White ultraviolet light polymerization resin composition, and preparation method and application method thereof

A technology for curing resins and compositions, applied in the field of white UV curable resin compositions, can solve the problems of high solid content, poor fluidity, and easy blocking of screen plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

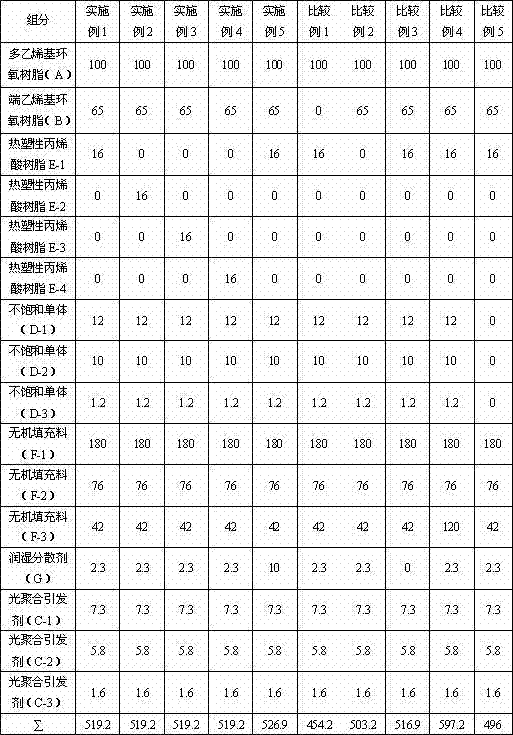

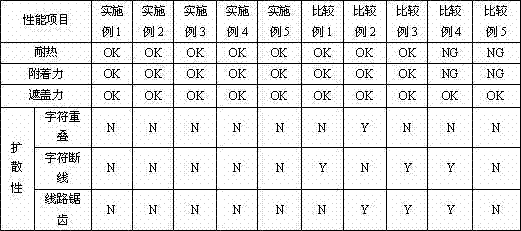

Examples

Embodiment

[0060]

[0061] Synthesize the polyvinyl epoxy resin (A) in the present invention according to the following implementation process.

[0062] 885 g of novolac epoxy resin (manufactured by Kukdo Chemical Co., Ltd., YDPN-638, epoxy equivalent 177) was added to a four-necked flask equipped with a stirrer, and heated to 85°C. Next, 0.6 g of p-hydroxyanisole as a thermal polymerization inhibitor and 1.78 g of triphenylphosphine as an esterification catalyst were added. After the temperature was raised to 95°C, 306 g of acrylic acid was slowly added dropwise until the acid value was less than 0.5 mgKOH / g, the temperature was lowered to 80°C, 210 g of hydroxyethyl methacrylate was added, and the mixture was stirred until the temperature was less than 70°C.

[0063]

[0064] Next, synthesize the vinyl-terminated long-chain epoxy resin (B) in the present invention according to the following implementation process.

[0065] Add 1300 g of solid bisphenol A epoxy resin (manufactured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com