Cooling method of steel plate

一种冷却方法、钢板的技术,应用在工件冷却装置、工件表面处理设备、金属轧制等方向,能够解决热传导率预测精度不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

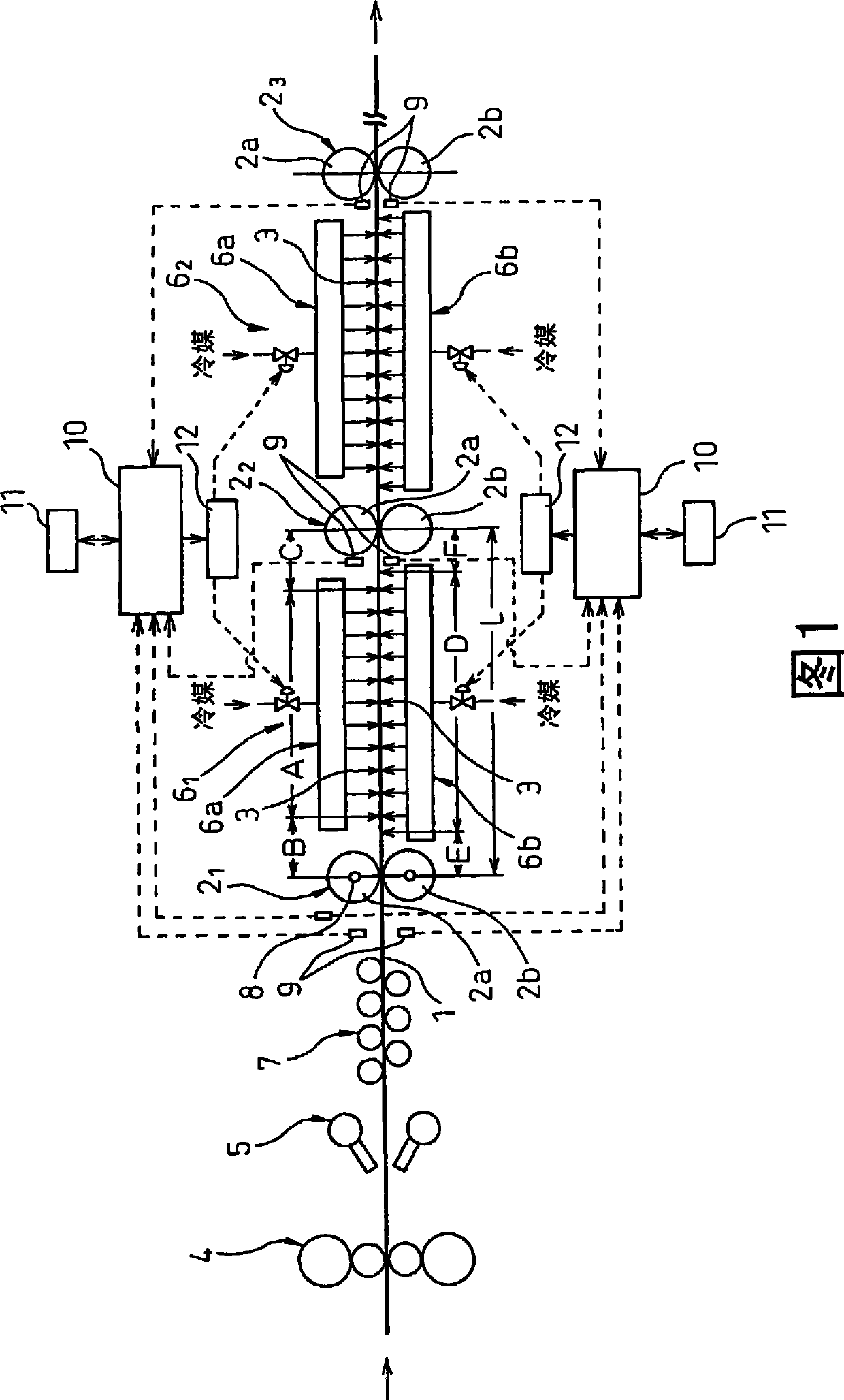

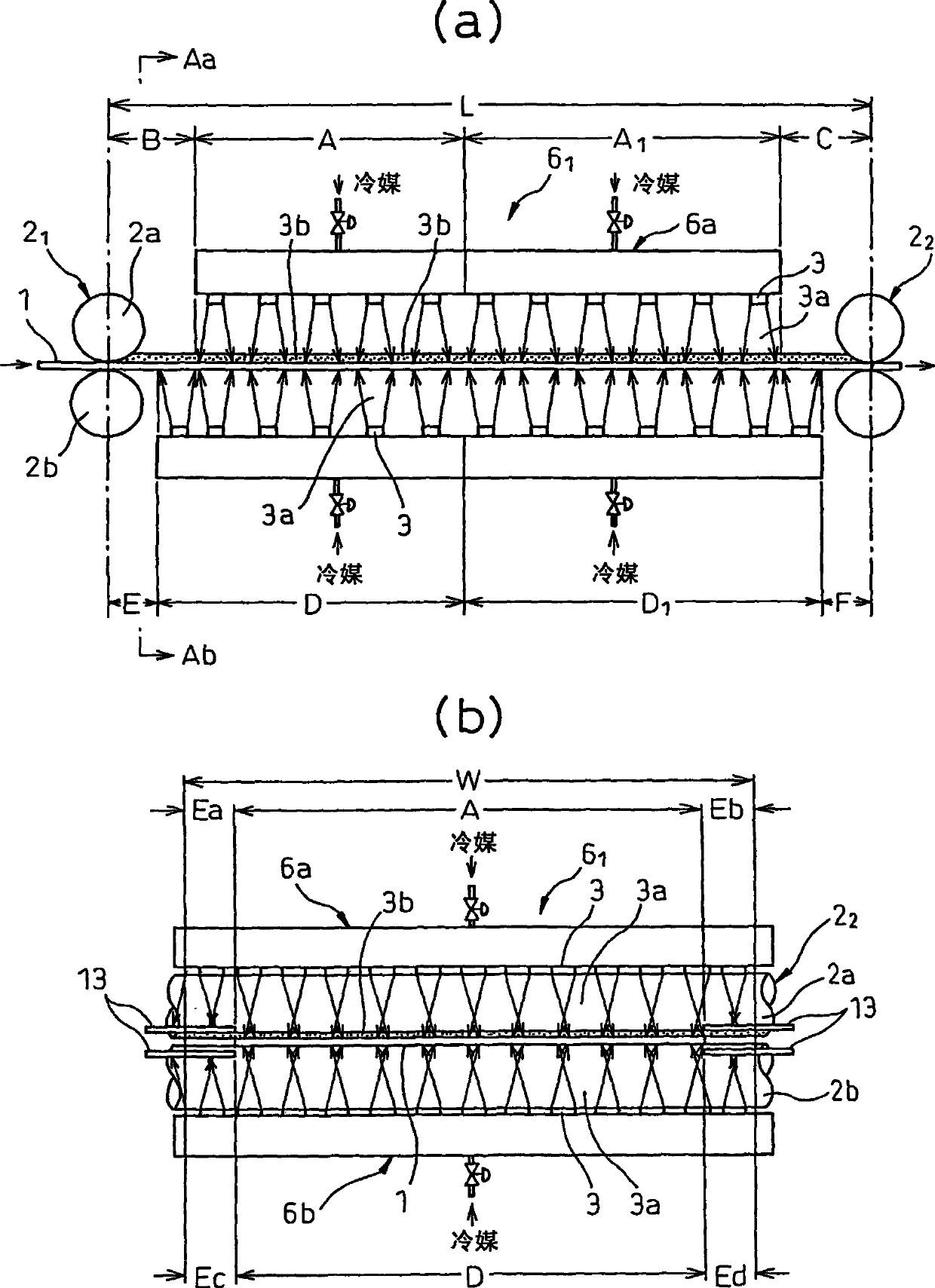

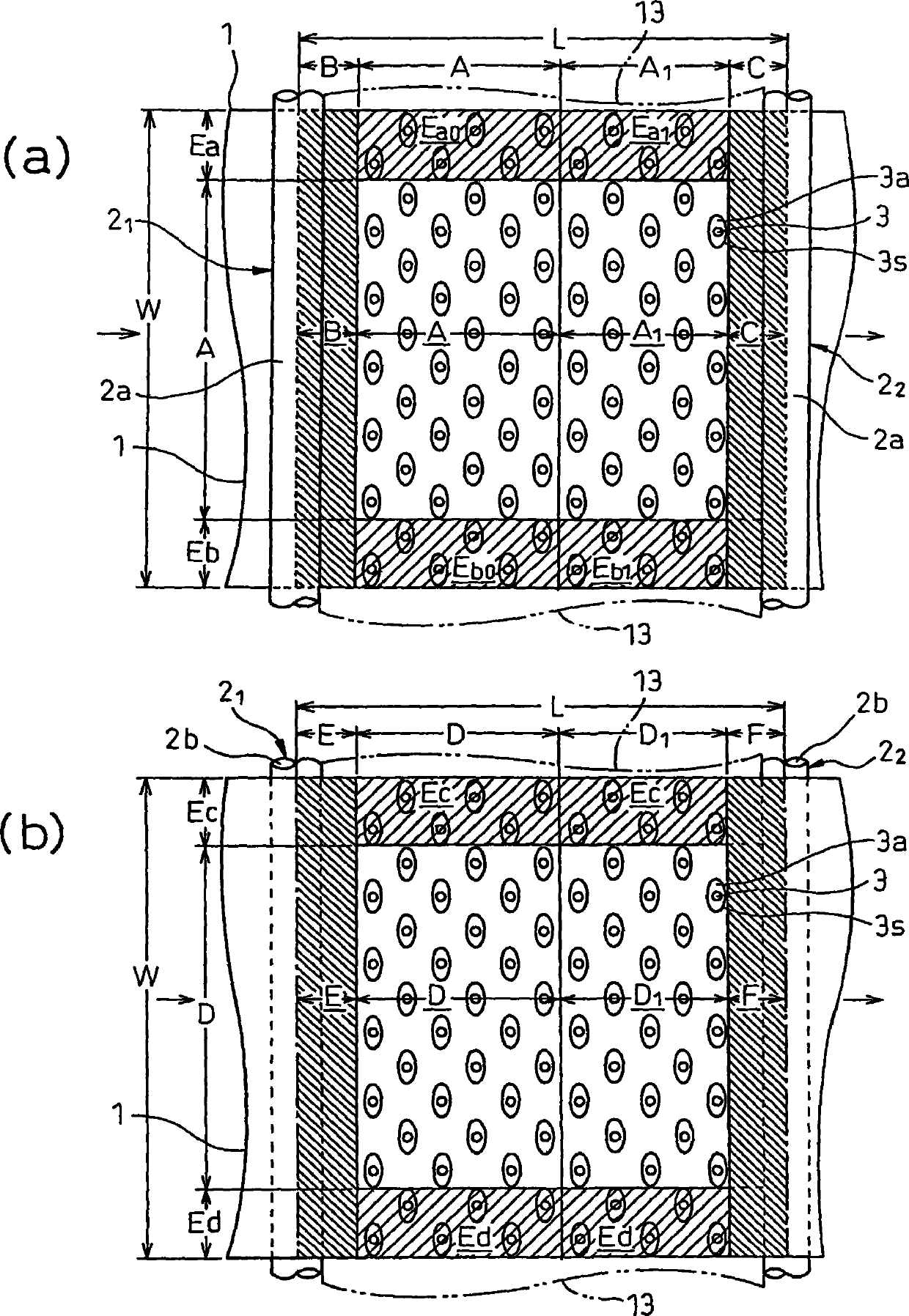

[0128] This embodiment is shown in Fig. 1~ image 3 The example of the cooling equipment for the steel plate as shown is to remove the scale of the steel plate (steel strip) after hot finish rolling with a plate thickness of 25mm, a plate width of 4000mm, and a temperature of 850°C. In bound roll pair 2 1 -2 2 Constraint conveying between the two 1 -2 2 Between the upper and lower nozzle group 6 1 An example of the case where each nozzle 3 of the upper and lower nozzle groups 6a, 6b sprays cooling water to cool the steel plate 1 to 400°C at a cooling rate of 30°C / sec.

[0129] In the actual cooling equipment, the upper and lower nozzle groups 6 connected between the constraining roller pairs 1 The cooling is shared by the upper and lower nozzle groups respectively arranged between multiple pairs of constrained roller pairs, and here is the upper and lower nozzle group 6 involving the constrained roller pairs. 1 Example of cooling in the unit. #

[0130] In this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com