Polyacrylate grafted vinyl chloride composite resin and preparation method thereof

A polyacrylate and composite resin technology, applied in the field of composite resin, can solve the problems of poor processing performance, copolymer resin tensile strength, modulus drop, poor weather resistance of copolymer resin, etc., and achieve high notched impact strength and processing fluidity Excellent, the effect of increasing the interface binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of polyacrylate latex:

[0032] In a nitrogen atmosphere, use deionized water as a solvent, add sodium dodecylbenzenesulfonate, potassium persulfate, ammonium bicarbonate, and butyl acrylate to the solvent, and polymerize at 65°C for 2 hours to prepare polyacrylate latex ;

[0033] The dosage of each ingredient is as follows:

[0034]

[0035] (2) Preparation of polyacrylate grafted vinyl chloride composite resin:

[0036] Nitrogen replaced the air in the reactor, and added deionized water, polyacrylate latex, sodium bicarbonate, hydroxypropyl methylcellulose, and cumyl peroxide neodecanoate in turn to the reactor, and stirred evenly; then Add vinyl chloride and react at 0.65MPa and 45°C; stop the reaction when the pressure of the reactor drops to 0.6MPa, discharge, dehydrate, and dry to obtain polyacrylate grafted vinyl chloride composite resin;

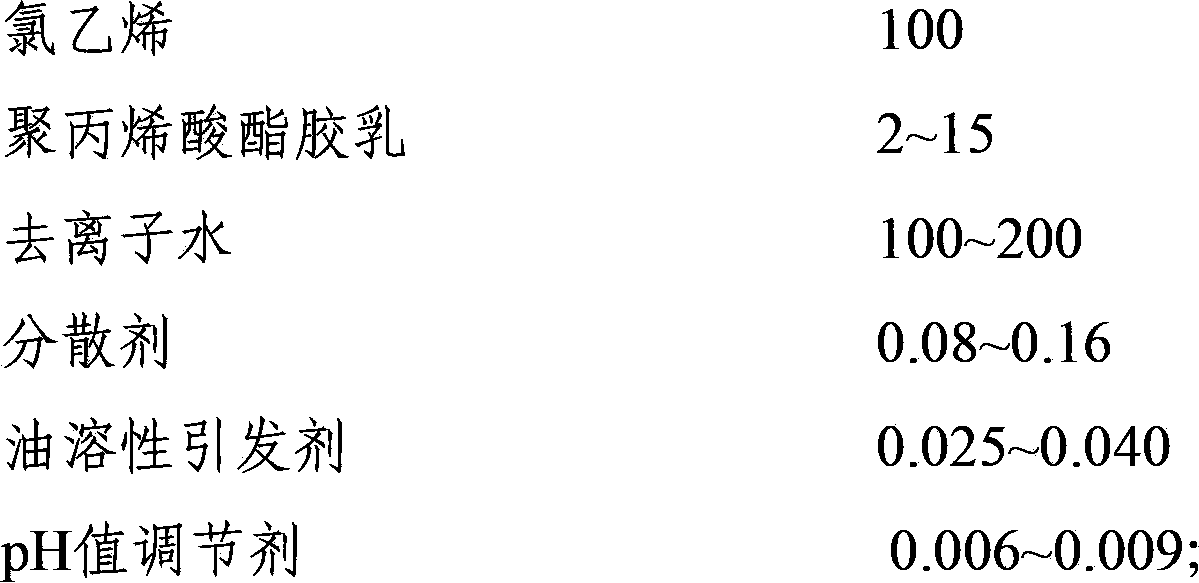

[0037] The dosage of each ingredient is as follows:

[0038]

Embodiment 2

[0040](1) Preparation of polyacrylate latex:

[0041] In a nitrogen atmosphere, use deionized water as a solvent, add sodium lauryl sulfate, ammonium persulfate, sodium hydroxide, and 2-ethylhexyl acrylate to the solvent, and polymerize at 95°C for 1 hour to prepare polyacrylic acid Ester latex;

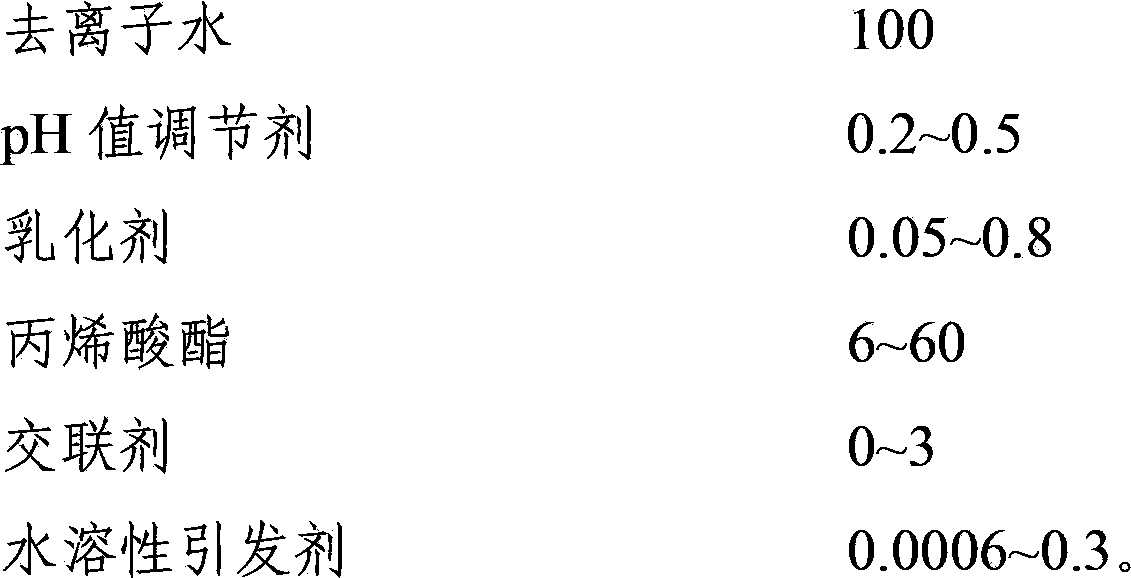

[0042] The dosage of each ingredient is as follows:

[0043]

[0044] (2) Preparation of polyacrylate grafted vinyl chloride composite resin:

[0045] Replace the air in the reaction kettle with nitrogen, add deionized water, polyacrylate latex, sodium hydroxide, polyvinyl alcohol, dibenzoyl peroxide and dibutyltin dilaurate to the reaction kettle in sequence, and stir evenly; then add chlorine Ethylene, react at 1.05MPa and 65°C; stop the reaction when the pressure of the reactor is reduced to 0.6MPa, discharge, dehydrate, and dry to obtain polyacrylate grafted vinyl chloride composite resin;

[0046] The dosage of each ingredient is as follows:

[0047]

Embodiment 3

[0049] (1) Preparation of polyacrylate latex:

[0050] In a nitrogen atmosphere, using deionized water as a solvent, adding sodium dodecylsulfonate, ammonium persulfate, sodium carbonate and a mixture of isobutyl acrylate and 1,4-butanediol diacrylate to the solvent, Polyacrylate latex was prepared by polymerizing at 80°C for 2 hours;

[0051] The dosage of each ingredient is as follows:

[0052]

[0053]

[0054] (2) Preparation of polyacrylate grafted vinyl chloride composite resin:

[0055] Nitrogen replaced the air in the reaction kettle, and added deionized water, polyacrylate latex, sodium carbonate, methylcellulose, azobisisobutyronitrile and fatty acid zinc to the reaction kettle in sequence, and stirred evenly; then added vinyl chloride, and React at 1.05MPa and 65°C; stop the reaction when the pressure of the reactor drops to 0.6MPa, discharge, dehydrate, and dry to obtain polyacrylate grafted vinyl chloride composite resin;

[0056] The dosage of each ingre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com