Ten-layer co-extrusion packaging film and production method thereof

A packaging film and film technology, which is applied in the field of flexible packaging film and packaging film, can solve the problems of unbalanced stress, increased manufacturing cost, and high film haze, so as to ensure the stability of oxygen barrier, improve curl resistance, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention is a ten-layer co-extrusion packaging film, the film is a ten-layer co-extrusion layered structure, the bottom layer of which is attached to the packaged object is a water-blocking and breathable layer, and the ten-layer structure contains 6 to 9 water-blocking layers. Air-permeable layer, an adhesive layer is sandwiched between the water-blocking and air-permeable layers, and the total number of layers of the adhesive layer and the water-blocking and air-permeable layer is 10; wherein, any layer of the water-blocking and air-permeable layer is one of homopolymerized PP and copolymerized PP One or its blend resin layer, or one or two or three blend resin layers in MLDPE, LLDPE and LDPE, any one layer of the adhesive layer is an ethylene-propylene copolymer resin layer, or a copolymer resin layer of ethylene or propylene and an α-olefin monomer containing an ester functional group; and the initial melting temperature of the water-blocking and breatha...

Embodiment 2

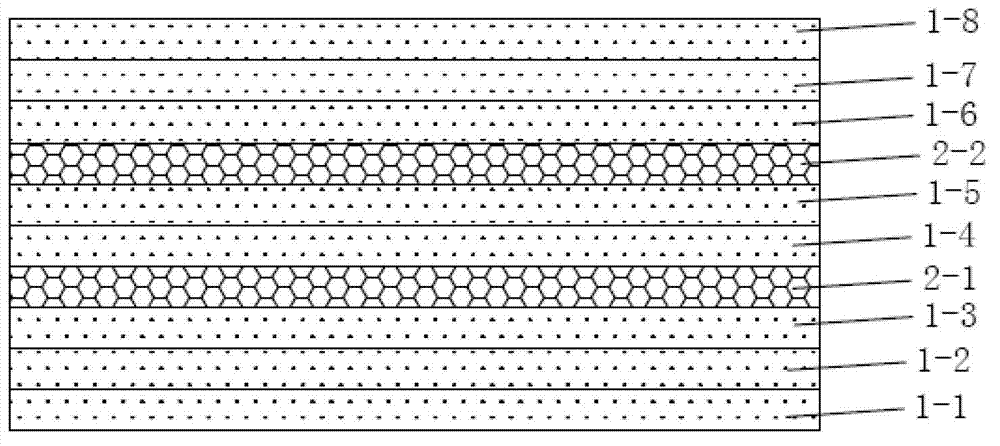

[0031] On the basis of embodiment 2, the preferred embodiment of the present invention is: the structural expression of described film is: A / A / adh / A / A / A / A / adh / A / A, or A / A / A / adh / A / A / adh / A / A / A, in the formula: from left to right, it represents the layers of the film laid from top to bottom, A represents the water-blocking and breathable layer, and adh represents the adhesive layer. Among them, the film structure A / A / A / adh / A / A / adh / A / A / A such as figure 1 shown.

[0032] In the above-mentioned embodiment, the packaging film can realize the water-blocking and breathable function; and the symmetrical laying of each layer of the film can prevent the film from curling after extrusion, and improve the curl resistance of the film. And in these two film structures, a continuous double water-blocking and breathable layer or three water-blocking and breathable layers is designed on the side close to the packaged object, so that the mechanical properties of the film are enhanced.

[003...

Embodiment 3

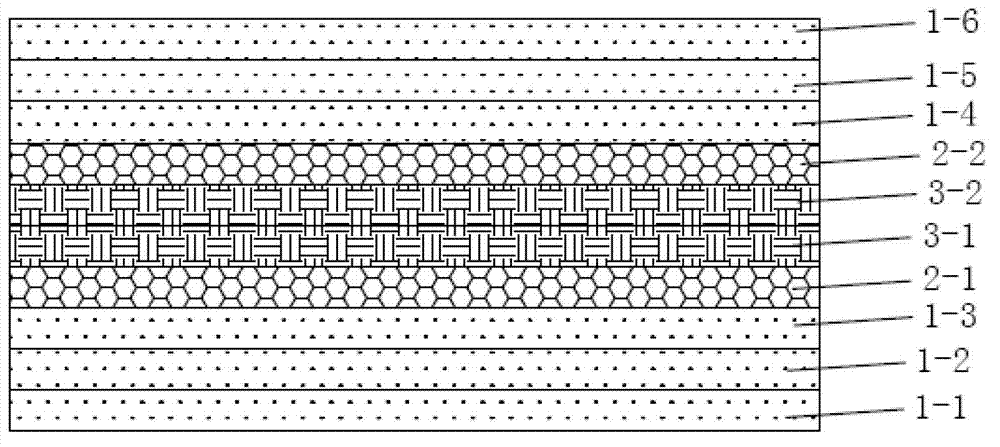

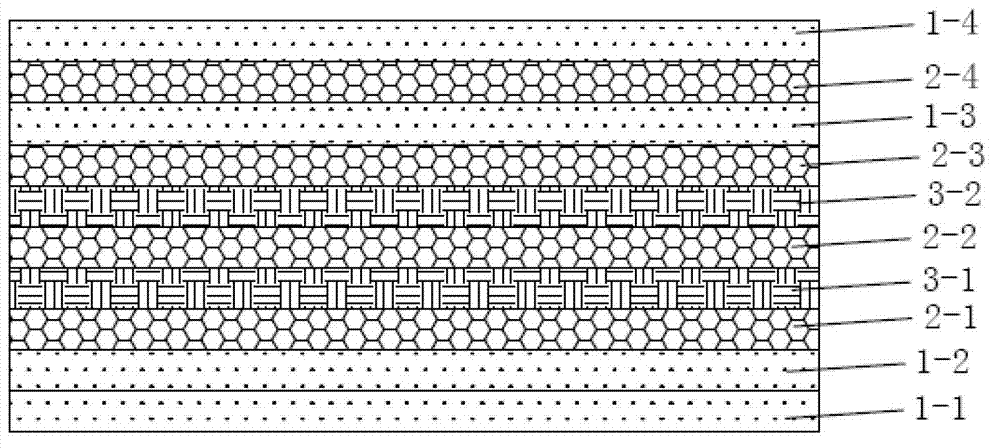

[0036] The present invention is a ten-layer co-extrusion packaging film, the film is a ten-layer co-extrusion layered structure, the bottom layer of which is attached to the packaged object is a water-blocking and breathable layer, and the ten-layer structure contains 2 to 7 water-blocking layers. Breathable layer and 1 to 6 oxygen barrier layers, the total number of layers of water barrier breathable layer and oxygen barrier layer is 6 to 8, at least one oxygen barrier layer is sandwiched between two water barrier breathable layers, and adjacent An adhesive layer is sandwiched between the oxygen barrier layer and the water barrier and breathable layer, and the total number of layers of the adhesive layer, the water barrier and breathable layer and the oxygen barrier layer is 10; wherein, any one layer of the water barrier and breathable layer is One of homopolymerized PP and copolymerized PP or its blend resin layer, or one or two or three of MLDPE, LLDPE and LDPE blend resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com