High-stability waterborne epoxy resin coating for woodware

A water-based epoxy resin, high-stability technology, used in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor dispersion stability of water-based epoxy coatings and volatile organic compound emission restrictions. Achieve the effects of not easy component migration, improved coating and leveling properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

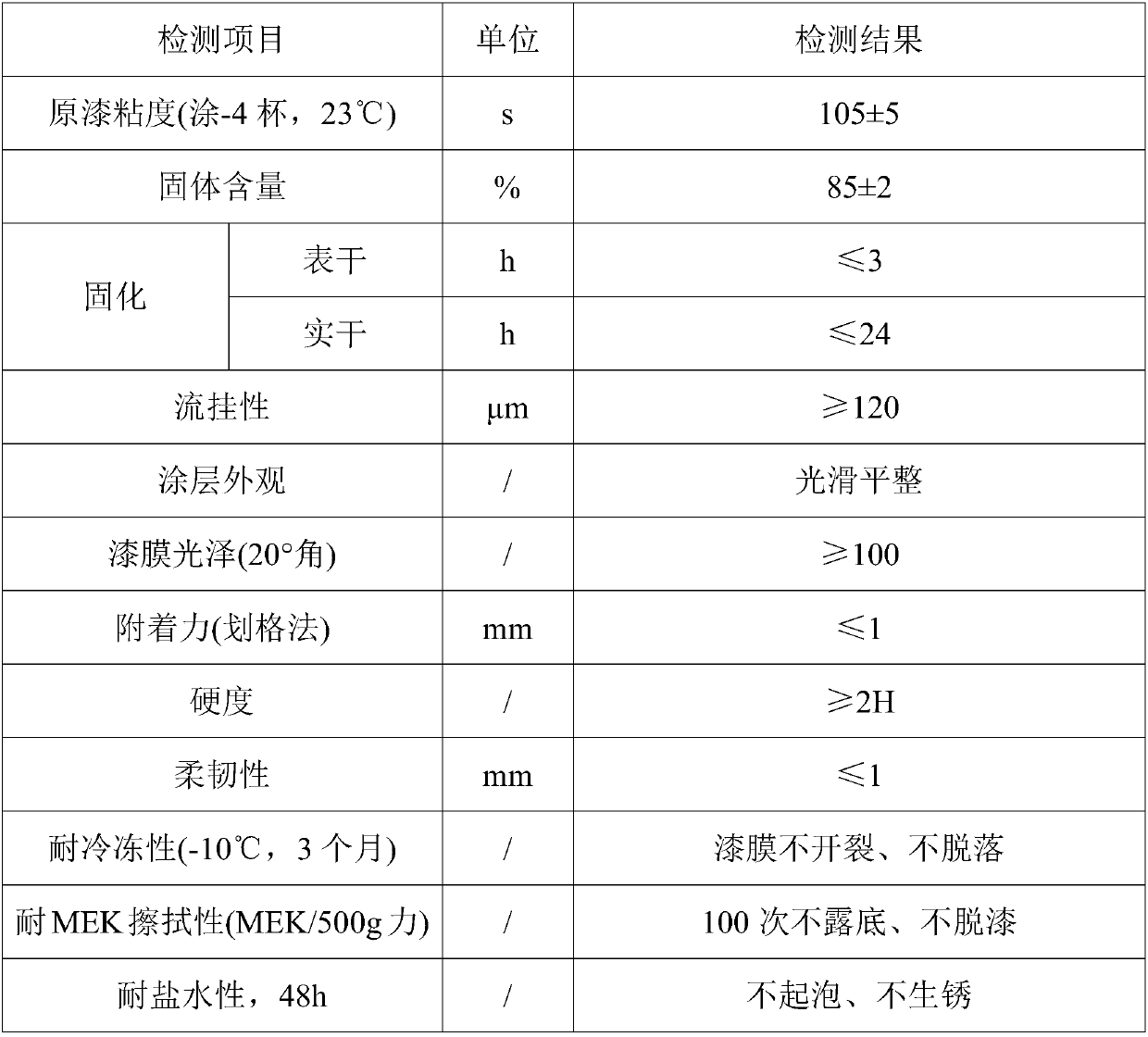

Image

Examples

Embodiment 1

[0018] A high-stability water-based epoxy resin coating for wood, including A component and B component, the weight ratio of A component and B component is 10:1;

[0019] The raw materials of component A include by weight: 120 parts of bisphenol A epoxy resin, 10 parts of water-based polyurethane emulsion, 50 parts of filler, 4 parts of composite dispersant, 4 parts of stearic acid, 4 parts of polyethylene glycol, 5 parts of defoaming agent, 3 parts of wetting agent, 4 parts of leveling agent; wherein the filler includes by weight: 6 parts of glass fiber, 8 parts of microencapsulated red phosphorus, 4 parts of aluminum hydroxide, and 10 parts of hollow glass microspheres Parts, 3 parts of precipitated barium sulfate, 7 parts of calcined kaolin, 1 part of magnesium oxide;

[0020] The raw materials of component B include by weight: 18 parts of water-based curing agent, 2 parts of ethylene glycol butyl ether acetate, 6 parts of alcohol ester twelve, and 30 parts of deionized wat...

Embodiment 2

[0023] A high-stability water-based epoxy resin coating for wood, including A component and B component, the weight ratio of A component and B component is 10:2;

[0024] The raw materials of component A include by weight: 80 parts of bisphenol A type epoxy resin, 22 parts of water-based polyurethane emulsion, 40 parts of filler, 8 parts of composite dispersant, 2 parts of stearic acid, 7 parts of polyethylene glycol, 2 parts of defoaming agent, 4 parts of wetting agent, 2 parts of leveling agent; wherein the filler includes by weight: 12 parts of glass fiber, 4 parts of microencapsulated red phosphorus, 8 parts of aluminum hydroxide, and 4 parts of hollow glass microspheres Parts, 7 parts of precipitated barium sulfate, 4 parts of calcined kaolin, 3 parts of magnesium oxide;

[0025] The raw materials of component B include by weight: 10 parts of water-based curing agent, 4 parts of ethylene glycol butyl ether acetate, 4 parts of alcohol ester twelve, and 50 parts of deionize...

Embodiment 3

[0028] A high-stability water-based epoxy resin coating for wood, comprising A component and B component, the weight ratio of A component and B component is 10:1.2;

[0029] The raw materials of component A include by weight: 110 parts of bisphenol A epoxy resin, 16 parts of water-based polyurethane emulsion, 48 parts of filler, 5 parts of composite dispersant, 3.5 parts of stearic acid, 5 parts of polyethylene glycol, 4 parts of defoaming agent, 3.2 parts of wetting agent, 3.5 parts of leveling agent; wherein the filler includes by weight: 8 parts of glass fiber, 7 parts of microencapsulated red phosphorus, 5 parts of aluminum hydroxide, and 8 parts of hollow glass microspheres Parts, 4 parts of precipitated barium sulfate, 6 parts of calcined kaolin, 1.5 parts of magnesium oxide;

[0030] The raw materials of component B include by weight: 16 parts of water-based curing agent, 2.5 parts of ethylene glycol butyl ether acetate, 5.5 parts of alcohol ester twelve, and 35 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com