Ultraviolet-cured adhesive, preparation method therefor and application of ultraviolet-cured adhesive

A technology of curing glue and ultraviolet light, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., which can solve the problems of poor weather resistance, inability to take into account toughness, adhesion, temperature resistance and moisture resistance, Insufficient adhesion and other problems, to achieve the effect of temperature resistance balance, moisture resistance balance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

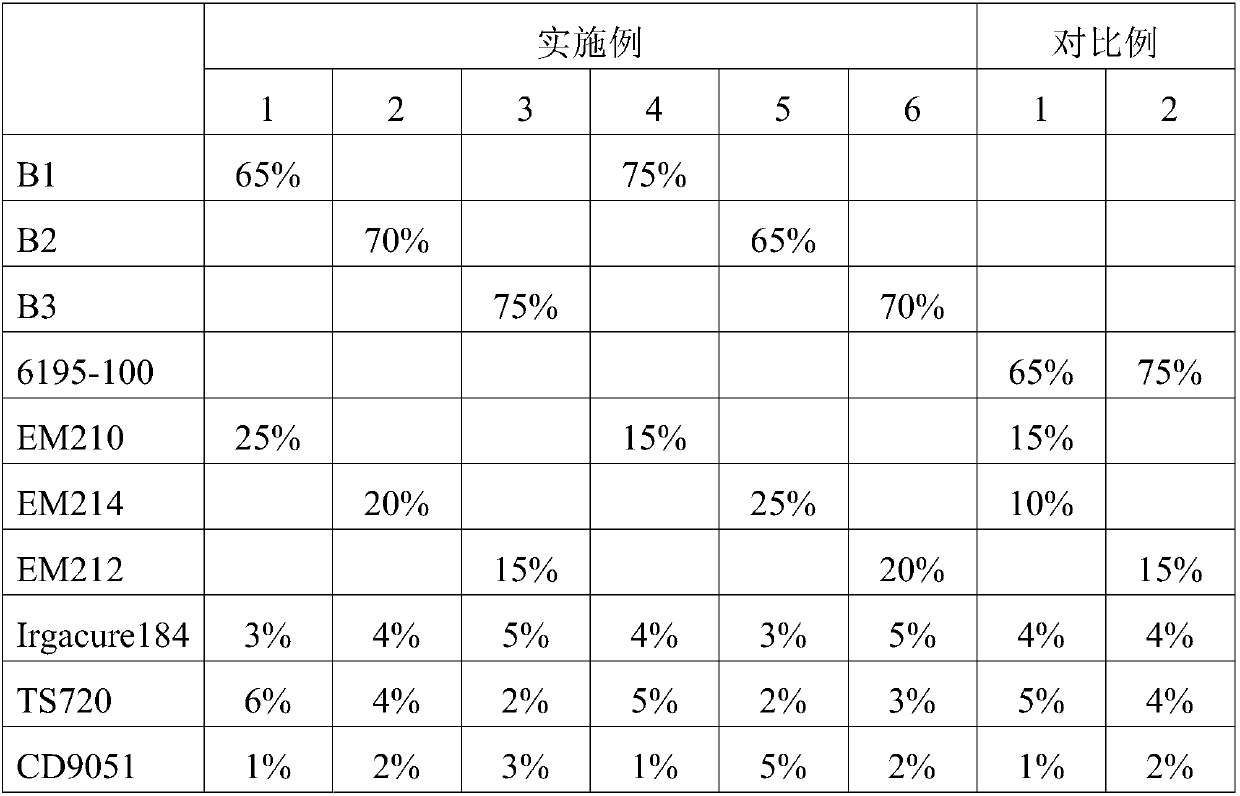

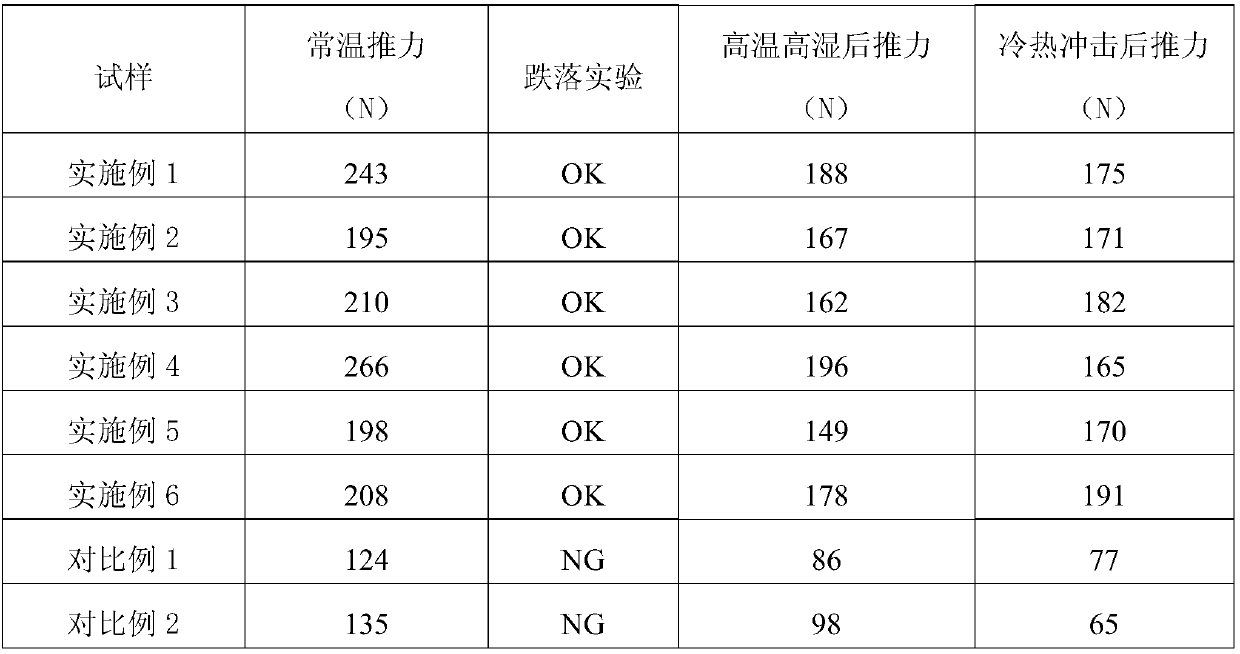

Method used

Image

Examples

Synthetic example 1

[0041] In a 500 ml glass four-necked flask equipped with a stirrer, a thermometer and a condenser tube, add 93 grams of VORANOL 2070 (Dow Chemical, average molecular weight 700, functionality 3, medium molecular weight triol), 2,2-dihydroxy 375 grams of methylpropionic acid, 0.47 grams of p-toluenesulfonic acid, the temperature of the kettle was raised to 142 ° C for 2 hours with stirring, and then the reaction was carried out under reduced pressure distillation until the acid value was below 9 mg / g KOH, and the terminal was obtained after cooling and purification. Hydroxyl hyperbranched polyether polyester A1.

[0042] In a 500 ml clean and dry glass four-necked flask equipped with a stirrer, a thermometer and a condenser tube, add 140 g of toluene-2,4-diisocyanate, 104 g of hydroxypropyl acrylate, 0.25 g of hydroquinone and 0.3 gram of dibutyltin dilaurate, 125 milliliters of acetone, measure the initial NCO value, react at room temperature for 3 hours, heat up to 48°C to co...

Synthetic example 2

[0044] In a 500 ml glass four-neck flask equipped with a stirrer, a thermometer and a condenser tube, add 200 grams of VORANOL 2120 (Dow Chemical, average molecular weight 2000, functionality 2, polypropylene glycol), 2,2-dimethylol 187.5 grams of propionic acid, 0.39 grams of p-toluenesulfonic acid, the temperature of the kettle was raised to 145 ° C for 2.5 hours under stirring, and then the reaction was carried out under reduced pressure distillation until the acid value was below 9 mg / g KOH. Polyether polyester A2.

[0045] In a 500 ml clean and dry glass four-neck flask equipped with a stirrer, a thermometer and a condenser tube, add 140 grams of toluene-2,4-diisocyanate, 92.8 grams of hydroxyethyl acrylate, 0.3 grams of p-hydroxyanisole and 0.3 g of dibutyltin dilaurate, 150 ml of acetone, measure the initial NCO value, react at room temperature for 2 hours, then raise the temperature to 55°C to continue the reaction, stop when the NCO value is half of the initial value,...

Synthetic example 3

[0047] In a 500 ml glass four-neck flask equipped with a stirrer, a thermometer and a condenser tube, add 200 grams of VORANOL 222-056 (Dow Chemical, average molecular weight 2000, functionality: 2, polyethylene glycol), 2,2- 187.5 grams of dimethylolpropionic acid, 0.39 grams of p-toluenesulfonic acid, the temperature of the kettle was raised to 135 ° C for 3 hours under stirring, and then the reaction was carried out under reduced pressure distillation until the acid value was below 9 mg / g KOH, after cooling and purification The hydroxyl-terminated hyperbranched polyether polyester A3 was obtained.

[0048] In a 500 ml clean and dry glass four-necked flask equipped with a stirrer, a thermometer and a condenser tube, add 140 g of toluene-2,4-diisocyanate, 104 g of hydroxypropyl acrylate, 0.25 g of hydroquinone and 0.25 gram of dibutyltin dilaurate, 150 milliliters of acetone, measure the initial NCO value, react at room temperature for 4 hours, heat up to 45°C to continue the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com