Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Resilience balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer calcium carbonate polypropylene composite material

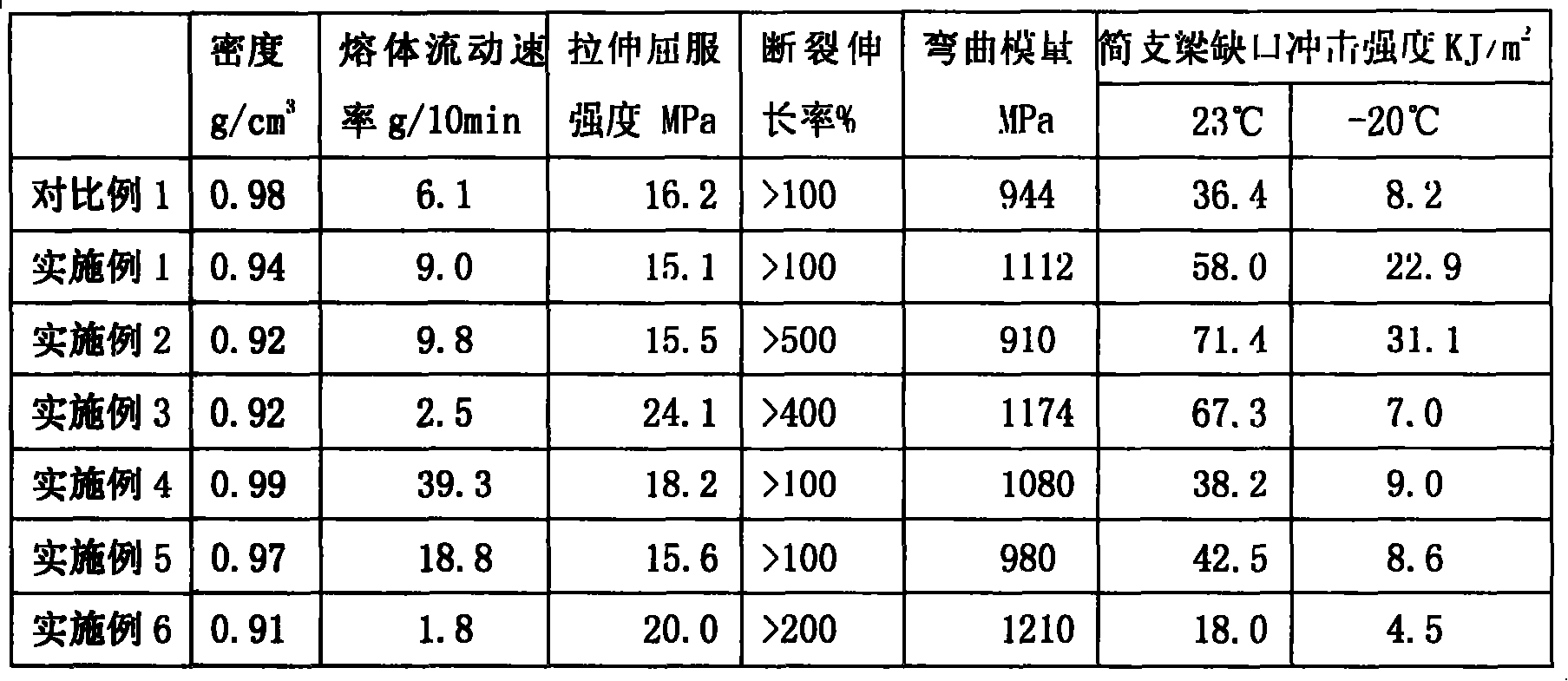

The invention discloses nano calcium carbonate polypropylene composite material. The composite material comprises 100 portions of polypropylene resin, 1 to 15 portions of nano calcium carbonate, 1 to 20 portions of elastomer, and 0.1 to 1 portion of stabilizing agent. The composite material is prepared by method of melt compounding by adopting an internal mixer or double screw extruder. Good rigidity is kept when the toughness of the composite is obviously improved; the composite has good cold impact resistance performance, and is applicable to injection moulding production of automobile parts, i.e. bumper, mudguard, etc.

Owner:CHINA PETROLEUM & CHEM CORP

Hot-stamp-molded article, process for production of steel sheet for hot stamping, and process for production of hot-stamp-molded article

ActiveCN102939399AAchieve lightweightHigh strengthHot-dipping/immersion processesFurnace typesHot stampingAustenite grain

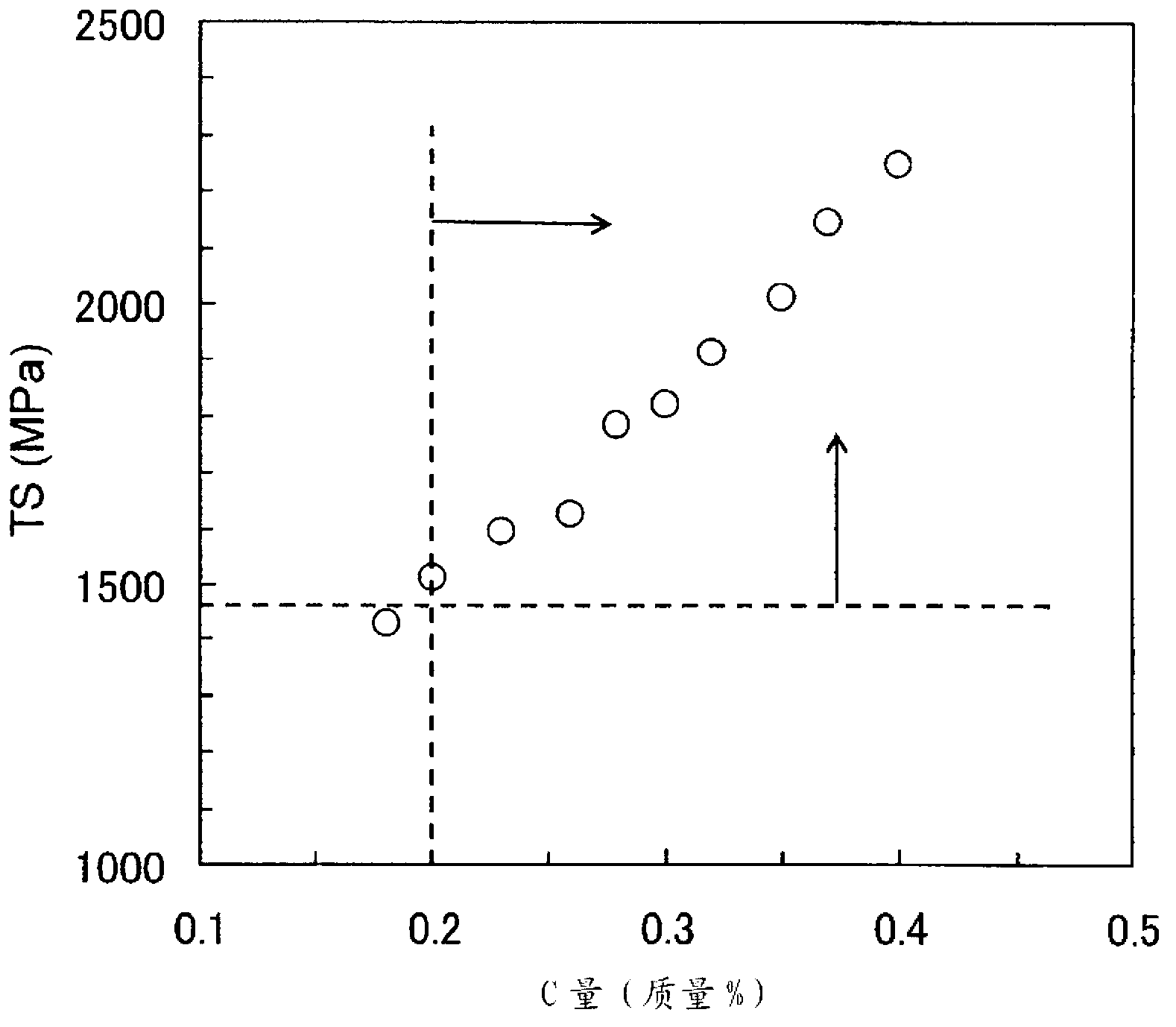

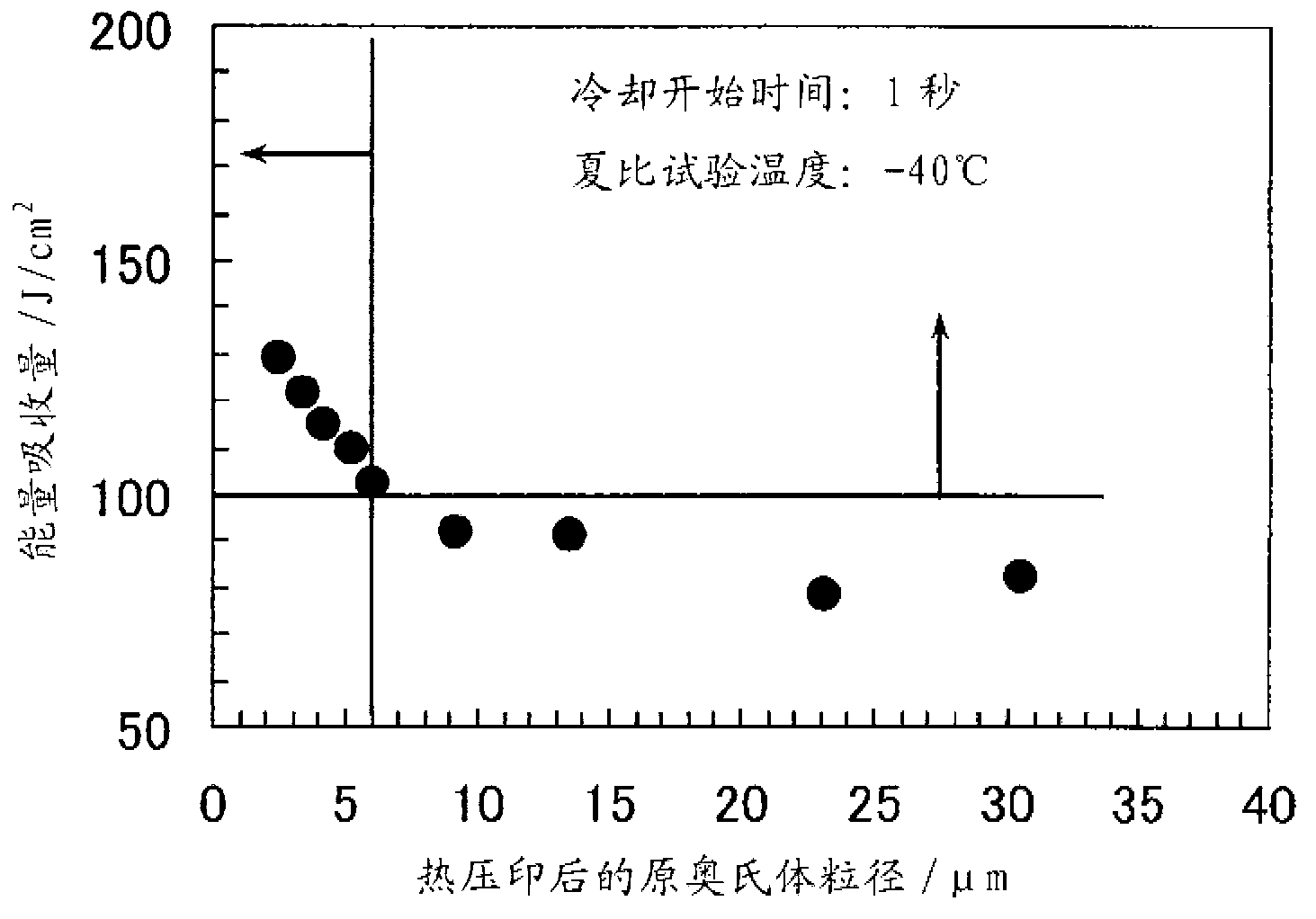

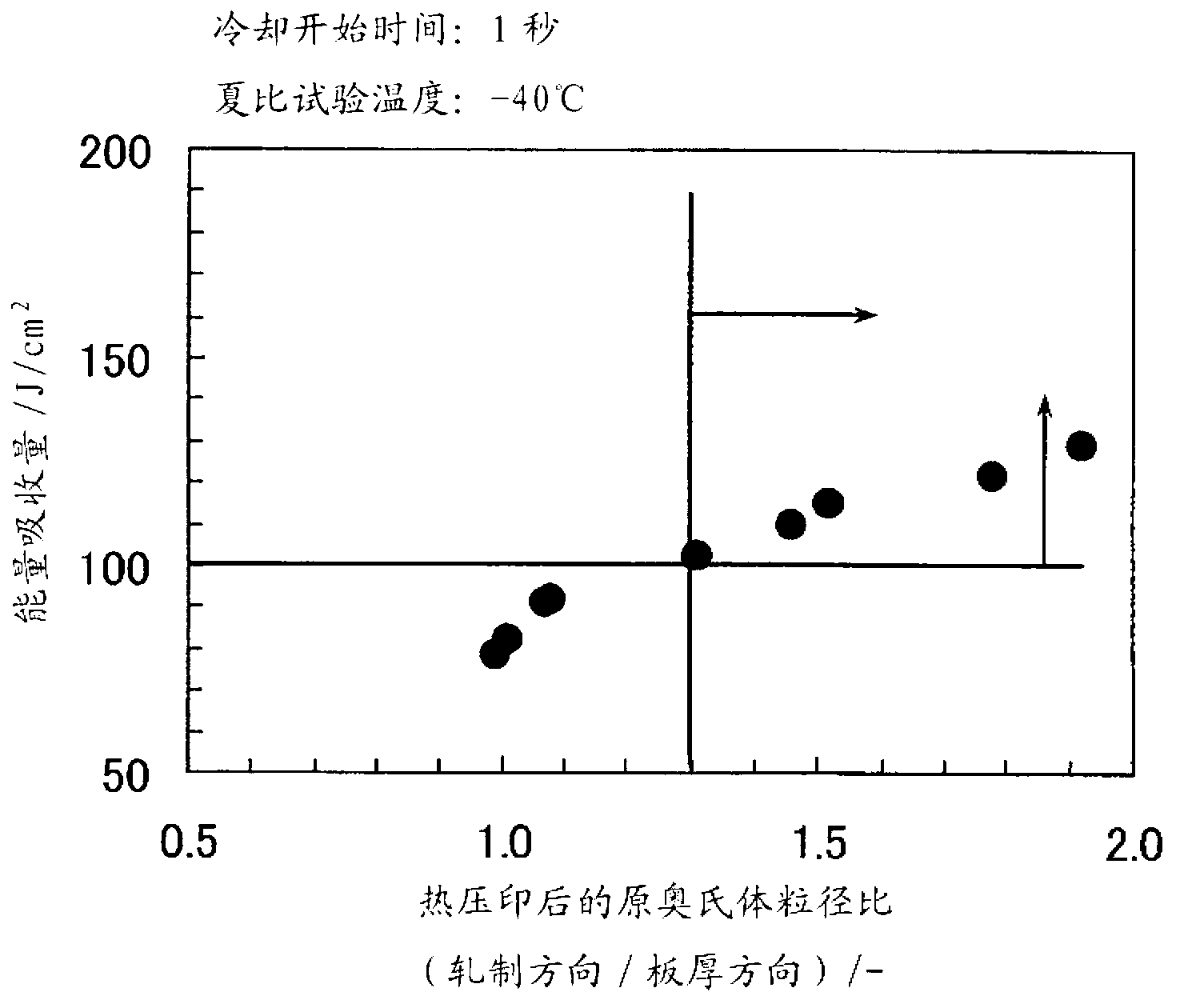

A hot-stamp-molded article comprises, in mass%, 0.20 to 0.35% of C, 0.1 to 0.5% of Si, at least one element selected from Mn and Cr in the total amount of 1 to 3%, 0.005 to 0.06% of Al, 0.002 to 0.1% of Ti, 0.002 to 0.1% of Nb, 0.003 to 0.007% of O, 0.015% or less of P, 0.01% or less of S, 0.004% or less of N, and a remainder made up by Fe and unavoidable impurities, wherein the dimensional ratio of the length of a prior austenite grain in the rolling direction to that in the thicknesswise direction is 1.3 to 2.5 inclusive, the prior austenite grain has an average particle diameter of 6 [mu]m or less, martensite is contained at a proportion of 98% or more, and the tensile strength is 1470 MPa or more.

Owner:NIPPON STEEL CORP

Flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and preparation method thereof

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

Nylon 66 nano composite material and preparation method thereof

The invention discloses a composite nanometer material and making method of polyhexamethylene adipamide (nylon 66), which comprises the following parts: 100wt% nylon 66, 5-20wt% elastic body and 5-30wt% inorganic nanometer particle, wherein these materials are blended to fuse and squeeze under 260-280 deg. c. The invention balances the rigidity, flexibility and fire resistance and size stability, which expands the applying domain of nylon 66.

Owner:EAST CHINA UNIV OF SCI & TECH

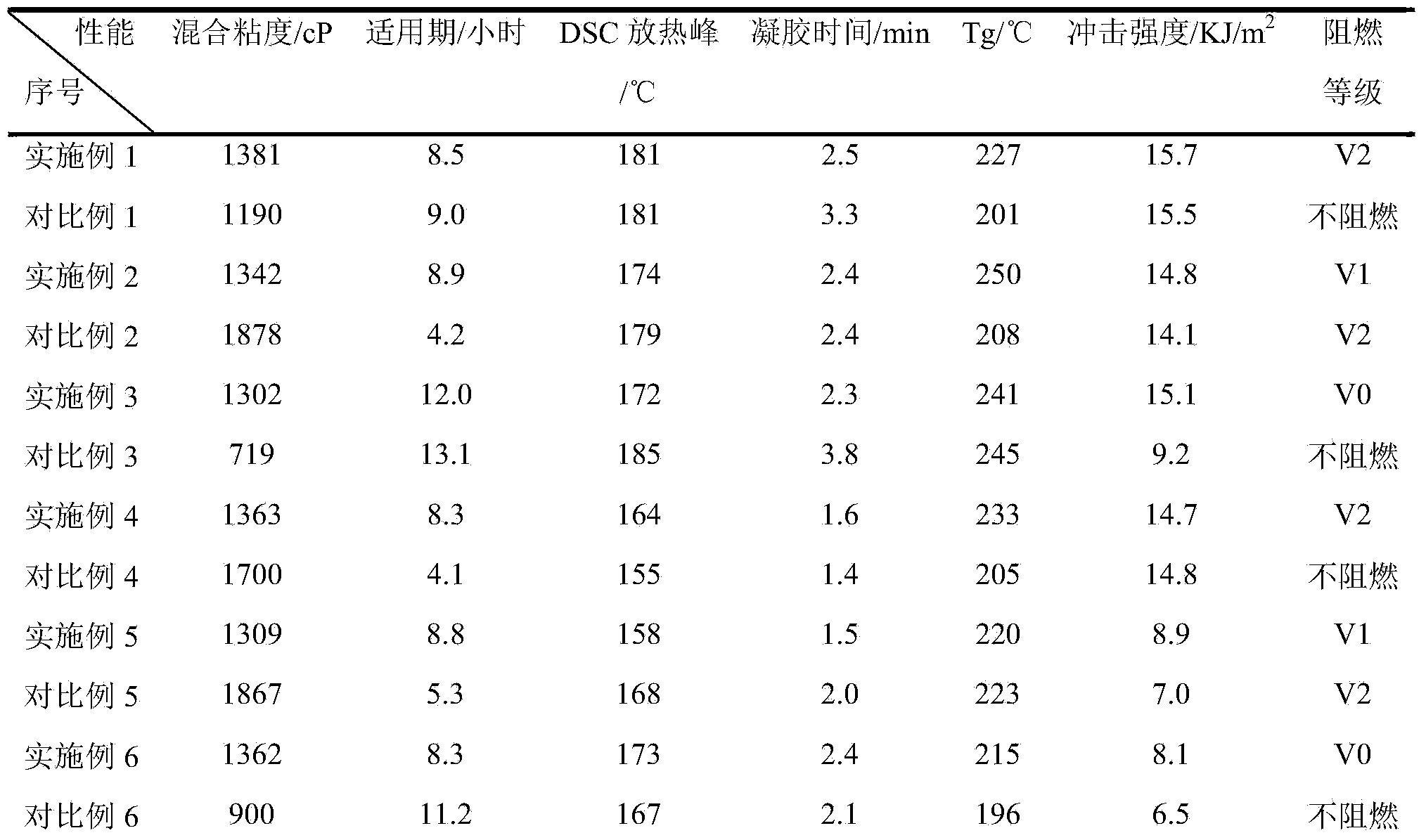

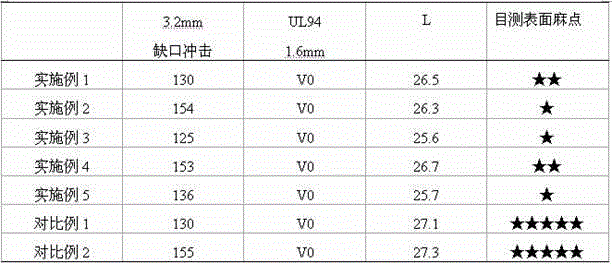

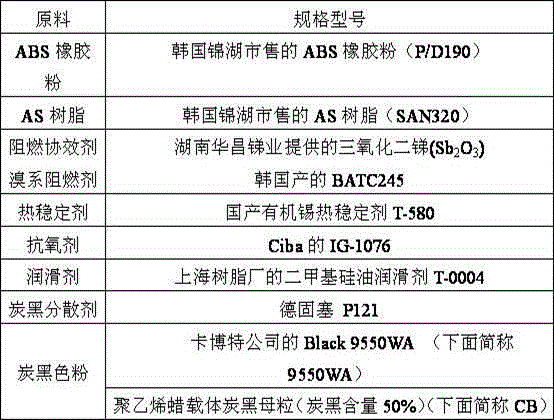

Flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness and preparation method of ABS resin

The invention relates to a flame-retardant acrylonitrile butadiene styrene (ABS) resin with excellent surface glossiness and high blackness. The ABS resin comprises the following components in parts by weight: 20-60 parts of ABS rubber powder, 40-80 parts of AS (Acrylonitrile-Styrene) resin, 2-6 parts of flame-retardant synergist, 5-25 parts of brominated flame retardant, 0.1-1 part of heat stabilizer, 0.1-1 part of antioxidant, 0.1-1 part of lubricating agent, 0.1-2 parts of carbon black dispersing agent and 0.1-5 parts of carbon black powder, wherein the carbon black dispersing agent is a block polymerization amphipathic siloxane compound of which one end is provided with a lipophilic group and of which the other end is provided with a hydrophilic group; the carbon black powder is pure carbon black or carbon black master-batches with polyolefin or ethylene vinyl acetate copolymer as a carrier. The invention also provides a method for preparing the flame-retardant ABS resin. The flame-retardant ABS resin has extremely high surface glossiness and balanced toughness and fluidity and is particularly suitable for household appliance industry with the requirements of high glossiness and flame retardant property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Polyphenyl ether polypropylene resin composition and preparation method thereof

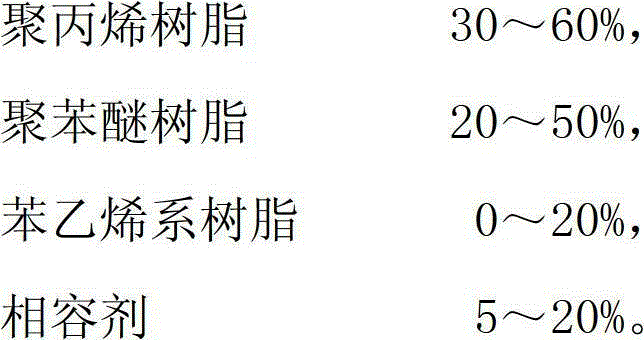

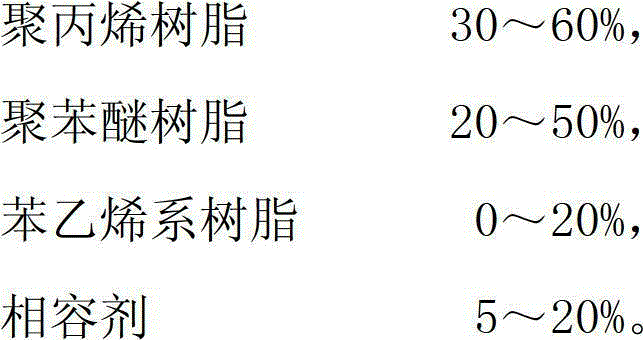

The invention relates to a polyphenyl ether polypropylene resin composition and a preparation method thereof. The composition comprises, by mass, 30% to 60% of polypropylene resins, 20% to 50% of polyphenyl ether resins, 0% to 20% of styrene resins and 5% to 20% of compatilizers. The preparation method includes the following steps of uniformly mixing the polyphenyl ether resins, the styrene resins and the compatilizers to obtain a premix, placing the premix in a double-screw extruder, simultaneously adding the polypropylene resins in a side-feed mode, performing a melt extrusion and granulating. The polyphenyl ether polypropylene resin composition and the preparation method thereof have the advantages that the property of the polyphenyl ether polypropylene resin composition is between those of thermoplastic polyolefin and engineering plastics, a good balance among the rigidity, toughness, heat resistance and processing performance of the material is achieved, the polyphenyl ether polypropylene resin composition can be applied to various fields such as automobile dashboards, automobile seat base plates, electric tool shells, fluid engineering components and food utensils, and the polyphenyl ether polypropylene resin composition and the preparation method thereof have a good application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

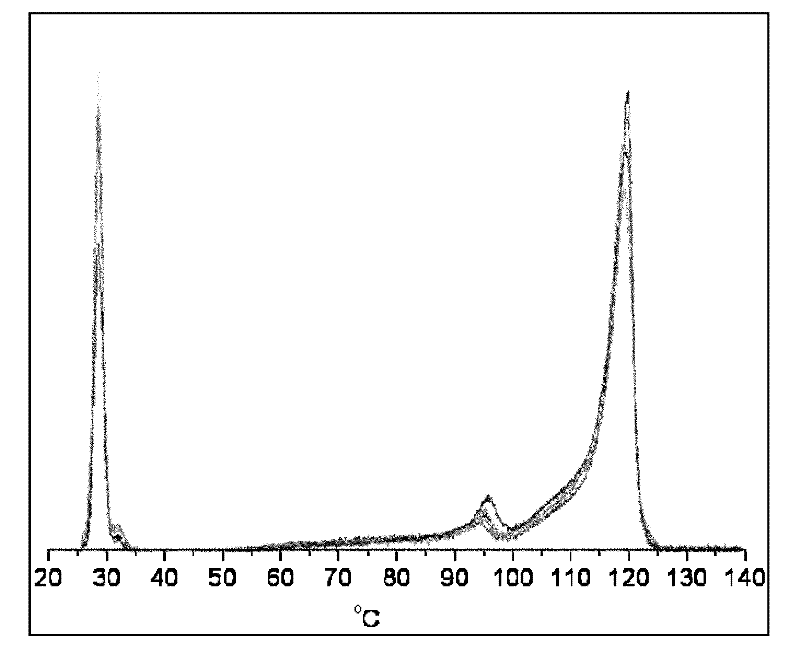

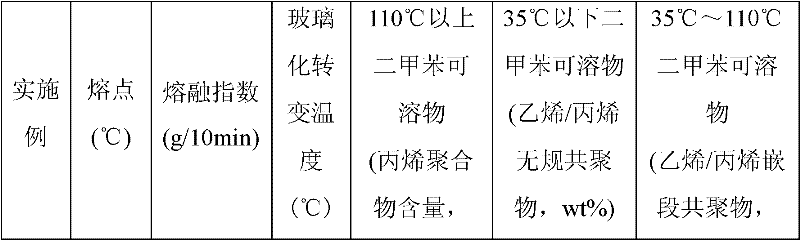

Multi-phase copolymer polypropylene in-reactor alloy and preparation method thereof

The invention discloses a multi-phase copolymer polypropylene in-reactor alloy and a preparation method thereof. In the method, a compound catalyst which is prepared by combining a Ziegler-Natta catalyst and a metallocene catalyst is adopted; propylene polymerization and ethylene / alpha-olefin copolymerization which are sequentially performed are catalyzed by the components of the two catalysts together; thus a polypropylene resin phase which is mainly prepared under the action of the Ziegler-Natta catalyst is uniformly mixed with an ethylene / alpha-olefin random copolymer rubber phase which is mainly prepared under the action of the metallocene catalyst in a polymerizer; and in the method, the ethylene / alpha-olefin block copolymer which is generated under the action of the Ziegler-Natta catalyst can be utilized as a compatilizer between the resin phase and the rubber phase, so that dispersion stability of the two phases (the resin phase and the rubber phase) is guaranteed, and balance between rigidity and toughness of the material is effectively realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Environment-friendly modified polypropylene profiled bar base station antenna casing and preparation method

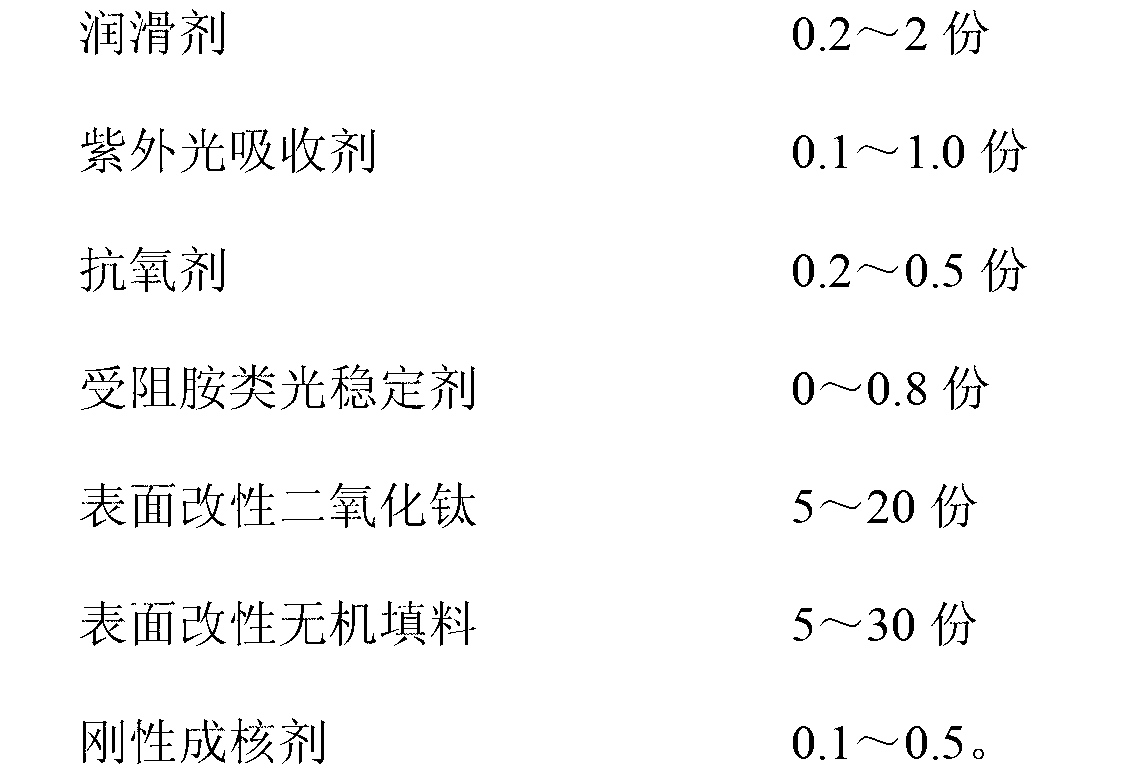

The invention discloses an environment-friendly modified polypropylene profiled bar base station antenna casing, which satisfies the required strength, modulus and hear resistance requirements of the base station antenna housing profiled bar, and more importantly, the melt-strength improvement can reach extrusion moulding treatment requirement of the complex section structural profile bar. The PP profile bar base station antenna casing has good machinery performance and greatly enhances the ultraviolet light resistant performance. The modified polypropylene profiled bar base station antenna casing comprises the following raw materials by mass: 100 parts of low melt flow rate polypropylene resin, 0.2-2 parts of lubricant, 0.1-1.0 parts of ultraviolet light absorbent, 0.2-0.5 parts of anti-oxidant, 0-0.8 parts of hindered amine light stabilizer, 5-20 parts of surface modified titanium dioxide, 5-30 parts of surface modified inorganic filling material and 0.1-0.5 parts of rigid nucleating agent.

Owner:NANJING UNIV OF TECH +1

Modified polypropylene material with low molding shrinkage and without buckling deformation and preparation method of modified polypropylene material

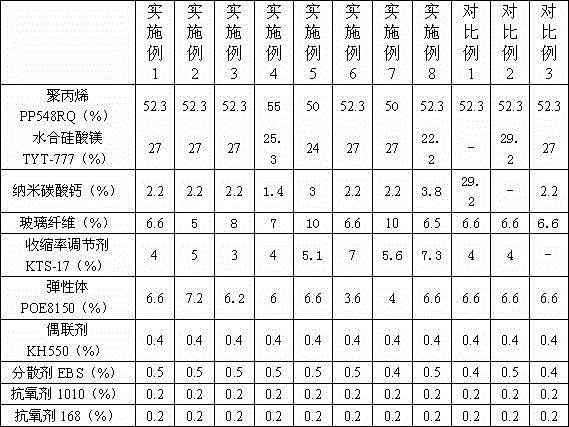

The invention discloses a modified polypropylene material and a preparation method thereof. The modified polypropylene material comprises the following ingredients by mass percentage: 50-55% of polypropylene, 25-30% of filler, 5-10% of glass fiber, 3-8% of shrinkage regulator, 3-8% of elastomer, 0.5-1% of coupling agent, 0.4-1% of dispersing agent, and 0.2-0.5% of antioxidant. The preparation method comprises the steps of mixing weighed PP (polypropylene) resin and the coupling agent in a high speed mixer, adding the other ingredients than the glass fiber for mixing for 5-10min, fusing, mixing, extruding, cooling, drying, pelleting and packaging the mixed material and the glass fiber, and obtaining the modified polypropylene material. According to the polypropylene material and the preparation method, horizontal and vertical flow shrinkages of polypropylene are reduced to below 0.8%, the difference between the shrinkages is very small (below 0.1%), the polypropylene material has excellent processability and rigidity and balanced toughness, a product made of modified polypropylene is free from warpage, no fiber exists on the surface of the product, and the application field of the polypropylene material is expanded greatly.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

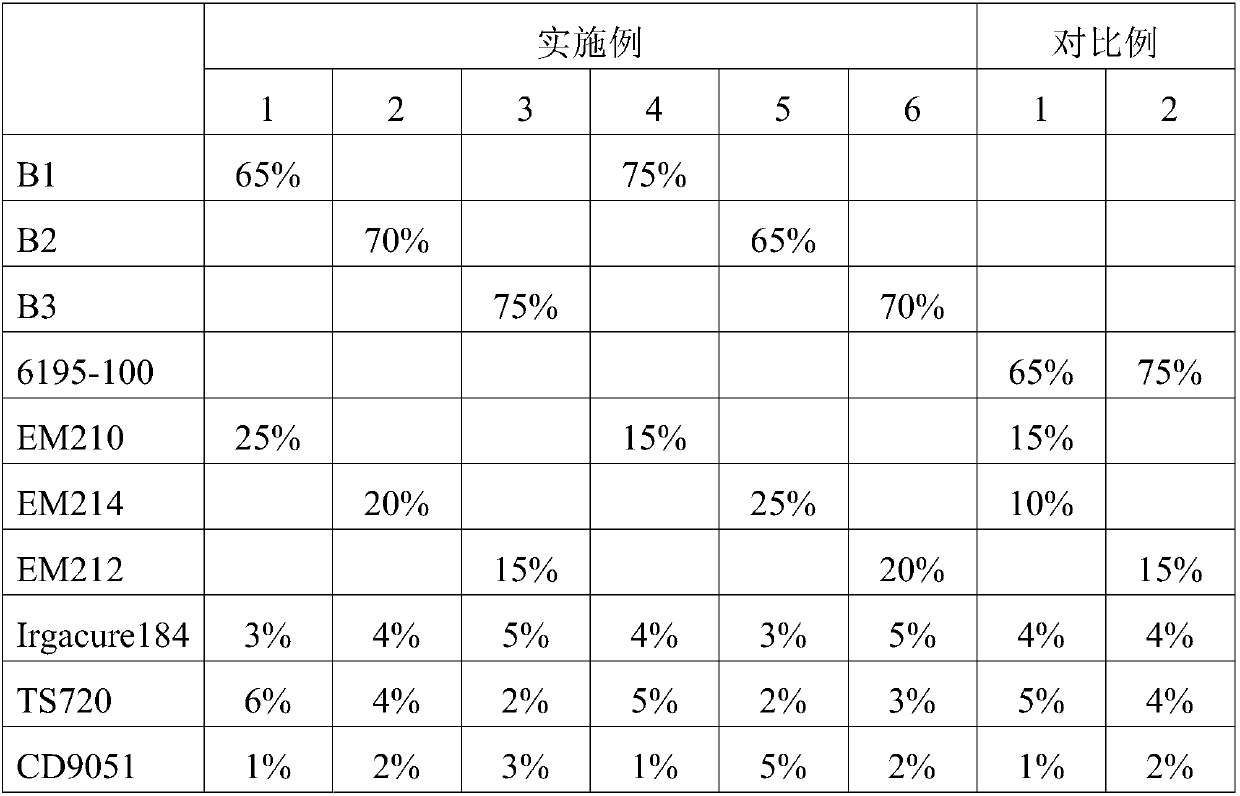

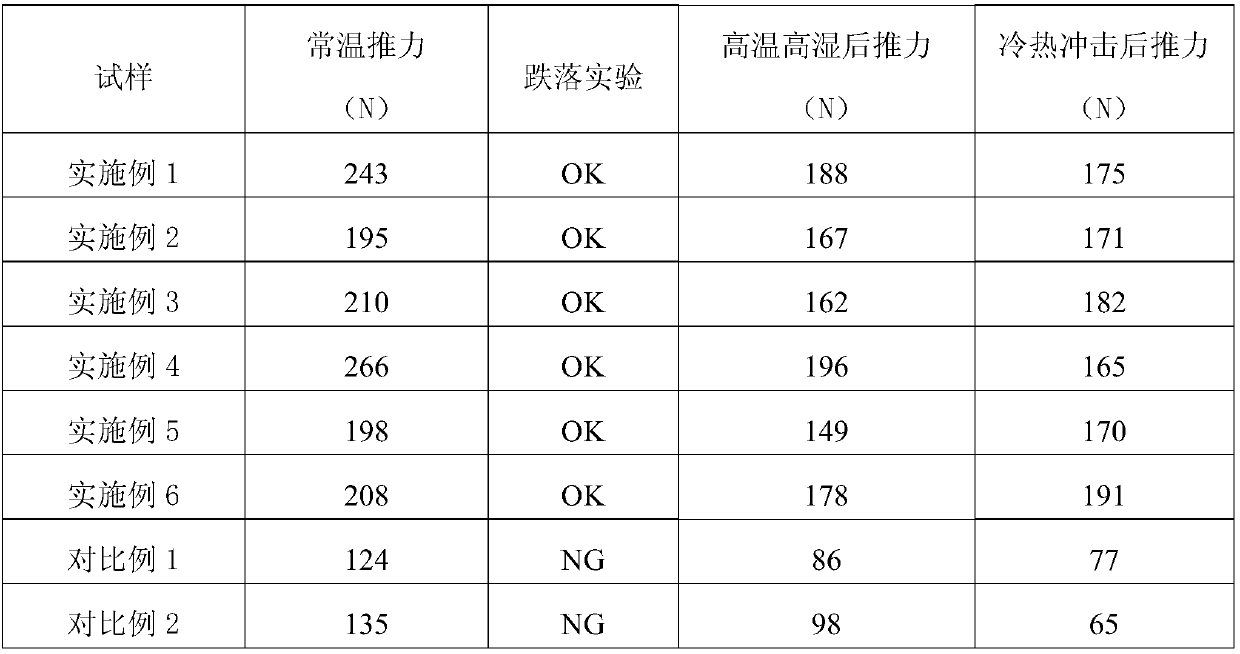

Ultraviolet-cured adhesive, preparation method therefor and application of ultraviolet-cured adhesive

ActiveCN107936903ASave energyShort curing timePolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention belongs to the technical field of adhering of electronic material structures and discloses a preparation method for an ultraviolet-cured adhesive and an application of the ultraviolet-cured adhesive. The ultraviolet-cured adhesive is prepared from the following ingredients in percentage by weight: 50% to 90% of polyether-based hyperbranched polyurethane acrylate, 5% to 35% of acrylate reactive diluent, 1% to 8% of photoinitiator, 1% to 15% of thixotropic powder and 1% to 10% of auxiliaries. According to the ultraviolet-cured adhesive disclosed by the invention, ultraviolet is adopted to initiate chain polymerization, the curing time is short and is generally 5 to 15 seconds, and the production efficiency is high; and the ultraviolet-cured adhesive is applicable to adhering fixation of lenses on LED (Light Emitting Diode) lamp bars and can simultaneously give attention to the balance of toughness, adhering power, temperature resistance and moisture resistance.

Owner:GUANGZHOU MECHANICAL ENG RES INST

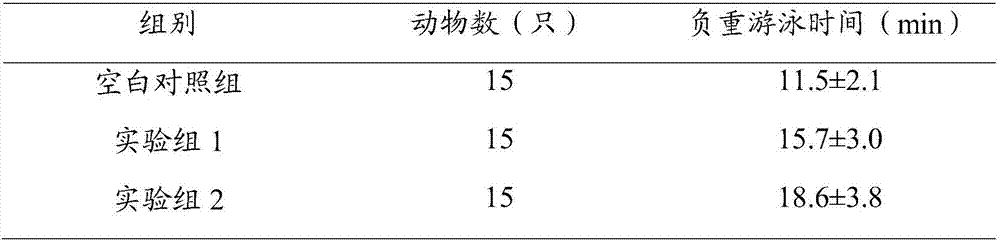

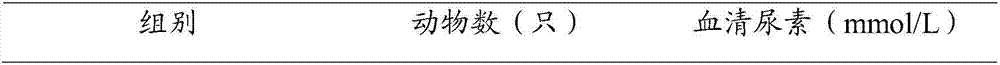

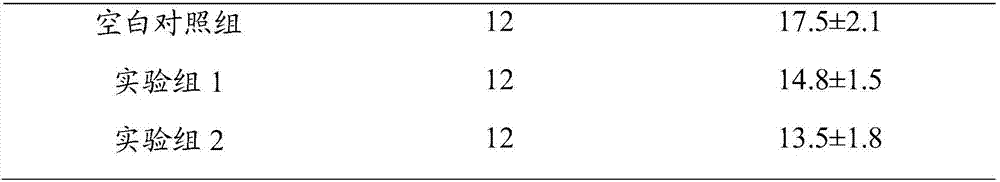

A protein bar containing an edible and medicinal component and a preparing method thereof

PendingCN107485027ADelays fatigueReduce fatigueSugar food ingredientsLipidic food ingredientsProtein barPhysical exercise

The invention relates to a protein bar containing an edible and medicinal component and a preparing method thereof. Raw materials of the protein bar include, by weight, 16-22 parts of syrup, 3-10 parts of honey, 18-25 parts of protein powder, 5-15 parts of an edible and medicinal raw material, 24-39 parts of a dried food material, 7-15 parts of chocolate, 3-10 parts of grease, 2-10 parts of glycerin and 0.6-1.4 parts of an additive. Through introducing the edible and medicinal raw material into the protein bar, feeling of fatigue in an exercise process can be effectively retarded, fatigue after exercise is relieved, functions of bodies are protected, athletic ability of bodies is improved, and functions of the protein bar are diversified. Various components are reasonably combined so that toughness and hardness of the protein bar are well-balanced.

Owner:BEIJING TONGRENTANG HEALTH PHARMA

Strengthened and toughened polypropylene composite and its preparing process

A three-element composition is prepared from polypropene (PP) (72-91 wt%), POE or MPOE (1-13) and BaSO4 (7-20) through mixing, stirring, kneading and extruding out. Its advantages are high impact strength, high toughness, high P / C ratio, high resistance to thermal or ultraviolet ageing, and low cost.

Owner:SUN YAT SEN UNIV

Abrasion-resistant high-flame-retardance PC material and preparation method thereof

The invention provides an abrasion-resistant high-flame-retardance PC material. The abrasion-resistant high-flame-retardance PC material is prepared from, by weight, 70-80 parts of PC, 5-12 parts of glass fibers, 1-5 parts of flexibilizer, 5-8 parts of compatilizer, 3-5 parts of abrasion-resistant agent, 0.1-1 part of coupling agent, 0.1-1 part of anti-dripping agent, 0.1-1 part of flame retardant, 0.2-2 parts of antioxygen, 0.2-2 parts of ultraviolet light absorber and 0.2-2 parts of lubricant. The invention further provides a preparation method of the abrasion-resistant high-flame-retardance PC material. The PC material has good abrasion resistance, high flame retardance and excellent mechanical performance; the PC material is low in cost, high in cost performance, simple in production technological process, easy to implement, free of environmental pollution and small in harm to human health.

Owner:太仓市华鼎塑料有限公司

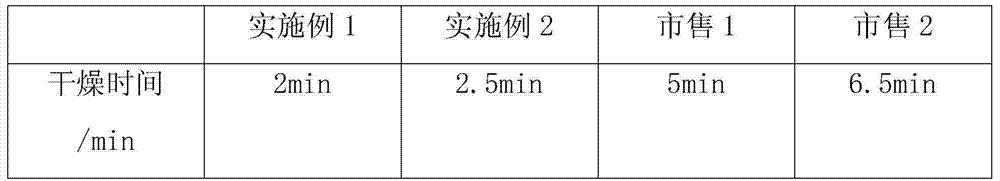

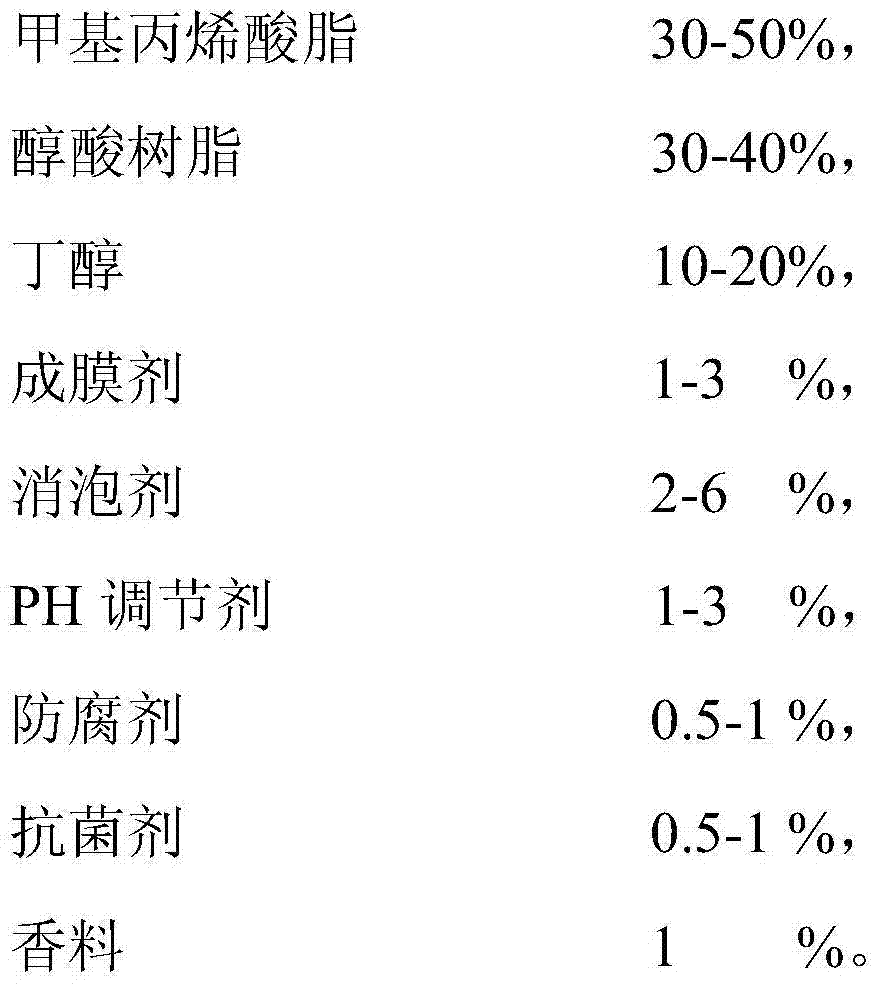

Plant-type environmental-friendly quick-drying furniture antibacterial varnish

InactiveCN104513595AFast dryingNo pollutionPaints with biocidesPolyester coatingsAdditive ingredientPreservative

The invention provides a plant-type environmental-friendly quick-drying furniture antibacterial varnish. The plant-type environmental-friendly quick-drying furniture antibacterial varnish comprises following ingredients, by weight, 30 to 50% of methyl acrylate, 30 to 40% of alkyd, 10 to 20% of butanol, 1 to 3% of a film forming agent, 2 to 6% of an antifoaming agent, 1 to 3% of a pH conditioning agent, 0.5 to 1% of an preservative, 0.5 to 1% of an antibacterial agent, and 1% of a perfume. Alkyd is selected as a base material of the plant-type environmental-friendly quick-drying furniture antibacterial varnish, so that drying speed of the plant-type environmental-friendly quick-drying furniture antibacterial varnish is high; and the antibacterial agent containing certain traditional Chinese medicine ingredients is added, so that the plant-type environmental-friendly quick-drying furniture antibacterial varnish is nontoxic and harmless, and environmental pollution is avoided.

Owner:TIANJIN YICHENG SHUOSHEN ENVIRONMENTAL PROTECTIONDEV CO LTD

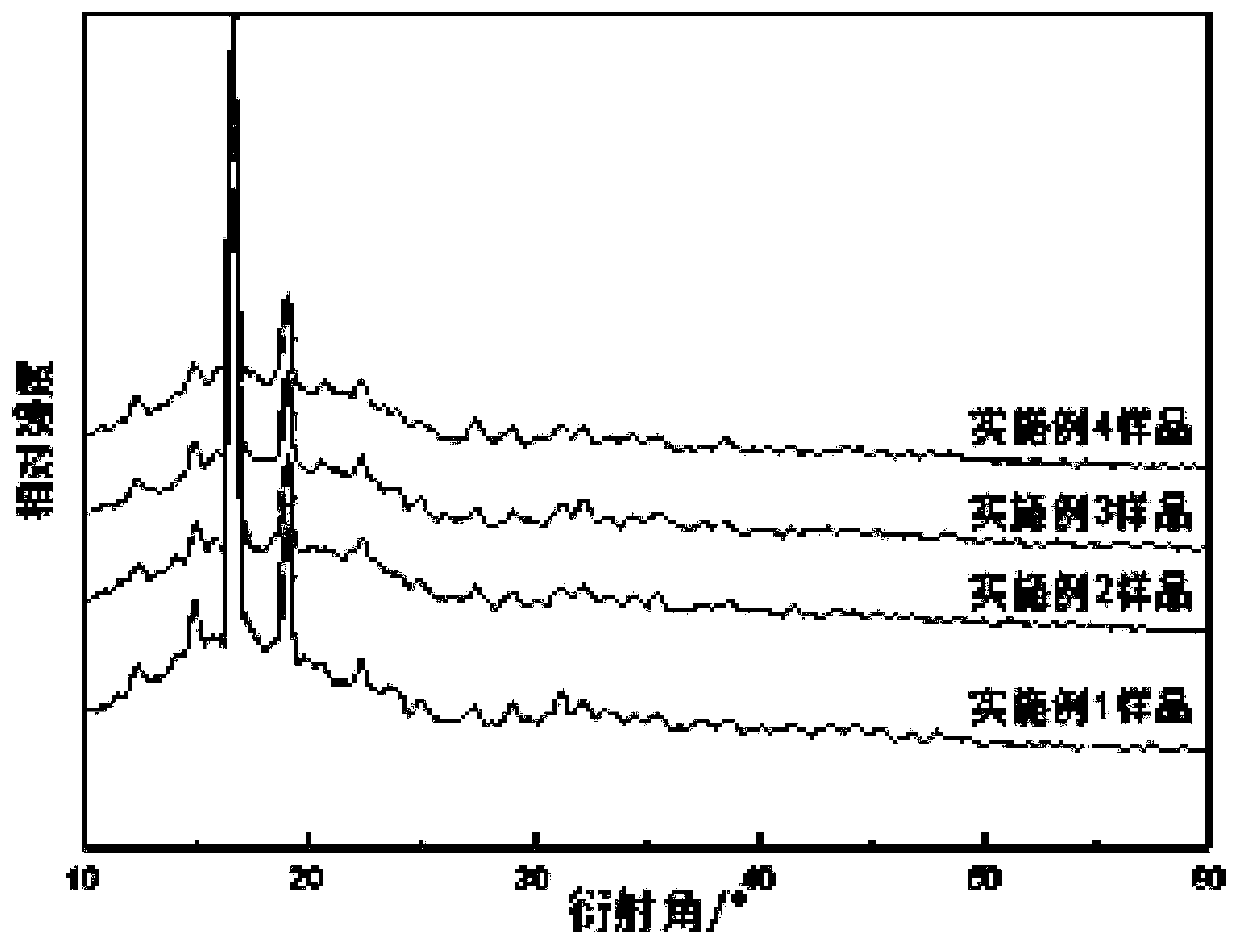

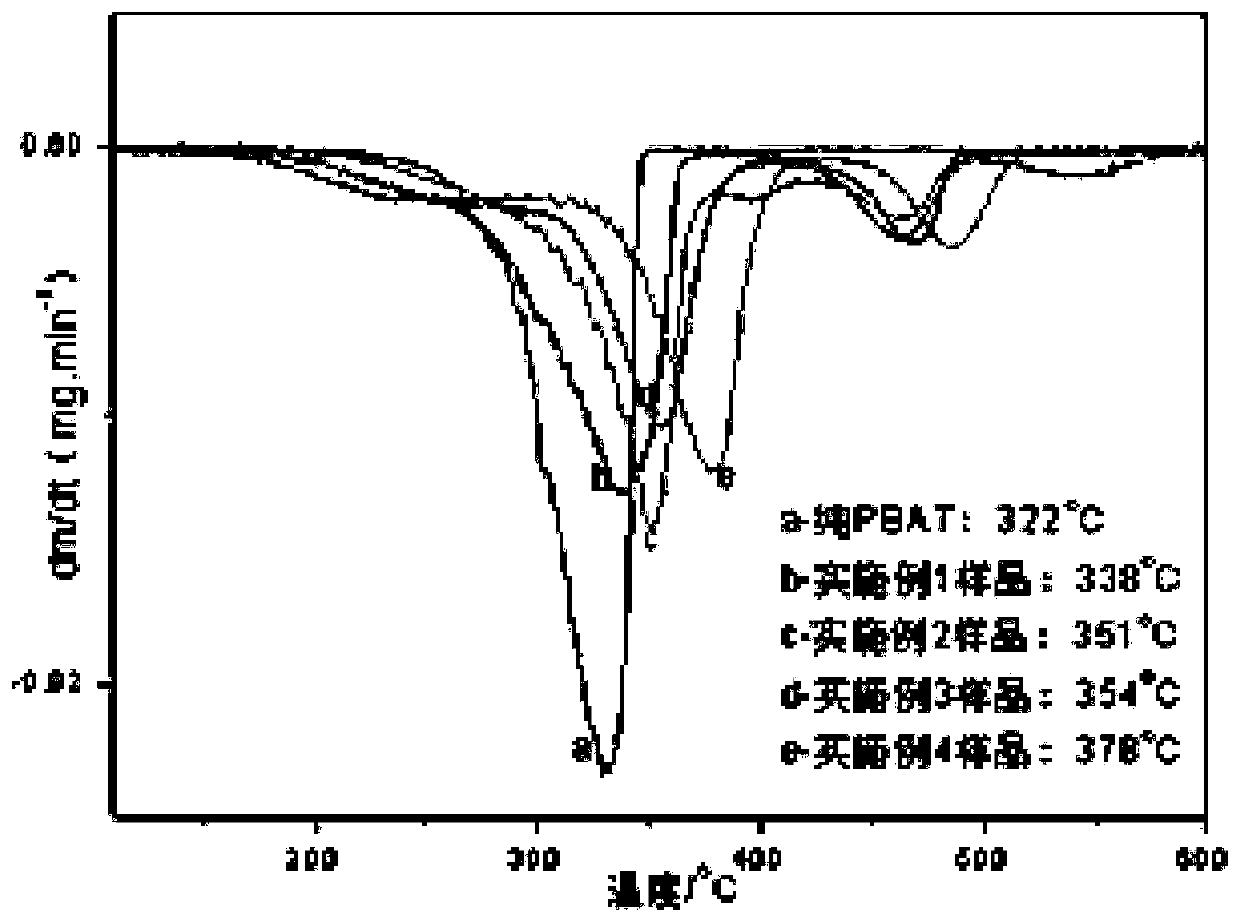

High-content-rice husk fiber-filled PBAT-based composite material and preparation method and application thereof

The invention relates to the technical field of degradable materials, in particular to a high-content-rice husk fiber-filled PBAT-based composite material. The composite material comprises the following components: in parts by weight, 90-110 parts of rice husk powder, 35-90 parts of PBAT, 10-25 parts of PLA, 2-5 parts of a super dispersant, 5-20 parts of a compatibilizer, 1-4 parts of a heat stabilizer and 2-4 parts of a lubricant. The raw materials are mixed and stirred in a high-speed mixer at 120 DEG C, and then crushing, extrusion and injection moulding are performed. The rice husk powderas agricultural processing waste has rich raw material sources, low price and biodegradability at the same time, the rice husk powder is adopted as filler of the degradable polymer PBAT, and the rigidity and toughness of the composite material can be balanced well under the action of the processing aids; and the method has simple operation and low production cost, and is beneficial to industrial production of PBAT degradable composite materials.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

NMT-based PBT composition and manufacturing method

The invention provides NMT-based PBT plastic composition and manufacturing method, which is prepared from, by weight, 25-80 parts of polybutylene terephthalate, 1-25 parts of polybutylene terephthalate, 5-50 parts of glass fiber, 10-50 parts of thermal conductive additive, 3-20 parts of flexibilizer, 0.1-10 parts of nucleating agent, 0.1-10 parts of flowing modifying agent, 0.1-5 parts of heat stabilizer, 0.1-5 parts of weathering agent, 0.1-5 parts of lubricating agent, and 0.1-3 parts of pigment. It, by different raw materials and ratios, produces thermal plastic PBT compositions of easy molding, high strength, good tenacity, good heat-conducting property, and high adhesive strength with metal, meeting requirements for nanometer molding technology.

Owner:安特普工程塑料(苏州)有限公司

Quantum-dot dispersed resin forming body, preparation method thereof and quantum-dot dispersed body

PendingCN108546314AReduce the problem of poor water resistanceGood compatibilityQuantum dotResin matrix

The invention discloses a quantum-dot dispersed resin forming body, a preparation method thereof and a quantum-dot dispersed body, wherein the quantum-dot dispersed resin forming body comprises quantum dots dispersed in a polymeric material; a molecular chain of the polymeric material comprises a hydrophilic resin chain segment, an amphiphilic resin chain segment and a hydrophobic resin chain segment. The quantum-dot dispersed resin forming body, the preparation method thereof and the quantum-dot dispersed body disclosed by the invention have the beneficial effects that by the amphiphilic resin chain segment, the hydrophilic resin chain segment and the hydrophobic resin chain segment are introduced into a same dispersed system, so that when better compatibility of the dispersed system is ensured, the defects generated by single resin matrix is solved.

Owner:NANJING TECH CORP LTD

Microcellular-foamed high-strength polypropylene composite material

The invention discloses a microcellular-foamed high-strength polypropylene composite material. The composite material is prepared from, by weight, 100 parts of polypropylene, 0.001-0.01 part of organic peroxide, 10-15 parts of K resin, 1-5 parts of an inorganic foaming agent coated with organic macromolecules, 5-15 parts of talcum powder and 1-5 parts of auxiliaries, wherein the auxiliaries comprise a surfactant, a foaming stabilizing agent and a thermal stabilizing agent, and the particle size of the talcum powder ranges from 100 mesh to 5,000 mesh. According to the microcellular-foamed high-strength polypropylene composite material, the raw materials adopted in the formula are easy to obtain and low in cost, especially the foaming agent NaHCO3 is economical and environmentally friendly, and the microcellular-foamed polypropylene material which is used for an automobile, has injection molding grade closed holes and is uniform in foam hole distribution, high in foaming rate and excellent in physical and mechanical properties can be prepared through cooperation of the foaming agent NaHCO3 and other components.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

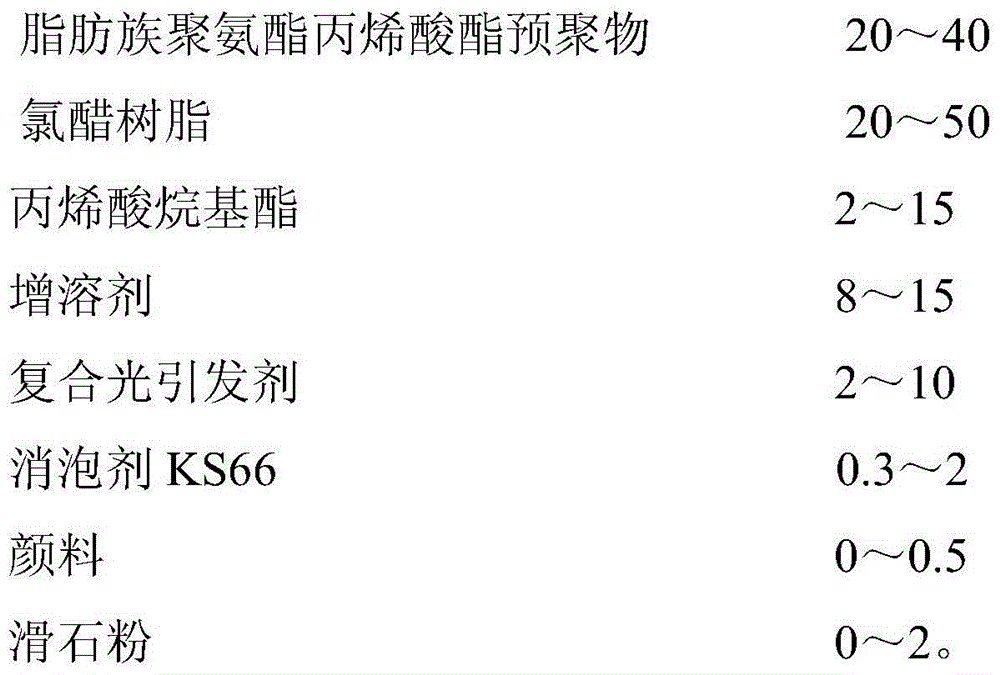

Screen printing peelable UV (ultraviolet) ink as well as preparation method and application of screen printing peelable UV ink

The invention belongs to the field of functional fine high-molecular materials, and discloses screen printing peelable UV (ultraviolet) ink as well as a preparation method and application of the screen printing peelable UV ink. The UV ink consists of 20-40 mass parts of aliphatic polyurethane acrylate prepolymer, 20-50 mass parts of vinyl chloride-vinyl acetate resin, 2-15 mass parts of alkyl acrylate, 8-15 mass parts of a solubilizer, 2-10 mass parts of composite photoinitiator, 0.3-2 mass parts of a defoaming agent KS66, 0-0.5 mass part of pigment and 0-2 mass parts of talc powder. The components in the ink have a synergistic effect, so that a cured film formed after the ink is cured is balanced in strength, toughness and adhesion, has good surface protection property and peelability and does not have residue during peeling after being used.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

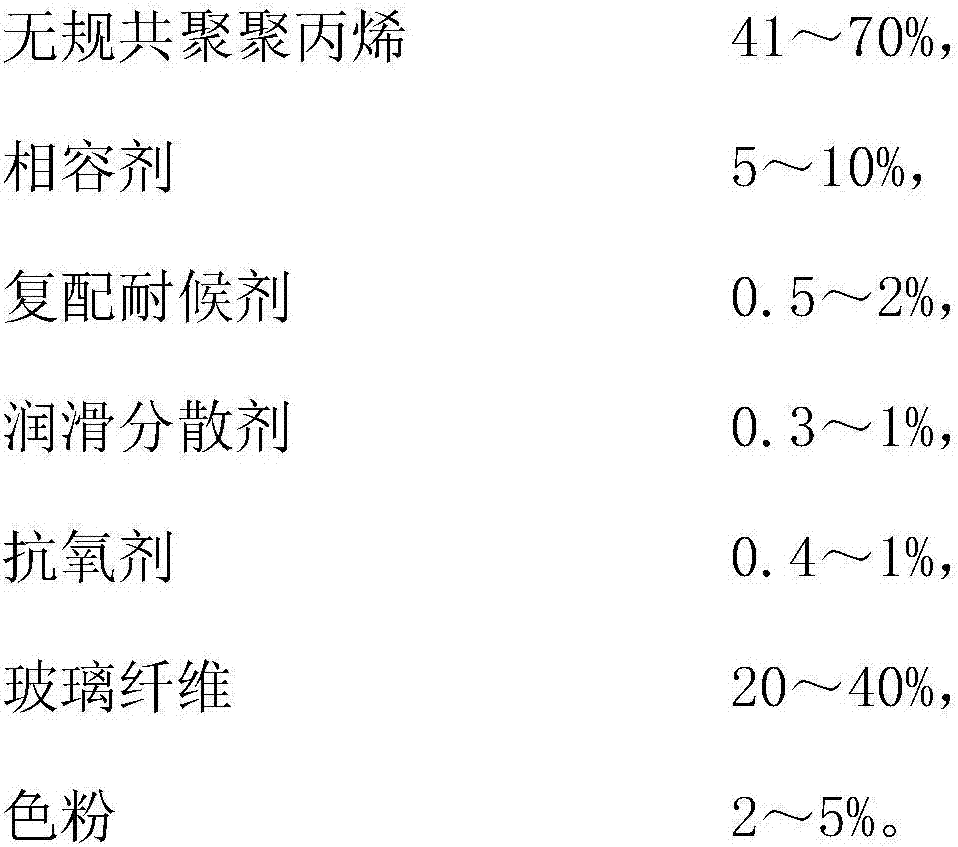

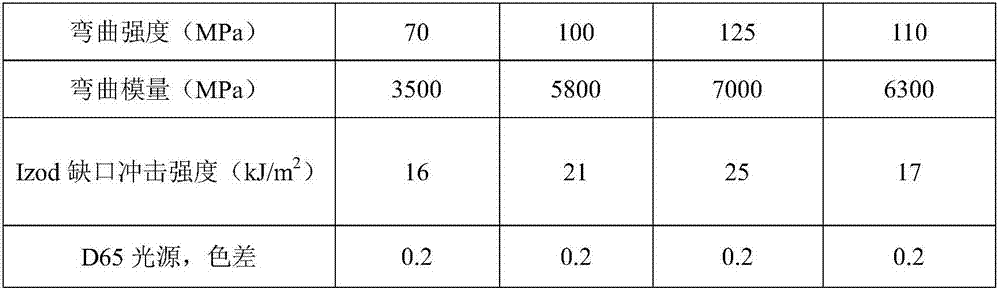

High-weather-resistant high-tenacity reinforced polypropylene material for post insulator and preparation method of reinforced polypropylene material

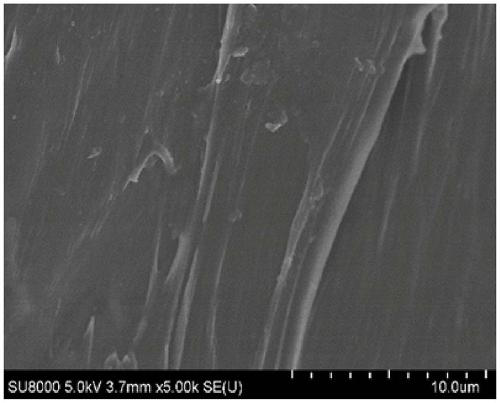

InactiveCN107987398AHigh retention rate of mechanical propertiesGood color stabilityLubricationPolypropylene

The invention discloses a high-weather-resistant high-tenacity reinforced polypropylene material for a post insulator and a preparation method of the reinforced polypropylene material. According to the key point of the technical scheme, the reinforced polypropylene material contains the following components in percentage by weight: 41%-70% of random copolymerization polypropylene, 5%-10% of a compatilizer, 0.5%-2% of a compound weather-resistant agent, 0.3%-1% of a lubrication dispersing agent, 0.4%-1% of an antioxidant, 20%-40% of glass fibers and 2%-5% of a toner. The high-weather-resistanthigh-tenacity reinforced polypropylene material for the post insulator has the advantages that the weather resistance and the tenacity are high, the retention rate of mechanical performance under a photothermal oxygen aging condition is high, the color stability is good, and the like.

Owner:GUANGDONG WAYLAM ENG PLASTICS

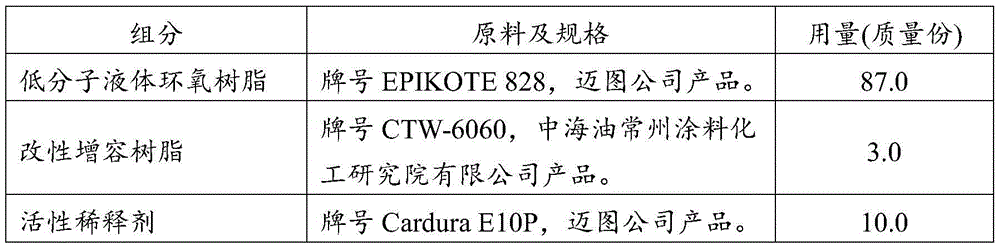

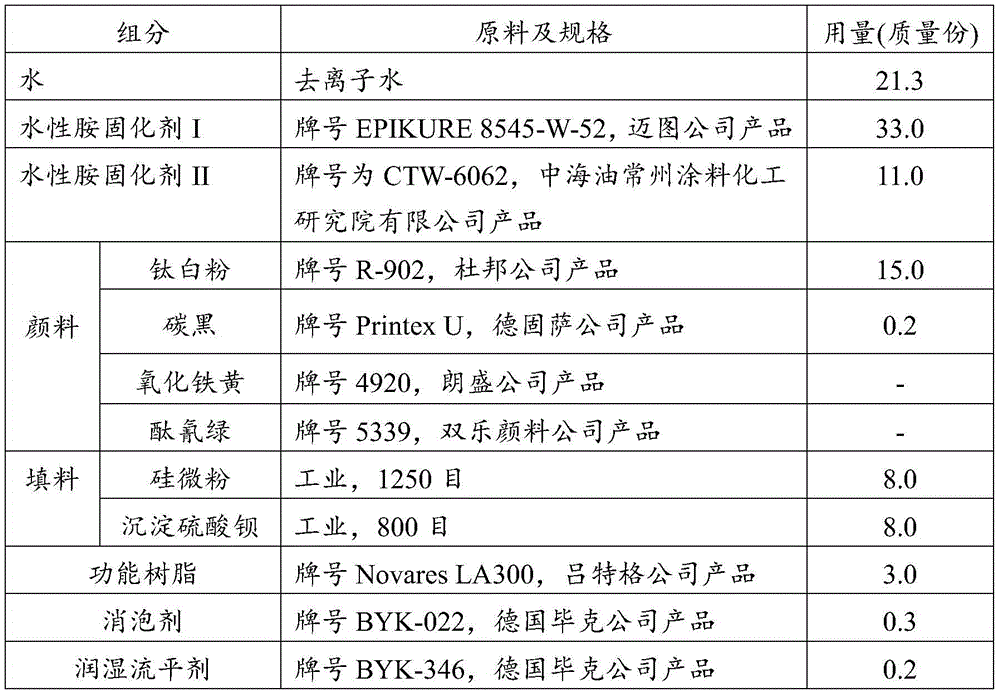

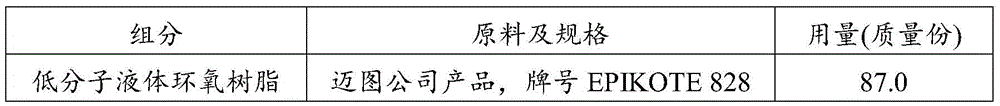

Special-type high-strength wear-resistant water-based epoxy paint and preparation method thereof

InactiveCN105907244AModerate hardnessGood flexibilityEpoxy resin coatingsDefoaming AgentsPolymer chemistry

The invention provides a special-type high-strength wear-resistant water-based epoxy paint and a preparation method thereof. The water-based epoxy paint comprises a component A and a component B. The component A comprises the following ingredients in parts by mass: 80-90 parts of water-based epoxy resin, 2-4 parts of modified compatibilizing resin and 5-15 parts of reactive diluent. The component B comprises the following ingredients in parts by mass: 40-45 parts of water-based amine hardener, 8-10 parts of tungsten carbide, 4-5 parts of spodumene, 3-5 parts of functional resin, 3-18 parts of pigment, 10-25 parts of filler, 0.1-0.5 part of defoaming agent, 0.1-0.3 part of wetting and leveling agent and 20-30 parts of water. The paint film formed by proportionally mixing the component A and component B of the water-based epoxy paint has the advantages of proper usable life, favorable constructability, favorable hardness, favorable wear resistance, favorable flexibility, favorable impact resistance, other physical and mechanical properties and chemical medium resistance, and is suitable to be used as a floor paint.

Owner:HUIZHOU CITY HUIYANG DISTRICT JIATAI PAINT CO LTD

High-tenacity transparent PS plastic cement material and preparation method therefor

The invention discloses a high-tenacity transparent PS plastic cement material. The high-tenacity transparent PS plastic cement material consists of the following raw materials in parts by weight: 70-85 parts of polystyrene (PS), 5-8 parts of polyether sulfone resin (PES), 7-12 parts of polyvinylidene fluoride (PVF) and 3-10 parts of a composite modifier. The invention further discloses a preparation method of the high-tenacity transparent PS plastic cement material. According to the preparation method disclosed by the invention, the PES, the PVF and the PS are blended so as to obtain the plastic cement material, a shock resistant modifier and a flexibilizer in the composite modifier are used for composite modification for the plastic cement material, so that the rigidity and the tenacity of PS products are effectively balanced, and the PS plastic cement material with high tenacity, high impact strength and favorable transparency is obtained.

Owner:JIN BAOLI TECH SUZHOU

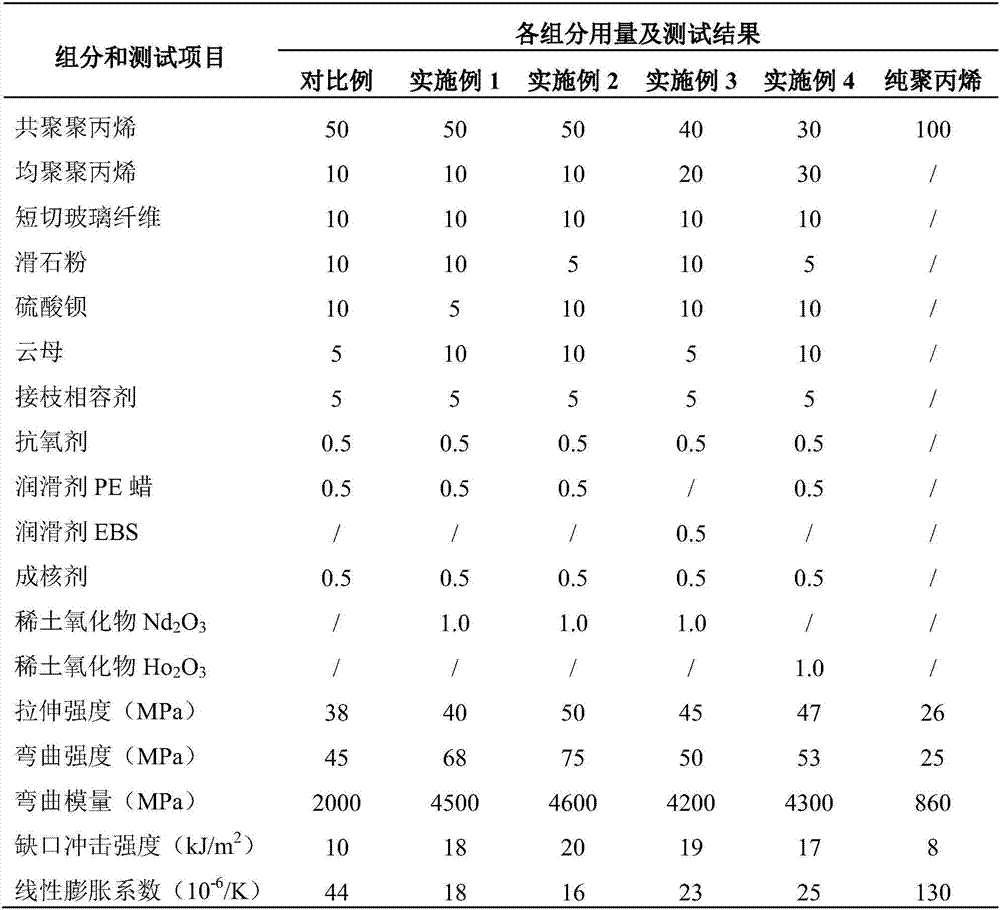

Composite material, preparation method thereof and air conditioner workpieces

The invention discloses a composite material, a preparation method thereof and air conditioner workpieces. The composite material comprises the following materials, in parts by weight: 50-70 parts of polypropylene, 10-20 parts of chopped glass fibers, 20-30 parts of an inorganic filler, 5-10 parts of a graft compatilizer, 0.2-0.8 part of an antioxidant, 0.5-2.0 parts of a lubricant, 0.1-1.0 part of a nucleating agent, and 0.5-2.0 parts of a rare earth oxide. The composite material has a low linear expansion coefficient and excellent dimensional stability, when the air conditioner workpieces are prepared by adopting the composite material, noise caused by thermal expansion and cold contraction in an air conditioner usage process can be effectively avoided.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Breathable nutritional soil for potted plant

InactiveCN106673867AWith loose ventilationStrong ability to retain water and fertilizerCalcareous fertilisersAnimal corpse fertilisersInsect pestAmmonium Hydrogen Carbonate

The invention discloses a breathable nutritional soil for a potted plant. The breathable nutritional soil comprises the following raw materials in parts by weight: 40-60 parts of pond silt, 2-6 parts of ammonium hydrogen carbonate, 4-8 parts of plant ash, 1-5 parts of defluorinated phosphate, 0.5-1.5 parts of gypsum powder, 0.1-0.5 part of magnesium humate, 0.4-0.8 part of zinc humate, 0.1-0.8 part of manganese humate, 0.5-1.5 parts of compound sodium nitrophenolate, 4-8 parts of modified cottonseed meal, 2-4 parts of shell powder, 4-10 parts of fly ash, 1-3 parts of microcrystalline cellulose, 1-5 parts of bean oil and 0.5-1.5 parts of diatomite. The nutritional soil can satisfy growth and development of a plant in the potting process; multiple mineral nutrients are specifically added according to the growth requirements of the plant; and meanwhile, the nutritional soil has the characteristics of loosening, ventilating, strongly preserving moisture and fertility, ensuring no disease or insect pest and the like, and can greatly increase the indoor maintenance survival rate.

Owner:蚌埠市凯婷农民种植专业合作社

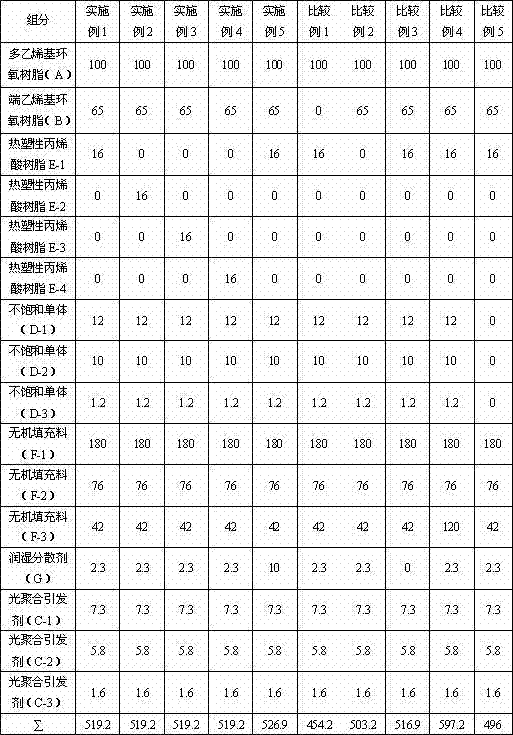

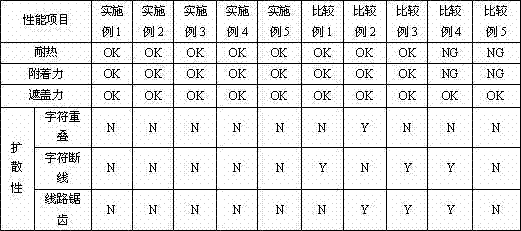

White ultraviolet light polymerization resin composition, and preparation method and application method thereof

ActiveCN102925033AHigh solid contentImproves wettability of inert fillersInksEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to white ultraviolet light polymerization resin composition, and a preparation method and an application method thereof. The composition comprises, by weight, the following raw materials: 100 parts of side chains multi-vinyl epoxy resin, 10-100 parts of vinyl end long chains epoxy resin, 1-30 parts of photopolymerization initiators, 5-100 parts of unsaturability monomer, 5-40 parts of thermoplastic acrylic resin, 35-400 parts of inorganic filling materials and 0.5-10 parts of wetting dispersants. The composition is grinded by a three-roll machine to reach certain fineness for printing. The composition is used for printing characters and patterns of circuit boards. By the aid of the composition, definition and plumpness of the characters are enhanced after the characters are printed, and diffusivity of the characters due to printing repeatedly for a plurality of times is reduced.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

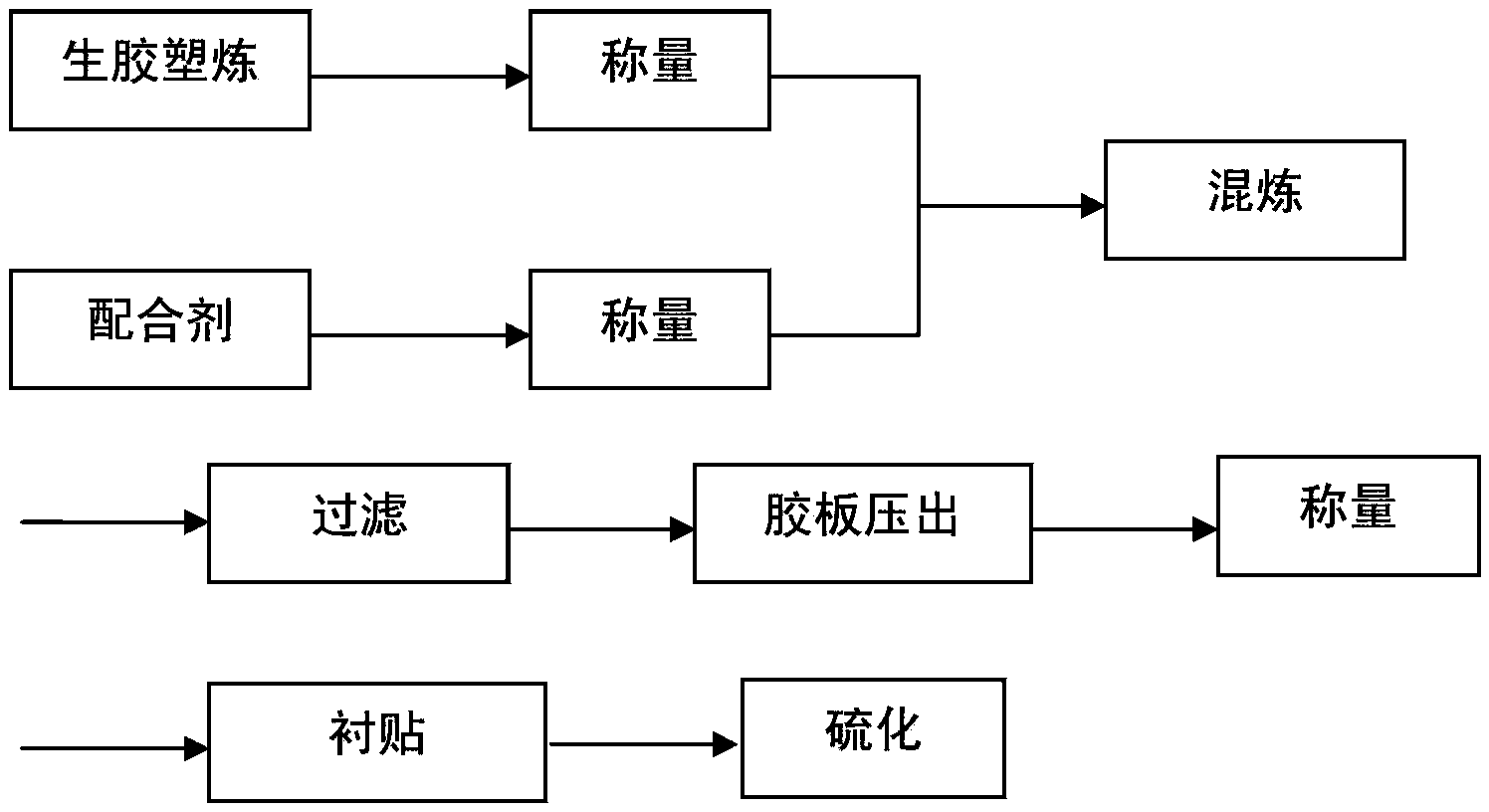

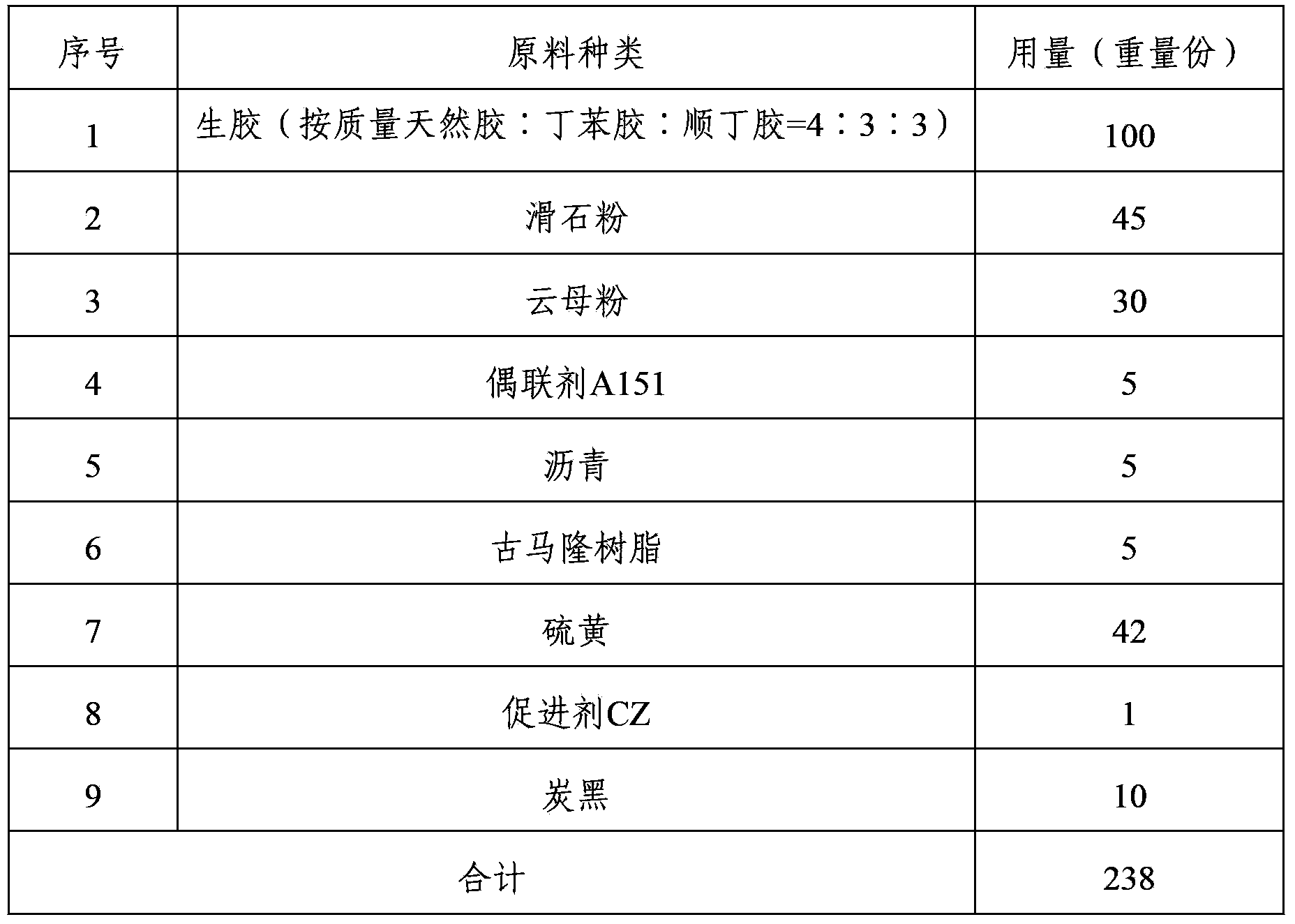

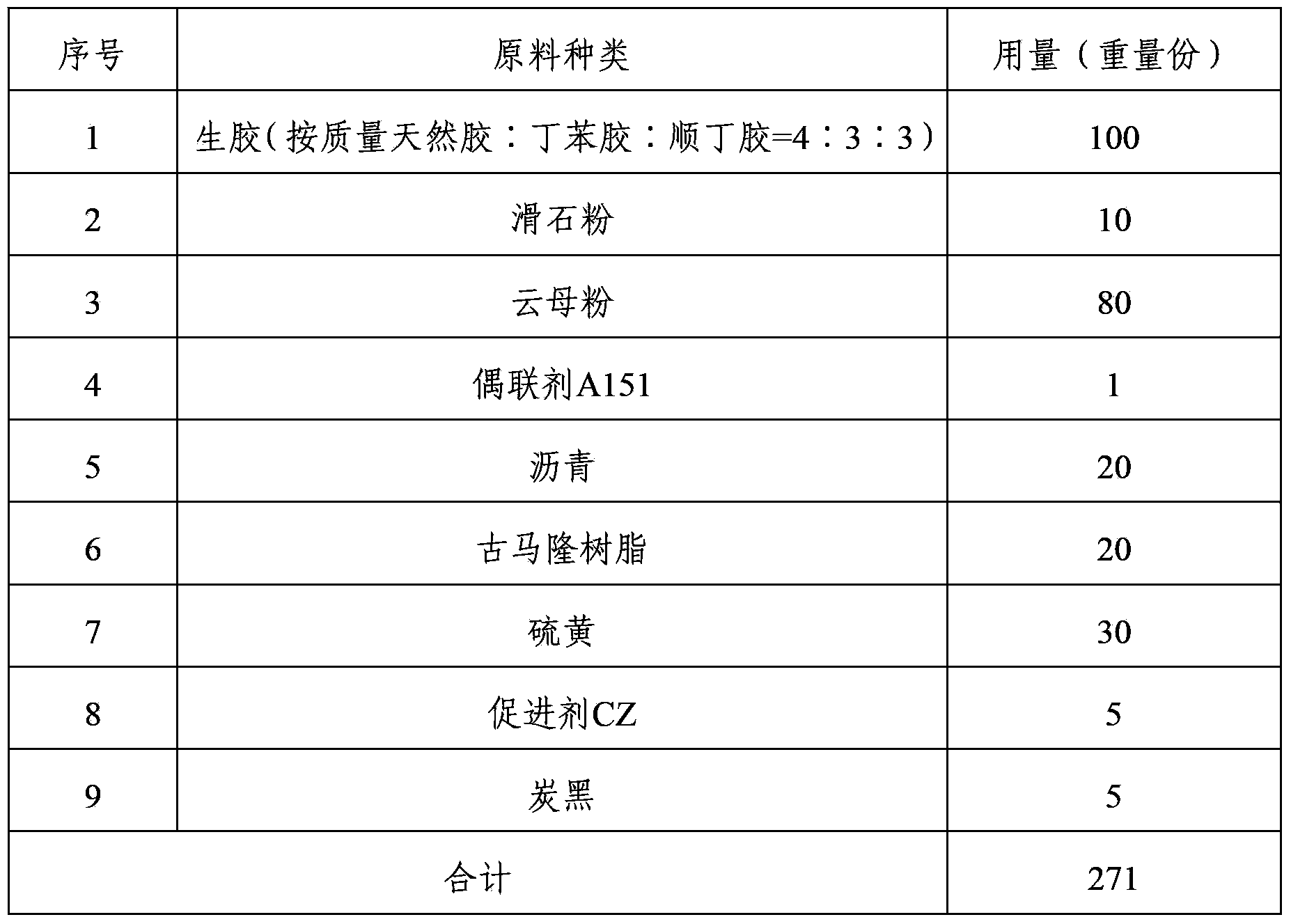

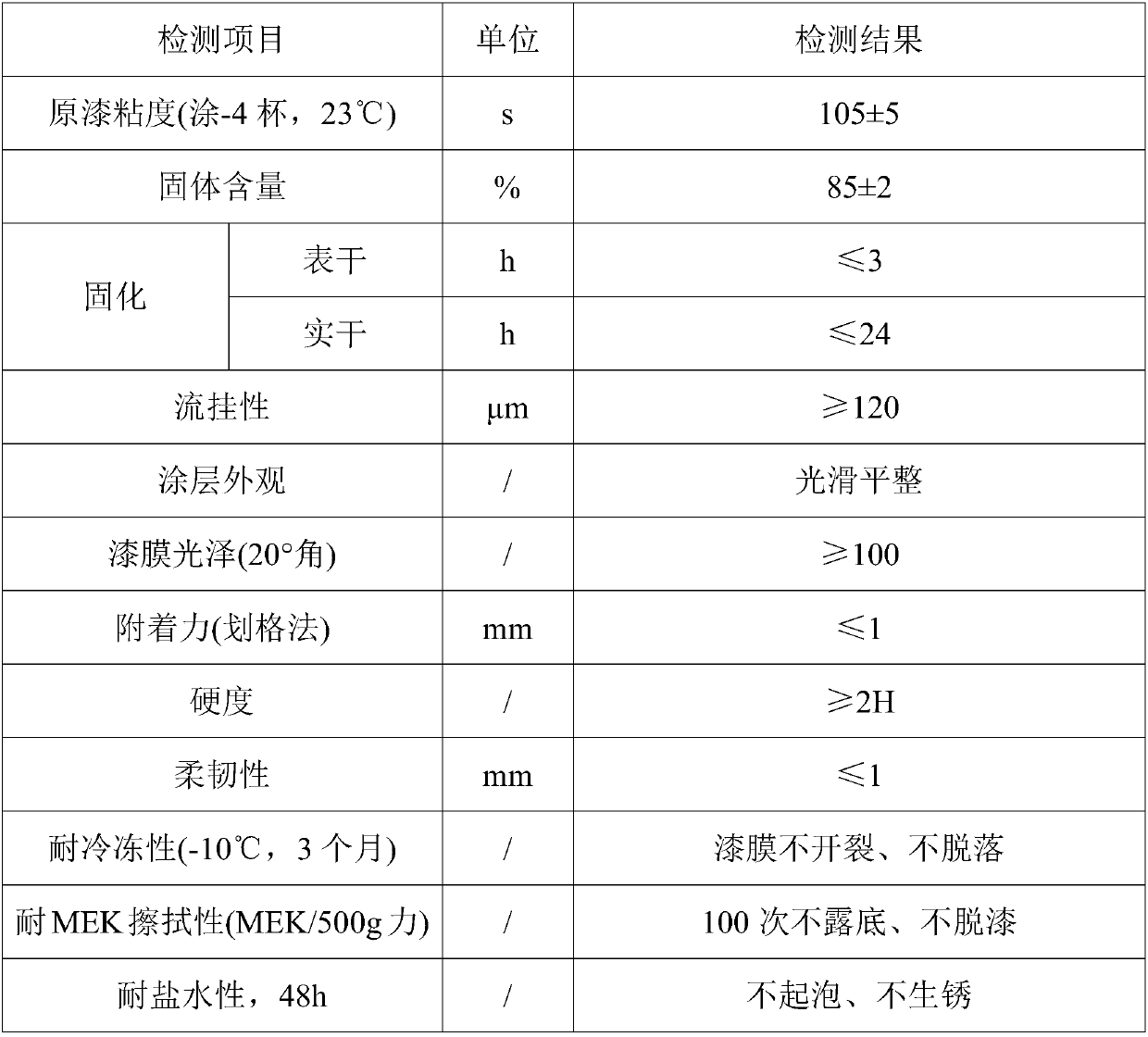

Anti-corrosion rubber composition and anti-corrosion rubber lining

The invention relates to an anti-corrosion rubber composition. The anti-corrosion rubber composition comprises the components of, by weight, 100 parts of raw rubber, 20-80 parts of talcum powder, 10-60 parts of mica powder, 0.5-10 parts of coupling agent, 0.5-15 parts of pitch, 1-20 parts of coumarone resin, 30-60 parts of sulphur, 0.1-5 parts of accelerant and 1-20 parts of dyeing agent. The invention also relates to an anti-corrosion rubber lining. The rubber lining produced through the anti-corrosion rubber composition provided in the invention can bear a working temperature of 130 DEG C under a high vacuum degree, is acid and alkali resistant at high temperatures and is applicable to a 11-stage flash device of an adhesive production line.

Owner:XIANYANG SAIFU ANTICORROSION EQUIP

Wear-resisting and high-rigidity polycarbonate lens

The invention discloses a wear-resisting and high-rigidity polycarbonate lens. The wear-resisting and high-rigidity polycarbonate lens comprises a polycarbonate substrate and a coating which covers the surface of the polycarbonate substrate, wherein the coating is prepared from the following raw materials: a silicon resin pre-polymer, polyurethane, epoxy resin, hydroxyethyl methylacrylate, polyester polyol, aluminum acetylacetonate, dibutyltin dilaurate, tetrabutylammonium hydroxide, methylhexahydrophthalic anhydride, 2-methylimidazole, bicyclic amidine, a solvent, a silane coupling agent andan auxiliary agent. The wear-resisting and high-rigidity polycarbonate lens provided by the invention has good wear resistance, high surface rigidity, excellent heat-resisting performance and long service life.

Owner:望江县天长光学仪器有限公司

High-stability waterborne epoxy resin coating for woodware

InactiveCN107936756AIncreased dispersionImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsParaffin waxFreeze-drying

The invention discloses a high-stability waterborne epoxy resin coating for woodware. The coating comprises an A component and a B component, wherein the A component comprises the following raw materials in parts by weight: 80-120 parts of bisphenol A type epoxy resin, 10-22 parts of waterborne polyurethane emulsion, 40-50 parts of filler, 4-8 parts of composite dispersant, 2-4 parts of stearic acid, 4-7 parts of polyethylene glycol, 2-5 parts of defoamer, 3-4 parts of wetting agent, and 2-4 parts of leveling agent; the B component comprises the following raw materials in parts by weight: 10-18 parts of waterborne curing agent, 2-4 parts of ethylene glycol butyl ether acetate, 4-6 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), and 30-50 parts of deionized water; and thecomposite dispersant is prepared by the following process: mixing dichloronated polyethylene glycol, sodium hydroxide, tetrabutylammonium bromide, and p-aminophenol to obtain a mixture, performing heating and stirring on the mixture, and performing heating and stirring continuously; performing cooling, then adding gelatin, liquid paraffin and water, and performing uniform stirring; and performingcooling to room temperature, and then performing freeze drying, so as to obtain the composite dispersant.

Owner:合肥林邦门业有限公司

Aqueous epoxy terrace paint and preparation method thereof

ActiveCN105482618AGood emulsification and dispersionModerate concentrationEpoxy resin coatingsWorking lifeReactive diluent

The present invention provides an aqueous epoxy terrace paint, comprising a component A and a component B. The component A comprises 80-90 parts of low molecular weight liquid epoxy resin,2-4 parts of a modified resin compatibilizer and 5-15 parts of a reactive diluent. The component B comprises 20-0 parts of water, 40-45 parts of an aqueous amine curing agent, 3-5 parts of a functional resin, 3-18 parts of a pigment, 10-25 parts of a filler, 0.1-0.5 part of a defoamer and 0.1-0.3 part of a wetting leveling agent. The components A and component B of the aqueous epoxy terrace paint are mixed according to a certain proportion to form a film with suitable working life and good workability. The film has good hardness, wear resistance, flexibility, impact resistance and other physical and mechanical properties and chemical resistance. The invention also provides a preparation method of the aqueous epoxy terrace paint.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com