Preparation method of light-resistant MDI (diphenyl-methane-diisocyanate) polyurethane

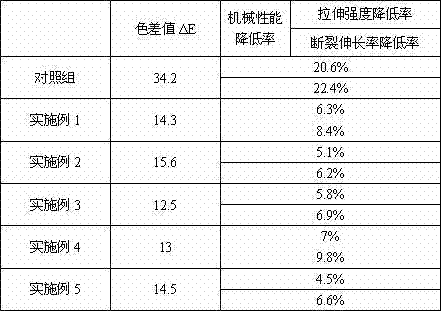

A technology of polyurethane and light resistance, which is applied in the field of preparation of light resistance MDI type polyurethane, to achieve the effect of reducing color difference change and gloss change, improving dispersion and improving mechanical property retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Preparation of surface-modified nano-ZnO:

[0023] Weigh 0.01 parts by mass of γ-aminopropyltrimethoxysilane coupling agent and dissolve it in 50 parts by mass of toluene, then add 2 parts by mass of nano-ZnO, stir at a constant speed for 20 min, then sonicate for 10 min, then reflux and stir 6 h; followed by centrifugation, the centrifuged precipitate was placed in ethanol for Soxhlet extraction for 6 h, and dried under low pressure at 100 °C for 12 h to obtain modified nano-ZnO.

[0024] Step 2: Preparation of light-resistant MDI polyurethane:

[0025] Take N,N-dimethylformamide: a mixture of butyl acetate with a mass ratio of 3:1 as solvent and solid MDI polyurethane as solute to prepare a polyurethane solution with a mass fraction of 10%; then add 1 part by mass The modified nano-ZnO and 0.1 mass part of organic anti-aging agent were stirred at 1000 rpm for 1 h, and then vacuum pumped to coat the film and dried at 100 °C for 6 h to obtain the light-resistan...

Embodiment 2

[0029] Step 1: Preparation of surface-modified nano-ZnO:

[0030] Weigh 0.03 parts by mass of γ-aminopropyltriethoxysilane coupling agent and dissolve it in 100 parts by mass of toluene, then add 4 parts by mass of nano-ZnO, stir at a constant speed for 20 min, then sonicate for 20 min, and then reflux Stir for 12 h; then perform centrifugation, place the centrifuged precipitate in ethanol for Soxhlet extraction for 12 h, and dry under low pressure at 100 °C for 12 h to obtain modified nano-ZnO.

[0031] Step 2: Preparation of light-resistant MDI polyurethane:

[0032] Take N,N-dimethylformamide: a mixture of butyl acetate with a mass ratio of 3:1 as solvent and solid MDI polyurethane as solute to prepare a polyurethane solution with a mass fraction of 15%; then add 2 parts by mass The modified nano-ZnO and 0.5 parts by mass of organic anti-aging agent were stirred at 1000 rpm for 2 h, and then vacuum pumped to coat the film and dried at 100 °C for 12 h to obtain the light-re...

Embodiment 3

[0036] Step 1: Preparation of surface-modified nano-ZnO:

[0037]Weigh 0.05 parts by mass of 3-isocyanatopropyltrimethoxysilane coupling agent and dissolve it in 200 parts by mass of toluene, then add 6 parts by mass of nano-ZnO, stir at a constant speed for 60 minutes, then ultrasonicate for 60 minutes, and then reflux Stir for 24 h; then perform centrifugation, place the centrifuged precipitate in ethanol for Soxhlet extraction for 12 h, and dry under low pressure at 100 °C for 12 h to obtain modified nano-ZnO.

[0038] Step 2: Preparation of light-resistant MDI polyurethane:

[0039] Use the mixture of N,N-dimethylformamide: butyl acetate with a mass ratio of 3:1 as solvent and solid MDI polyurethane as solute to prepare a polyurethane solution with a mass fraction of 10%-30%; then add 6 parts by mass of modified nano-ZnO and 1 part by mass of organic anti-aging agent, stirred at 2000 rpm for 4 h, then vacuum pumped, and then dried for 6 h at 100 ° C to obtain the light-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com