Method and device for controlling strip shape and precision of hot rolling steel strips and plates

A technology of steel plate shape and hot-rolled strip steel, which is applied in the field of hot-rolled strip steel and steel plate shape and precision control and equipment, can solve the problems of large equipment investment, achieve uniform rolling temperature, and improve the effect of thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

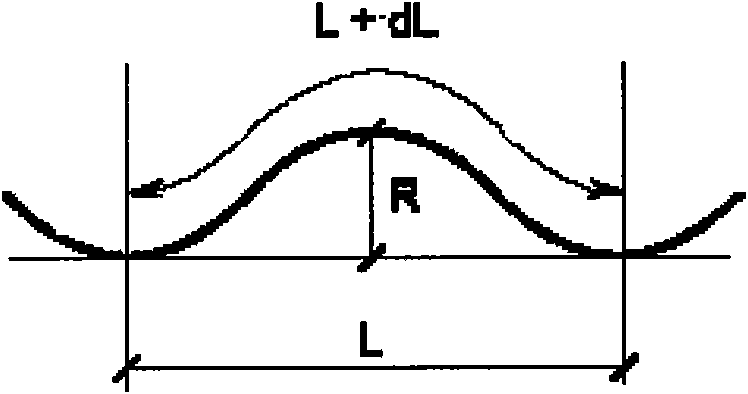

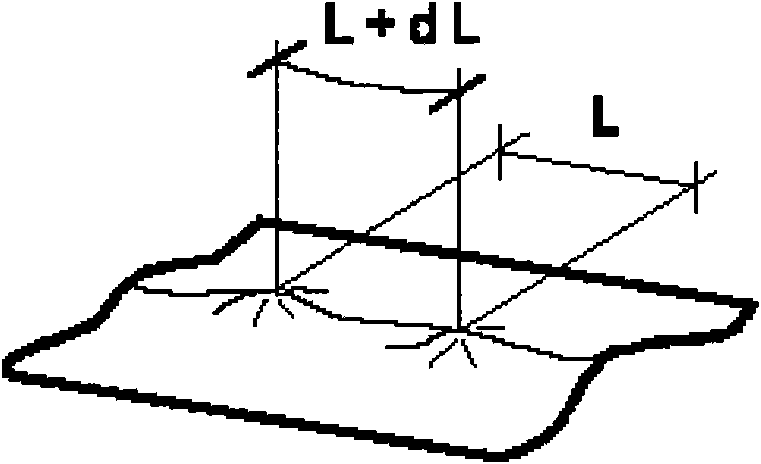

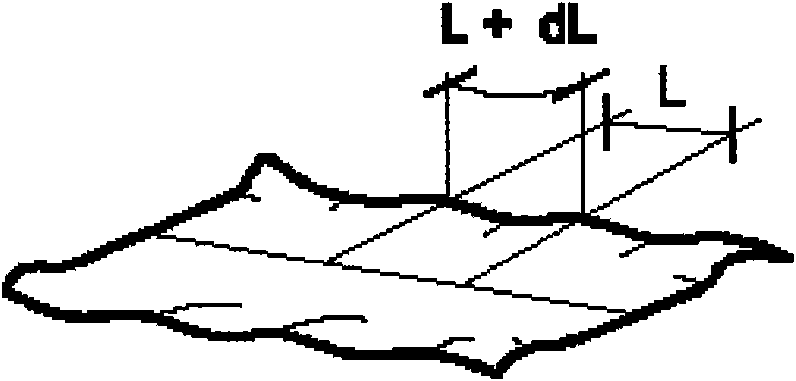

[0034] Attached below Figure 6-8 The present invention is described in further detail:

[0035] The gas mist cooling device 1 is arranged before and after the reversible steel plate rolling mill 2, and is arranged between the front of the rolling mill 2 and the stand of the rolling mill 2 in the tandem hot strip rolling mill 2; the gas mist cooling device 1 is mainly composed of a control valve station, a cooling set Pipe, intermediate pipeline and automatic control system, in which the control valve station, cooling header and intermediate pipeline station include two kinds of pipelines: gas and water. The gas mist cooling device 1 is connected with the measuring instrument 3, the measuring instrument 3 controls the valve opening of the control valve station, and the nozzle 4 sprays out the cooling water atomized by air, that is, the gas mist cooling medium.

[0036] The invention calculates the cooling effect of the strip steel / steel plate through the gas mist cooling mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com