Temperature control device for hot rolling mill

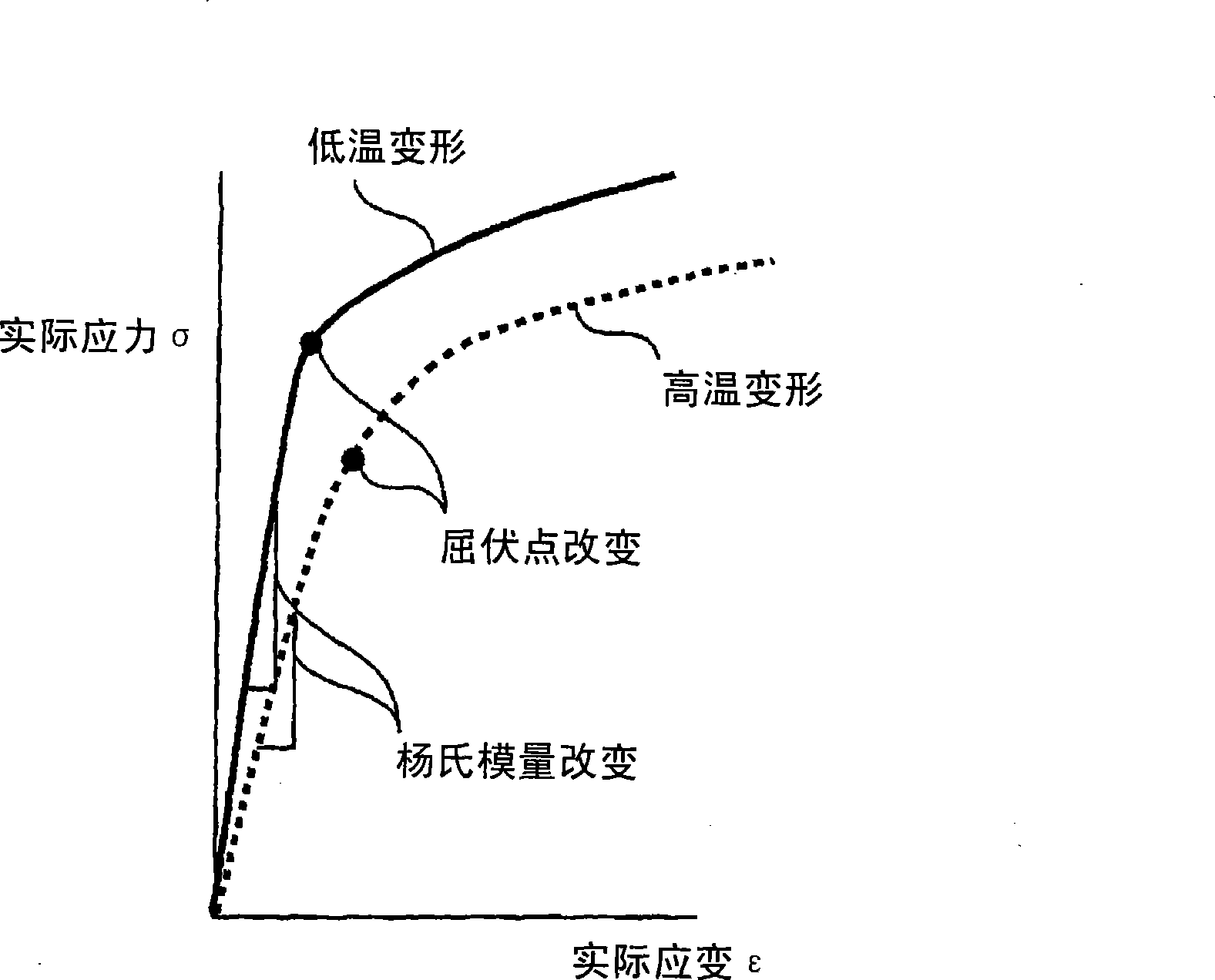

A technology of temperature control device and rolling mill, applied in the direction of temperature control, metal rolling, metal rolling, etc., can solve the problems of large temperature change of rolling material, high-precision control of limited temperature, large temperature change of rolling material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to illustrate the present invention in detail, it will now be described with reference to the accompanying drawings. The same or corresponding parts in each drawing are marked with the same reference numerals, and the repeated explanations are simplified or even omitted as appropriate.

[0037] Embodiment 1

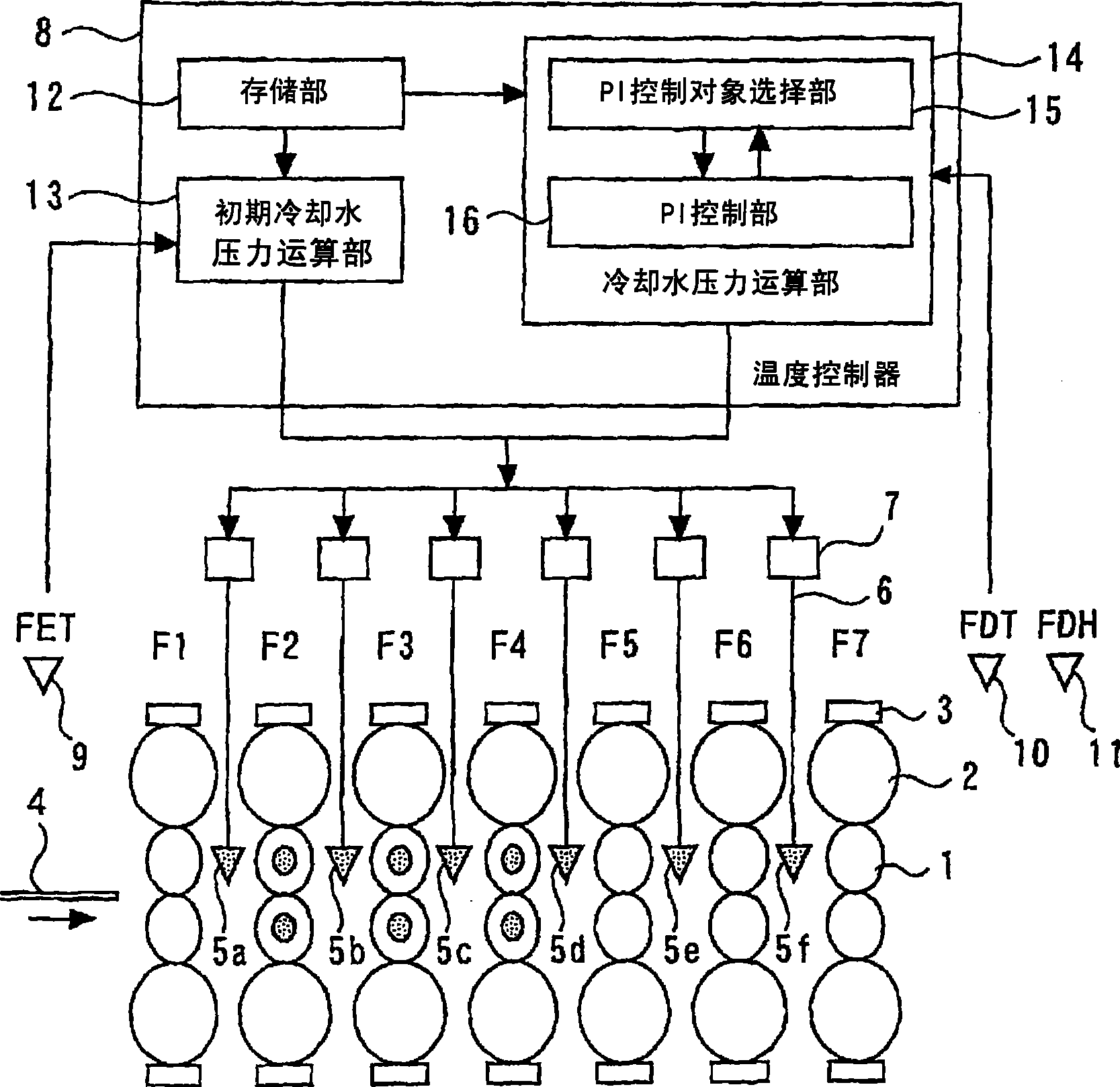

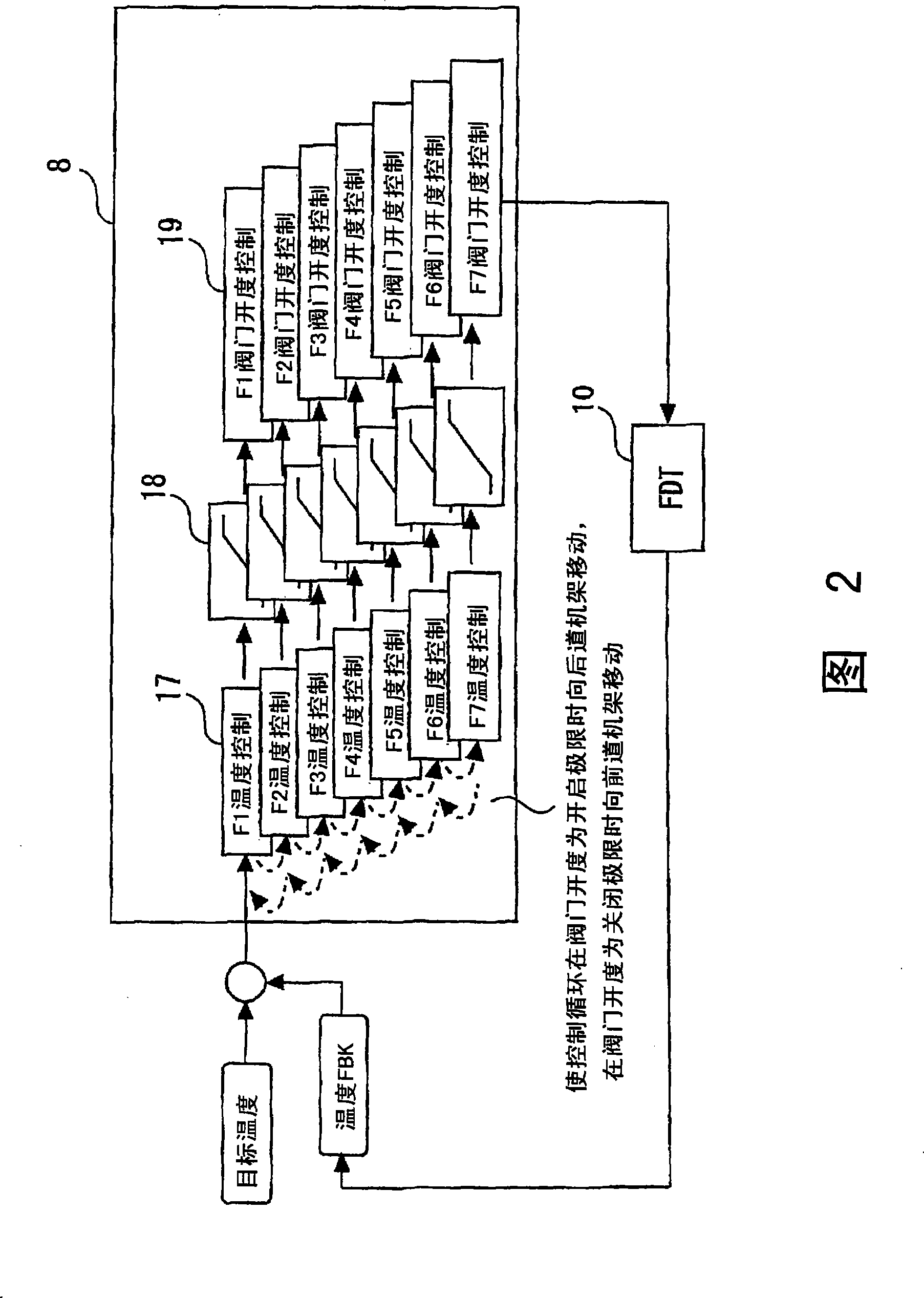

[0038] figure 1 It is an overall configuration diagram showing a temperature control device for a hot rolling mill according to Embodiment 1 of the present invention. Fig. 2 is a block diagram showing a main part of a temperature controller according to Embodiment 1 of the present invention. exist figure 1 And in FIG. 2, as an example, the hot-rolling finishing mill which arrange|positioned 7 rolling stands (F1-F7) in series is shown.

[0039] First, the structure of the temperature control device of the hot rolling mill will be described.

[0040] exist figure 1 And in Fig. 2, there are action roll 1, back-up roll 2, pressing device 3 etc. on each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com