Hollow thermoplastic rubber filling particles for filling artificial turf and preparation method thereof

A technology of thermoplastic rubber and filling particles, which is applied in the field of hollow thermoplastic rubber filling particles for artificial turf filling and its preparation, can solve the problems of high cost and decreased water permeability, and achieve cost savings, improved water permeability, and excellent elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of High Viscosity Base Resin:

[0042] Mix 50kg of SEBS, 400640kg of naphthenic oil, 8kg of polyethylene, 2kg of additives (including 10100.5kg of antioxidant, 0.5kg of antistatic agent E-13080.5kg, 0.5kg of blocking agent oleic acid amide, and 0.5kg of dispersant polyethylene wax), and mix Uniform, melt blending and granulation on a twin-screw extruder, the temperature is controlled at 180-230°C;

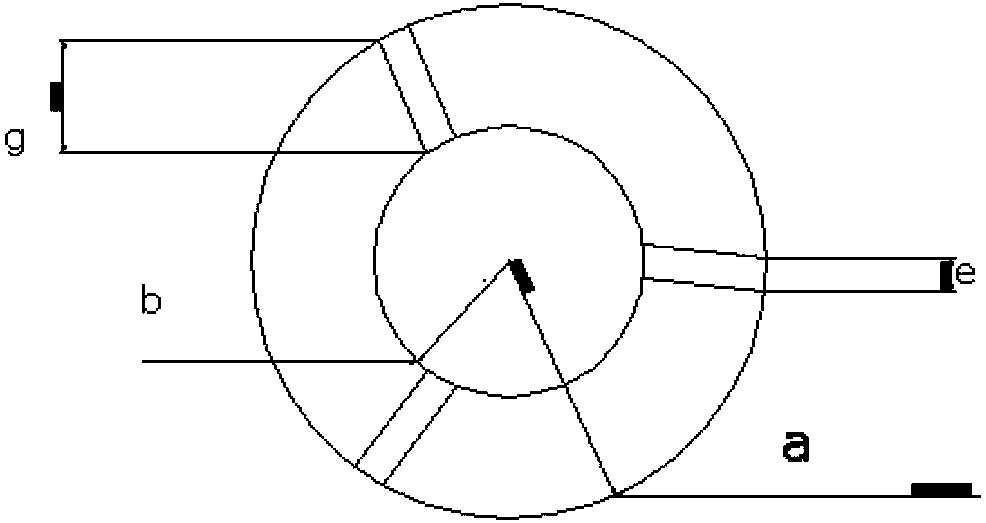

[0043] Preparation of hollow thermoplastic rubber filled particles:

[0044] 60kg of high-viscosity basic resin, 35kg of nano-calcium carbonate, 3kg of color masterbatch, 3kg of additives (anti-aging agent UV-5311kg, titanate coupling agent 2kg), mix the above raw materials evenly, and melt them together on a twin-screw extruder Mixed, extruded through an underwater granulation device equipped with a die to obtain hollow thermoplastic rubber filled particles with an inner diameter of 2mm, an outer diameter of 3.5mm, a length of 9mm, and a wall thickness of 1.5mm...

Embodiment 2

[0046] Preparation of High Viscosity Base Resin:

[0047]Mix 60kg of SEBS, 400630kg of naphthenic oil, 8kg of polyethylene, 2kg of additives (including 1680.5kg of antioxidant, 0.5kg of antistatic agent E-10180.5kg, 0.5kg of blocking agent erucamide, and 0.5kg of dispersant polypropylene wax), mix Uniform, melt blending and granulation on twin-screw extruder, temperature control 160 ~ 200 ℃.

[0048] Preparation of hollow thermoplastic rubber filled particles:

[0049] High-viscosity basic resin 65kg, nano-calcium carbonate 30kg, color masterbatch 3kg, additives 2kg (anti-aging agent UV-3271kg, aluminate coupling agent and titanate coupling agent mixed according to the weight ratio of 1:1, a total of 1kg) , mix the above raw materials evenly, melt and blend them on a twin-screw extruder, and extrude them through an underwater granulation device equipped with a die to obtain a hollow pellet with an inner diameter of 2.5mm, an outer diameter of 5mm, a length of 11mm, and a wall...

Embodiment 3

[0051] Preparation of High Viscosity Base Resin:

[0052] 55kg of SEBS, 400635kg of naphthenic oil, 8kg of polyethylene, 2kg of additives (0.5kg of antioxidant, 0.5kg of antistatic agent E-10200.5kg, antiblocking agent are erucamide and oleamide with a weight ratio of 1:1. The mixture is 0.5kg, and the dispersant is a mixture of polyethylene wax and polypropylene wax with a weight ratio of 1:1 (0.5kg), mixed evenly, melted, blended and granulated on a twin-screw extruder, and the temperature is controlled at 180-230°C;

[0053] Preparation of hollow thermoplastic rubber filled particles:

[0054] 70kg of high-viscosity basic resin, 25kg of nano-calcium carbonate, 3kg of color masterbatch, 2kg of additives (anti-aging agent UV-3271kg, borate coupling agent 1kg), mix the above raw materials evenly, and melt them on the twin-screw extruder mixed, and extruded through an underwater granulation device equipped with a die to obtain hollow thermoplastic rubber filled particles with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com