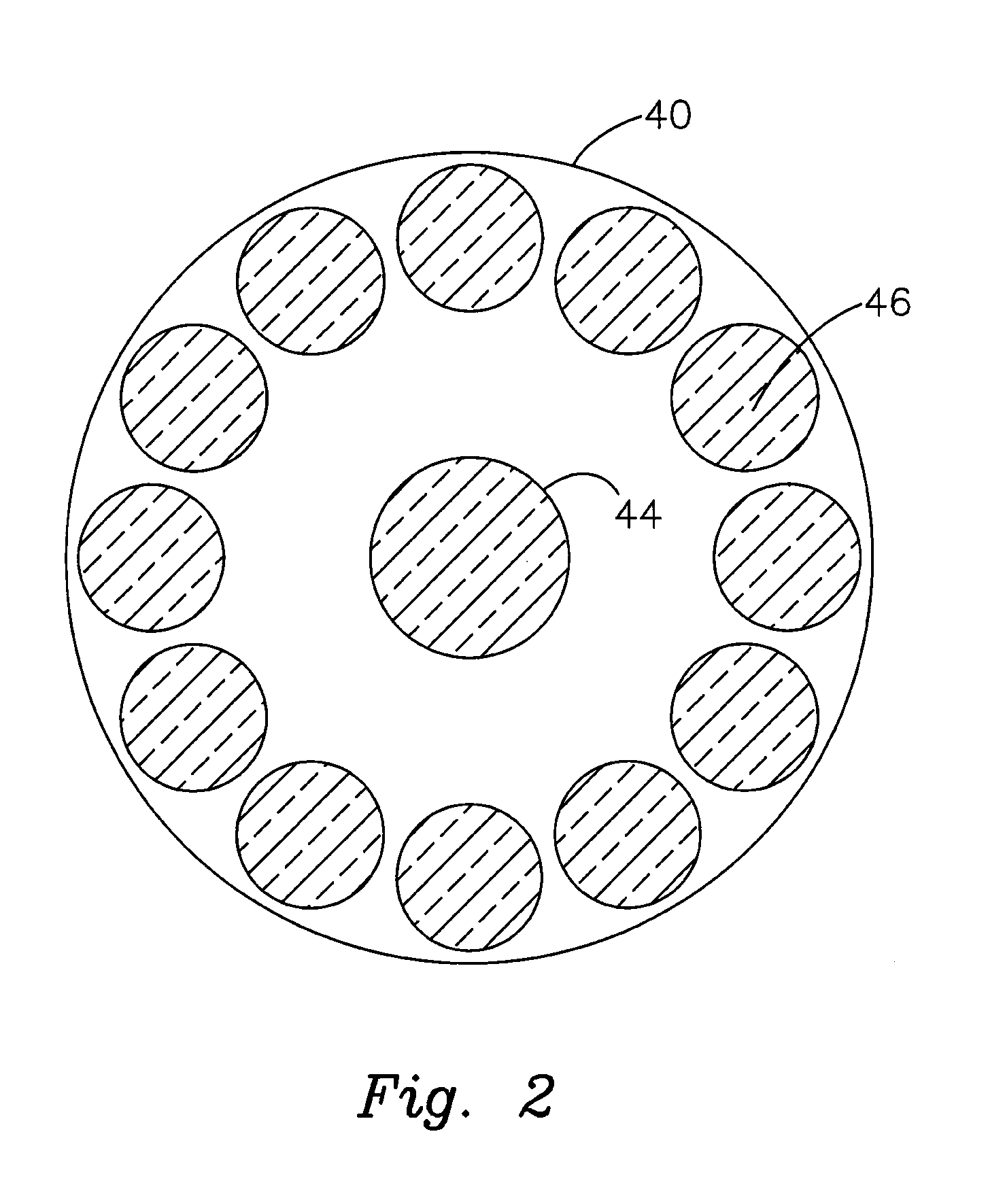

Fuel injectors (10) for internal combustion engines are modified and equipped with fiber optic fuel pressure sensors (12) and fiber optic combustion pressure sensors (14). The combustion pressure sensors (14) are located in separate channels (26) formed in the fuel injectors with the lower portion (22) of the channels leading to the combustion chambers. Above the combustion pressure sensors (14) are fiber optic leads (24). In the preferred embodiments the sensors (46) are equipped with diaphragms (40) of novel shape (48) and employ multiple pairs of fibers (86, 88), temperature sensitive components (72, 74, 126) and novel compensation and status monitoring circuits (FIGS. 6, 9, 10, 14, 15, 18).

Owner:WLODARCZYK MAREK T +1

Method of retrofitting an unitized injector for ultrasonically stimulated operation

InactiveUS6880770B2High speedCombustion-air/fuel-air treatmentFuel-injection pumpsBiomedical engineeringMagnetostriction

A method involves retrofitting conventional injectors with needles having magnetostrictive portions and wound coils configured and disposed so as to subject the magnetostrictive portions of the needles to ultrasonically oscillating magnetic fields.

Owner:KIMBERLY-CLARK WORLDWIDE INC

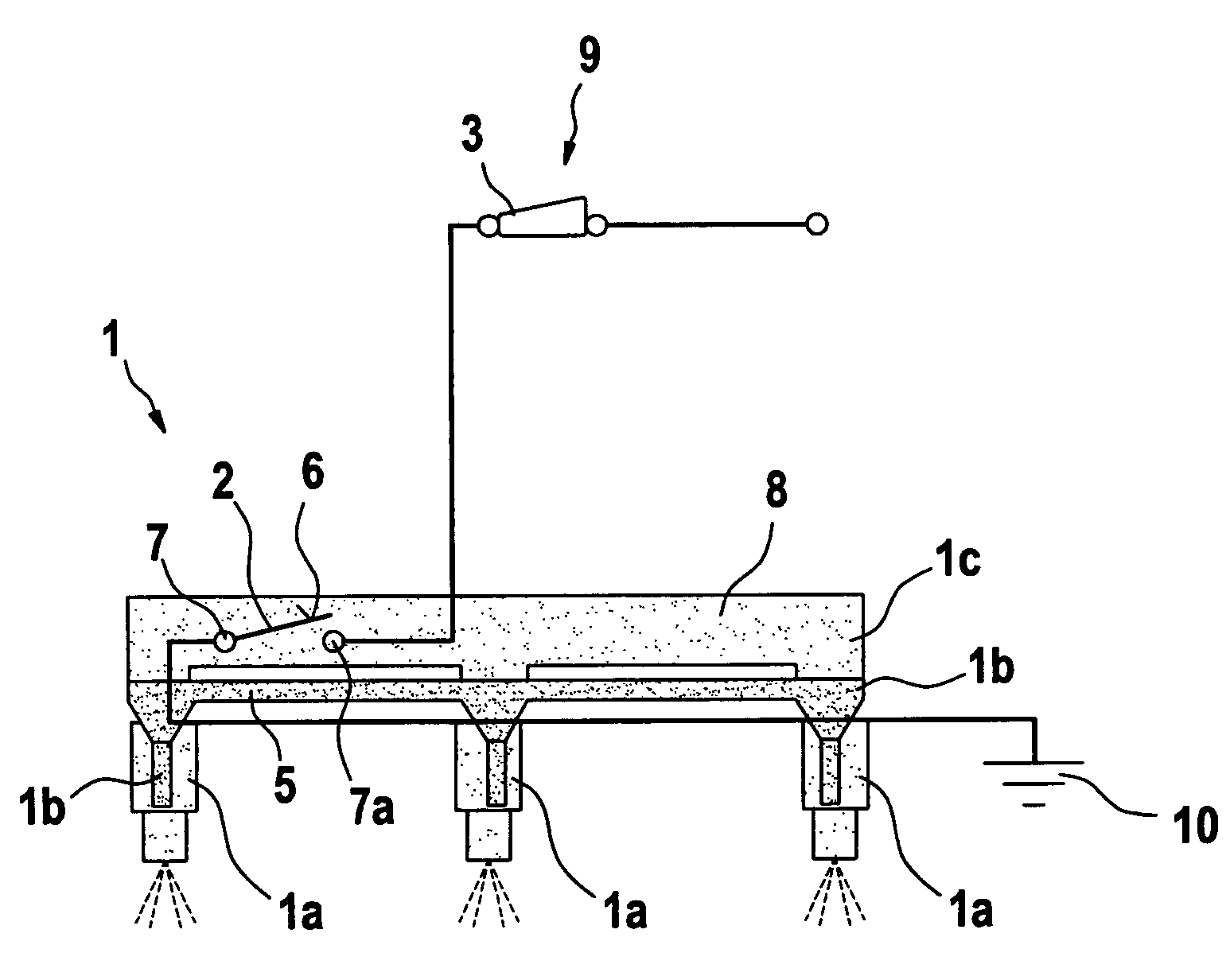

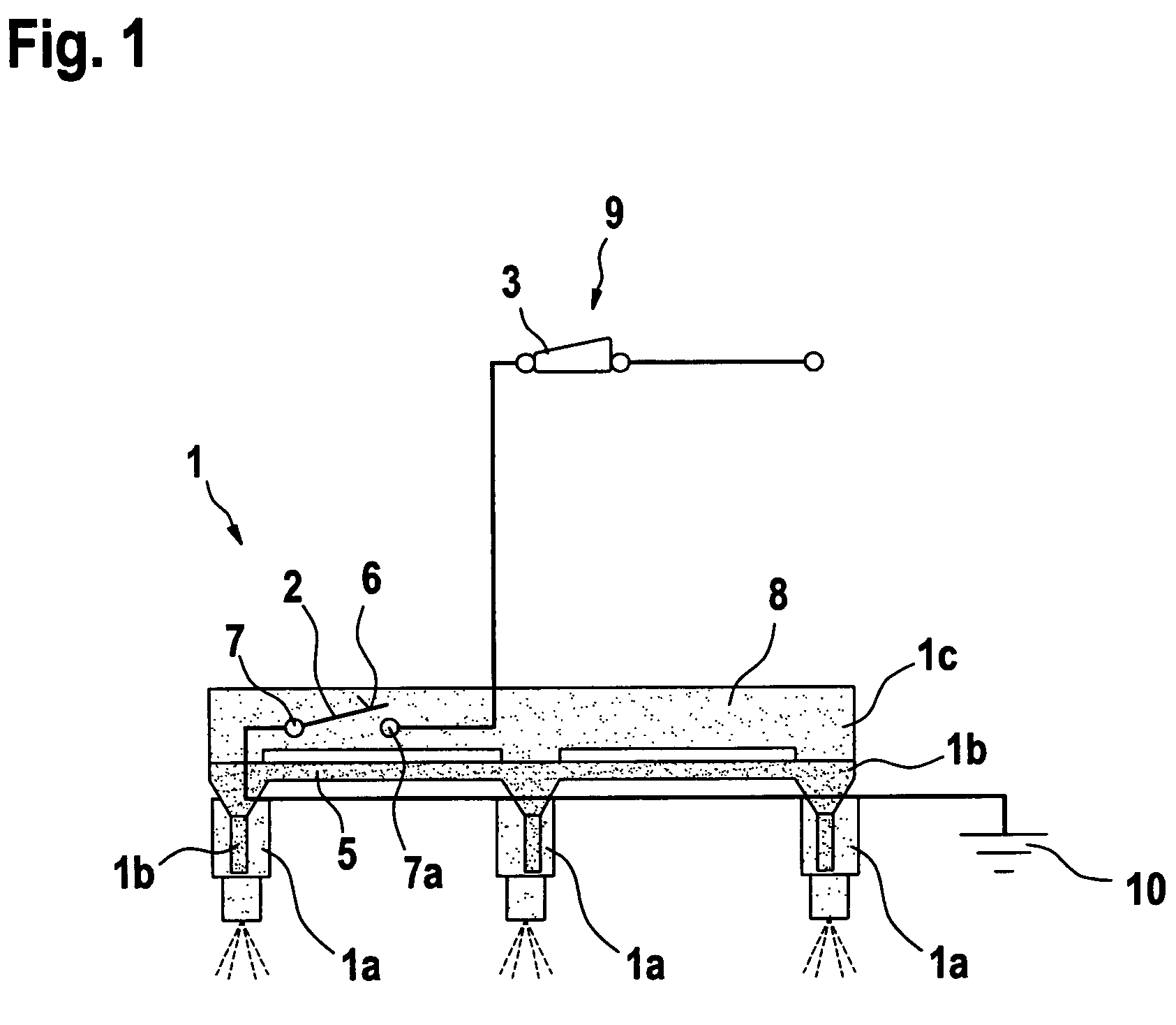

Fuel injection system

InactiveUS7669585B2Quality improvementLiquid surface applicatorsInternal combustion piston enginesFuel injectionInjector

A fuel injection system (1) with at least one fuel injector (1a) and a heatable adapter (1b), which is connected to a fuel rail (1c) and to the fuel injector (1a) of the fuel injection system (1); a thermoswitch (2) is provided in the fuel rail (1c), which is connected with an external door contact switch (3) and with the heatable adapter (1b). The thermoswitch (2) includes a thermosensor, so that a reliable cold start is ensured by the fact that, when a previously specified fuel temperature is fallen below, the thermoswitch (2) switches over and causes fuel (8) to be heated.

Owner:ROBERT BOSCH GMBH

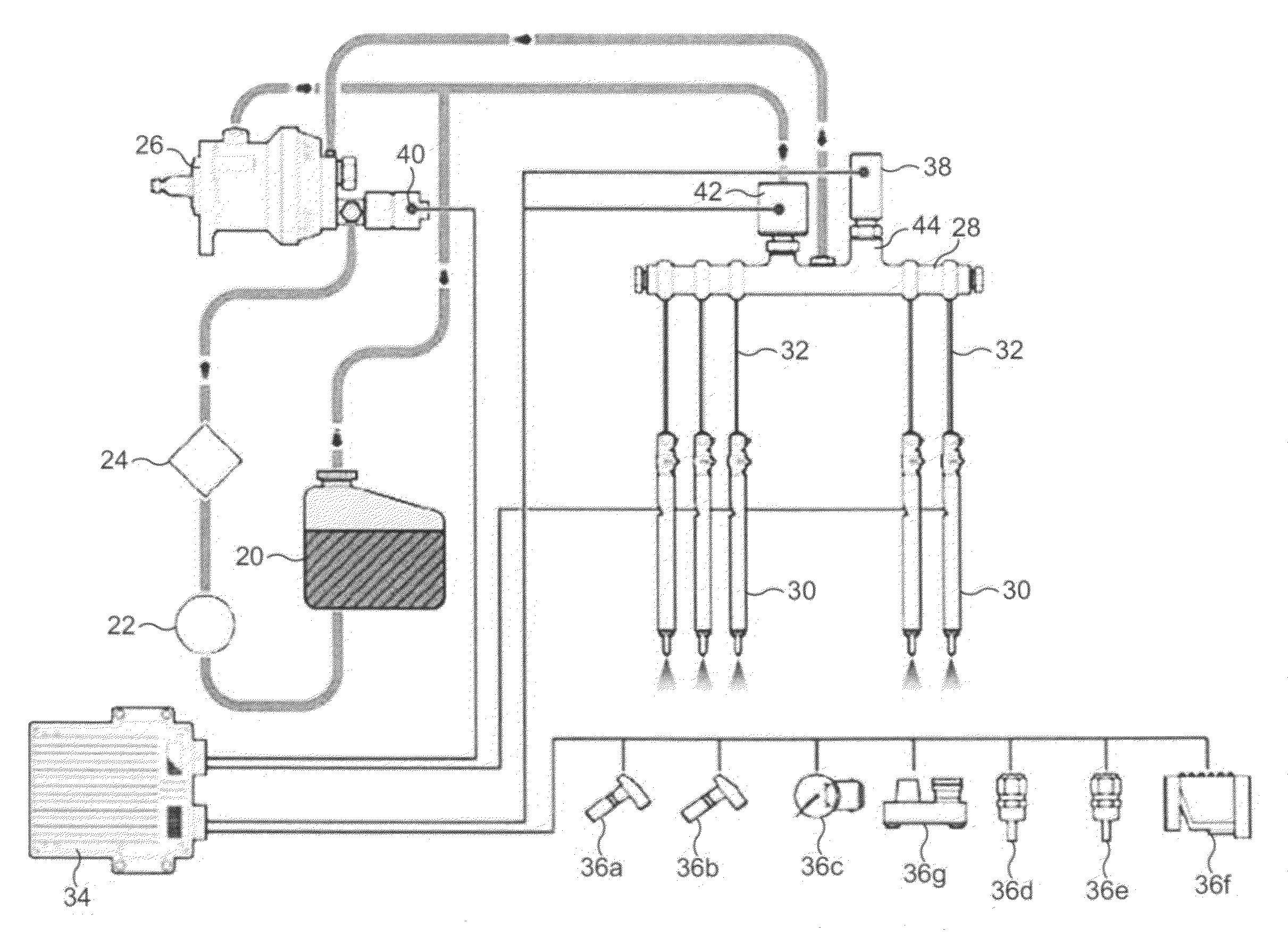

Fuel Injection Feedback System and Method

ActiveUS20120073361A1Easy to installInternal-combustion engine testingElectrical controlElectricityCavitation

A fuel injection feedback system comprises a light source disposed inside a fuel injector, an optical sensor disposed inside the fuel injector, and a computing device electronically connected to the optical sensor. The light source is a device configured to emit light capable of being reflected by cavitation. The light source could be disposed on or within the needle or nozzle of the fuel injector, or at a variety of other locations inside the fuel injector. The optical sensor is configured to detect an intensity of light caused by receiving light reflected from cavitation occurring inside the fuel injector.

Owner:CUETO OMAR

Fuel injection device and method for examining the same

A fuel injection device includes a fuel injection valve for injecting fuel. A pressure sensor is configured to output detection signal correspondingly to pressure of the fuel. The fuel injection device further includes a storage unit for storing individual difference information, which indicates an output characteristic of the detection signal. The output characteristic is obtained by an examination. The individual difference information indicates a relationship between change in test pressure and change in detection signal. The test pressure is actually applied to the pressure sensor in the examination. The change in detection signal is attributed to the change in test pressure.

Owner:DENSO CORP

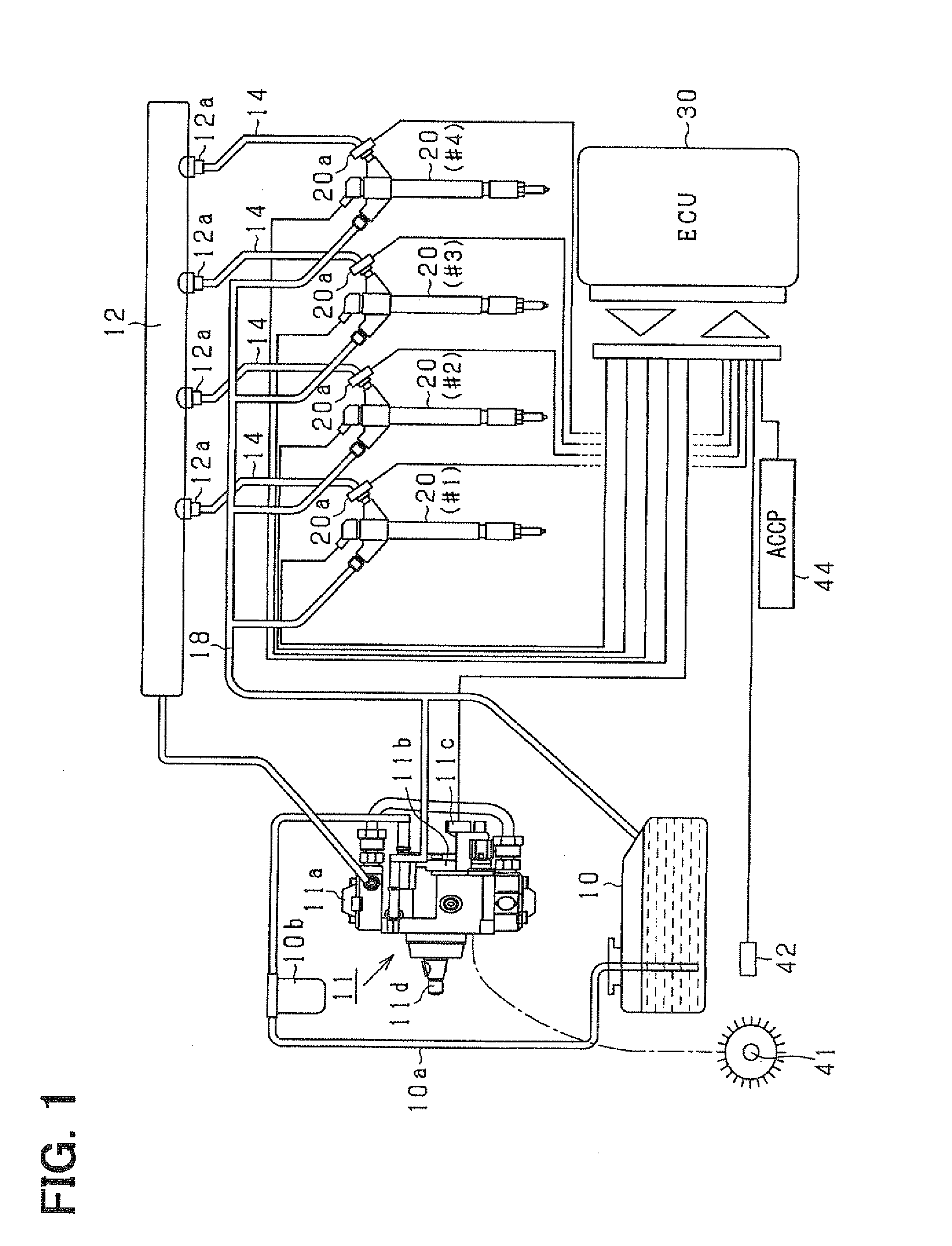

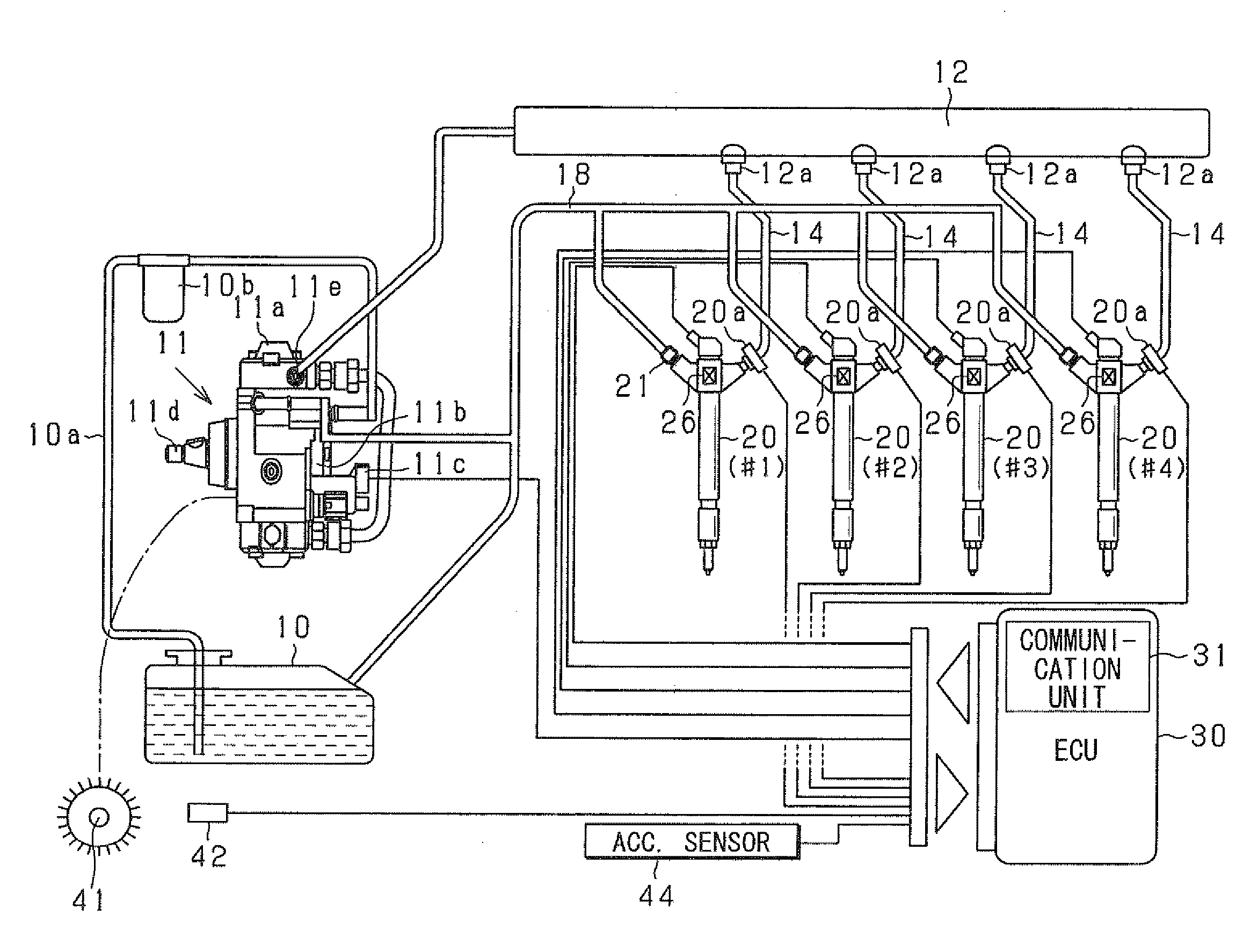

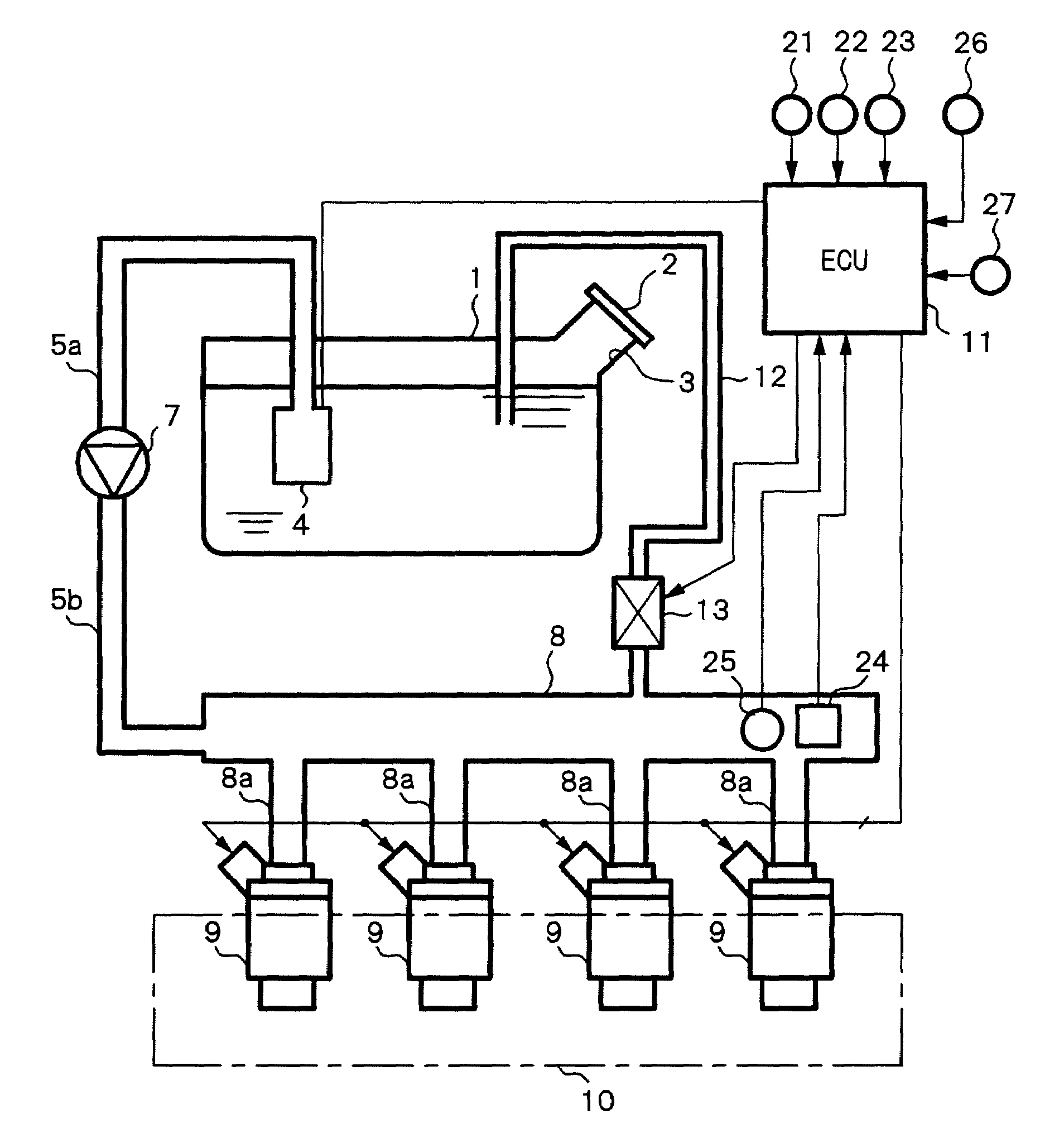

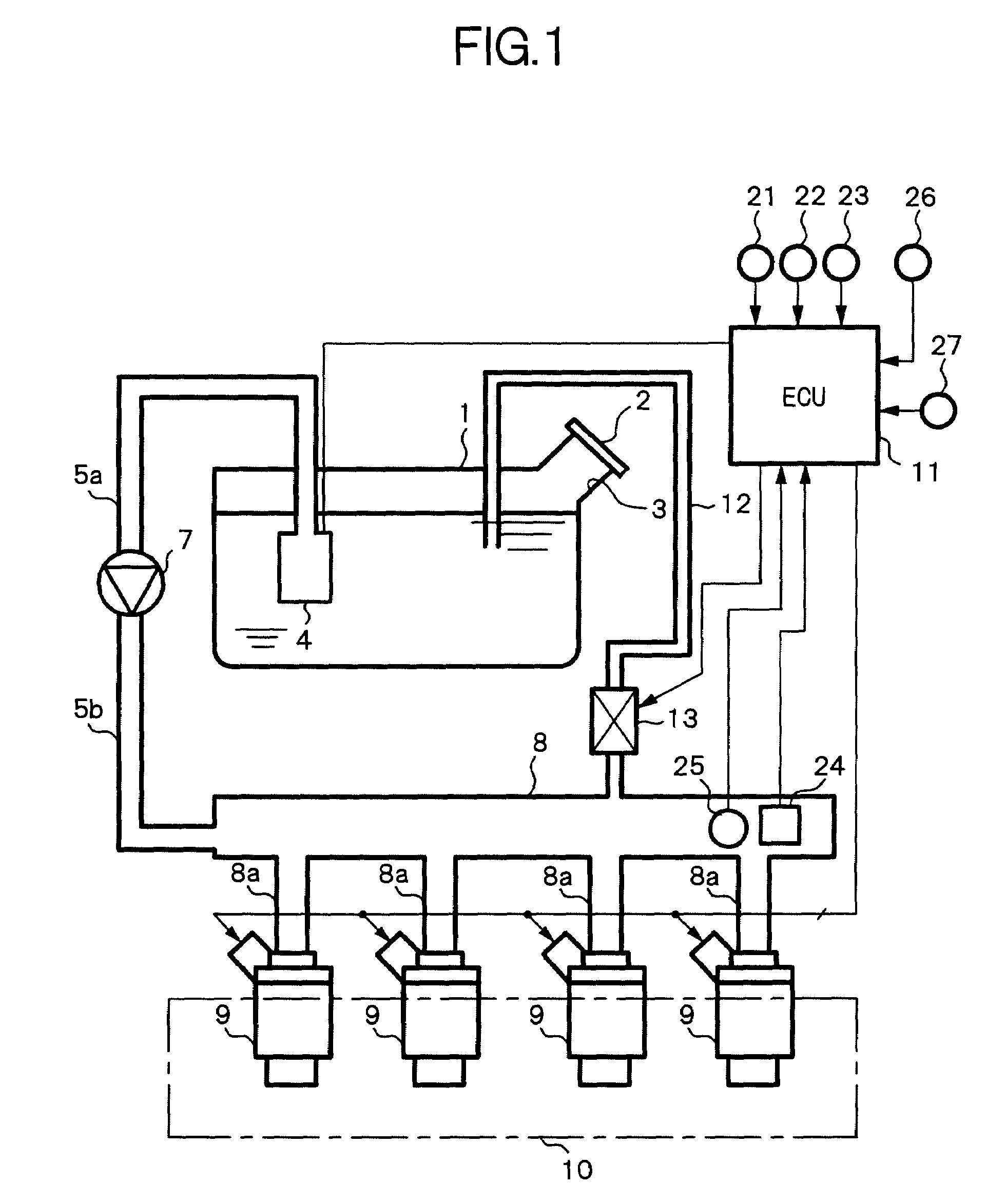

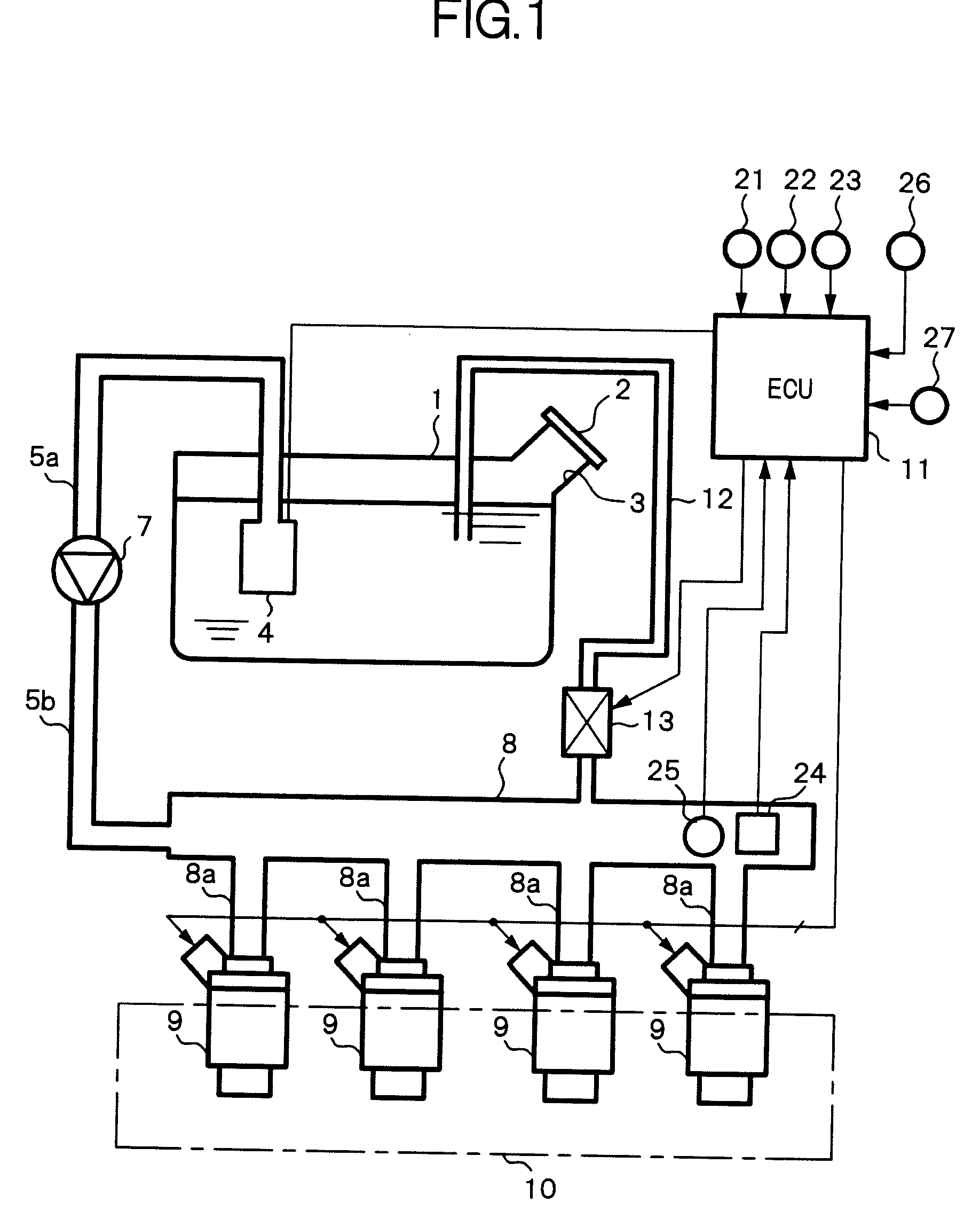

Fuel injection controller for internal combustion engine

ActiveUS20090063012A1Improve accuracyData variationElectrical controlInternal combustion piston enginesInjection pressureCommon rail

A common rail type fuel injection system of an engine includes: a common rail for accumulating and holding high-pressure fuel; a fuel pump for pressure-feeding fuel to the common rail; and an injector for injecting the high-pressure fuel accumulated and held in the common rail. A pressure sensor is disposed in a fuel suction pod of the injector. An ECU sequentially detects a fuel pressure varied when the injector injects the fuel and sequentially detects a fuel pressure varied when the fuel pump pressure-feeds the fuel. When the injector injects the fuel the ECU computes injection pressure by the detection values of these pressures and computes injection characteristics by the injector on the basis of the injection pressure.

Owner:DENSO CORP

Fuel pressure measuring device, fuel pressure measuring system, and fuel injection device

ActiveUS20110006130A1Facilitate easeGuaranteed accuracyElectrical controlLiquid transferring devicesCommon railInternal combustion engine

It is used with a fuel injection system for an internal combustion engine which supplies fuel to an injector (fuel injection valve) from a common rail (accumulator) through a high-pressure pipe to spray the fuel from a spray hole formed in the injector. A thin-walled portion 70bz is formed in a path member (e.g., an injector body 4z, the high-pressure pipe, or a connector 70z connecting the injector and the high-pressure pipe) and defined by a locally thin wall of the path member. A strain gauge 60z (strain sensor) is affixed to the thin-walled portion 70bz to measure strain of the thin-walled portion 70bz arising from the pressure of fuel in a high-pressure fuel path 70az.

Owner:DENSO CORP

Fuel pressure sensor/sensor mount assembly, fuel injection apparatus, and pressure sensing apparatus

InactiveUS7963155B2Improve installabilityMinimized in sizeInternal-combustion engine testingMachines/enginesPressure senseEngineering

A fuel pressure sensor / sensor mount assembly in which a fuel pressure sensor is so mounted as to exposed to a high-pressure fuel path through which fuel is supplied to a fuel injector, a fuel injection apparatus equipped with a built-in fuel pressure sensor, and a pressure sensing apparatus working to measure the pressure of fuel in a fuel injector are provided. The fuel pressure sensor / sensor mount assembly is disposed between the high-pressure fuel path and the fuel injector, thus permitting the size of the fuel injector to be minimized without sacrificing the accuracy in measuring the pressure of the fuel. The fuel injection apparatus and the a pressure sensing apparatus are designed to ensure desired accuracy in measuring the pressure of the fuel.

Owner:DENSO CORP

Popular searches

Devices using optical means Relative volume flow measurements Indirect mass flowmeters Fuel injection control Special purpose recording/indication apparatus Automatic initiations Liquid fuel feeders Vehicle position/course/altitude control Special data processing applications Position/direction control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com