Anti-scratching polypropylene material with ultraviolet aging resistance and preparation method thereof

A polypropylene material, anti-ultraviolet light technology, applied in the field of anti-ultraviolet light aging and anti-scratch polypropylene material and its preparation field, can solve the problem of surface hardness of the shielding ultraviolet light effect material, poor anti-scratch effect, affecting the scope of application, etc. problems, to achieve the effect of strong UV shielding performance, high retention rate of mechanical properties, and small degree of pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

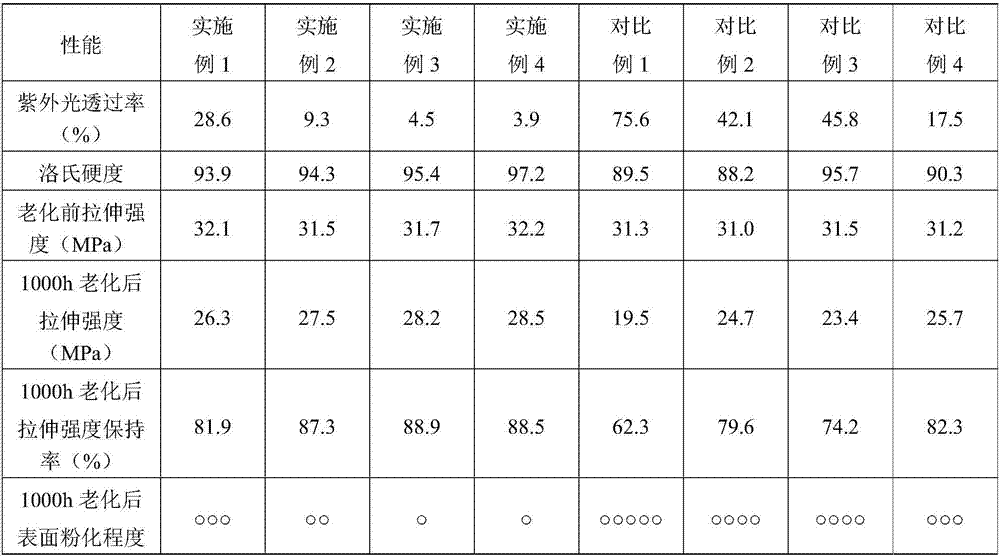

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned anti-ultraviolet aging and scratch-resistant polypropylene material comprises the following steps:

[0044] 1) Prepare coated nano-titanium dioxide by liquid phase precipitation;

[0045] 2) Weighing coated nano-titanium dioxide and other raw materials, mixing, melting, extruding, and granulating to obtain an anti-ultraviolet aging and scratch-resistant polypropylene material.

[0046] Preferably, in step 1), the preparation method of coated nano-titanium dioxide is as follows: first prepare nano-titanium dioxide powder suspension, then heat to 85°C, add sodium silicate and dilute sulfuric acid, adjust the pH value to 8-9, and then Aging for 2 hours, drying at 120° C. to obtain coated nano-titanium dioxide.

[0047] Preferably, in step 2), the extrusion is carried out in a twin-screw extruder, the speed of the extruder is 180-600 rpm, and the temperature of each zone is: 160-180°C in the first zone, 190-220°C in the second ...

Embodiment 1

[0054] A kind of anti-ultraviolet light aging scratch-resistant polypropylene material, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0055] Step 1: Prepare the nano-titanium dioxide powder into a suspension with a mass fraction of 1.5%, use 50g / L sodium hexametaphosphate as a dispersant, and ultrasonically oscillate for 30 minutes, then move the dispersed titanium dioxide suspension to a constant temperature magnetic stirrer and heated to 85°C, while adding dropwise 0.2mol / L sodium silicate solution and 0.2mol / L dilute sulfuric acid solution, adjusting the pH value to 8-9, keeping it for 2 hours, and drying at 120°C to obtain into coated nano-titanium dioxide;

[0056]Step 2: Weigh polypropylene resin, coated nano-titanium dioxide, benzotriazole light stabilizer, inorganic filler, coupling agent, antioxidant and lubricant in parts by mass, and mix in a high-speed mixer for 1- After 3 minutes, mix evenly and add i...

Embodiment 2

[0059] An anti-ultraviolet aging and scratch-resistant polypropylene material, its raw material formula is shown in Table 1, its preparation method is the same as in Example 1, and its specific material properties are shown in Table 2.

[0060] Among them, the polypropylene resin is a mixture of homopolymerized PP and copolymerized PP at a ratio of 5:1, and its melt flow rate (230°C / 2.16kg) is 25g / 10min and 7g / 10min respectively, and the coated nano-titanium dioxide is deposited by liquid phase The surface of nano-titanium dioxide particles is coated with a dense and uniform silicon dioxide film, and the particle size of nano-titanium dioxide is 1-100nm, and the benzotriazole light stabilizer is 2-(2'-hydroxyl-5'- tert-octylphenyl) benzotriazole, the inorganic filler is barium sulfate and talcum powder 1:1, the particle size is 5μm and 7μm respectively, the coupling agent is KH550, and the antioxidant is tetrakis[β-(3,5 -Di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com