Weather-resistant polyformaldehyde composition and preparation method thereof

A polyoxymethylene compound and weather-resistant technology, applied in the field of weather-resistant polyoxymethylene compound and its preparation, can solve problems such as poor effect, and achieve the effects of reducing loss, improving weather resistance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

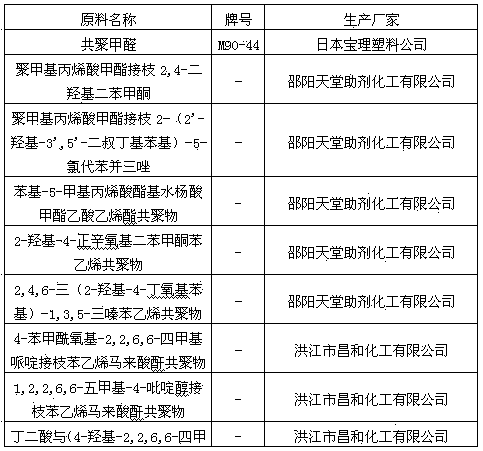

[0027] Embodiment 1: The weather-resistant polyoxymethylene compound adopts the following raw material formulation and preparation method.

[0028] Preparation steps: (1) Add the dispersant and polyoxymethylene into the mixer according to the following mass fractions, and stir at room temperature for 2 to 3 minutes until the mixture is uniform; separately add the ultraviolet absorber, light stabilizer, antioxidant, ultraviolet shielding agent, The free radical quencher and the formaldehyde absorbent are placed in a mixer and mixed evenly. (2) Put the mixed material into the twin-screw extruder through the hopper for melt blending and extrusion, and turn on the vacuum pump of the extruder. The temperature of each section from the barrel to the head is 170°C, 175°C, 175°C, 180°C, 185°C, 180°C, 178°C, 175°C, 170°C, the die temperature is 170°C, and the screw speed is 170 rpm , Feeding speed 10rpm. (3) The extruded melt strands are water-cooled, granulated, sieved, and fully dri...

Embodiment 2

[0038] Embodiment 2: The weather-resistant polyoxymethylene compound adopts the following raw material formulation and preparation method.

[0039] Preparation steps: The weather-resistant polyoxymethylene compound was prepared according to the method steps described in Example 1. After xenon lamp aging, thermo-oxygen aging and hydrothermal aging of the standard test sample for 1200h, the mechanical properties were compared with those of unaged POM. The results are shown in Tables 2, 3 and 4.

[0040] Each raw material is weighed according to the following mass fraction:

[0041] Polyoxymethylene copolymer 96.3wt.%;

[0042] Polymeric UV absorber: phenyl-5-methacrylate methyl salicylate vinyl acetate copolymer 0.6wt.%;

[0043] Polymeric stabilizer: 1,2,2,6,6-pentamethyl-4-pyridinol grafted styrene maleic anhydride copolymer 0.1wt.%;

[0044] Antioxidant: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.03wt.%, 1,3,5-tris(3,5-di-tert-butyl-...

Embodiment 3

[0049] Embodiment 3: The weather-resistant polyoxymethylene compound adopts the following raw material formulation and preparation method.

[0050] Preparation steps: except that the extrusion process conditions in step (2) are different, the rest is prepared according to the method described in Example 1 to prepare weather-resistant polyoxymethylene composites. The process conditions of step (2) in this example are: the screw speed is 150 rpm, the feeding speed is 12 rpm, the die temperature is 175 °C; the temperature of each section from the barrel to the machine head is 165 °C, 170 °C, 175 °C, and 180 °C , 185°C, 178°C, 175°C, 170°C, 165°C.

[0051] After xenon lamp aging, thermo-oxygen aging and hydrothermal aging of the standard test sample for 1200h, the mechanical properties were compared with those of unaged POM. The results are shown in Tables 2, 3 and 4.

[0052] Each raw material is weighed according to the following mass fraction:

[0053] Polyoxymethylene copoly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com