Screen printing peelable UV (ultraviolet) ink as well as preparation method and application of screen printing peelable UV ink

A technology of screen printing and ink, applied in the direction of ink, application, household utensils, etc., can solve the problem that it is difficult to meet the higher requirements of the mechanical properties of the cured film, achieve good surface protection and peelability, and facilitate coating operations way, to meet the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

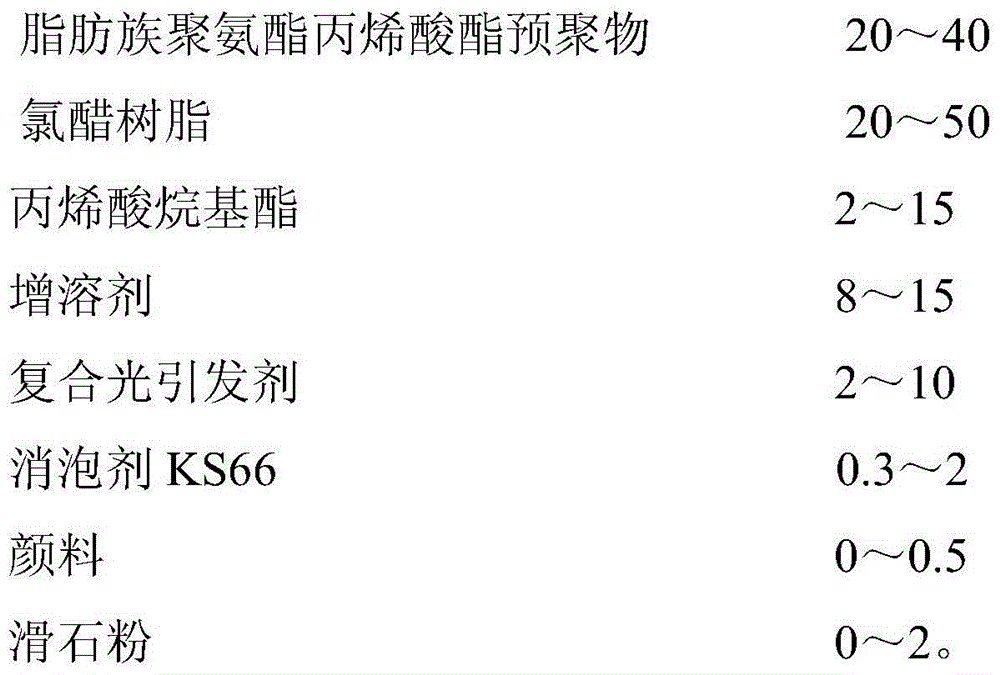

Method used

Image

Examples

Embodiment 1

[0038] A kind of screen printing peelable UV ink, prepared by the following method:

[0039] (1) 20 parts by mass of U25-20d, 15 parts by mass of BR32, 32 parts by mass of vinyl chloride resin (L14 / 60), 4 parts by mass of octadecyl methacrylate, 6.5 parts by mass of dioctyl adipate, 3 parts by mass of ITX, 2 parts by mass of EDB, 0.6 parts by mass of KS66, 0.5 parts by mass of phthalocyanine blue and 2 parts by mass of talc powder were mixed by a high-speed disperser at a speed of 30 rpm for 20 minutes to obtain an initial mixture;

[0040] (2) The initial mixed liquid is finely ground by a three-roller machine, and finally passed through the fineness test (GB / T6753.1-2007), and the obtained uniform and fine fluid is the peelable UV ink for screen printing. The fineness of the particles in the ink is not greater than 5 microns.

Embodiment 2

[0042] A kind of screen printing peelable UV ink, prepared by the following method:

[0043](1) 15 parts by mass of U25-20d, 5 parts by mass of BR32, 50 parts by mass of vinyl chloride resin (CP427), 2 parts by mass of octadecyl acrylate, 3 parts by mass of PEG600DA, 12 parts by mass of dioctyl sebacate , 1.2 parts by mass of ITX, 0.8 parts by mass of EDB, 0.3 parts by mass of KS66 and 0.5 parts by mass of phthalocyanine blue pigment were mixed at a speed of 30 rpm for 20 minutes by a high-speed disperser to obtain an initial mixture;

[0044] (2) The initial mixed liquid is finely ground by a three-roller machine, and finally passed through the fineness test (GB / T6753.1-2007), and the obtained uniform and fine fluid is the peelable UV ink for screen printing. The fineness of the particles in the ink is not greater than 5 microns.

Embodiment 3

[0046] A kind of screen printing peelable UV ink, prepared by the following method:

[0047] (1) 10 parts by mass of U25-20d, 30 parts by mass of BR32, 20 parts by mass of vinyl chloride resin (L3112), 15 parts by mass of octadecyl acrylate, 3 parts by mass of PEG600DA, 12 parts by mass of dioctyl sebacate , 6 parts by mass of ITX, 4 parts by mass of EDB, 2 parts by mass of KS66 and 2 parts by mass of talcum powder were mixed for 20 minutes at a speed of 30 rpm by a high-speed disperser to obtain an initial mixture;

[0048] (2) The initial mixed liquid is finely ground by a three-roller machine, and finally passed through the fineness test (GB / T6753.1-2007), and the obtained uniform and fine fluid is the peelable UV ink for screen printing. The fineness of the particles in the ink is not greater than 5 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com