Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High retention rate of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Immersion-resistant single-component deacidified organic silicon sealant composition and preparation method thereof

ActiveCN105295828AGood adhesionEnsure safetyNon-macromolecular adhesive additivesOther chemical processesSilicon dioxideFumed silica

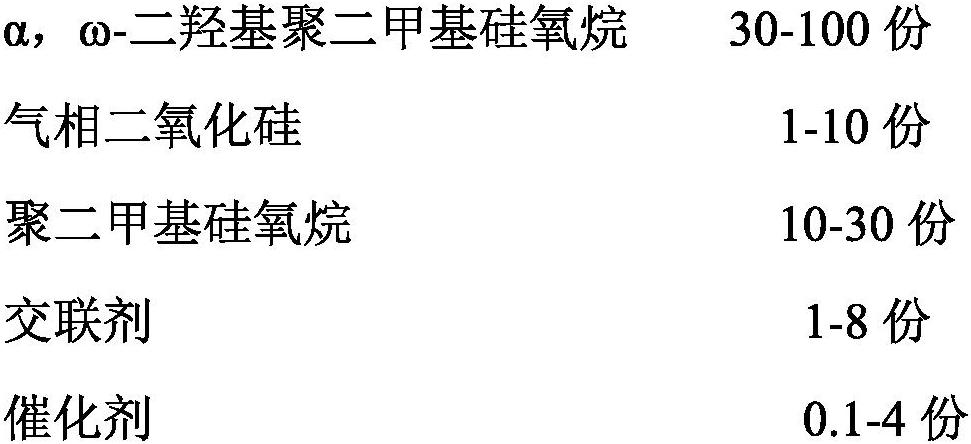

The invention discloses an immersion-resistant single-component deacidified organic silicon sealant composition and a preparation method thereof. The composition comprises the following components in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethyl siloxane, 5-50 parts of fumed silica, 10-30 parts of polydimethylsiloxane, 5-15 parts of a crosslinking agent, 0.01-0.5 part of a catalyst, 1-5 parts of a waterproof agent and 0.1-1 part of a tackifier. The single-component deacidified organic silicon sealant has excellent adhesive property, and the safety and stability of the single-component deacidified organic silicon sealant in the using process are ensured; and the single-component deacidified organic silicon sealant still has excellent adhesive property with a base material after being subjected to long-term immersion or short-term high-temperature boiling treatment and is high in mechanical property retention rate and better in waterproofness as comparison with a common silicone sealant.

Owner:CHENGDU GUIBAO SCI & TECH

A polarity-modified polypropylene composite material and a preparing method thereof

InactiveCN104086894AIncrease polarityHigh retention rate of mechanical propertiesPolypropylene compositesAdhesion force

A polarity-modified polypropylene composite material and a preparing method thereof are disclosed. The composite material comprises following components by weight: 60-90% of polypropylene, 5-15% of a flexibilizer, 0-30% of a mineral filling material, 1-3% of a polarity additive, 0.1-0.3% of an assistant polarity additive, 0.4-3% of an anti-ageing agent and 0-0.5% of a coloring agent. The assistant polarity additive is a nonionic ester type surfactant. According to the composite material and the preparing method thereof, by addition of an extremely low amount of the polarity additive and the assistant polarity additive, the adhesion force of the composite material and a coating is enhanced and the composite material maintains excellent mechanical properties. The method can be performed by adoption of a double-screw extruder at present and has characteristics of simple preparation, easy implementation and operation, easy industrial production and wide application prospect.

Owner:CGN JUNER NEW MATERIALS +1

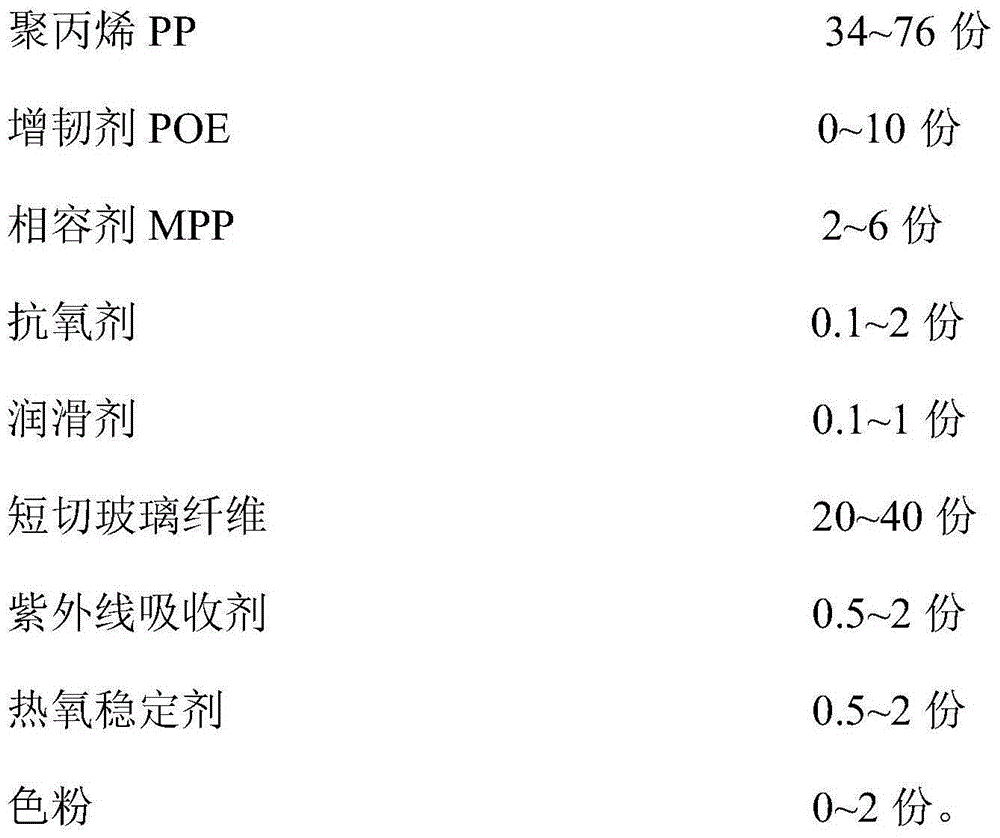

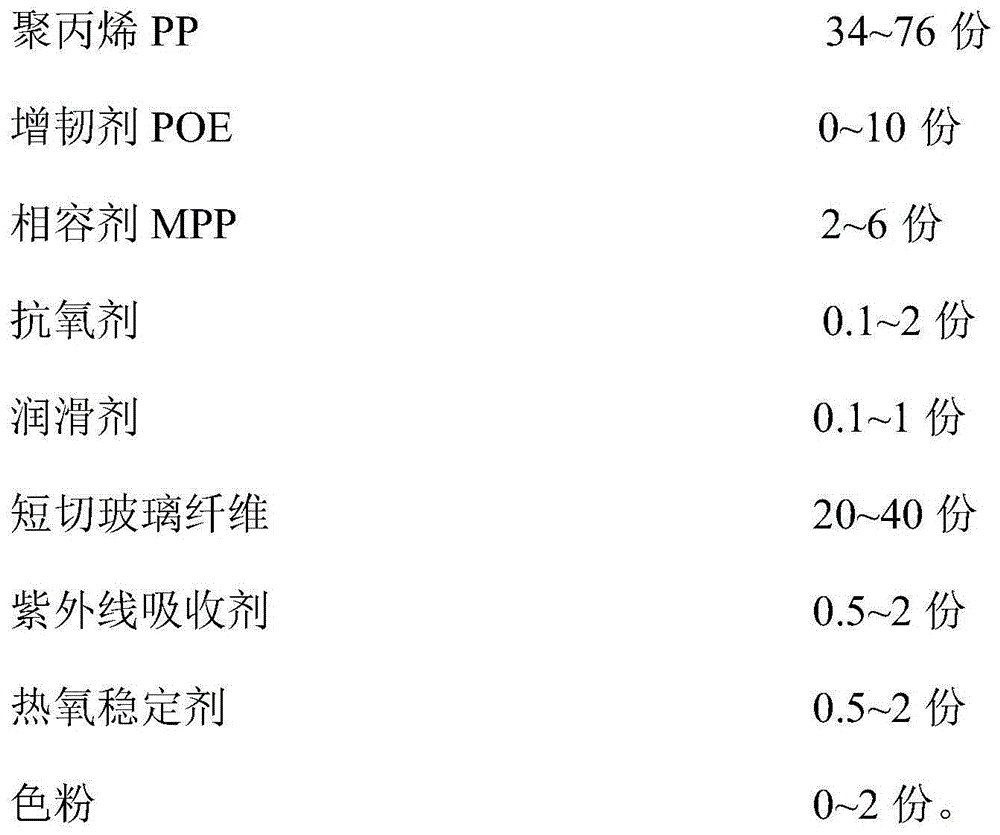

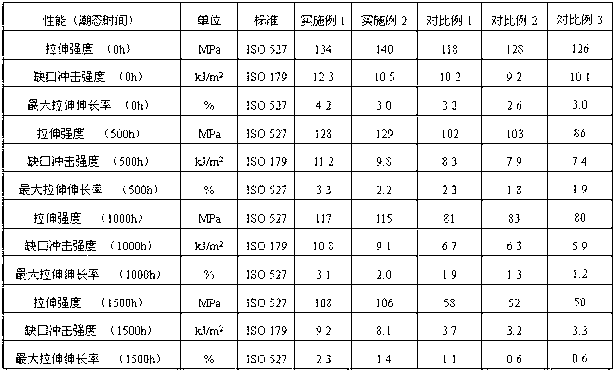

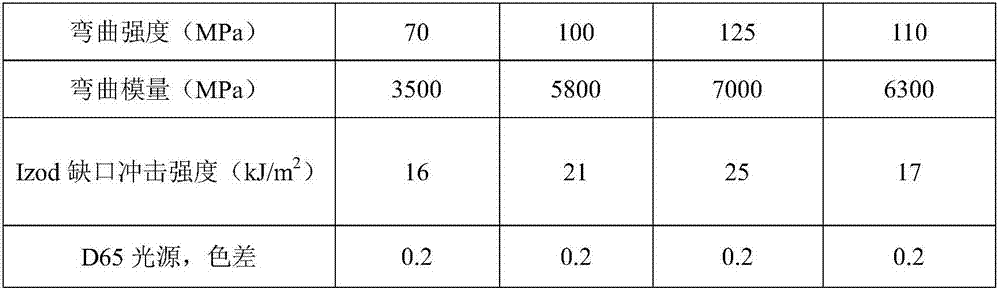

High-weather-resistant anti-aging glass fiber reinforced polypropylene material and preparation method thereof

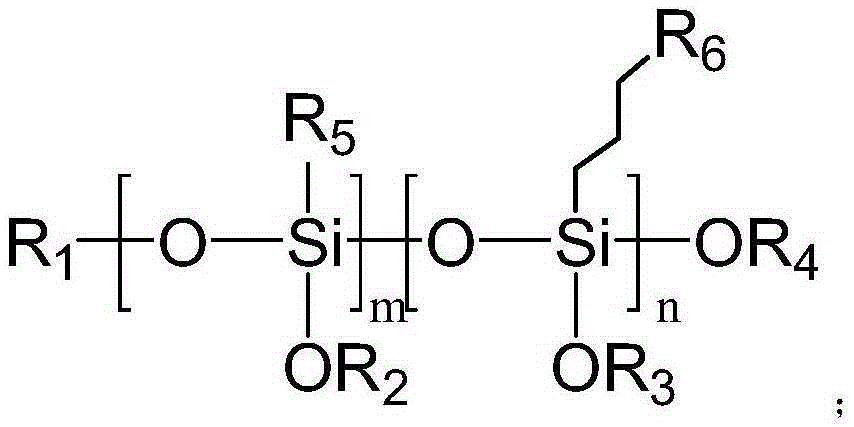

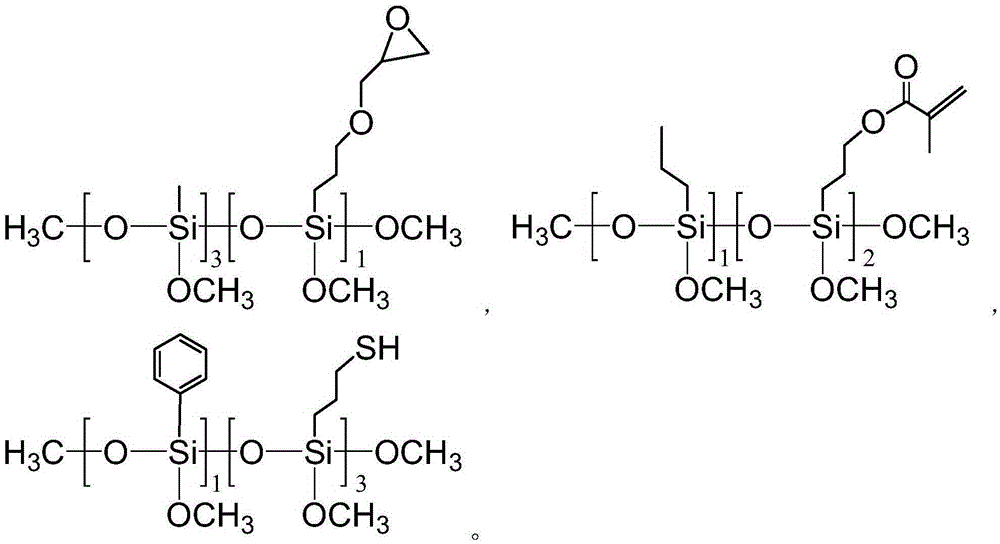

The invention discloses a high-weather-resistant anti-aging glass fiber reinforced polypropylene material. Through the synergistic action of such components of the material as polypropylene (PP), a chopped glass fiber, a compatible flexibilizer, an anti-oxidant, a lubricant, a coupling agent, one or more ultraviolet light absorbers, a thermo-oxidative stabilizer and one or more toners, as well as reasonable selection of specific components in parts by weight, changes in the color difference of color glass fiber reinforced PP can be greatly reduced under the light-heat aging condition, and the mechanical property retention rate can be high; when the material is applied to automobile parts, household appliances and other products, the problems that the product properties are degraded and the product colors are changed due to long-term exposure of such products in the open air or a high-temperature environment can be effectively solved. The invention further discloses a preparation method of the material. The preparation method is simple to operate, low in cost and high in production benefit; the material obtained according to the preparation method is high in mechanical property, retention rate and color stability, and very suitable for industrialized production; through the preparation method, not only can the service life of the material be prolonged, but also environmental pollution can be reduced.

Owner:NANJING LIHUA ENG PLASTIC

Glass-fiber-reinforced hydrolysis-resistant polyester material and preparation method thereof

InactiveCN102702699AGood mechanical propertiesHigh retention rate of mechanical propertiesPolyesterGlass fiber

The invention provides a glass-fiber-reinforced hydrolysis-resistant polyester material which is prepared from the following raw materials in percentage by weight: 30-80% of polyester, 5-40% of glass fiber, 3-10% of compatilizer, 0.3-20% of hydrolytic reagent, 0.1-0.5% of antioxidant and 0.1-0.5% of lubricant. The invention also provides a preparation method of the glass-fiber-reinforced hydrolysis-resistant polyester material, which comprises the following steps: mixing the raw materials according to the percentage by weight, putting in a screw rod machine, extruding, and cooling with water to granulate, wherein the rotation speed of the screw rod machine is 180-600 rpm, and the temperature is 235-255 DEG C. The material provided by the invention has the advantages of better mechanical properties, high hydrolysis resistance, high mechanical property retentivity, favorable flowability, fewer surface floating fibers, excellent processability and low cost, and has very wide application prospects in the fields of electronics, electricity, automobiles, home appliances and the like.

Owner:SHANGHAI SUNNY

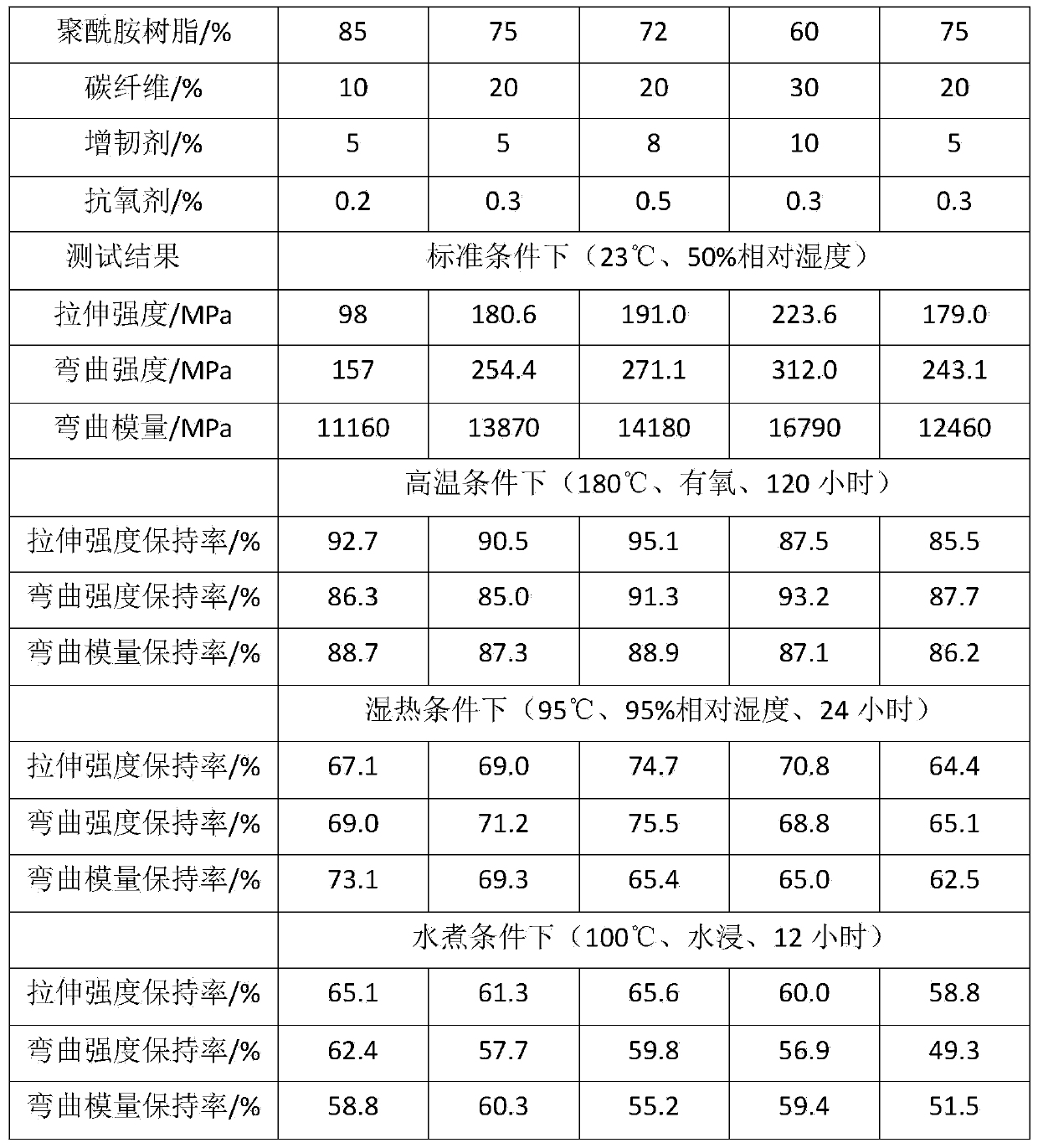

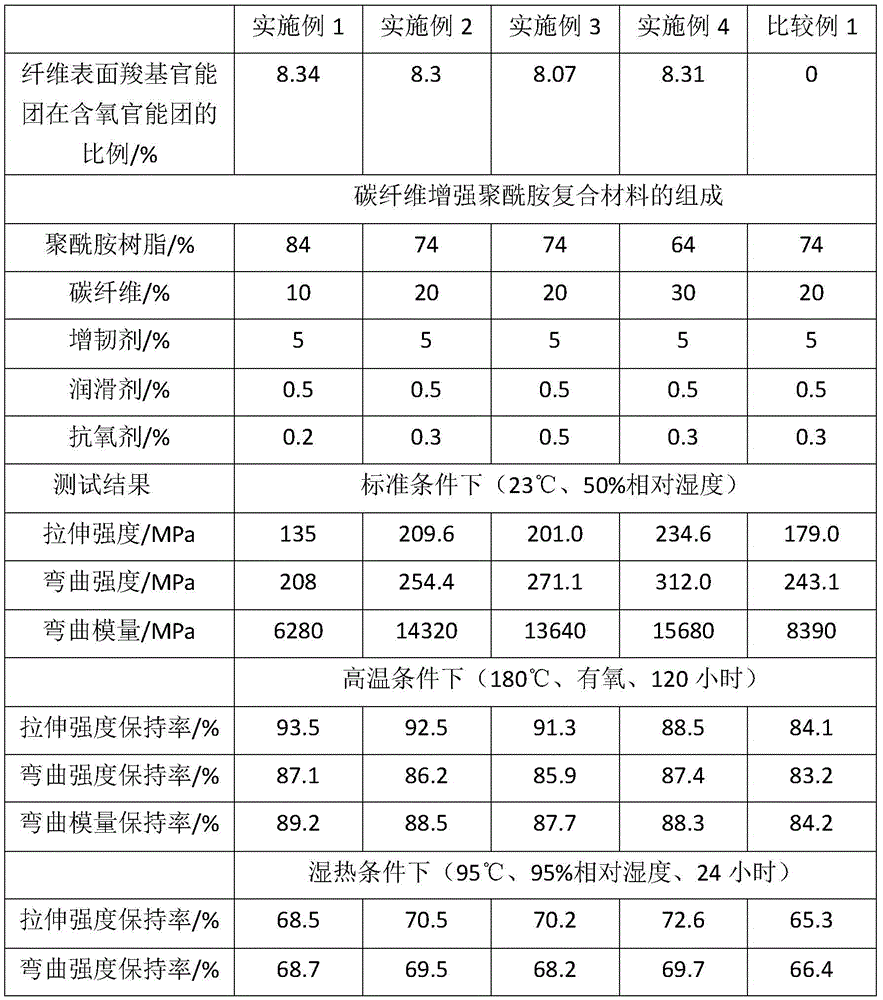

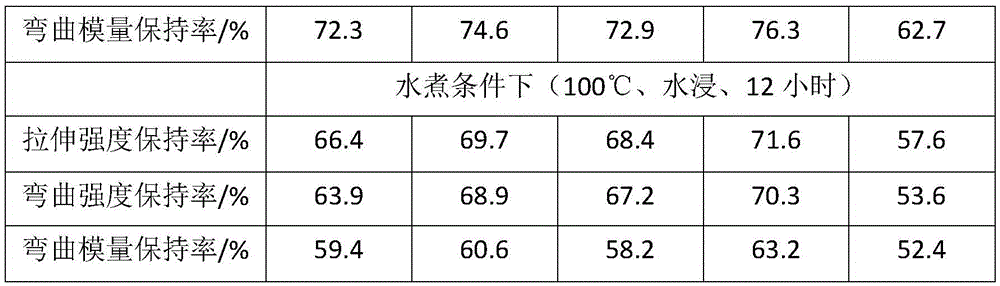

High-rigidity high-durability carbon fiber enhanced polyamide composite material and preparation method thereof

The invention discloses a high-rigidity high-durability carbon fiber enhanced polyamide composite material and a preparation method thereof. The high-rigidity high-durability carbon fiber enhanced polyamide composite material is prepared from the following raw materials by weight percent: 60-90% of polyamide resin, 5-10% of flexibilizer, and 10-30% of surface treated carbon fibers, wherein the surface treated carbon fibers are carbon fibers treated with a polyurethane prepolymer previously. Compared with the prior art, the high-rigidity high-durability carbon fiber enhanced polyamide composite material has the advantages that on one hand, no any solvent is used in the surface treatment process of the carbon fibers, the process is simple, the attachment effect of the polyurethane prepolymer on the surface of the fibers is good and an excellent bonding interface layer can be provided for the composite material, and on the other hand, the interface debonding phenomenon caused by factors such as moisture diffusion and thermal expansion is effectively prevented by virtue of effective fiber surface treatment, and as a result, the durability of the composite material in complex environments, especially under a high-humidity condition, is improved.

Owner:ZHEJIANG PRET NEW MATERIALS +2

High polar polypropylene composite material as well as preparation method thereof and application to automobile exterior trim materials

The invention discloses a high polar polypropylene composite material. The raw material composition comprises the following components in percentages by weight: 50-88% of polypropylene, 5-15% of a flexibilizer, 0-30% of a mineral filler, 5-10% of modified polyvinyl chloride, 1-5% of hyperbranched polyesteramide, and 0.1-5% of an auxiliary agent. Modified polyvinyl chloride and hyperbranched polyesteramide are added, so that polarity of the polypropylene composite material is improved, excellent mechanical properties are maintained, and the product can be used as a material special for exteriortrim of automobiles. A preparation method of the high polar polypropylene composite material is provided, and the method employs a double screw extruder for realization, the preparation is simple, the method is easy to carry out and operate, industrial production is easy, and the method has wide application prospects.

Owner:CGN JUNER NEW MATERIALS +1

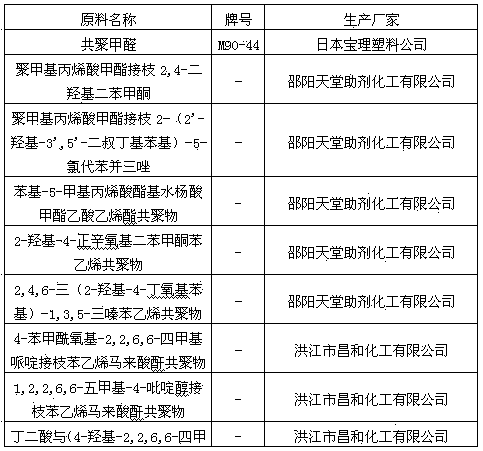

Weather-resistant polyformaldehyde composition and preparation method thereof

The invention discloses a weather-resistant polyformaldehyde composition which is prepared from following raw materials, in a fusion manner, by mass, 91.5-97.5% of a copolymerized polyformaldehyde resin, 0.1-0.6% of a polymerization-type ultraviolet absorbent, 0.1-1.0% of a polymerization-type light stabilizer and 1.0-5.0% of an ultraviolet shield agent. In the polyformaldehyde composition, the large-molecularized ultraviolet absorbent and the large-molecularized light stabilizer are employed with addition of the ultraviolet shield agent, so that the polyformaldehyde composition can effectively absorb, shield and reflect ultraviolet in sun and prevent the ultraviolet from entering the polyformaldehyde, thereby effectively stopping photo-degradation of the polyformaldehyde, avoiding molecule chain interruption to form hydroxyl groups and carboxyl groups, so that the weather resistance of the polyformaldehyde composition is enhanced. In the invention, the ultraviolet absorbent and the light stabilizer are both large-molecularized ultraviolet absorbents so that the polyformaldehyde composition is excellent in weather resistance and meanwhile volatilization and migration of small molecules in an additive can be prevented. The polyformaldehyde composition is prolonged in service life under an illumination environment and a wet and hot environment, is increased in use value and can satisfy requirement in special fields.

Owner:KAILUAN ENERGY CHEM +1

Polypropylene composite flame-retardant material for vehicle interior decoration as well as preparation method and application thereof

ActiveCN110713657AHigh retention rate of mechanical propertiesImprove mechanical propertiesPolypropylene compositesLimiting oxygen index

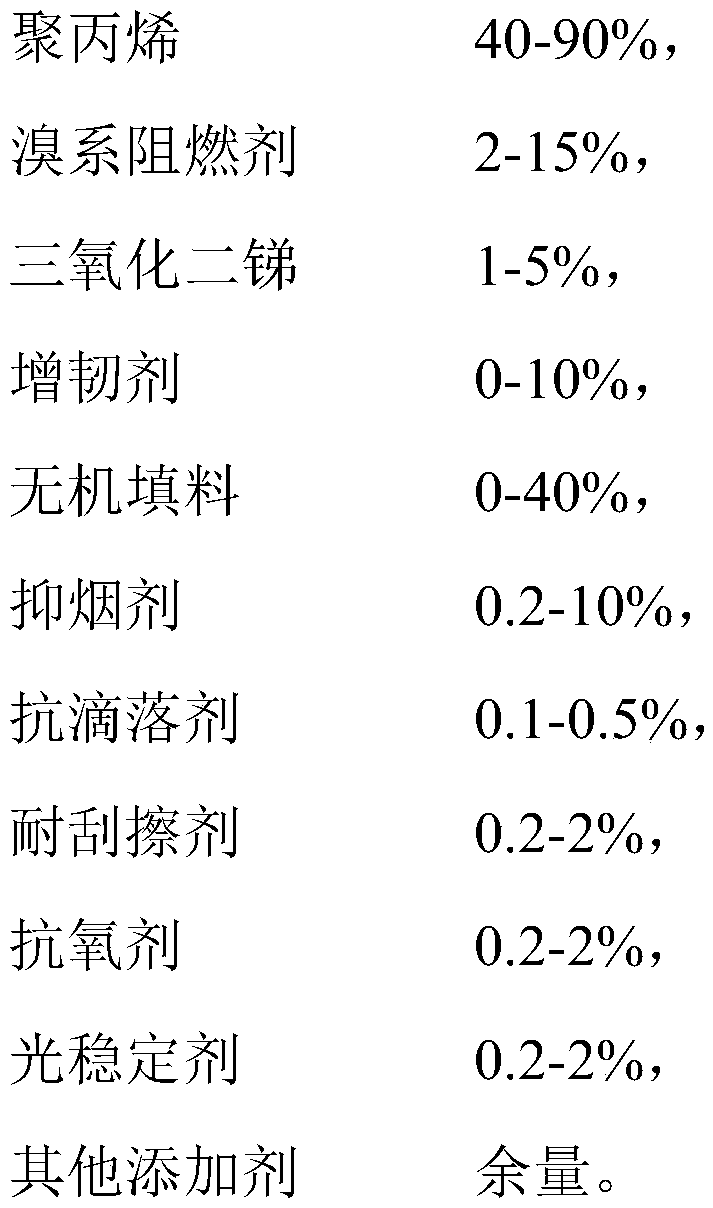

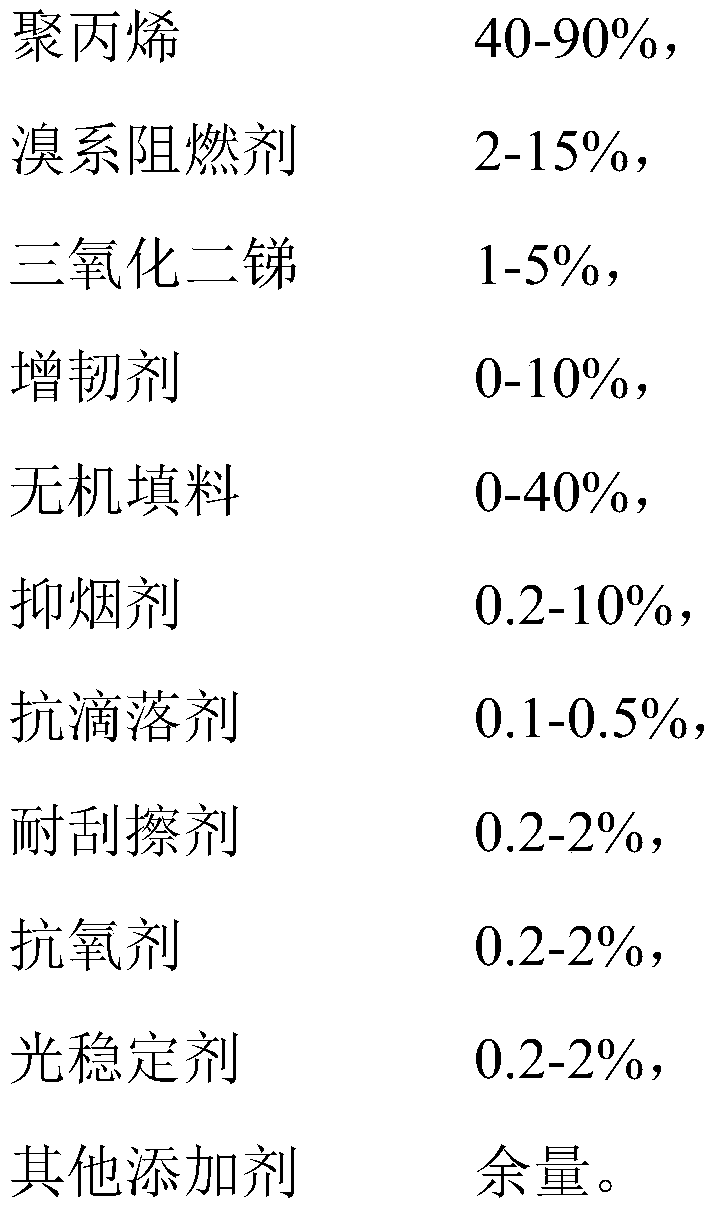

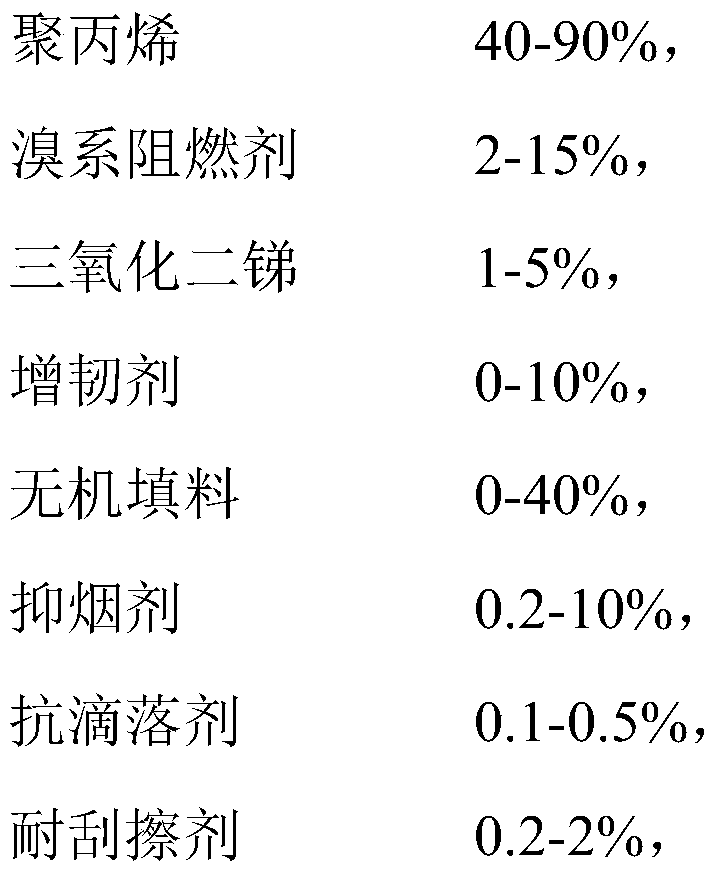

The invention belongs to the technical field of flame retardance, in particular to a polypropylene composite flame-retardant material for vehicle interiors. Based on a condition that the total mass ofthe polypropylene composite flame-retardant material is 100%, the composite flame-retardant material comprises the following raw material components in percentage by mass: 40-90% of polypropylene, 2-15 of a brominated flame retardant, 1-5% of antimonous oxide, 0-10% of a flexibilizer, 0-40% of an inorganic filler, 0.2-10% of a smoke suppressant, 0.1-0.5% of an anti-dripping agent, 0.2-2% of a scratch-resistant agent, 0.2-2% of an antioxidant, 0.2-2% of a light stabilizer and other additives. The polypropylene composite flame-retardant material for vehicle interior decoration has good tensilestrength, bending property, impact strength and other mechanical properties, and also has the properties of high limit oxygen index, low smoke density grade, low odor, low total carbon, light resistance and the like.

Owner:江苏沃特新材料科技有限公司

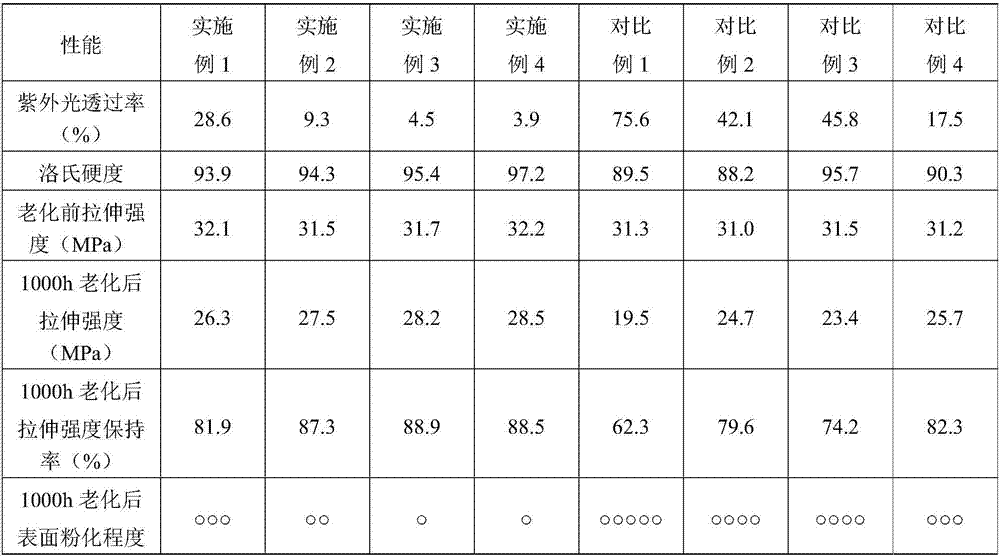

Anti-scratching polypropylene material with ultraviolet aging resistance and preparation method thereof

The invention discloses an anti-ultraviolet aging and scratch-resistant polypropylene material and a preparation method thereof. The anti-ultraviolet aging and scratch-resistant polypropylene material is composed of polypropylene resin, coated nano-titanium dioxide, benzotriazole light stabilizer, inorganic filler, coupling agent, antioxidant and lubricant. At the same time, a preparation method of an anti-ultraviolet aging and scratch-resistant polypropylene material is also disclosed. In the present invention, a layer of dense and uniform silicon dioxide film is coated on the surface of nano-titanium dioxide particles by a liquid-phase deposition method to prepare coated nano-titanium dioxide, which can effectively avoid the degradation of polypropylene substrates by nano-titanium dioxide. The compound use of benzotriazole light stabilizers makes the prepared polypropylene material have strong UV shielding performance, high retention rate of mechanical properties after UV aging for 1000 hours, small degree of pulverization, high surface hardness and scratch resistance The effect is good, and it can be widely used in home appliance shells, automotive interiors and other products.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

High-performance carbon fiber reinforced polyamide composite material and preparation method thereof

InactiveCN105542448AImprove compatibilityHigh retention rate of mechanical propertiesPolyamideMechanical properties of carbon nanotubes

The invention discloses a high-performance carbon fiber reinforced polyamide composite material, which comprises the following components in percentage by weight: 60-85% of polyamide resin, 3-10% of flexibilizer and 10-30% of surface functionalized carbon fiber. The high-performance carbon fiber reinforced polyamide composite material has the beneficial effects that 1. the surface carboxyl functionalization of carbon fiber is realized, the surface structure of the carbon fiber is not damaged in the whole reaction process, the self mechanical property of the carbon fiber is not influenced, and the compatibility between the carbon fiber and a resin matrix can be improved by introducing the surface carboxyl functional group of the carbon fiber; and 2. the interface unsticking phenomenon caused by thermal expansion, water diffusion and other factors can be effectively prevented, and the carbon fiber reinforced polyamide composite material can be guaranteed to have high mechanical property conservation rate in an environment of high temperature and high humidity.

Owner:SHANGHAI PRET COMPOSITES

Non-halogen fire-retardant Nylon 6 and Nylon 66 alloy

A non-halogen fire-retardant nylon6 and nylon66 alloy consists of nylon6 30-65wt%, nylon66 30-65wt%, fire retardantA0.1-15wt%, fire retardantB0.1-15wt%, carbon-forming agent 0.1-2wt%, antioxidant 0.1-1wt% and anti-ultraviolet agent 0.1-1wt%. It has no environmental pollution, has efficient fire-retardant performance, better rigid, heat-resisting performances and stable size. It can be used for various household electrical appliances.

Owner:SHANGHAI SUNNY

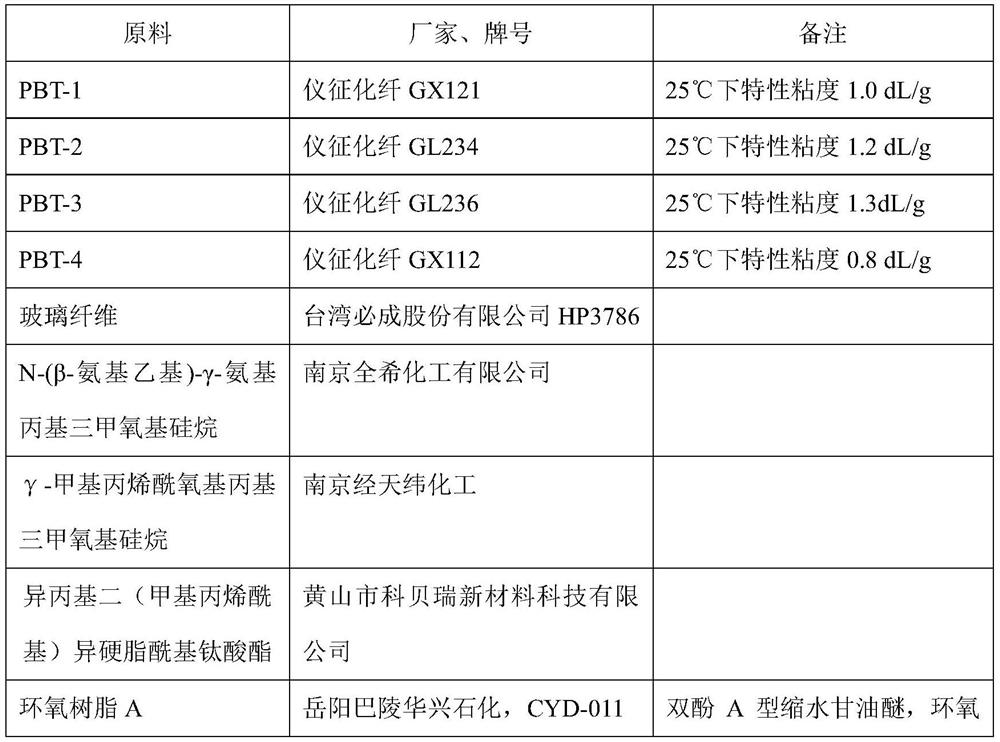

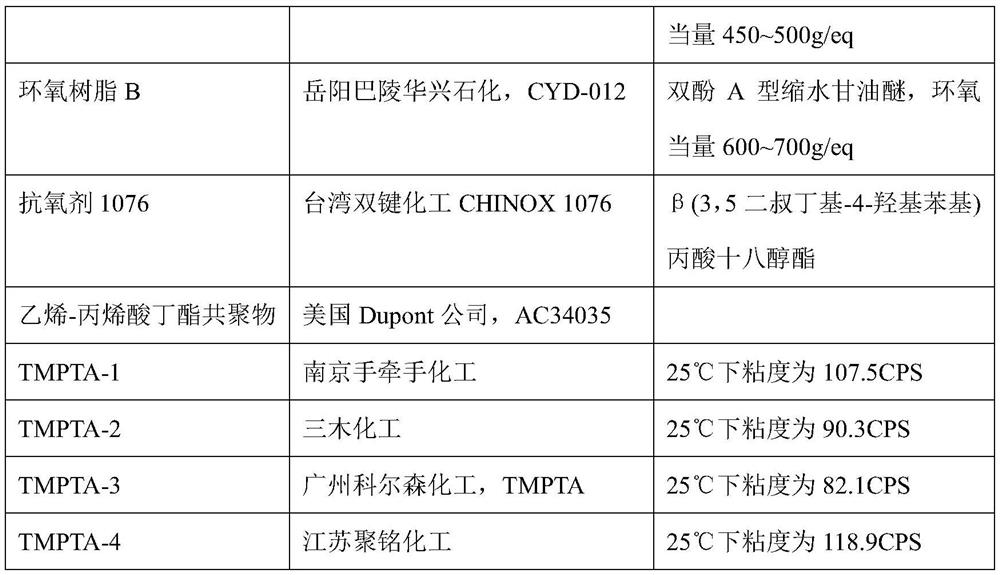

PBT composition resistant to cyclic injection molding, preparation method and product thereof

ActiveCN113583396AHigh retention rate of mechanical propertiesStop breakingPlastic recyclingEpoxyMultiple injection

The invention discloses a PBT composition resistant to cyclic injection molding and a preparation method thereof. The PBT composition resistant to cyclic injection molding is prepared from the following components in parts by weight: 50 to 80 parts of PBT, 10 to 40 parts of glass fiber, 1 to 3 parts of an epoxy resin, 0.1 to 0.3 part of an antioxidant, 2 to 8 parts of an ethylene-butyl acrylate copolymer and 0.5 to 2 parts of trimethylol propane triacrylate. According to the invention, through the synergistic effect of trimethylol propane triacrylate, an ethylene-butyl acrylate copolymer and an epoxy resin, breakage of a PBT molecular chain is effectively prevented, so that the degradation degree of the PBT material in multiple injection molding processes is reduced, and the mechanical property retention rate of the PBT composition after multiple injection molding is further improved; and the mechanical property retention rate of the PBT composition is greater than or equal to 97% after secondary injection molding, the mechanical property retention rate is greater than or equal to 91% after third injection molding, and the PBT composition is suitable for multiple times of cyclic injection molding.

Owner:KINGFA SCI & TECH CO LTD

Method for quickly and efficiently recycling high-performance resin-based carbon fiber composite material

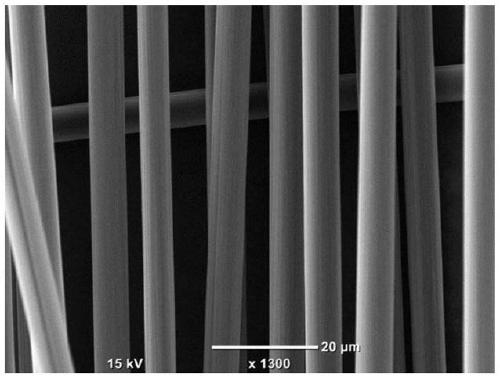

ActiveCN110172177AImprove surface topographyHigh retention rate of mechanical propertiesAcetic acidPotassium hydroxide

The invention discloses a method for quickly and efficiently recycling a high-performance resin-based carbon fiber composite material. The method is used for solving the technical problem of poor practicability of an existing method for recycling the carbon fiber reinforcement resin-based composite material. According to the technical scheme, the method comprises the steps that a waste carbon fiber reinforcement resin-based composite material is put into glacial acetic acid and pretreated for 30-40 minutes at 108-112 DEG C. The pretreated waste carbon fiber reinforcement resin-based compositematerial is put into a drying oven of 90-95 DEG C for being dried, then put into a mixed solution degradation system with dimethyl sulfoxide and potassium hydroxide and degraded for 40-70 minutes at 150-180 DEG C, and the solid product after degradation is separated, cleaned through deionized water and dried. The dried solid product is weighed, and the degradation rate is calculated. According tothe method, the recycle efficiency is high, the conditions are mild, the surface appearance of recycled carbon fibers is good, and the retention rate for the mechanical properties is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Preparation method of light-resistant MDI (diphenyl-methane-diisocyanate) polyurethane

InactiveCN102924901AHigh retention rate of mechanical propertiesExcellent anti-UV light aging performanceCompatibilizationChromatic aberration

According to the invention, a light-resistant MDI (diphenyl-methane-diisocyanate) polyurethane material is prepared by compounding MDI polyurethane, a coupling agent modified nano ZnO and organic anti-aging auxiliary. By adopting the coupling agent modified nano ZnO, the agglomeration phenomenon of the nano particles is reduced, and the dispersibility of nano ZnO and the compatibility with polyurethane are improved. The nano ZnO particle and the organic anti-aging auxiliary are in an excellent synergic effect; and by adding the modified nano ZnO and the organic anti-aging auxiliary, the chromatic aberration change and the gloss change of the MDI polyurethane are reduced, the mechanical performance retention rate is improved, and an unexpected beneficial technical effect is realized. Through the invention, the prepared MDI polyurethane has excellent anti-UV (ultraviolet) light aging performance, and the problem of low light resistance of the existing MDI polyurethane is solved.

Owner:上海井上高分子制品有限公司

Halogen-free flame-retardant polycarbonate/styrene resin alloy as well as preparation method and application thereof

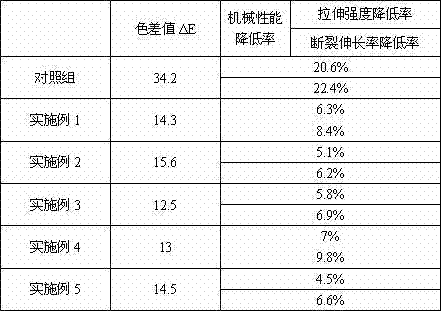

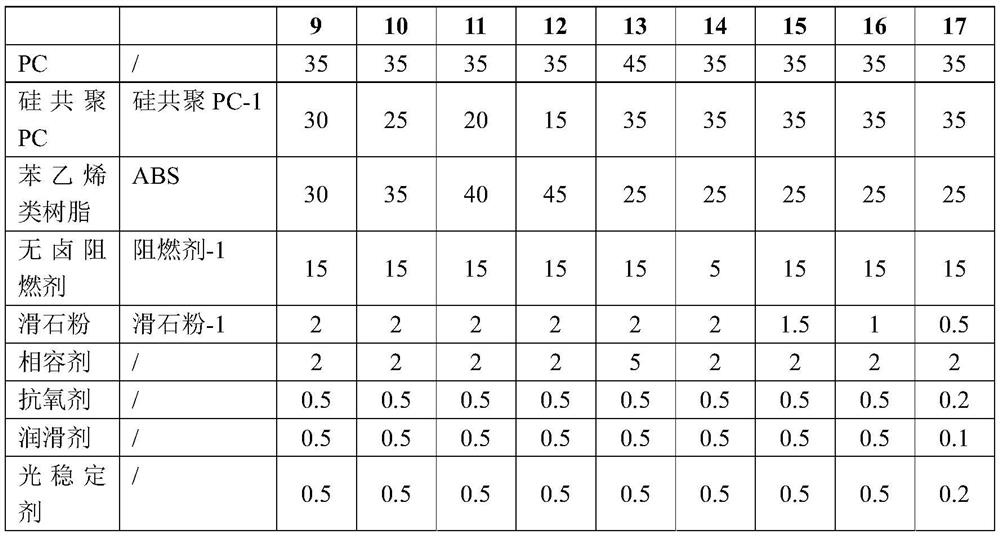

ActiveCN114736500AExcellent heat and humidity resistanceImprove flame retardant performancePolycarbonateHot and humid

The invention discloses a halogen-free flame-retardant polycarbonate / styrene resin alloy as well as a preparation method and application thereof. The damp-heat aging resistant halogen-free flame retardant polycarbonate / styrene resin alloy is prepared from the following components in parts by weight: 35 to 45 parts of polycarbonate resin, 15 to 35 parts of silicon copolymerized polycarbonate resin, 25 to 45 parts of styrene resin, 5 to 15 parts of phosphazene halogen-free flame retardant, 2 to 5 parts of compatilizer, 0.5 to 2 parts of talcum powder and 0.5 to 1.5 parts of other auxiliaries. Through the synergistic effect of the phosphazene halogen-free flame retardant, the silicon copolymerized polycarbonate resin, the talcum powder and other components, the heat and humidity resistance of the halogen-free flame-retardant polycarbonate / styrene resin alloy is improved, the mechanical property retention rate in a hot and humid environment is high, and the alloy is high in oxygen index and good in flame retardant property.

Owner:WUHAN JINFA TECH CO LTD +1

Self-repairing coating system

ActiveCN108929625AHigh mechanical strengthIncreased durabilityConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsPolyesterCoating system

The invention belongs to the technical field of protection. An elastomer, which is prepared through co-curing between styrene-acrylate copolymer that contains hydroxyl groups and is well compatible with fuel oil and polyester and / or polyurethane, is taken as the middle coating. Through resilience and oil-absorbing swelling, holes can be rapidly blocked. The invention relates to a self-repairing coating system, which has a multi-coating composite structure and at least comprises a middle coating and a polyurethane elastomer / polyurea outer coating. The middle coating is a hydroxyl-containing styrene-acrylate copolymer-polyurethane elastomer, the styrene accounts for 6.5 to 25.2 wt.% of the hydroxyl-containing styrene-acrylate copolymer, and the thickness of the middle coating is not less than 1.5 mm. The provided self-repairing coating system has good mechanical properties, is convenient to construct, has the advantages of wide application range, quick blocking speed, good effect, and high strength maintaining rate, can be used to block holes or cracks of an oil storing container in time, and is especially suitable for preventing the leakage, when a fuel oil container is broken downor a crack or hole appears in the interior of a high pressure oil storage container.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

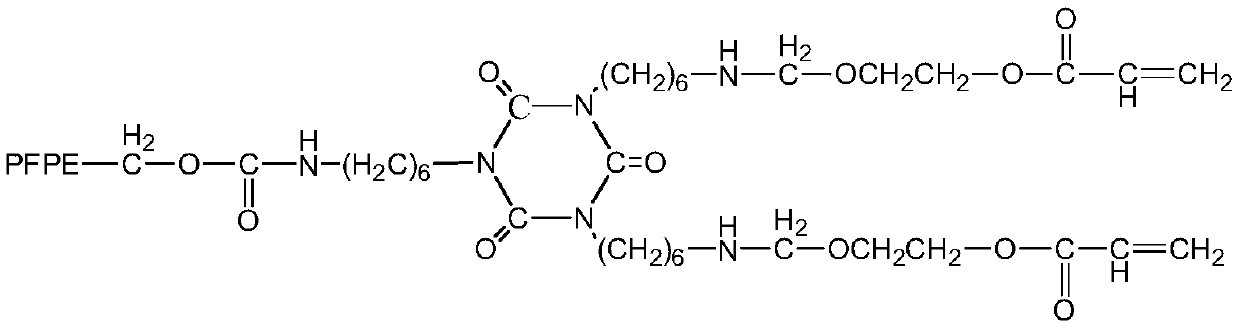

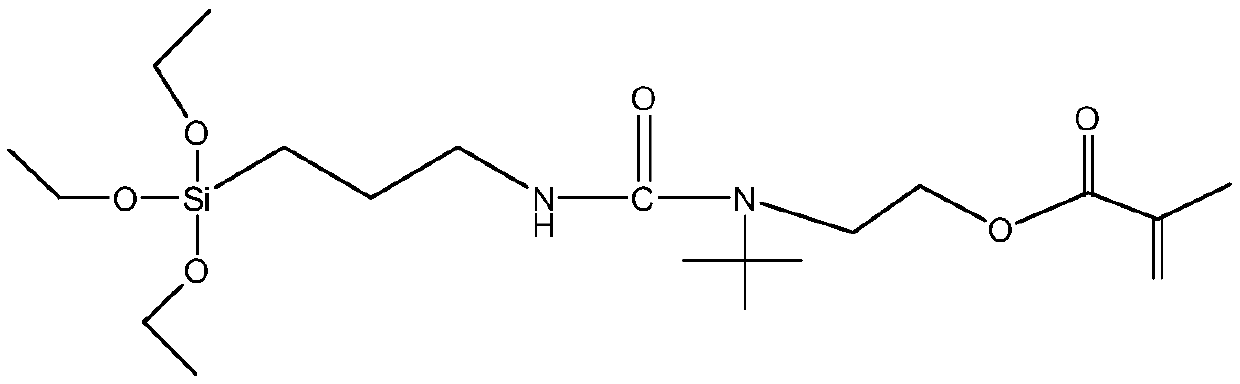

Ultraviolet curing adhesive with high hydrophobicity and preparation method of ultraviolet curing adhesive

InactiveCN110628378AImprove hydrophobicityHigh retention rate of mechanical propertiesPolyureas/polyurethane adhesivesMethacrylateAdhesive

The invention discloses an ultraviolet curing adhesive with high hydrophobicity. The ultraviolet curing adhesive consists of the following raw materials in percentage by weight: 30-60 parts of fluorine modified urethane acrylate resin, 20-40% of a silane modified acrylate monomer, 15-30% of a methacrylate monomer and 1-7% of a photoinitiator. The ultraviolet curing adhesive with high hydrophobicity, which is disclosed by the invention, is good in hydrophobicity, high in mechanical property retention rate after being soaked into water, large in contact angle with the water, excellent in cured substance property, high in adhesion reliability and wide in application range.

Owner:YANTAI DARBOND TECH

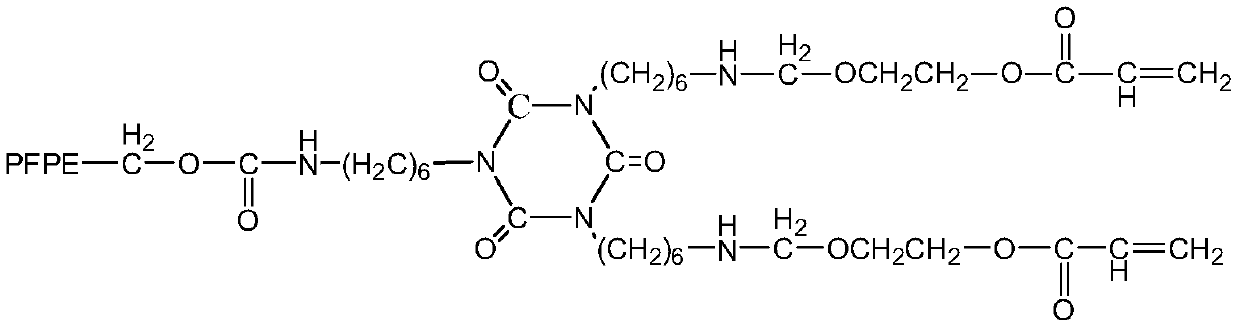

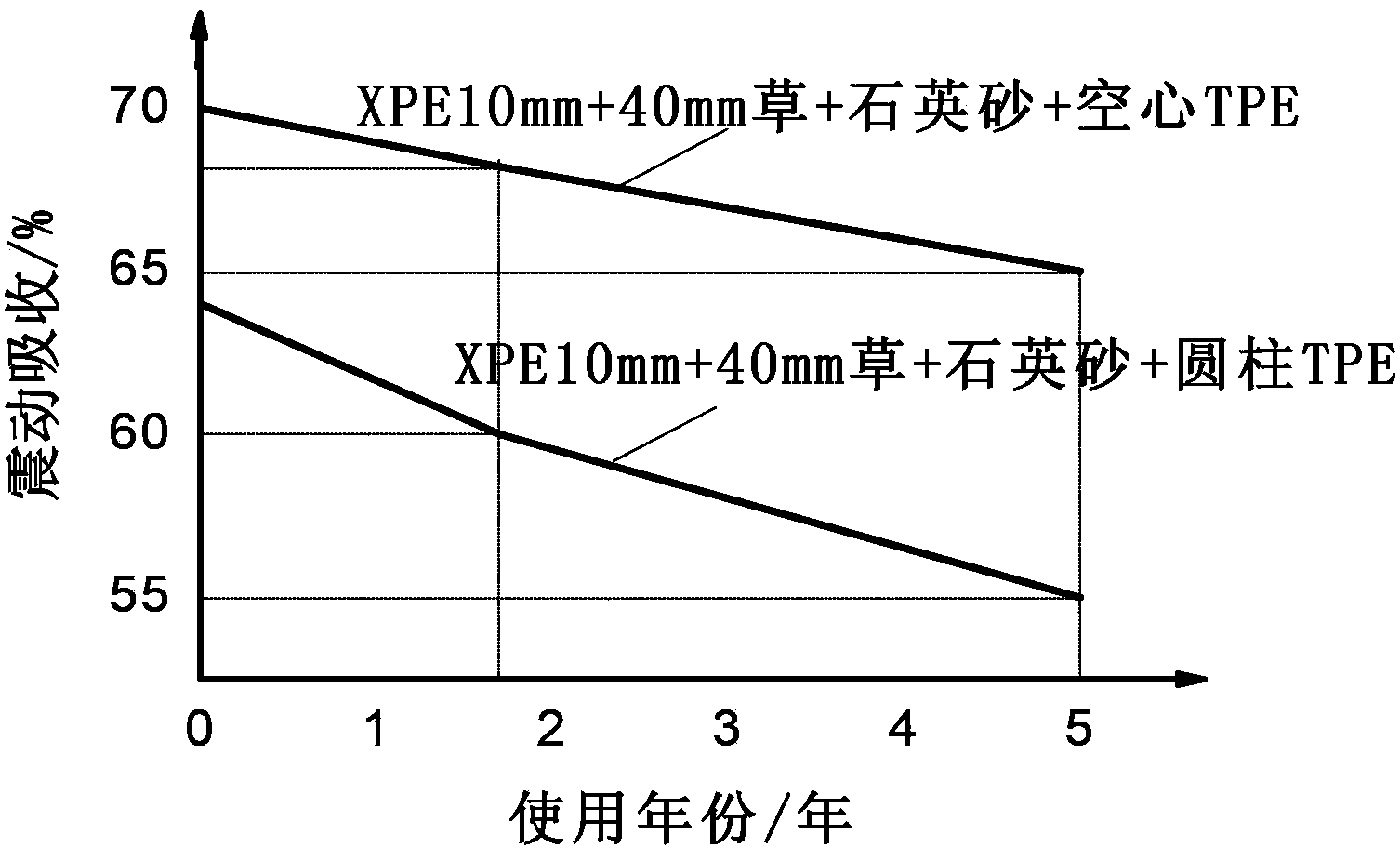

Hollow thermoplastic rubber filling particles for filling artificial turf and preparation method thereof

The invention discloses a hollow thermoplastic rubber filling particle for artificial turf filling and a preparation method of the hollow thermoplastic rubber filling particle, wherein the hollow thermoplastic rubber filling particle is of a hollow tubular structure and prepared from the following components in parts by weight: 50-80 parts of high-viscosity basic resin, 20-40 parts of inorganic fillers, 0.1-5 parts of auxiliary and 0.1-10 parts of color master batches, wherein the auxiliary is a mixture formed by mixing an antiager with a coupling agent according to a weight ratio of (1-5):(1-5). The hollow thermoplastic rubber filling particle disclosed by the invention is formed by melting, blending, extruding and underwater granulating high-viscosity thermoplastic elastomers, and has the advantages of persistent elasticity, good water permeability, small packing density, low filling cost, recoverability and the like.

Owner:NANJING INST OF TECH +1

High-weather-resistant high-tenacity reinforced polypropylene material for post insulator and preparation method of reinforced polypropylene material

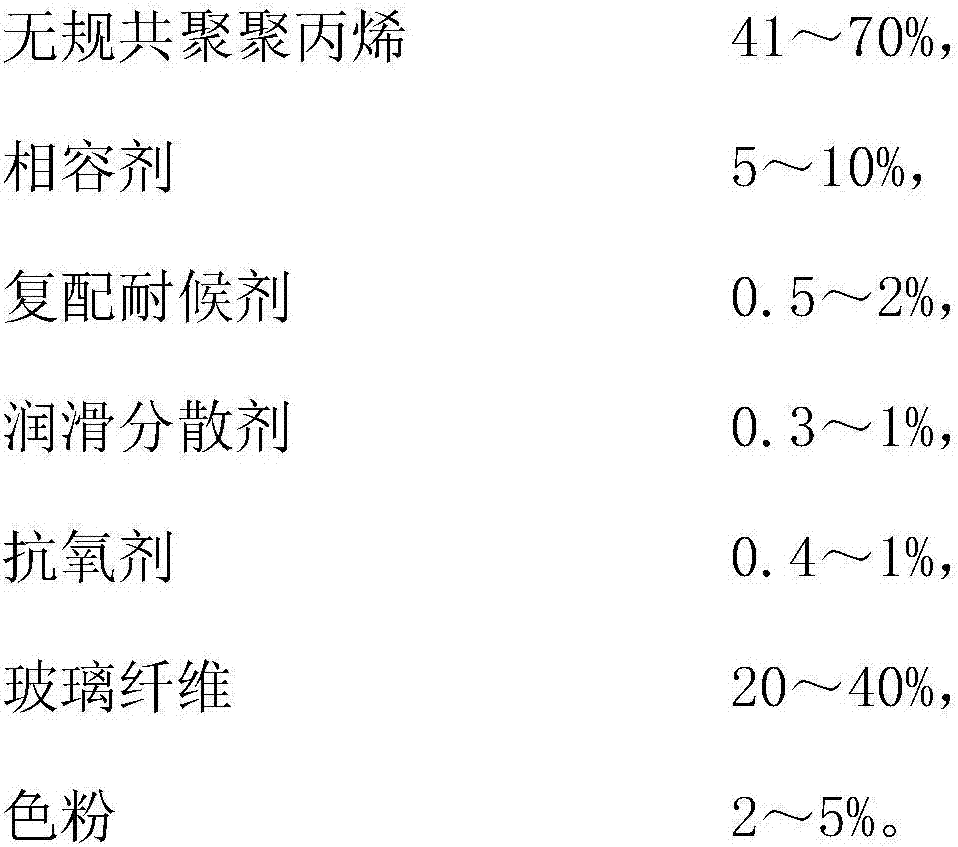

InactiveCN107987398AHigh retention rate of mechanical propertiesGood color stabilityLubricationPolypropylene

The invention discloses a high-weather-resistant high-tenacity reinforced polypropylene material for a post insulator and a preparation method of the reinforced polypropylene material. According to the key point of the technical scheme, the reinforced polypropylene material contains the following components in percentage by weight: 41%-70% of random copolymerization polypropylene, 5%-10% of a compatilizer, 0.5%-2% of a compound weather-resistant agent, 0.3%-1% of a lubrication dispersing agent, 0.4%-1% of an antioxidant, 20%-40% of glass fibers and 2%-5% of a toner. The high-weather-resistanthigh-tenacity reinforced polypropylene material for the post insulator has the advantages that the weather resistance and the tenacity are high, the retention rate of mechanical performance under a photothermal oxygen aging condition is high, the color stability is good, and the like.

Owner:GUANGDONG WAYLAM ENG PLASTICS

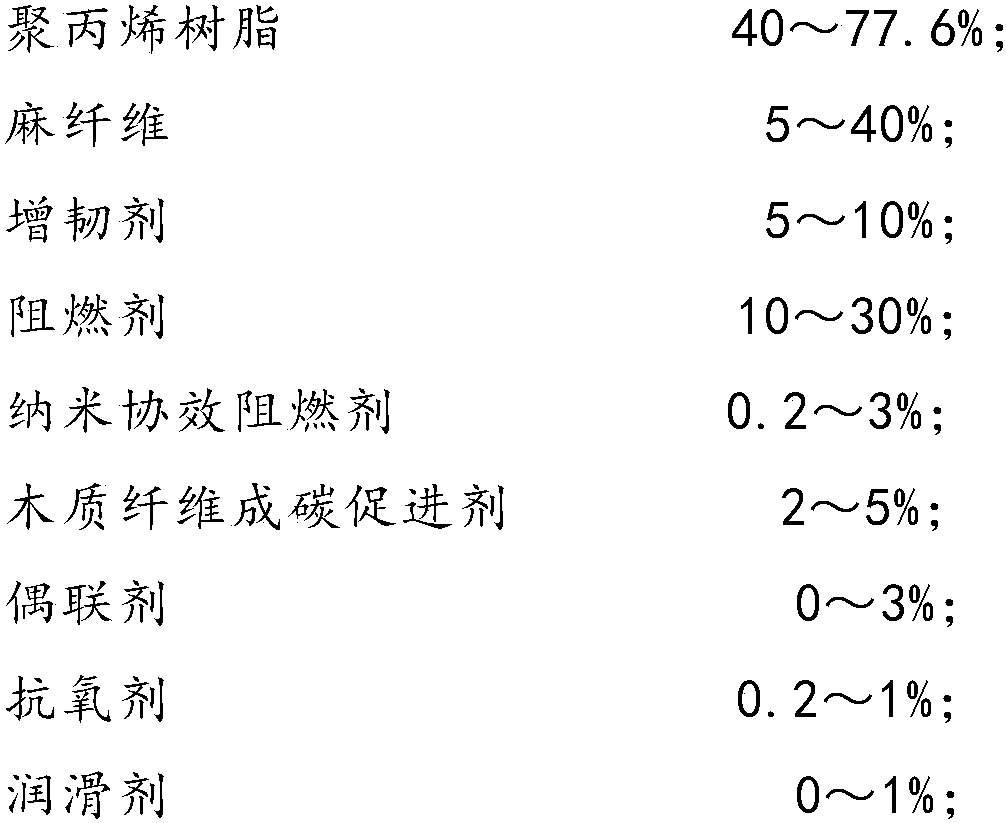

Lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises 40-77.6% of polypropylene resin, 5-40% of bast fibers, 10-30% of flame retardant, 5-10% of toughening agent, 0.2-3% of nano synergistic flame retardant, 2-5% of wood fiber carbon-forming accelerant, 0-3% of coupling agent, 0.2-1% of antioxidant and 0-1% of lubricating agent. The lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and the preparation method thereof have the advantages that polypropylene is used as the base material, the bast fibers are used as the reinforcement, the synergistic effects of halogen-free intumescent flame retardant, the nano synergistic flame retardant and the wood fiber carbon-forming accelerant are utilized, a banburying-extrusion two-stage continuous processing method is used, and accordingly the prepared composite material is excellent in flame retardance, and the bast fibers are evenly dispersed in the matrix.

Owner:SHANGHAI KINGFA SCI & TECH +1

Application of polypropylene as age inhibiting material caused by ultraviolet light

The present invention provides a polypropylene material and its application as UV-ray resisting and anti-ageing material. The described polypropylene material is made up by adding beta nucleating agent into the polypropylene material, and the addition of beta crystal type nucleating agent can make the polypropylene material produce beta crystal type conversion, as compared with alpha crystal type polypropylene material, after it is irradiated by UV ray, the retaining rate of mechanical performance of said material can be greatly raised, and the effect obtained by means of beta crystal type conversion can be identical to that obtained by adding UV-photostabilizer.

Owner:ZHEJIANG UNIV OF TECH

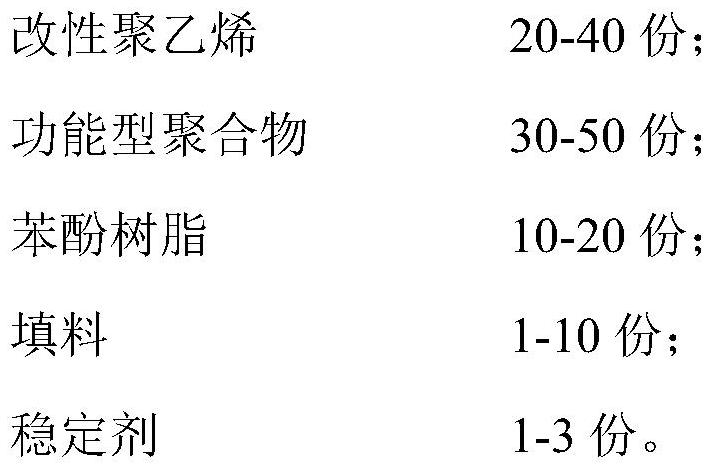

Adhesive resin for anti-ultraviolet aging type steel wire mesh framework polyethylene composite pipe

InactiveCN112812709AHigh peel strengthHigh tensile strengthNon-macromolecular adhesive additivesPolyether adhesivesUltravioletSunlight irradiation

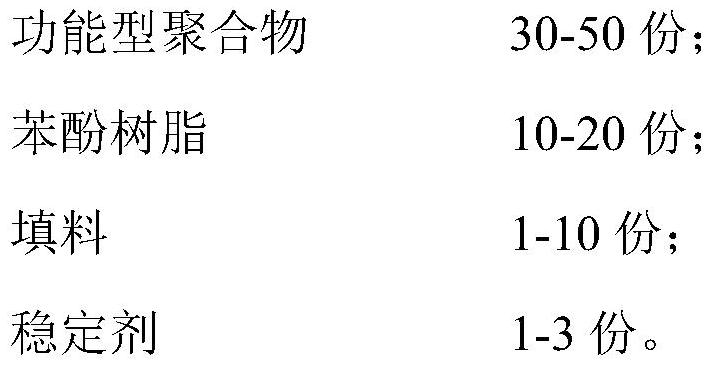

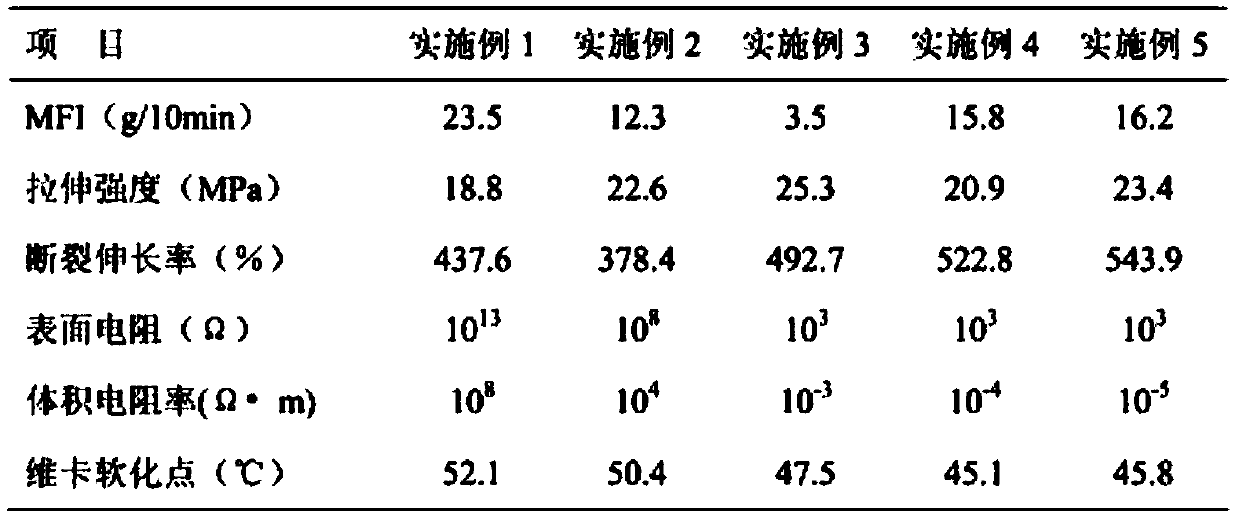

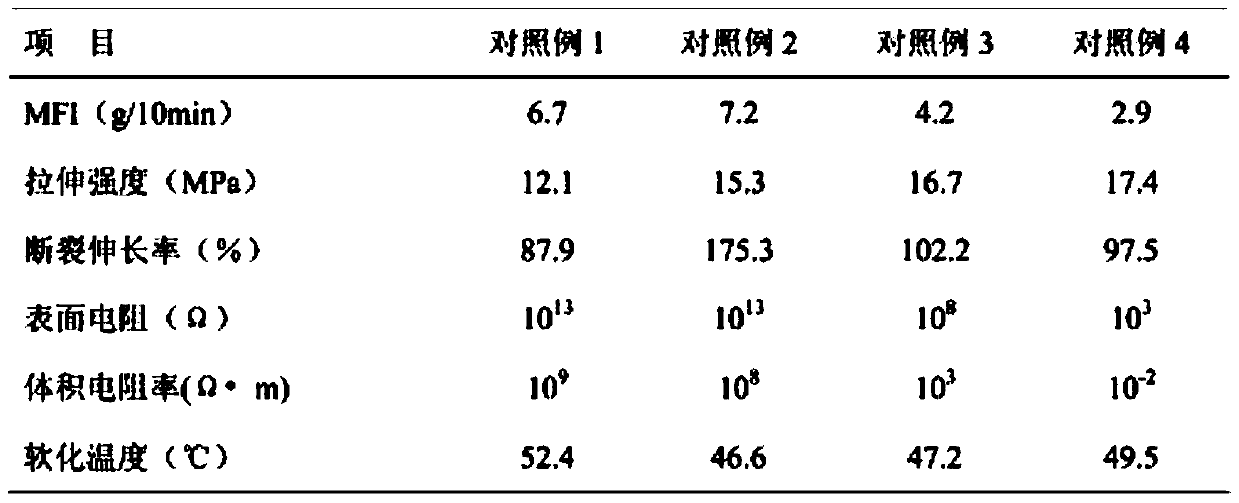

The invention provides an adhesive resin for an anti-ultraviolet aging type steel wire mesh framework polyethylene composite pipe. The adhesive resin comprises the following components by mass: 20-40 parts of modified polyethylene; 30-50 parts of a functional polymer; 10-20 parts of phenol resin; 1-10 parts of filler; and 1-3 parts of a stabilizer. The adhesive resin provided by the invention has the advantages of high peel strength, high tensile strength, high bonding strength, excellent ultraviolet aging resistance and high mechanical property retention rate after long-time sunlight irradiation, has great significance in enhanced production of composite pipes, and due to the excellent ultraviolet aging resistance, the prepared steel wire mesh framework polyethylene composite pipe is long in service life, and the enhanced production and the service life prolonging of the composite pipe are greatly improved.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

Ultraviolet curing adhesive with brine resistance, and preparation method thereof

InactiveCN113667446ALow water vapor transmission rateGood flexibilityPolyureas/polyurethane adhesivesPolymer scienceUltraviolet

The invention discloses an ultraviolet curing adhesive with brine resistance, and a preparation method thereof, and belongs to the technical field of photocuring materials. In order to solve the problem that a conventional ultraviolet curing adhesive has obvious limitation in application of saline-resistant water, the invention provides the ultraviolet curing adhesive which consists of a polyurethane acrylate prepolymer with a polybutadiene structure, an acrylate monomer, a photoinitiator, a cross-linking agent and a flatting agent. The adhesive has the advantages of low water vapor transmission rate, good chemical resistance and excellent flexibility. Particularly, the adhesive has better salt water resistance, high mechanical property retention rate after being soaked in salt water, large contact angle with water, excellent cured product performance and high bonding reliability, and is suitable for various coatings requiring strict humidity control. In addition, the preparation method of the ultraviolet curing adhesive is simple, short in flow, low in equipment dependence and suitable for industrial large-scale production.

Owner:长春艾德斯新材料有限公司

Glass-fiber-reinforced hydrolysis-resistant polyester material and preparation method thereof

InactiveCN102702699BImprove mechanical propertiesHigh retention rate of mechanical propertiesPolyesterGlass fiber

Owner:SHANGHAI SUNNY

A kind of pcl conductive plastic material and preparation method thereof

The invention discloses a PCL conductive shapable material, and a preparation method and an application thereof, and belongs to the field of functional polymer materials. The PCL conductive shapable material is composed of the following substances by the mass percentage: 49%-98.4% of PCL, 1%-30% of a plasticizer, 0.5%-20% of carbon nanotubes, and 0.1%-1% of an antioxidant. After the components are mixed, the PCL conductive shapable material is obtained by melting the mixture with a twin-screw or single-screw extruder or an internal mixer. The PCL is modified by the carbon nanotubes, and with addition of N-N-butyl sulfonamide, the PCL is plasticized and the carbon nanotubes are subjected to surface treatment, so good dispersion of the carbon nanotubes is achieved while the softening temperature of the composite material is reduced, and good conductivity and shapable effect are obtained. The prepared conductive shapable functional material has the advantages of small volume resistance, low softening temperature and the like, and has good application prospects in the fields of hot compress medical apparatus and instruments, medical insulation pads, electric blankets and the like.

Owner:湖南博晟新材料科技有限公司

A kind of preparation method of high temperature resistant phenolic resin with organic silicon resin as curing agent

The invention relates to a method for preparing high-temperature resistant phenolic resin with organic silicon resin as a curing agent. The method comprises the following steps: heating an organic silicon resin precursor in an oil bath under nitrogen protection, and stirring to react to obtain organic silicon resin prepolymer having a crosslinking degree of 10-20 percent; heating and uniformly mixing with phenolic resin in a mass ratio of (0.1-0.3):1 in under nitrogen protection, injecting the mixed solution into a mold cavity, and reacting at negative pressure; and curing, and removing the mold to obtain the high-temperature resistant phenolic resin. The preparation method is simple in process and strong in operability, is free of overflow of small molecules in the curing process, and is applicable to industrial production. By adopting the method, organic silicon resin is selected as a curing agent, and the cured phenolic resin has strong instant heat resistance, and has relatively high mechanical performance retention rate and residual carbon rate at high temperature.

Owner:DONGHUA UNIV

A kind of thermoplastic phosphogypsum filling material and preparation method thereof

ActiveCN105837857BIncrease added valueSustainable Consumption GuaranteeThermoplasticFilling materials

The invention relates to deep processing modification and application of phosphorus ore byproduct phosphorus gypsum, and discloses a phosphorus gypsum filling material with thermoplastic processing performance. The phosphorus gypsum filling material is characterized in that a first cladding layer with flowing lubricity is formed on the surface of dry powdery phosphorus gypsum, a second hydrophobic layer is formed on the first cladding layer, and a third hot melt layer is formed on the second hydrophobic layer. The invention further provides a preparation method. Inorganic lubricant powder and the phosphorus gypsum are collided, ground and refined under the action of a high-speed jet mill by virtue of flowing lubricity of the inorganic lubricant powder, and anchoring groups of a dispersing agent are embedded with the phosphorus gypsum in a refining process of the dry powdery phosphorus gypsum, so that the phosphorus gypsum is endowed with high rheological processability, problems about high-filling application of the phosphorus gypsum filling material to plastics are radically solved, the phosphorus gypsum filling material is used for large products such as PVC enclosure wall baffle plates, agricultural seedling growing flowerpots, stone paper and garbage bags, the consumption of the phosphorus gypsum can be greatly improved, and the industrial application of the phosphorus gypsum to plastics is promoted.

Owner:陕西睿智环保建材有限公司

Polyester composite material, and preparation method, repairing method and application thereof

PendingCN114085496AImprove Dispersion and RestorationImprove repair performanceAdditive manufacturing apparatusPolymer chemistryPerylene derivatives

The invention discloses a polyester composite material. The polyester composite material comprises, by weight, 100 parts of polyester resin; 0.1 to 10 parts of an irradiation cross-linking agent; 10 to 35 parts of an epoxy polymer; and 100 to 300 ppm of tetrahydrofuran or derivatives thereof. According to the invention, the epoxy polymer and the tetrahydrofuran or the derivatives thereof are added into the irradiation cross-linked polyester composite material system, when the polyester composite material is damaged, the damaged part can be repaired through irradiation cross-linking, and the polyester composite material with good repairability (especially structural damage caused by oxidation and hydrolysis) is obtained.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

A kind of high-polarity polypropylene composite material and its preparation method and its application in automotive exterior materials

ActiveCN107722466BIncrease polarityHigh retention rate of mechanical propertiesPolypropylene compositesPolymer science

The invention discloses a high polar polypropylene composite material. The raw material composition comprises the following components in percentages by weight: 50-88% of polypropylene, 5-15% of a flexibilizer, 0-30% of a mineral filler, 5-10% of modified polyvinyl chloride, 1-5% of hyperbranched polyesteramide, and 0.1-5% of an auxiliary agent. Modified polyvinyl chloride and hyperbranched polyesteramide are added, so that polarity of the polypropylene composite material is improved, excellent mechanical properties are maintained, and the product can be used as a material special for exteriortrim of automobiles. A preparation method of the high polar polypropylene composite material is provided, and the method employs a double screw extruder for realization, the preparation is simple, the method is easy to carry out and operate, industrial production is easy, and the method has wide application prospects.

Owner:CGN JUNER NEW MATERIALS +1

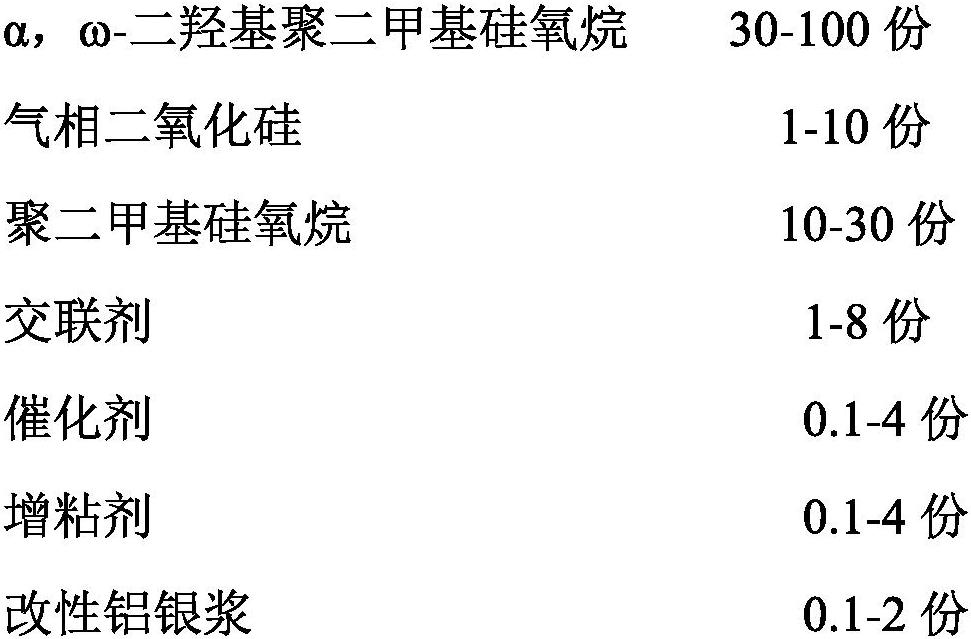

One-component deacidified silicone sealant for bonding outdoor handicrafts and preparation method thereof

ActiveCN109266300BImprove adhesionHigh glossNon-macromolecular adhesive additivesPtru catalystCross linker

The invention discloses single-component deacidified organosilicone sealant for bonding outdoor crafts, and a preparation method of the single-component deacidified organosilicone sealant. The single-component deacidified organosilicone sealant is prepared from the following raw materials in parts by weight: 30-100 parts of alpha-omega-dihydroxypolydimethylsiloxane, 1-10 parts of fumed silica, 10-30 parts of polydimethylsiloxane, 1- 8 parts of a crosslinking agent, 0.1-4 parts of a catalyst, 0.1-4 parts of a tackifier and 0.1-2 parts of modified aluminum-silver paste. The single-component deacidified organosilicone sealant for bonding the outdoor crafts is excellent in bonding performance when being used for filling base materials, aluminum materials, glass and the like of the crafts during bonding of the outdoor crafts; when being naturally damaged due to long-term ultraviolet irradiation and long-term exposure to air, the single-component deacidified organosilicone sealant still maintains good bonding performance with the base materials; furthermore, the sealant is high in retention rate of mechanical properties, and good glossiness can be maintained after the aluminum-silver paste is added for modification.

Owner:四川省俊川科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com