Hot-stamp-molded article, process for production of steel sheet for hot stamping, and process for production of hot-stamp-molded article

A manufacturing method, hot embossing technology, applied in the direction of manufacturing tools, chemical instruments and methods, metal rolling, etc., can solve the problems of insufficient control of structure, high aspect ratio, and inability to fully ensure strength and toughness, and achieve absorption Excellent energy properties, improved balance of strength and toughness, and improved energy absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

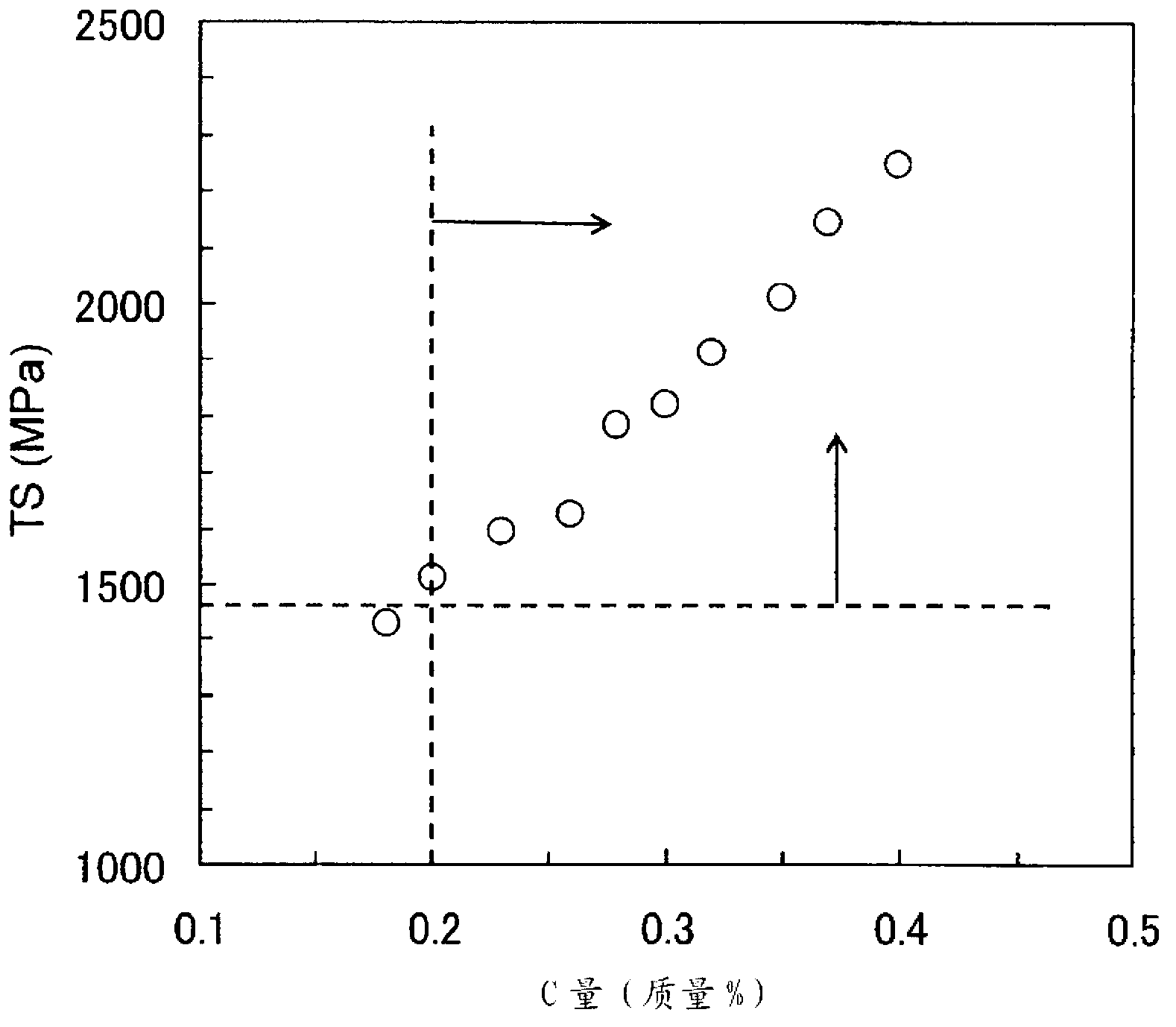

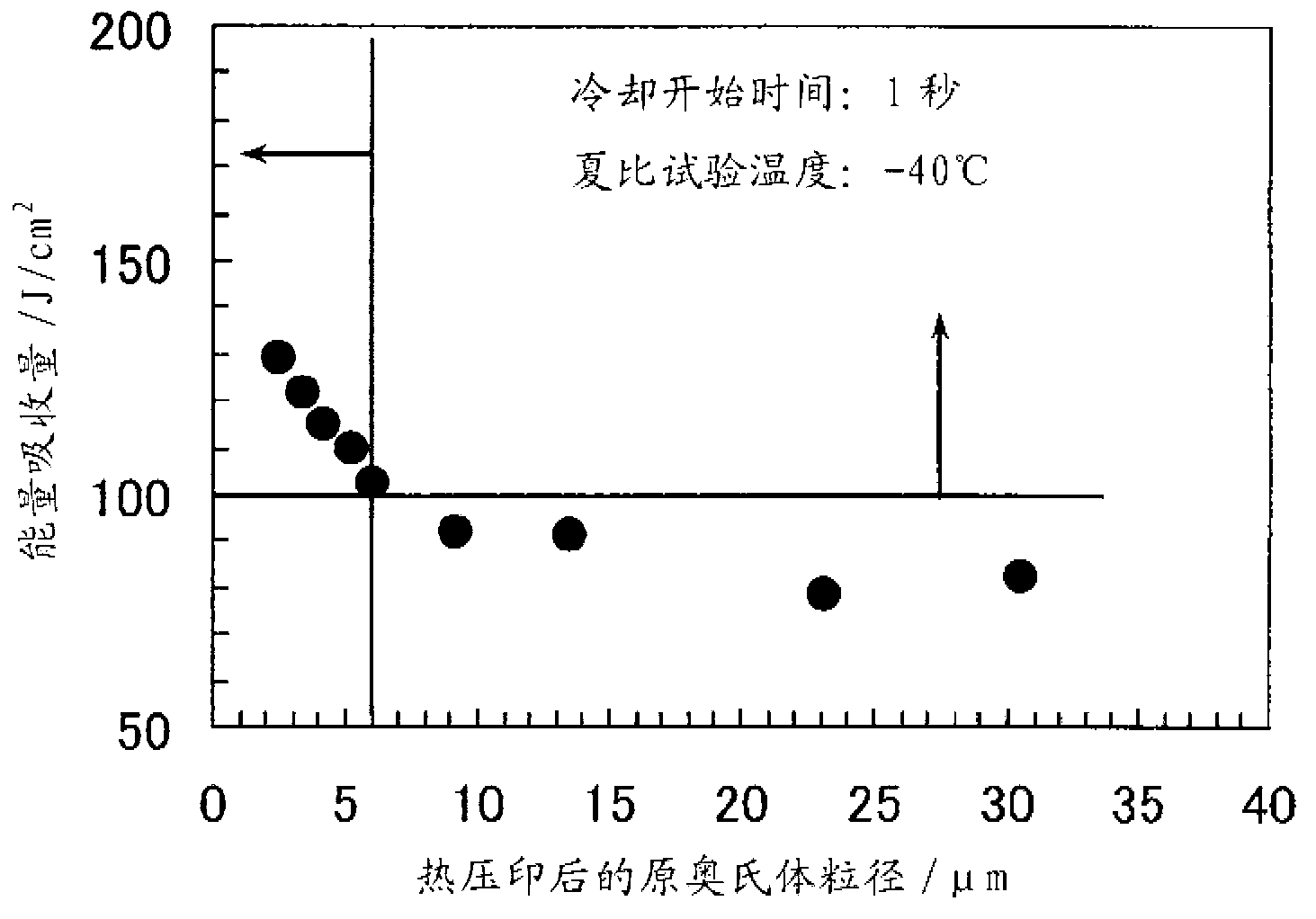

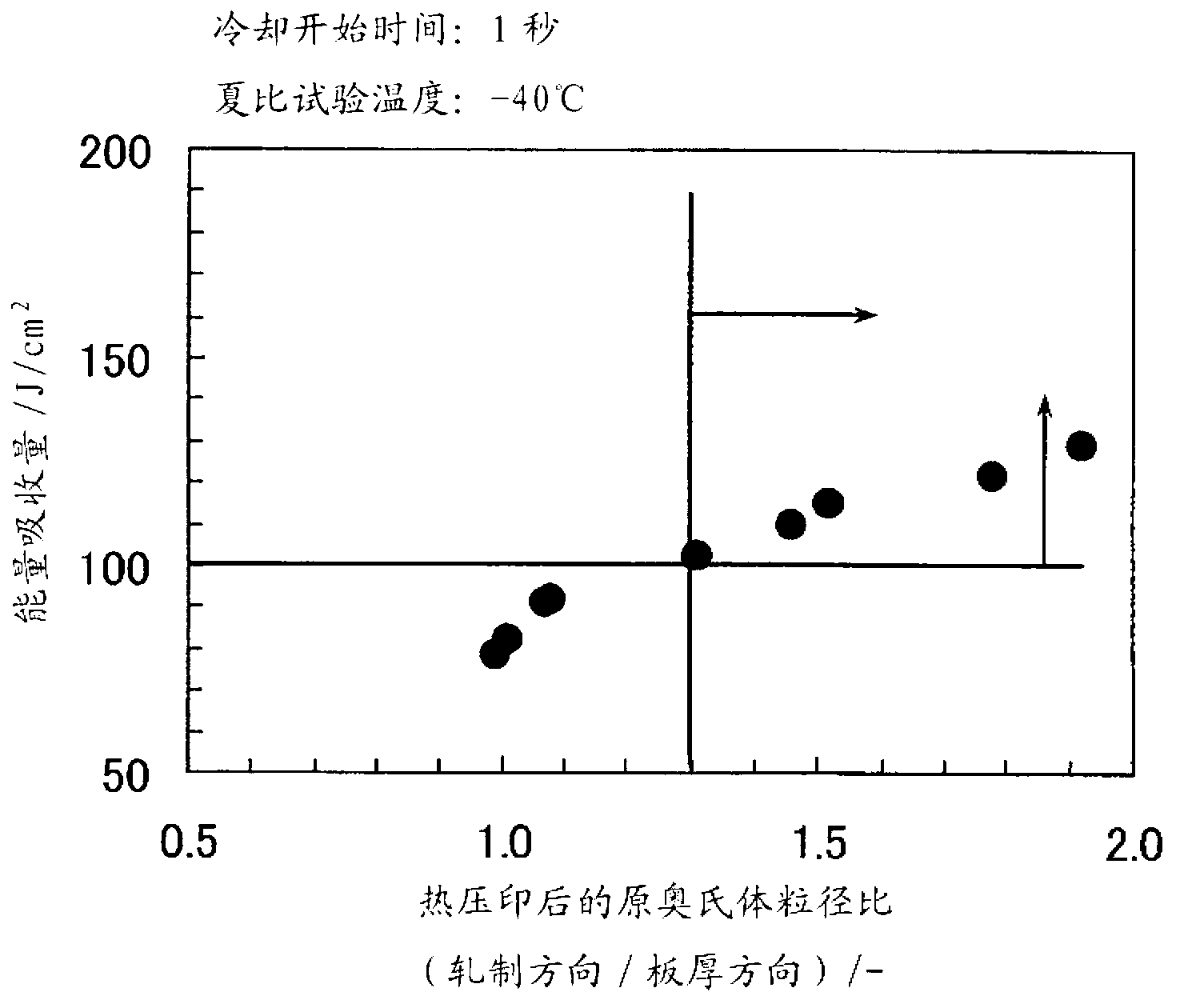

[0090] The steels (Steel A~Steel Y) with the composition shown in Table 2 were tapped from the converter, cast into slabs, and rolled under given hot rolling conditions (heating temperature: 1220°C, finish rolling temperature: 870°C, The total reduction applied by the first two stands of the stand: 65%, the time from the end of finish rolling to the start of cooling: 0.5 seconds, and the coiling temperature: 600°C) are hot-rolled to produce a hot-rolled plate with a thickness of 3 mm. steel plate. In Steels A~L and Steels U~Y, the grain size of prior austenite in the hot-rolled steel sheet is 6 μm or less, and the size ratio of the length of prior austenite in the rolling direction to the length in the thickness direction is 1.3 above. The hot-rolled steel sheet was cold-rolled to obtain a cold-rolled steel sheet with a thickness of 1.4 mm, and then continuously annealed under the conditions shown in Table 3, and a plating treatment was performed after the annealing if necess...

Embodiment 2

[0094] For I, U and Y steels in Table 2, with given hot rolling conditions (heating temperature: 1250°C, finish rolling temperature: 880°C, total reduction applied from the first two stands of the last stand: 60 %, the time from the end of finish rolling to the start of cooling: 0.8 seconds, coiling temperature: 550°C) to obtain a hot-rolled steel sheet with a thickness of 2 mm, and then pickle it. These hot-rolled steel sheets are directly heated to 880°C in a heating furnace, and after holding the heat for 120 seconds, they are inserted into a mold with a water supply port for spraying water from the surface and a discharge port for sucking in the water, and spray water through it. Heating-cooling treatment to cool to room temperature. In addition, after pickling, the same heating and cooling treatment was performed on hot-rolled steel sheets subjected to hot-dip galvanizing (GI, GA) or hot-dip aluminizing containing 10% Si. On the other hand, with the given hot rolling con...

Embodiment 3

[0097] Steel I in Table 2 was hot-rolled under the hot-rolling conditions shown in Table 5, and then cold-rolled at a reduction ratio of 50%. These steel plates were heated to 850° C. at the heating rate shown in Table 5, sandwiched in a mold having a water supply port for spraying water from the surface and a water discharge port for sucking in the water, and cooled to room temperature by spraying water. In addition, as a result of examining the cross-sectional structure with an optical microscope, the steel sheet provided with these heat histories contained 98% or more of martensite in terms of area ratio. Moreover, about the obtained steel plate, the material property was evaluated similarly to Example 1, and the obtained result is shown in Table 5. In addition, regarding the toughness, the Charpy test was carried out at -120°C, and the evaluation was performed in conversion to a plate thickness of 10 mm. In this case, 85 J / cm 2 The steel plate with the above energy absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com