Preparation method of benzaldehydes compound and novel double-metal catalyst loaded by mesoporous carbon for preparation method

A bimetallic catalyst and mesoporous carbon technology are used in the preparation of benzaldehyde compounds, catalyzing alcohol oxidation to prepare aldehydes or ketones, and in the field of bimetallic catalysts supported by new mesoporous carbon materials, which can solve the problem of limiting catalysts and reaction selection. It can improve the catalytic activity, high conversion rate of raw materials and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

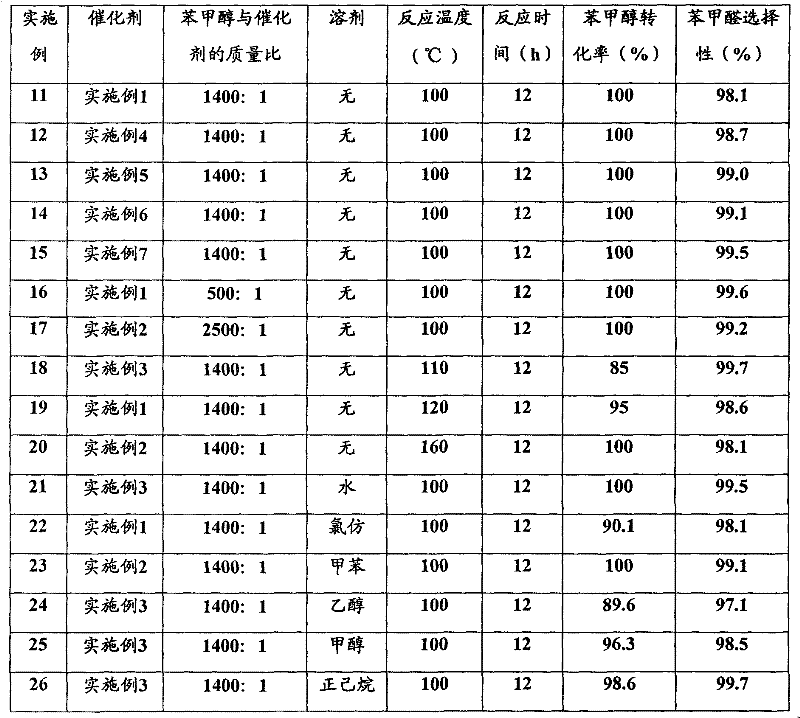

Examples

Embodiment 1

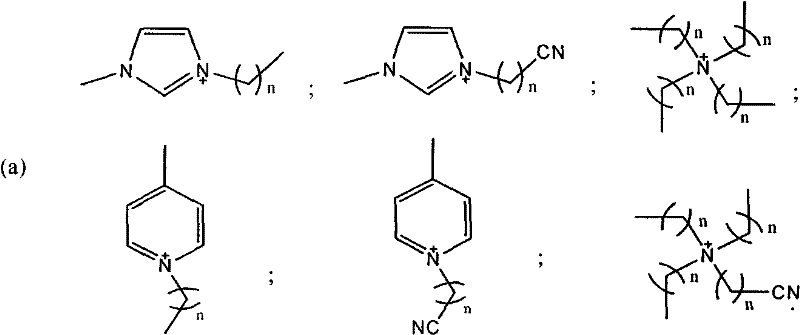

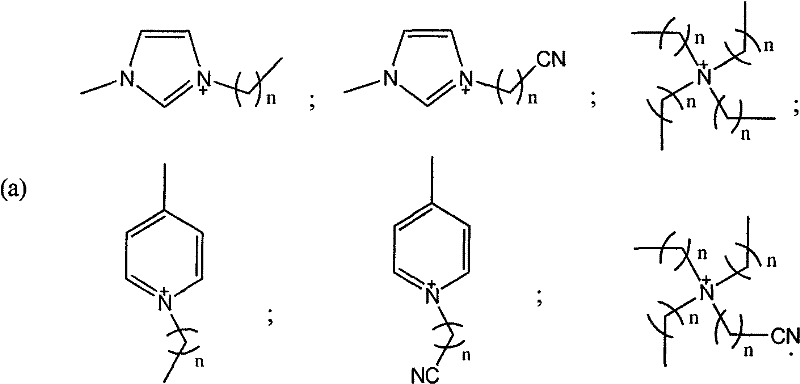

[0024] This embodiment provides a nitrogen-doped mesoporous carbon-supported Au-Pd catalyst, which is prepared by the following steps:

[0025](1) Mix 1g 1-ethyl-3-methylimidazolium dicyanamide salt with 1.5g templating agent SBA-15 at room temperature, then heat up to 900°C for 3 hours, cool to room temperature and use ammonium bifluoride Decompose SBA-15 to obtain 0.7g of nitrogen-doped mesoporous carbon material. Elemental analysis shows that the nitrogen content is 11.8%, and its specific surface area is 150-1200m 2 / g.

[0026] (2) Take 0.1 g of nitrogen-doped mesoporous carbon material and add it to 50 ml of ethanol, sonicate for 10 minutes, add 1 ml of ethanol solution of chloroauric acid and palladium chloride with a concentration of 1 mg / ml, and continue to sonicate for 10 minutes Add 10 mg of sodium borohydride for reduction, filter and wash with water several times, and dry to obtain a nitrogen-doped mesoporous carbon-supported Au-Pd catalyst.

Embodiment 2

[0028] This example provides a nitrogen and phosphorus co-doped mesoporous carbon-supported Au-Pd catalyst, which is prepared by the following steps:

[0029] (1) Mix 1g of 1-pentylcyano-3-methylimidazolium hexafluorophosphate with 1.5g of templating agent Ludox HS40 at room temperature, then heat up to 900°C for 2 hours, cool to room temperature and use ammonium bifluoride Decompose Ludox HS 40 to obtain 0.6g of nitrogen and phosphorus co-doped mesoporous carbon material. Elemental analysis shows that the nitrogen content is 11.3%, the phosphorus content is 0.1%, and its specific surface area is 150-1200m 2 / g.

[0030] (2), take 0.1g of the above nitrogen and phosphorus co-doped mesoporous carbon material and add it to 50ml ethanol, ultrasonic for 10 minutes, add 1ml of ethanol solution of chloroauric acid and palladium chloride with a concentration of 1mg / ml respectively, continue After ultrasonication for 10 minutes, 10 mg of sodium borohydride was added for reduction, su...

Embodiment 3

[0032] This example provides a nitrogen and sulfur co-doped mesoporous carbon-supported Au-Pd catalyst, which is prepared by the following steps:

[0033] (1), mix 1g 1-butyl-3-methylimidazolium dicyanamide salt, 0.5g 1-butyl-3-methylimidazolium ethyl sulfate salt and 2.5g templating agent Ludox HS 40 at room temperature , and then heated to 900 ° C for 2 hours, cooled to room temperature and decomposed Ludox HS 40 with ammonium bifluoride to obtain 0.7 g of nitrogen and sulfur co-doped mesoporous carbon material. Elemental analysis showed that the nitrogen content was 11.6%, and the sulfur content It is 0.3%, and its specific surface area is 150-1200m2 / g.

[0034] (2), take 0.1g of the above-mentioned nitrogen and sulfur co-doped mesoporous carbon material and add it to 50ml deionized water, sonicate for 10 minutes, add 1ml of the aqueous solution of chloroauric acid and palladium chloride with a concentration of 1mg / ml respectively, and continue After ultrasonication for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com