High-rigidity high-durability carbon fiber enhanced polyamide composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber reinforced polyamide composite materials, can solve the problems of no composite material performance evaluation, large amount of solvent consumption, cumbersome process, etc., and achieve excellent bonding interface layer, good adhesion effect and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

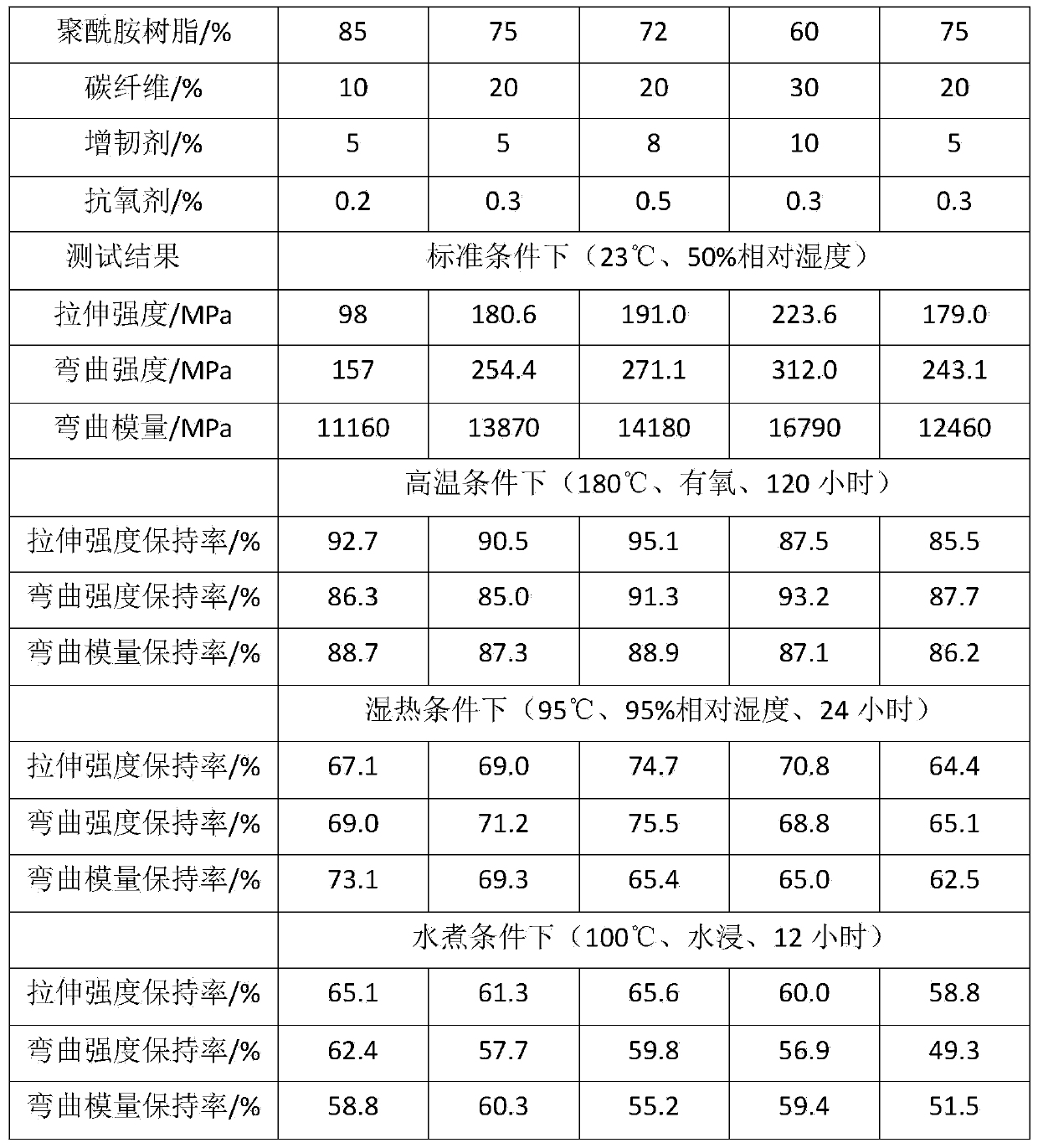

Examples

Embodiment 1

[0038] Soak 10 grams of short carbon fiber slices in an alkaline solution at 80°C for 10 minutes, spray 5 grams of polyurethane prepolymer aqueous emulsion with a solid content of 5% on the surface after filtration, put it in a vacuum drying oven, and dry it at 90°C with Dry under oxygen for 1 hour, then evacuate to 0.05MPa, heat up to 200°C, and heat for 2 hours to obtain surface-treated carbon fibers;

[0039] Dry 85g of polyamide resin at 100°C for 2 hours, weigh 5 grams of toughening agent and 0.2g of antioxidant, and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0040] The resin mixture is fed into the twin-screw extruder (screw diameter 35mm, length-to-diameter ratio L / D=36) through the main feed port, and the surface-treated carbon fiber is fed into the extruder through the side feed port. The section control temperature (from the feeding port to the nozzle outlet) is 220°C, 225°C, 230°C, 230°C, 230°C, 230°C, the speed of the twin-screw extruder ...

Embodiment 2

[0043] Soak 20 grams of short carbon fiber slices in an alkaline solution at 80°C for 30 minutes, spray 10 grams of polyurethane prepolymer aqueous emulsion with a solid content of 10% on the surface after filtration, put it in a vacuum drying oven, and dry it at 90°C with Dry under oxygen for 1 hour, then evacuate to 0.01MPa, heat up to 200°C, and heat for 2 hours to obtain surface-treated carbon fibers;

[0044] Dry 75g of polyamide resin at 100°C for 2 hours, weigh 5 grams of toughening agent and 0.3g of antioxidant, and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0045]The resin mixture is fed into the twin-screw extruder (screw diameter 35mm, length-to-diameter ratio L / D=36) through the main feed port, and the surface-treated carbon fiber is fed into the extruder through the side feed port. The section control temperature (from the feeding port to the nozzle outlet) is 220°C, 225°C, 230°C, 230°C, 230°C, 230°C, the speed of the twin-screw extruder...

Embodiment 3

[0048] Soak 20 grams of short carbon fiber slices in an alkaline solution at 80°C for 30 minutes, spray 10 grams of polyurethane prepolymer aqueous emulsion with a solid content of 20% on the surface after filtration, put it in a vacuum drying oven, and dry it at 90°C with Dry under oxygen for 1 hour, then evacuate to 0.01MPa, heat up to 200°C, and heat for 3 hours to obtain surface-treated carbon fibers;

[0049] Dry 65g of polyamide resin at 100°C for 2 hours, weigh 8 grams of toughening agent and 0.5g of antioxidant, and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0050] The resin mixture is fed into the twin-screw extruder (screw diameter 35mm, length-to-diameter ratio L / D=36) through the main feed port, and the surface-treated carbon fiber is fed into the extruder through the side feed port. stage control, the temperature (from feed inlet to nozzle outlet) is 220°C, 225°C, 230°C, 230°C, 230°C, 230°C, the speed of twin-screw extruder is 300 rpm A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com