Lightweight, environment-friendly and flame-retardant bast fiber reinforced polypropylene composite material and preparation method thereof

A composite material and hemp fiber technology, which is applied in the field of light-weight and environmentally friendly flame-retardant hemp fiber reinforced polypropylene composite material and its preparation field, can solve the problem of limiting the wide application of hemp fiber reinforced polypropylene material and the inability to guarantee the flame retardant performance of the composite reinforcement system. , destroying the ecological and environmental protection characteristics of plant fibers, etc., to achieve excellent repeated processing performance, ensure dispersion stability, and solve the effect of flammable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

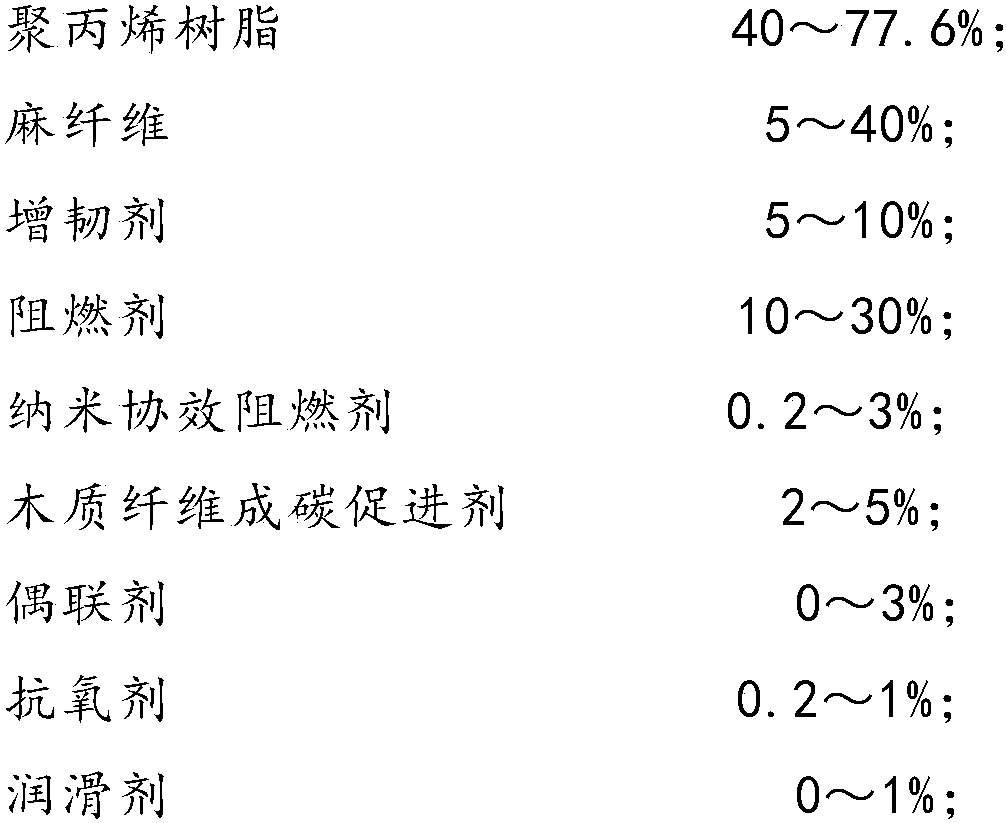

Method used

Image

Examples

Embodiment 1

[0031] It consists of the following raw materials: 55kg of polypropylene copolymer, 24kg of ammonium metaphosphate, 6kg of triazine char-forming agent, 5kg of ethylene-octene copolymer, 0.3kg of nano synergistic flame retardant, 2kg of wood fiber carbon-forming accelerator, flax Fiber 10kg, antioxidant 0.3kg, lubricant 0.3kg, vinyltriethoxysilane 0.2kg.

[0032] The preparation method of light-weight environment-friendly flame-retardant hemp fiber reinforced polypropylene composite material comprises the following steps:

[0033] 1) Pretreatment: use a high-speed mixer to mix alcoholized vinyltriethoxysilane and flax fibers evenly. The temperature of the high-speed mixer is 100° C., the rotation speed is 300 rpm, and the holding time is 8 minutes to obtain coupling-treated hemp fibers;

[0034] 2) Internal mixing: Weigh polypropylene, ethylene-octene copolymer, ammonium metaphosphate, triazine char-forming agent, flax fiber, antioxidant, lubricant according to the formula, put...

Embodiment 2

[0037] It is composed of the following raw materials: 45kg of polypropylene copolymer, 24kg of ammonium metaphosphate, 6kg of triazine char-forming agent, 5kg of ethylene-octene copolymer, 0.3kg of nano synergistic flame retardant, 3kg of wood fiber carbon-forming accelerator, sword Hemp fiber 20kg, antioxidant 0.3kg, lubricant 0.3kg, vinyltrimethoxysilane 0.3kg.

[0038] The preparation method of light-weight environment-friendly flame-retardant hemp fiber reinforced polypropylene composite material comprises the following steps:

[0039] 1) Pretreatment: use a high-speed mixer to mix alcoholized vinyltrimethoxysilane and sisal fibers evenly. The temperature of the high-speed mixer is 100° C., the rotation speed is 300 rpm, and the holding time is 12 minutes to obtain coupling-treated hemp fibers;

[0040] 2) Internal mixing: Weigh polypropylene, ethylene-octene copolymer, ammonium metaphosphate, triazine char-forming agent, sisal fiber, antioxidant, lubricant according to th...

Embodiment 3

[0043] It consists of the following raw materials: 35kg of polypropylene copolymer, 24kg of ammonium metaphosphate, 6kg of triazine char-forming agent, 5kg of ethylene-octene copolymer, 0.3kg of nano synergistic flame retardant, 5kg of wood fiber carbon-forming accelerator, ramie Fiber 30kg, antioxidant 0.3kg, lubricant 0.3kg, vinyl tris(β-methoxyethoxy)silane 0.3kg.

[0044]The preparation method of light-weight environment-friendly flame-retardant hemp fiber reinforced polypropylene composite material comprises the following steps:

[0045] 1) Pretreatment: Use a high-speed mixer to mix the alcoholized vinyl tris(β-methoxyethoxy)silane and hemp fiber evenly. The temperature of the high-speed mixer is 100°C, the rotation speed is 300rpm, and the holding time is 15min, and the coupling treatment is obtained. hemp fiber;

[0046] 2) Internal mixing: Weigh polypropylene, ethylene-octene copolymer, ammonium metaphosphate, triazine char-forming agent, ramie fiber, antioxidant, lu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com