Aqueous epoxy terrace paint and preparation method thereof

An epoxy floor and coating technology, applied in the direction of epoxy resin coatings and coatings, can solve the problems of poor compatibility, short pot life, poor construction, etc., achieve low volatility, improve weather resistance, and improve fullness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of waterborne epoxy floor paint of the present invention may further comprise the steps:

[0037] Step 1: Put low molecular weight liquid epoxy resin, modified compatibilizing resin and active diluent into the reaction kettle;

[0038] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0039] Step 3: After filtering with a 180-mesh silk screen, the A component of the water-based epoxy floor coating is obtained;

[0040] Step 4: Add water and water-based amine curing agent into the container, and stir evenly;

[0041] Step 5: Under stirring conditions, add pigments and fillers to the container, stir for 30 minutes after adding, and then disperse with a sand mill to a fineness of ≤25 μm to prepare a slurry;

[0042]Step 6: Add functional resin, defoamer, and wetting and leveling agent to the slurry prepared in Step 5 under stirring conditions, and continue stirring...

Embodiment 1

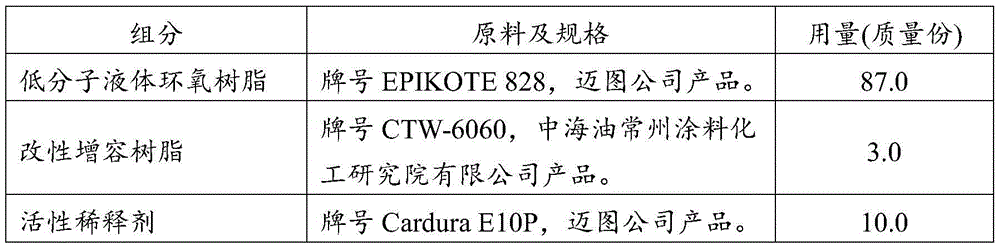

[0046] Table 1: Component A Formulation

[0047]

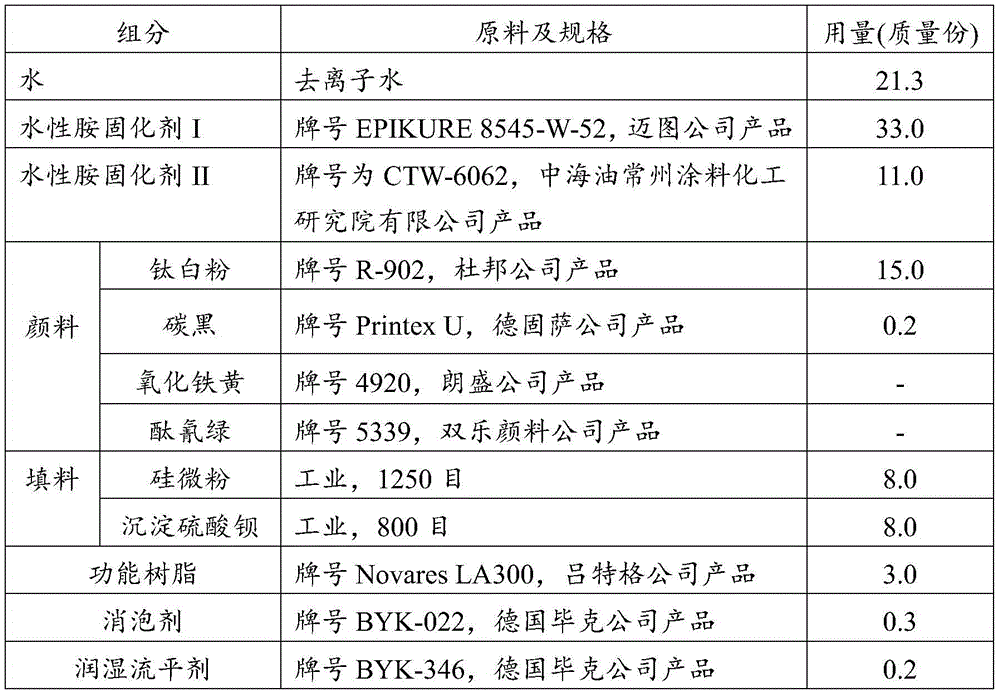

[0048] Table 2: Formulation of Part B

[0049]

[0050] Preparation Process:

[0051] Step 1: Put 87.0 low molecular weight liquid epoxy resin, 3.0 modified compatibilizing resin and 10.0 active diluent into the reaction kettle;

[0052] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0053] Step 3: After filtering with a 180-mesh silk screen, the A component of the water-based epoxy floor coating is obtained;

[0054] Step 4: Add deionized water 21.3, water-based amine curing agent I 33.0, water-based amine curing agent II 11.0 into the container, and stir evenly;

[0055] Step 5: Under stirring conditions, add titanium dioxide 15.0, carbon black 0.2, silicon micropowder 8.0, precipitated barium sulfate 8.0 to the container, stir for 30 minutes after adding, and then use a sand mill to disperse to a fineness of ≤ 25 μm to obtain s...

Embodiment 2

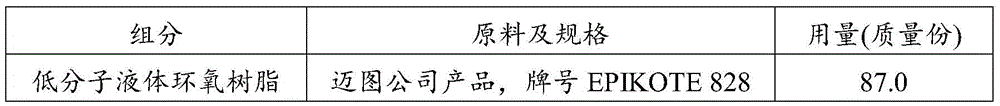

[0059] Table 3: Component A Formulation

[0060]

[0061]

[0062] Table 4: Formulation of Part B

[0063]

[0064] Preparation Process:

[0065] Step 1: Put 87.0 low molecular weight liquid epoxy resin, 3.0 modified compatibilizing resin and 10.0 active diluent into the reaction kettle;

[0066] Step 2: Under stirring conditions, slowly raise the temperature to 60°C, keep it at (60±2)°C for 1 hour, and then cool down to 40°C;

[0067] Step 3: After filtering with a 180-mesh silk screen, the A component of the water-based epoxy floor coating is obtained;

[0068] Step 4: Add 23.0 deionized water, 33.0 water-based amine curing agent I, and 11.0 water-based amine curing agent II into the container, and stir evenly;

[0069] Step 5: Under stirring conditions, add titanium dioxide 1.0, iron oxide yellow 3.0, phthalocyanine green 1.5, silicon micropowder 12.0, precipitated barium sulfate 12.0 into the container, stir for 30 minutes after adding, and then use a sand mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com