Catalyst used for synthesis of paraxylene through alkylation reactions between coking benzene and methanol and preparation method thereof

A p-xylene and catalyst technology, applied in the field of catalysts, can solve the problems of increased raw material costs, catalyst poisoning and deactivation, and inability to use directly, and achieve the effects of improving activity and selectivity, being less likely to be poisoned and deactivated, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

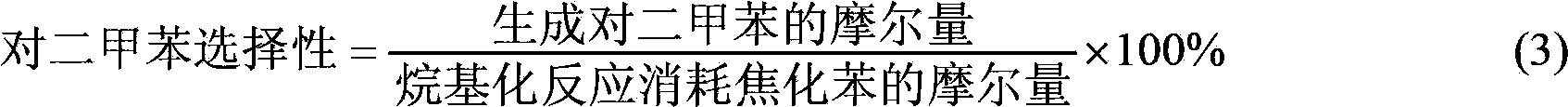

Method used

Image

Examples

Embodiment 1

[0031] Heat the HZSM-5 molecular sieve with a silicon-aluminum ratio of 300:1 and a particle size of 150nm in high-temperature water vapor at 550°C for 0.5 hours; take 6g of the HZSM-5 molecular sieve after the above treatment, add 0.2g of zinc oxide and 2g After uniform mixing with water, kneading and extruding into rods, drying at 80°C for 6 hours, and calcining at 300°C for 8 hours to obtain Catalyst 1.

Embodiment 2

[0033] Heat the SAPO-11 molecular sieve with a silicon-aluminum ratio of 10:1 and a particle size of 600nm in high-temperature water vapor at 300°C for 4 hours; take 10 g of the above-mentioned treated SAPO-11 molecular sieve and impregnate it in 4mol / L chromium nitrate After 2 hours in a mixed solution composed of magnesium sulfate with 6mol / L, dry at 160°C for 0.5 hour, and roast at 600°C for 2 hours to obtain catalyst 2, wherein the content of SAPO-11 molecular sieve is 76.9wt%, and the content of chromium oxide is 9.2wt%, the content of magnesium oxide is 13.9wt%.

Embodiment 3

[0035] The HZSM-5 molecular sieve with a silicon-aluminum ratio of 350:1 and a particle size of 100 nm was heat-treated in high-temperature water vapor at 400° C. for 3 hours; 5 g of the HZSM-5 molecular sieve after the above-mentioned treatment was added, and 0.5 g of nickel oxide and 2 g of After uniform mixing with water, kneading and extruding into rods, drying at 70°C for 8 hours, and calcining at 120°C for 10 hours to obtain catalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com