Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Solve flammable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

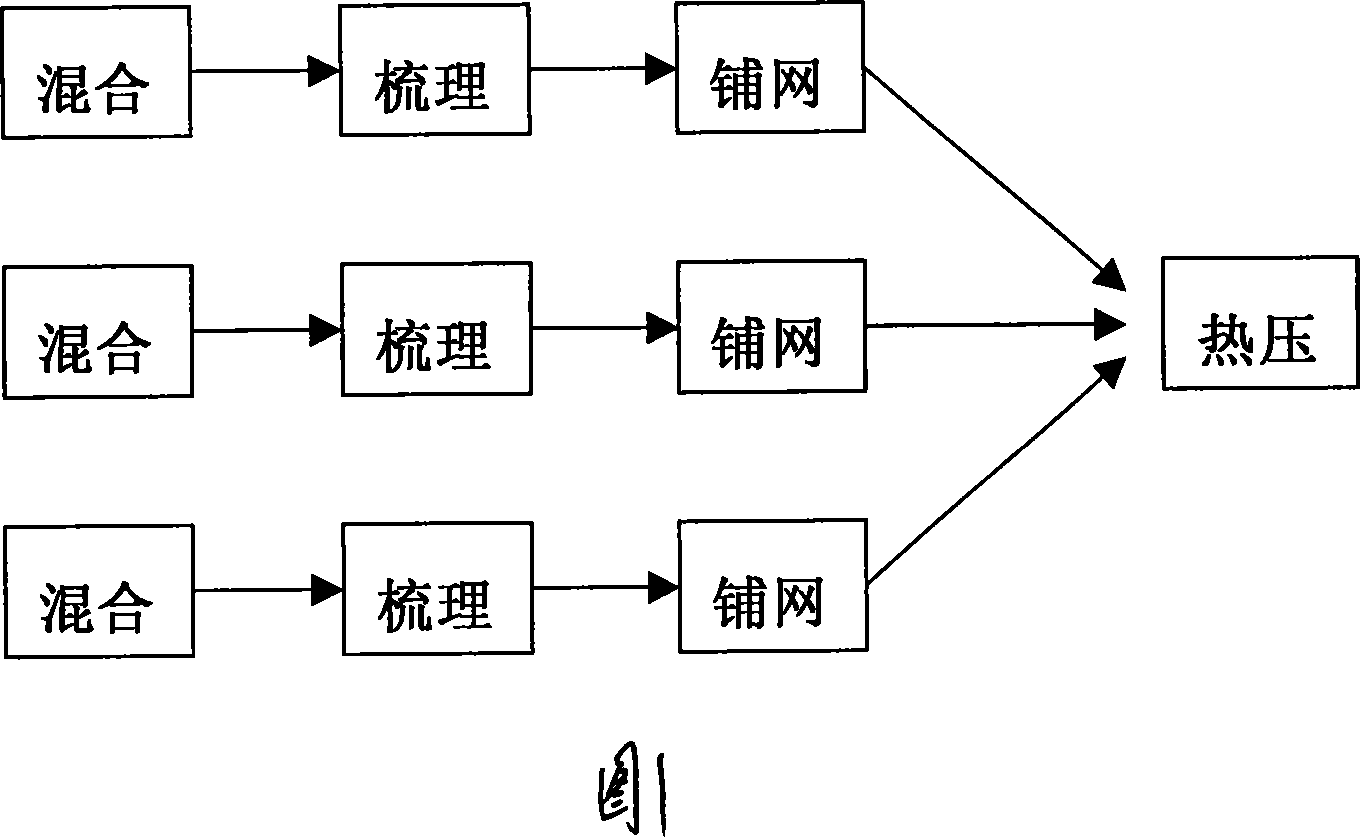

Sandwich structural fiber board

InactiveCN101096134AGood mechanical propertiesImprove insulation effectLayered productsVehicle componentsPolyesterOptoelectronics

The invention discloses a sandwich structure fiber plate. Flax fiber and polyester with low melting point are adopted as raw material. After two fibers with different proportion are mixed the mixture is combed into net and fire retardant is sprayed on the fiber net. Triple fiber nets are folded into the sandwich structure fiber plate, wherein components of upper and lower skin fiber nets are the same. The proportion of polyester with low melting point in the medium fiber net is small. Fiber net and decorative fabrics are pressed thermally together to fabricate the sandwich structure fiber plate. The invention is the no-harmful circumstance-protection fiber plate with good heat insulation, sound insulation and force performances. It is suitable for internal decorative plate of vehicle door especially.

Owner:CHINA PETROLEUM & CHEM CORP +1

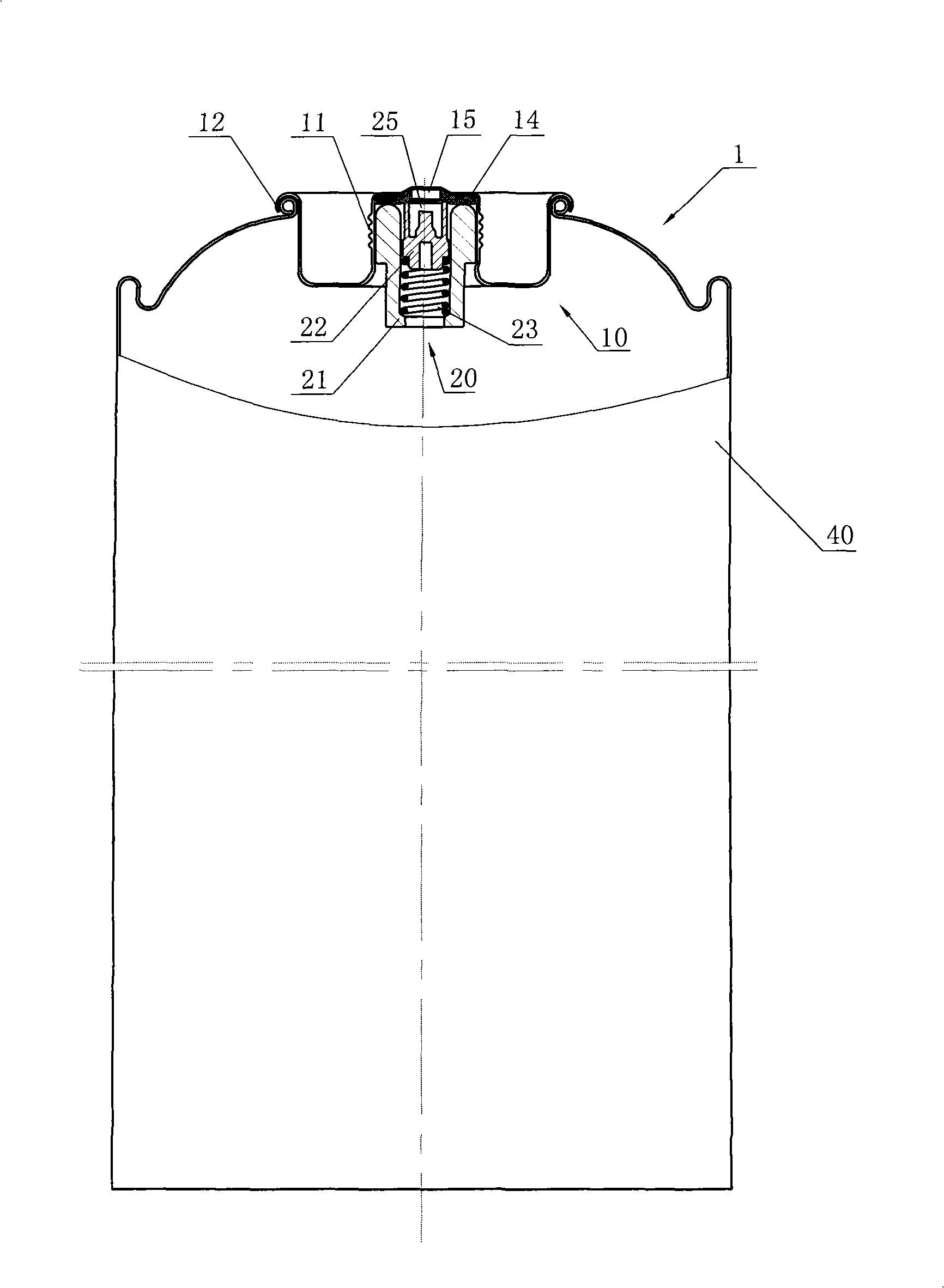

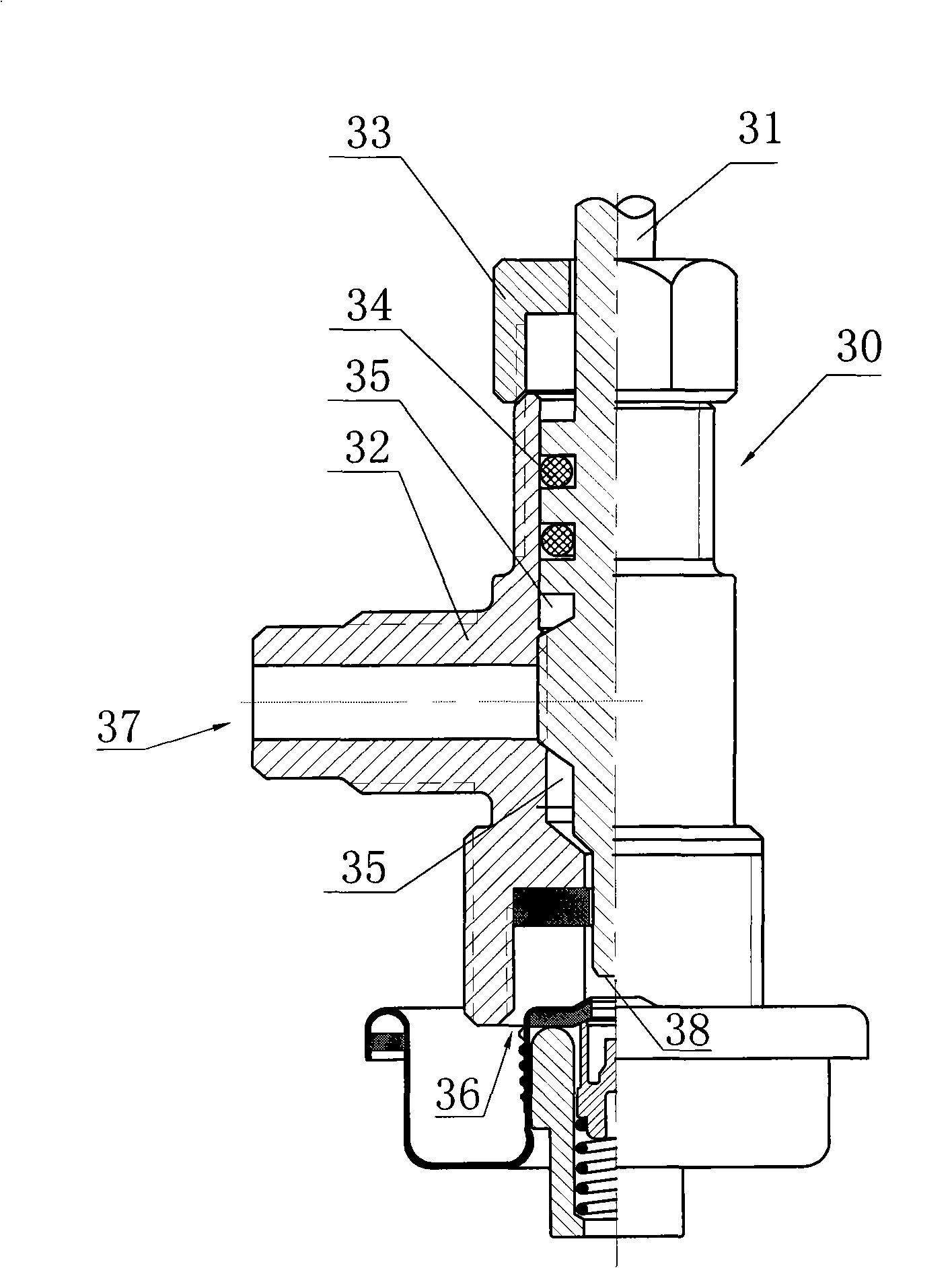

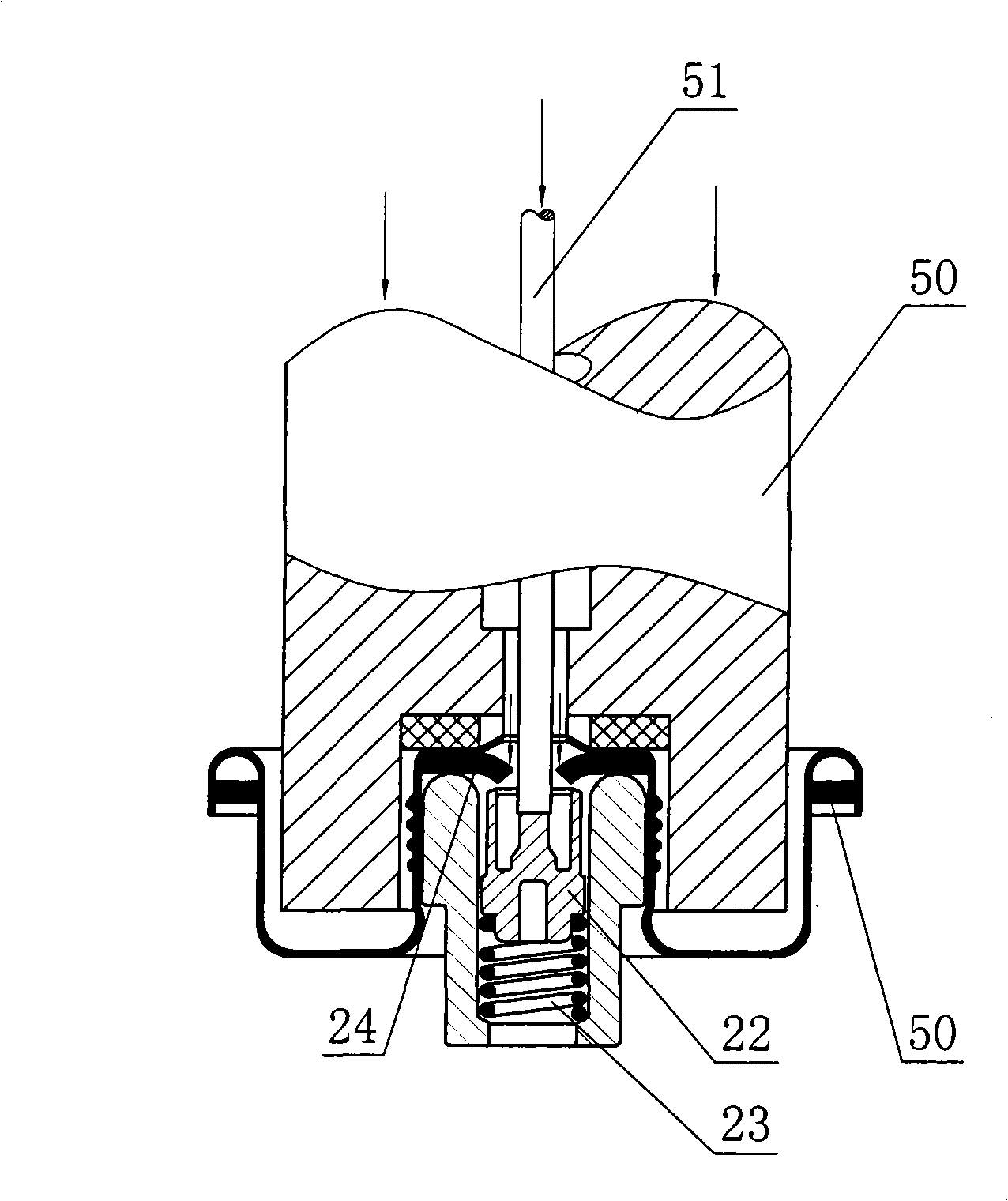

Carbon-hydrogen refrigerant for substituting R22

InactiveCN101402847ASolve the problem of high emission indexReduce noiseHeat-exchange elementsPressure vesselsVolumetric Mass DensityEngineering

The invention discloses a hydrocarbon refrigerant replacing R22, which comprises propane and isobutene; the propane accounts for 80 to 89 percent of the total mass; the isobutene accounts for 11 to 20 percent of the total mass. The hydrocarbon refrigerant is canned by a special refrigerating can; and the hydrocarbon refrigerant in the refrigerating can is discharged by a special bottle opener according to demands. The hydrocarbon refrigerant has a better filling characteristic, is mutually soluble with the existing lubricant, can be used in the refrigerating device of the existing R22 directly, can lead the running of refrigerating systems to be more optimized and also greatly improves the service life of compressors. The problems of ozonosphere destroying and higher greenhouse air discharge index caused by using the R22 refrigerant are solved. Moreover, the running noise is low, the self density is low, transport capacity can be saved and transport cost can be reduced. The special refrigerating can ensures the extreme low water content of the refrigerant in the can; and the special bottle opener can lead the refrigerant to be discharged according to demands, thus not only saving the resources, but also having no pollution as well as ensuring use safety.

Owner:周飞

All-solid-state polyelectrolyte film, its preparation and application method

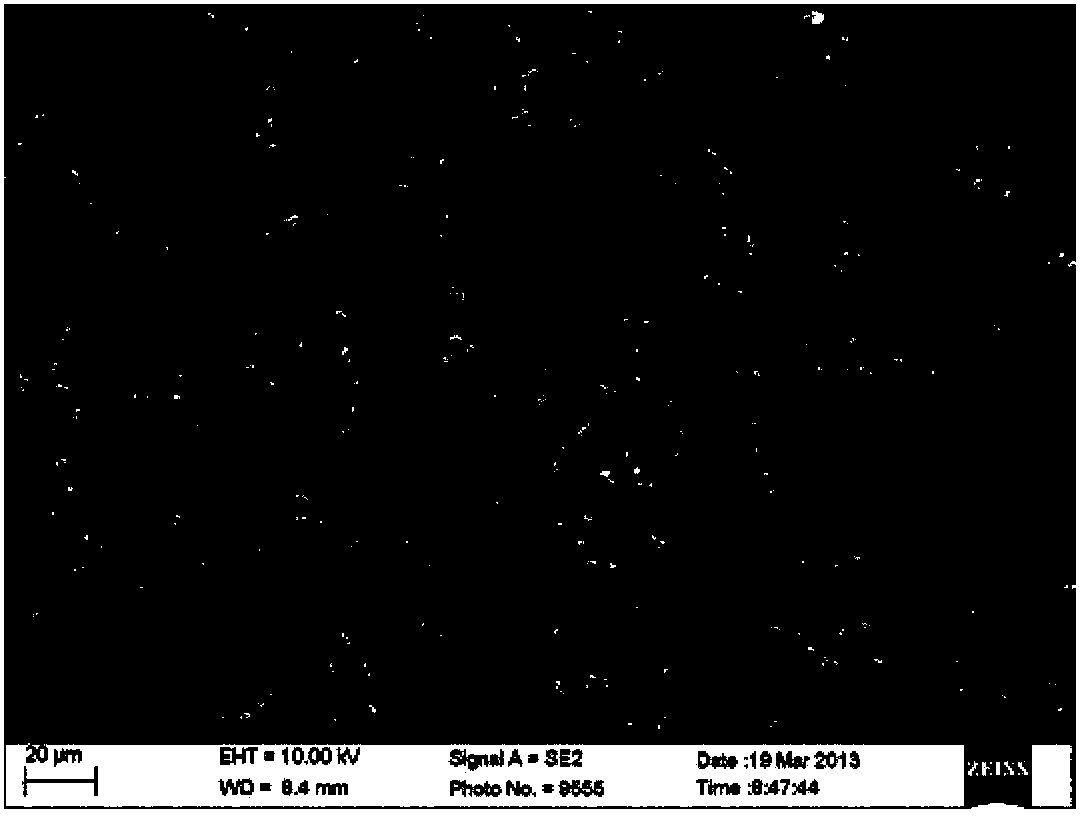

InactiveCN103367799AImprove thermal stabilityAchieve conductionSecondary cellsSolid state electrolytePolymer science

The invention provides an all-solid-state polyelectrolyte film based on polyvinyl formal or its homolog and a preparation method thereof. Through stepwise reaction of polyvinyl formal or its homolog and boric acid, oxalic acid, and a lithium salt in an organic solvent system, the solid-state polyelectrolyte film with polyvinyl acetal as a main chain and a lithium mono(oxalato)borate structure grafted on a polymer molecular chain can be formed. With low cost and simple operation, the all-solid-state polyelectrolyte film prepared by the invention can realize large-scale production, and has ideal ionic conductivity, electrochemical stability window and mechanical properties. Therefore, the all-solid-state polyelectrolyte film can be used as all-solid-state electrolyte in polymer lithium ion batteries to improve the safety performance of the lithium ion batteries.

Owner:浙江爱科新材料有限公司

Hot-melt adhesive for bonding layer of artificial leather and preparation method as well as application thereof

InactiveCN102618204AImprove high temperature resistanceGood chemical resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a hot-melt adhesive for the bonding layer of artificial leather and a preparation method as well as application thereof. The preparation method comprises the following steps of: firstly reacting low polymer polyalcohol, an expoxy resin and aromatic polyhydroxy special polyether with diisocyanate, then adding a hydrophilic chain extender and a micromolecule polyalcohol chain extender for carrying out chain extension reaction to obtain an intermediate product, neutralizing by using organic amine, emulsifying by using water to generate a polyurethane emulsion, finally removing an organic solvent at a reduced pressure to obtain a waterborne polyurethane emulsion, adding a special organic silicon surface active agent, a FeCl3 aqueous solution, a waterborne curing agent, natural rubber, chloroprene rubber, nitrile butadiene rubber and a thickening agent, and preparing the hot-melt adhesive for the bonding layer of artificial leather. The bonding layer of artificial leather is used for compositing spinning fabrics and PVC (Polyvinyl Chloride) / cloth in the fields of bags, suitcases and clothing. The prepared adhesive has the excellent performances of firm bonding strength, water resistance, acid resistance, alkali resistance and the like and is applied to the artificial leather fields of clothing, bags, suitcases and the like.

Owner:江阴市诺科生物新材料科技有限公司

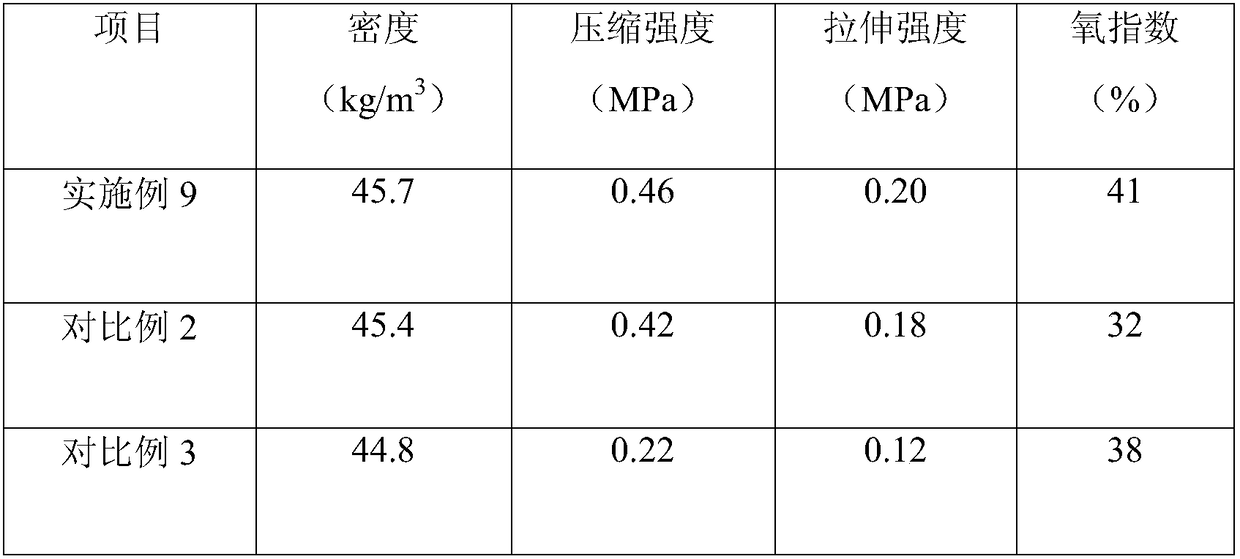

Non-combustible gel polymer electrolyte as well as preparation method and application thereof

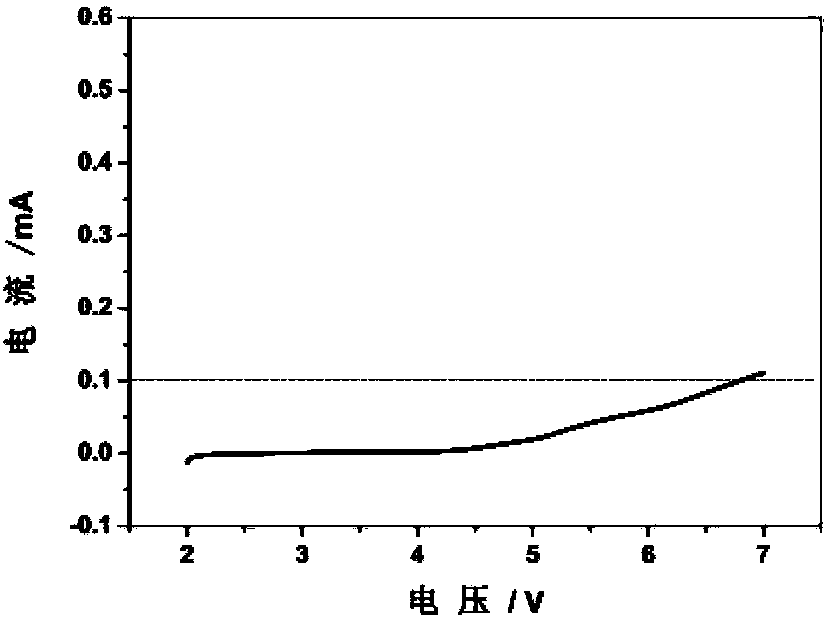

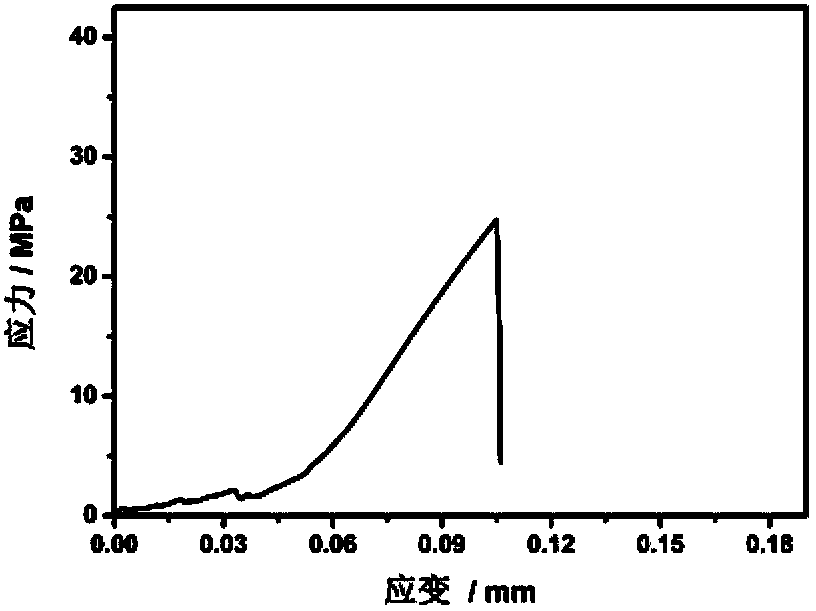

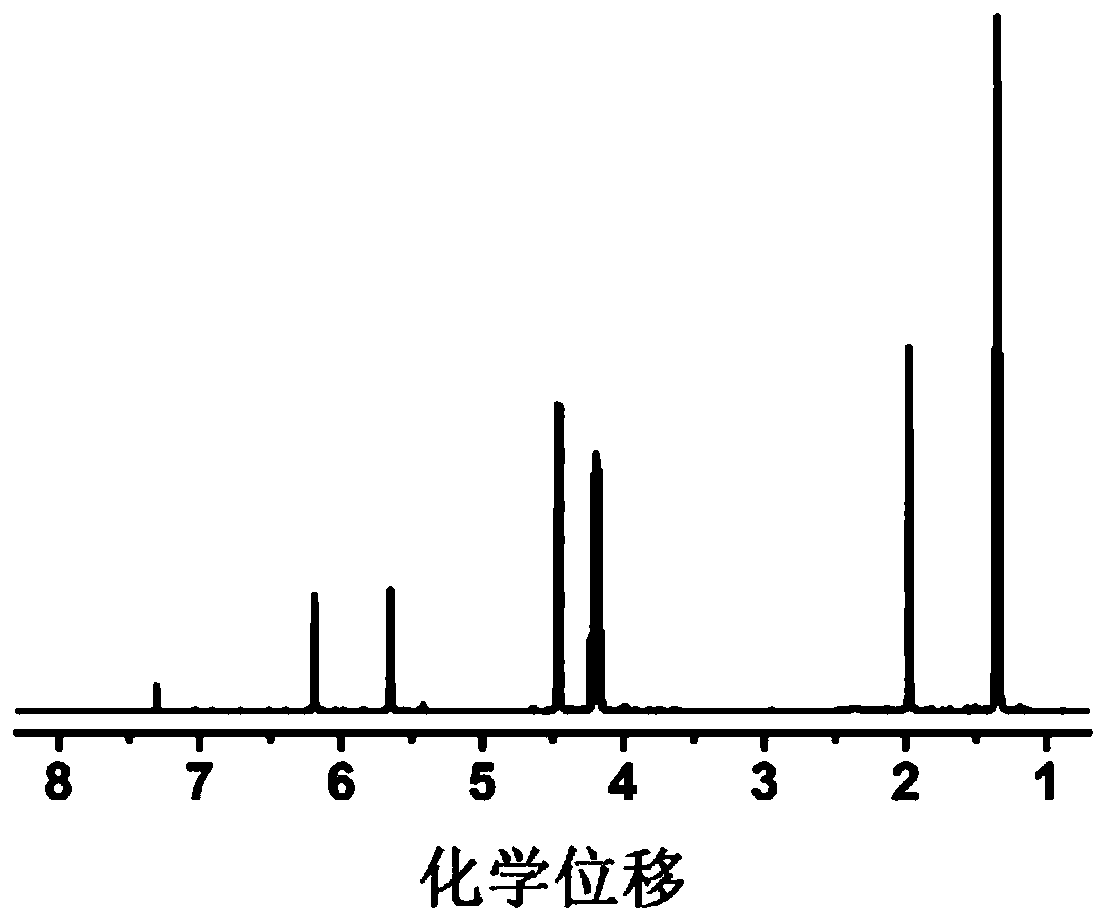

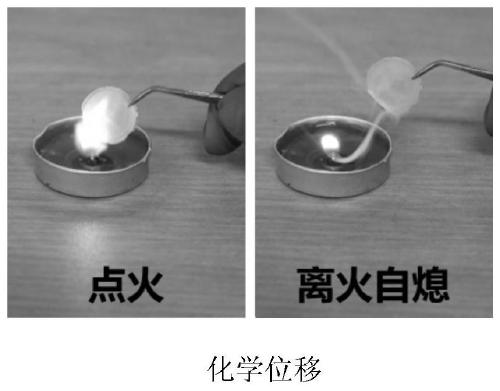

ActiveCN111253523AHigh phosphorus contentSolve flammableFinal product manufactureLi-accumulatorsElectrical batteryPlasticizer

The invention discloses a non-combustible gel polymer electrolyte. The non-combustible gel polymer electrolyte is prepared by the steps: dissolving a vinyl phosphorus-containing compound, a vinyl compound and a lithium salt which are uniformly mixed into a plasticizer; and then adding an initiator, pouring into a mold, flattening or dropwise adding into a diaphragm assembled between a positive electrode and a negative electrode of a battery to infiltrate the diaphragm, and heating at the temperature of 50-80 DEG C for 3-24 h to polymerize the monomer in situ, and thus obtaining the non-combustible gel polymer electrolyte. The gel polymer electrolyte has relatively high phosphorus content, cannot be ignited when meeting open fire, and also has relatively high ionic conductivity, lithium iontransference number and electrochemical window at room temperature. When the electrolyte is applied to a lithium battery, side reaction caused by migration of a vinyl phosphorus-containing compound can be avoided, and damage to electrochemical performance can be reduced while incombustibility is achieved.

Owner:SICHUAN UNIV

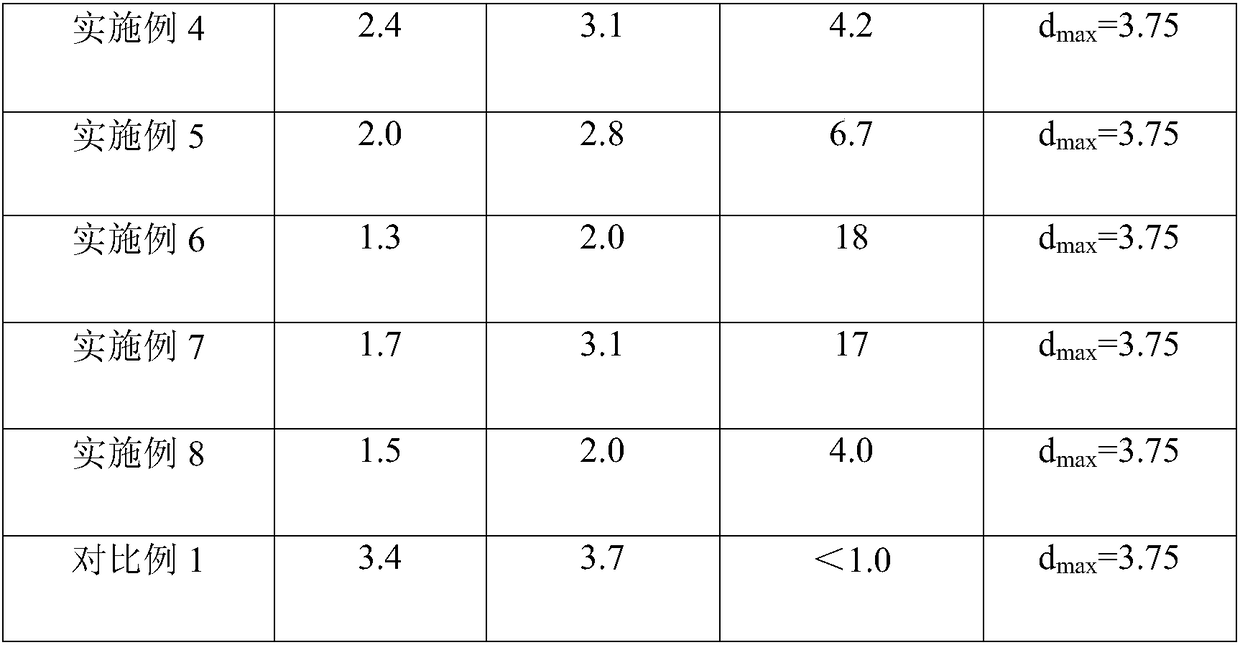

Self-thermal-insulating energy-saving wall body material based on iron tailings powder and preparation method of wall body material

InactiveCN103121855ALess investment in equipmentIncrease dosageSolid waste managementCeramicwareBuilding energyEconomic advantage

The invention discloses a novel self-thermal insulating energy-saving wall body material mainly made from iron tailings powder, as well as a preparation method of the wall body material, belonging to the technical field of the novel wall body material and building energy saving. The novel iron tailings powder self-thermal-insulating energy-saving wall body material is mainly prepared from the iron tailings powder in the presence of cement serving as a gelatinization material by using a foaming technology, straw cutting, super-light weight aggregate, an interface treatment technology and various admixtures. The wall body material has the beneficial effects that the requirement of saving 65% of energy in severe cold areas is reached without being adhered with a polystyrene board outside, a wall body and the thermal insulating function are formed at one time, effect of no self ignition is achieved, A-grade fire resistance requirement is reached, the inflammable problem of the current high-molecule outer wall thermal-insulating material is solved, and the service life of the wall body material is as long as the service life of a building. A great quantity of iron tailings powder is used for saving energy and utilizing waste and the industrial policy of national building energy saving and wall body innovation is met; and compared with the similar products, the wall body material has remarkable technological and economic advantages, can be widely used in the field of buildings and can generate enormous economic and social benefits.

Owner:肖力光

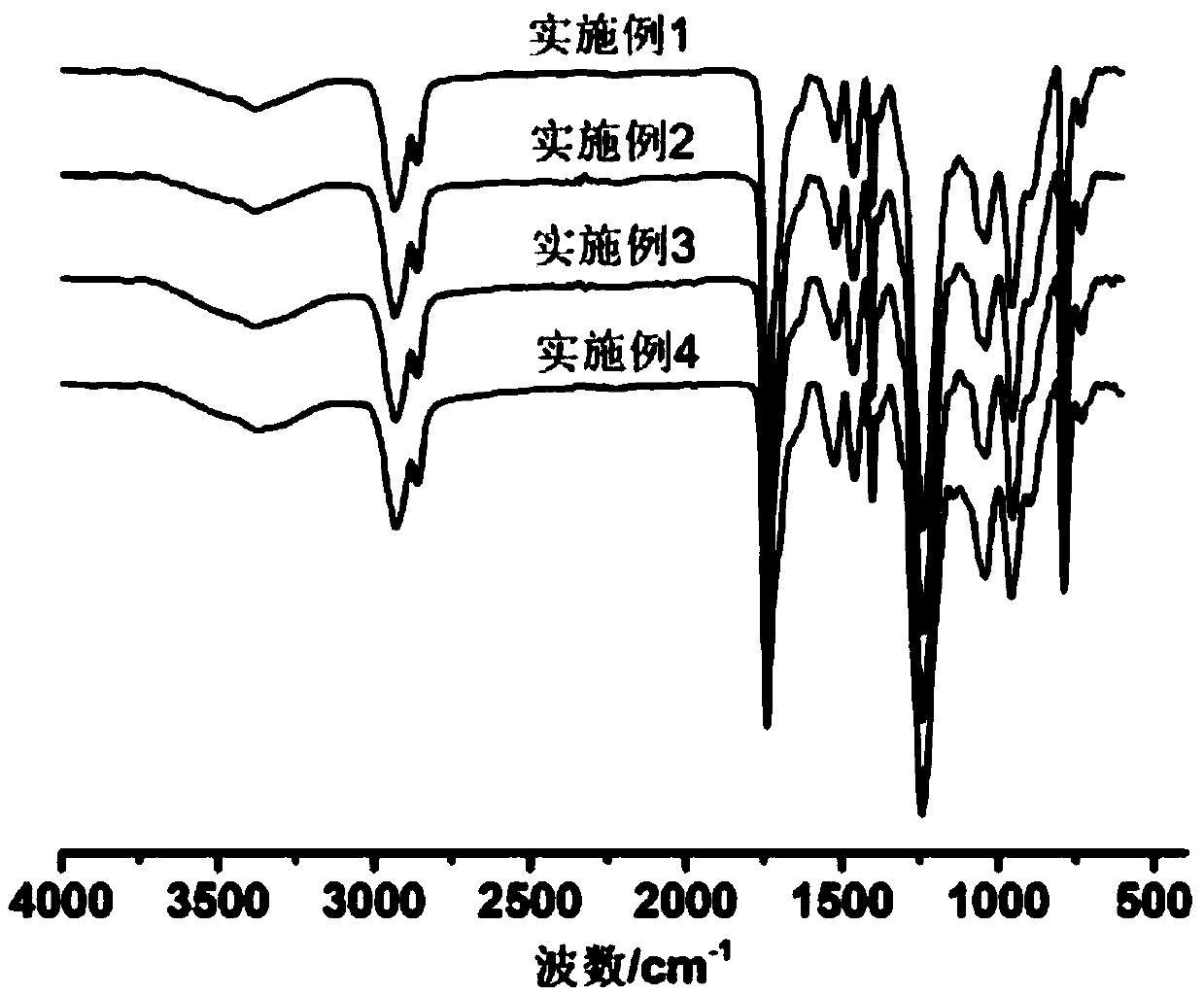

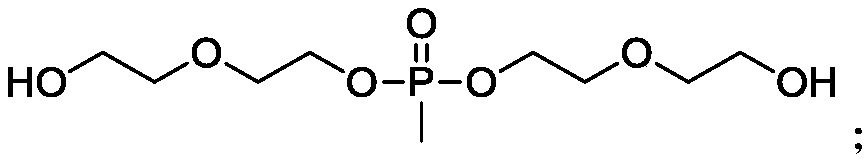

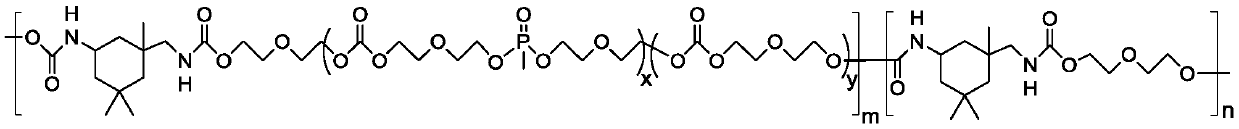

Phosphorus-containing flame-retardant thermoplastic polyurethane, solid electrolyte and lithium battery

InactiveCN109593179AReduce usageReduce pollutionSolid electrolytesSecondary cellsSolid state electrolytePolyol

The invention discloses phosphorus-containing flame-retardant thermoplastic polyurethane, solid electrolyte and a lithium battery. The polyhydric alcohol raw material in the phosphorus-containing flame-retardant thermoplastic polyurethane contains phosphorus-containing polycarbonate dihydric alcohol. The solid electrolyte contains 40%-90% of the phosphorus-containing flame-retardant thermoplasticpolyurethane and 10%-60% of lithium salt in percentage by weight. A preparation method of an electrolyte membrane of the solid electrolyte comprises the steps of dissolving the phosphorus-containing flame-retardant thermoplastic polyurethane and the lithium salt in a solvent to obtain film casting liquid, and preparing the electrolyte membrane by virtue of the film casting liquid. The electrolytehas high ionic conductivity, heat resistance and flame-retardant stability.

Owner:ANHUI UNIVERSITY

Rare earth magnesium-alloy material for 3D printing and preparation method of same

ActiveCN104762541AImprove flame retardant performanceMicrostructureAdditive manufacturing apparatusRare-earth elementSlag

The invention belongs to the technical field of 3D printing materials and discloses a rare earth magnesium-alloy material for 3D printing and a preparation method of the same. The preparation method particularly comprises following steps: (1) weighing raw materials according to element mass ratio of Mg:Mn:Re being 85-97:2-10:1-5; (2) adding pure magnesium, pure manganese and magnesium alloy into a pre-heated crucible, adding a cover agent and smelting the mixture under atmospheric conditions; (3) after the mixture smelted completely, adding an Mg-Re intermediate alloy and pure rare earth elements, melting the components with stirring uniformly and increasing the temperature to 700-750 DEG C; (4) adding a refining agent for refining the alloy for 2-25 min, allowing the refined alloy to stand, removing floated slag, adding the refined alloy into a sand mould trough to obtain a rare earth magnesium alloy base metal; and (5) smelting and atomizing the base metal to obtain the rare earth magnesium-alloy material. The rare earth magnesium-alloy material is excellent in flame retarding performance, is easy to control in powder shape and particle size, can be smelted without protective gas so that a problem of flammability during preparation of the magnesium alloy powder through an atomization method is solved, and can be used for laser 3D printing.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

"Pomegranate-type" fireproof thermal insulation plate, preparation method thereof and composite thermal insulation plate

ActiveCN103601995ASolve flammableSolve problems such as molten drippingHeat proofingFire proofingThermal insulationPotassium silicate

The invention relates to a "pomegranate-type" fireproof thermal insulation plate. The "pomegranate-type" fireproof thermal insulation plate is a fireproof thermal insulation plate having a structure similar to pomegranate, and is prepared by subjecting each polystyrene particle monomer to composite treatment to form a structure of pomegranate seeds. The "pomegranate-type" fireproof thermal insulation plate comprises 40-80 parts by weight of expandable polystyrene particles, 20-60 parts by weight of an inorganic surface-covering packaging material, and 2-10 parts by weight of a fire retardant, wherein the inorganic surface-covering packaging material is one or more selected from silica sol, sodium silicate and potassium silicate. The organic thermal insulation material in the fireproof thermal insulation plate is isolated by the inorganic material, and cannot drop, and therefore the fireproof thermal insulation plate has good fireproof effects. The invention also relates to a preparation method of the fireproof thermal insulation plate and a composite thermal insulation plate comprising the fireproof thermal insulation plate. The fireproof thermal insulation plate can be used as building materials.

Owner:营口圣泉高科材料有限公司

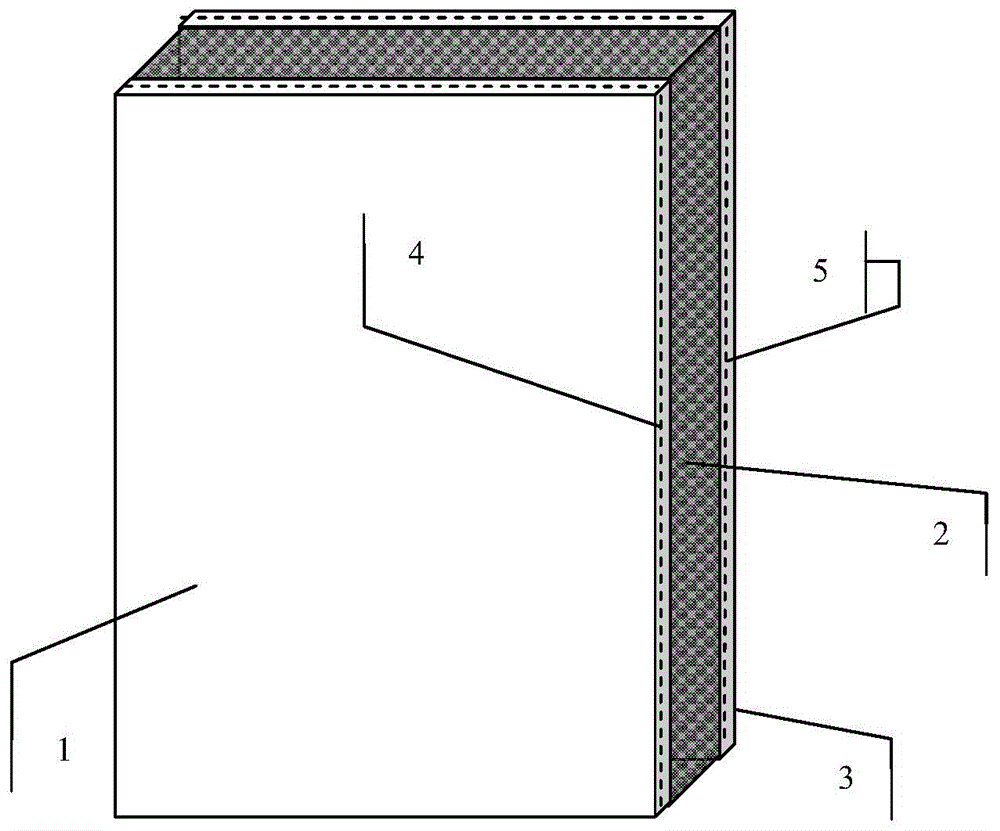

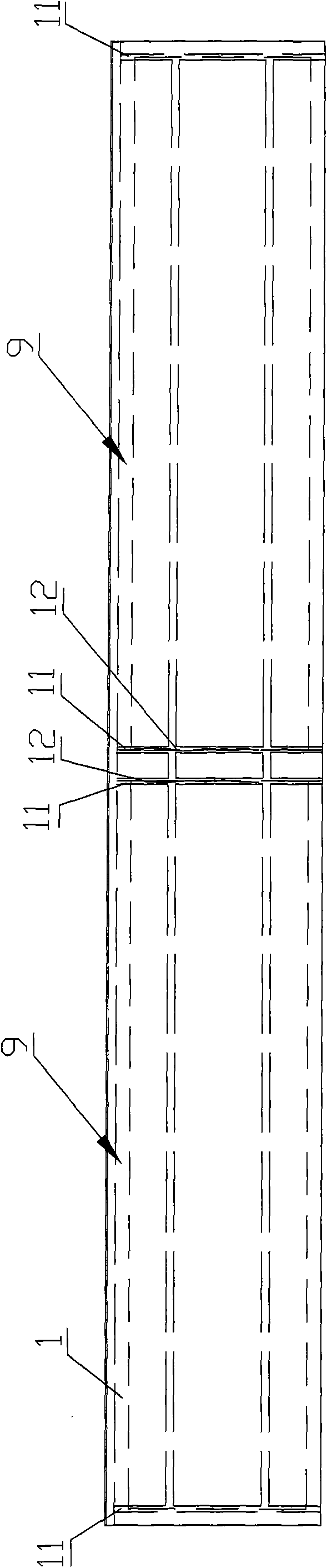

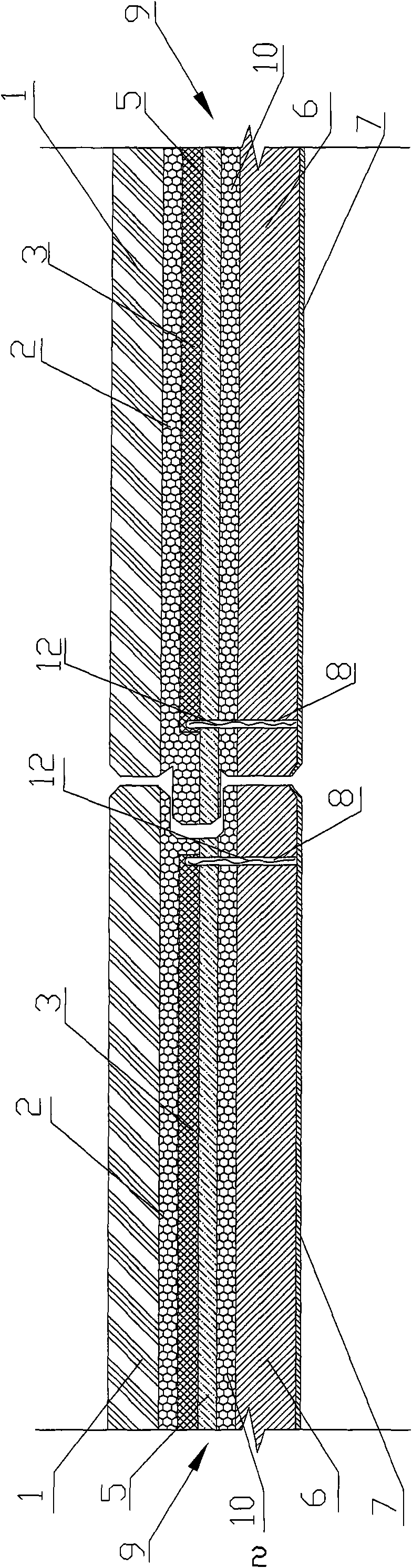

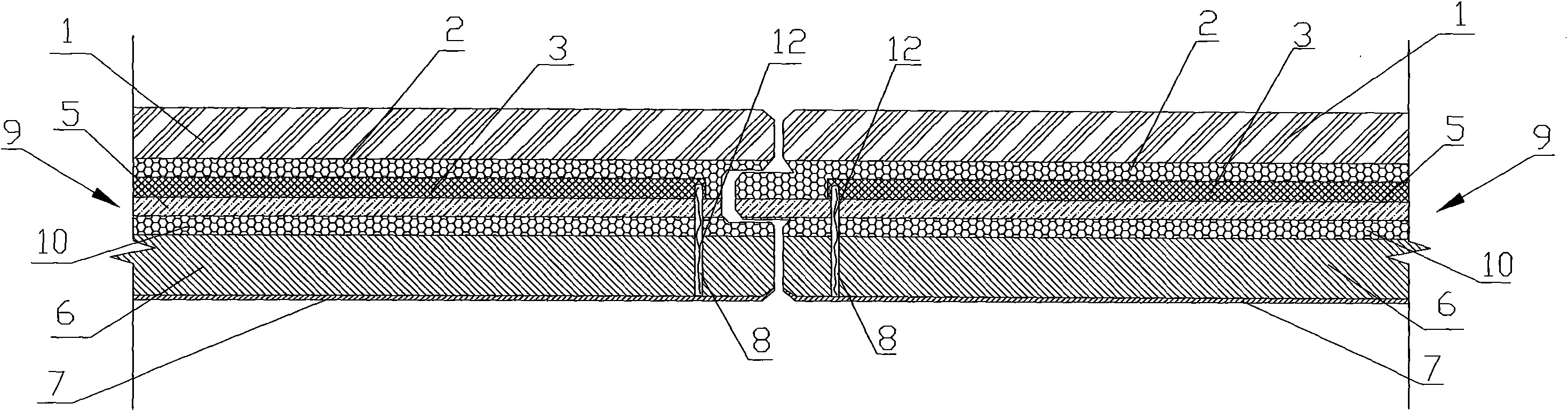

Self-heating floor and manufacturing method thereof

ActiveCN101846357ASolve flammableAvoid it happening againLighting and heating apparatusElectric heating systemEpoxyGlass fiber

The invention discloses a self-heating floor and a manufacturing method thereof. The floor comprises a substrate, a surface layer, and a conductive heating sheet which is arranged between the substrate and the surface layer, wherein the conductive heating sheet comprises a glass fiber epoxy resin base layer, a conductive heating layer which is arranged on the upper surface of the glass fiber epoxy resin base layer, an upper flame-retardant protection layer which covers the upper surface of the glass fiber epoxy resin base layer and coats the conductive heating layer, and a lower flame-retardant protection layer which covers the lower surface of the glass fiber epoxy resin base layer; the upper flame-retardant protection layer is bonded on the lower surface of the surface layer; and the lower flame-retardant protection layer is bonded on the upper surface of the substrate. The conductive heating sheet can be prevented from being burned when heated to a higher temperature by arranging the flame-retardant protection layers so as to ensure the use safety of the floor. The upper flame-retardant protection layer and the lower flame-retardant protection layer can be made of a glass fiber cloth which is soaked by an epoxy resin. In the method for manufacturing the self-heating floor, the upper flame-retardant protection layer and the lower flame-retardant protection layer are bonded on the glass fiber epoxy resin base layer in vacuum under the pressure of 0.09MPa and 1 to 20MPa in turn so as to prevent the glass fiber epoxy resin base layer from foaming.

Owner:SINO MAPLE JIANGSU CO LTD

Flame-retardant coated-type polystyrene pre-expanded bead and its preparation method

ActiveCN103923339ASolve flammableSolve problems such as molten drippingPotassium silicatePolystyrene particle

The invention relates to a flame-retardant coated-type polystyrene pre-expanded bead and its preparation method. The pre-expanded bead mainly comprises 40 to 80 parts of expandable polystyrene particles, 20 to 60 parts of an inorganic coating material and 2 to 10 parts of a flame retardant agent, wherein the inorganic coating material is one or more substance from silicon sol, sodium silicate and potassium silicate, the silica sol concentration is 20-60%, if the soluble silicate is used, the modulus can be 2-4, and concentration can be 10-50%. The flame-retardant coated-type polystyrene pre-expanded bead has the advantages of simple preparation process and low cost, and can well solve the problems that polystyrene foam materials are flammable and easy to drop.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

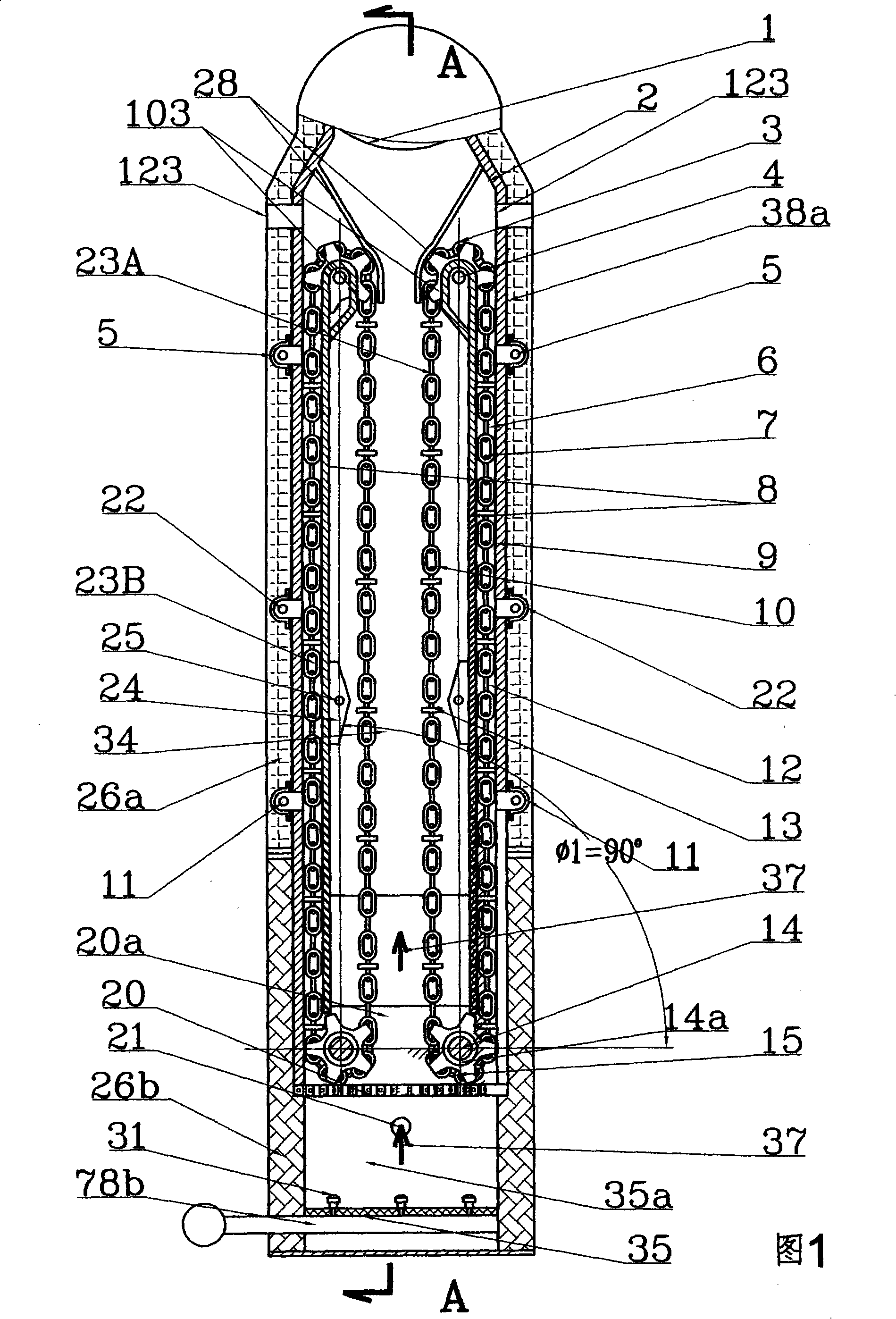

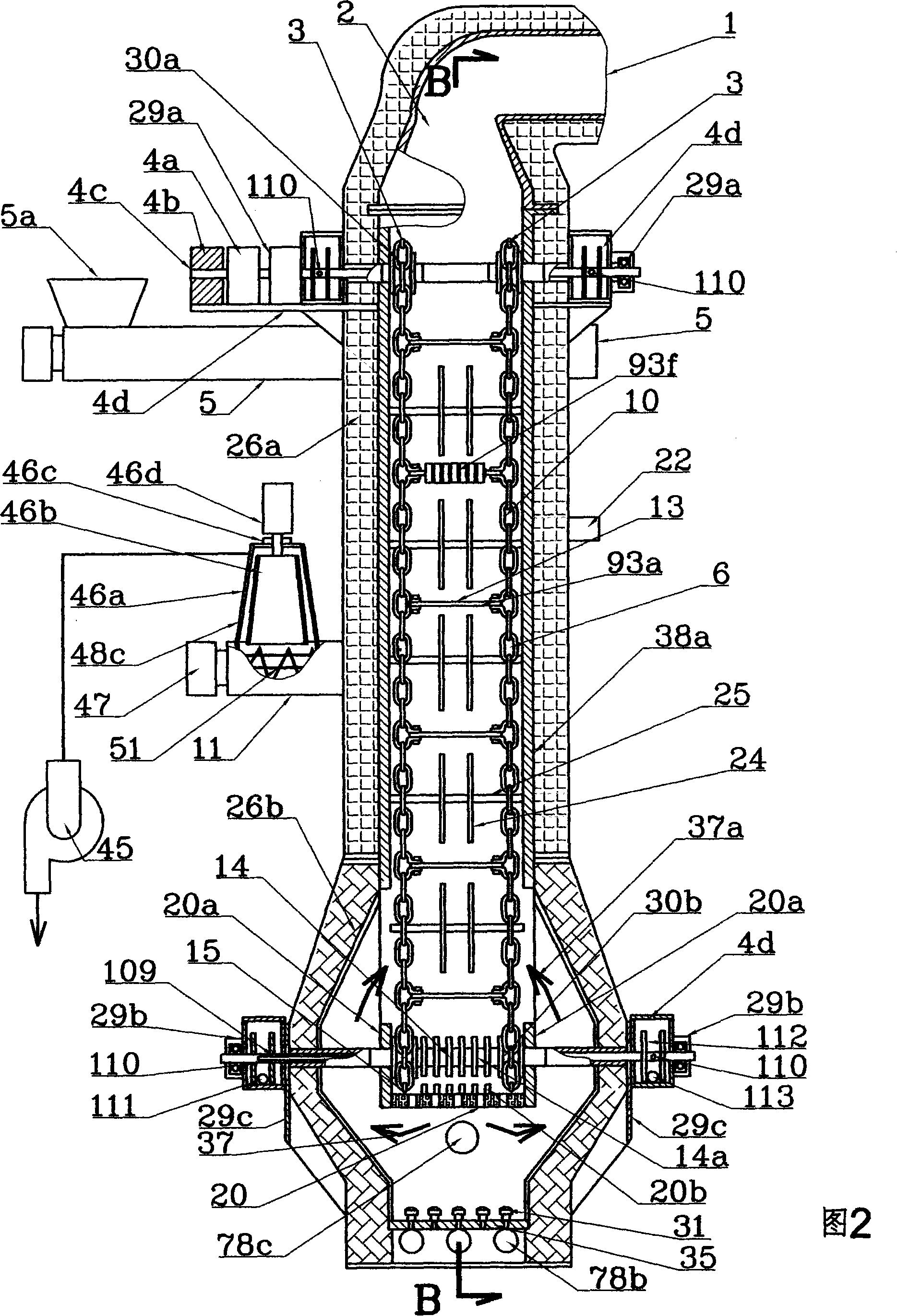

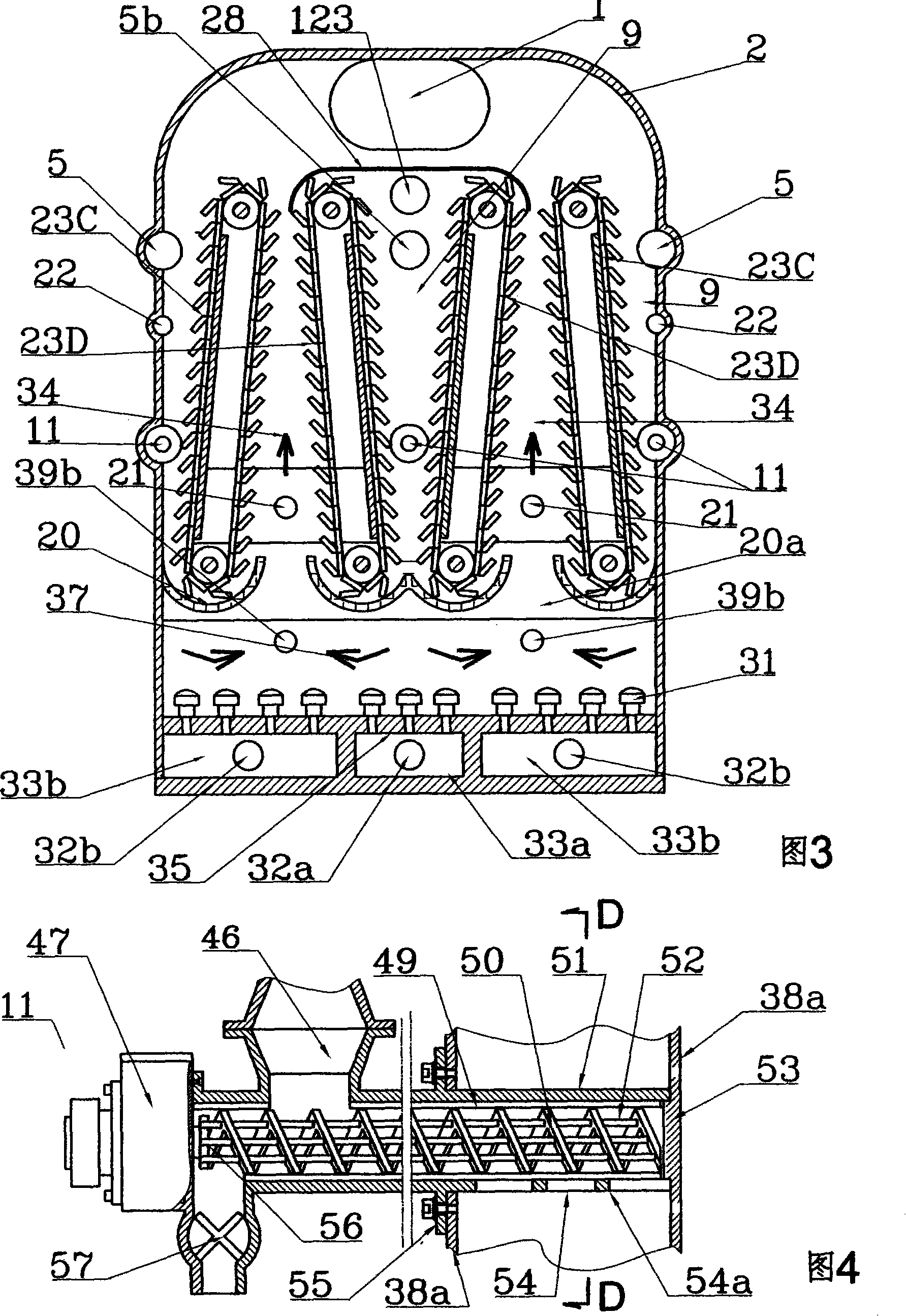

Chain track enterclose type anoxia ebb fried drying, burning and burningcandle decomposition apparatus

InactiveCN101161599AEasy dischargeImprove energy savingSludge treatment by de-watering/drying/thickeningIncinerator apparatusDecompositionSewage treatment

The invention discloses to a chain way dividing wall type anoxia weak explosion drying, incineration and ablative pyrogenation device which comprises a heat generation system, a constant temperature space and a mechanical and electrical integration complete equipment of control system, wherein, the constant temperature space is a closed shell formed by vertical walls, an upper end cap and a low end cap, the average temperature in the constant temperature space is between 80 DEG C and 1000 DEG C, the shell a cylinder around which a heat-resistant thermal insulating layer is arranged; each chain way heat exchanger comprises a cable chain, a cable chain driving device and a dividing wall chamber; the raw materials pass through a up-chain way and a down-chain way taken as a moisture evaporation section, a pyrogenation gas evaporation section and a high temperature section to continuously finish the evaporation and the pyrogenation of the moisture as well as the pulverization and the drying or the incineration of the charcoal. The invention meets the requirements of drying and manufacturing combustible gas and charry or liquid fuel on the basis of the principles of the dividing wall, the radiation, the constant weak and general explosion of anoxic / anaerobic explosion water and ablation heat transfer principle. The invention has higher ability of heat and mass transfer, the volume of the system is greatly decreased, all the energy can be supplied by the raw materials, the treatment cost is greatly decreased, and the invention is particularly suitable for sludge minimization treatment in sewage treatment plants.

Owner:天津市石化通用机械研究所有限公司 +1

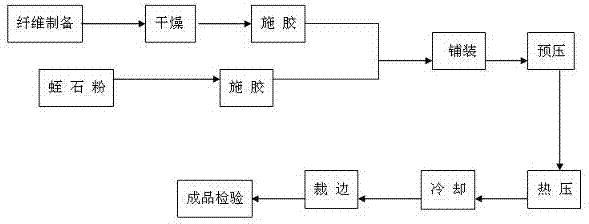

Production method of vermiculite flame retardant medium density fiberboard

InactiveCN102259369AGood mechanical propertiesSolve environmental problemsWood working apparatusFlat articlesEnvironmental resistanceFiber

The present invention is a production method of vermiculite flame retardant medium density fiberboard, which includes selection of raw materials, preparation of surface layer, bottom layer and core layer, paving, pre-pressing, hot pressing, cooling, stacking, edge cutting, physical mechanics and combustion performance tests, etc. process steps. Advantages: due to the separate sizing of the surface layer, bottom layer and core layer materials, the amount of vermiculite added is based on the percentage of absolute dry fiber weight, the mechanical properties of the medium density fiberboard made by the present invention are better than the existing flame retardant and wood fiber Mechanical properties of medium density fiberboard made with mixed sizing. The results of the combustion performance test show that due to the addition of vermiculite accounting for 30-70% of the dry fiber weight in wood fibers, the heat release rate, total heat release, total smoke release, smoke yield and Mass loss rate, delayed ignition time. Tests have proved that with the increase of the amount of vermiculite added, the flame retardant performance of the product will increase. This product solves the problems of flammability and environmental protection, has low cost, and has both practical significance and promotion value.

Owner:NANJING FORESTRY UNIV

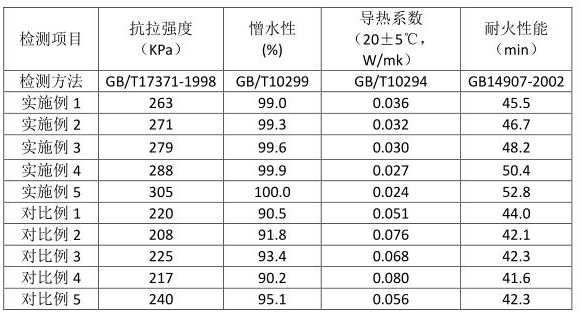

External wall heat-insulation material for constructional engineering and preparation method thereof

InactiveCN109704806ASimple manufacturing methodRaw materials are easy to getCeramicwareFiberMicrosphere

The invention discloses an external wall heat-insulation material for constructional engineering. The external wall heat-insulation material is prepared from the following raw materials in parts by weight: 15 to 20 parts of water-quenched slag, 20 to 30 parts of portland cement, 10 to 15 parts of hollow spherical zirconium oxide, 5 to 10 parts of silicon micro-powder, 10 to 20 parts of glass wool,10 to 20 parts of ceramic fiber cotton, 5 to 10 parts of hollow ceramic microspheres, 3 to 7 parts of expansive soil, 5 to 10 parts of attapulgite, 5 to 10 parts of a functional auxiliary agent basedon PPS-biphenylvinylsiloxy-heptacyclopentyl substituted derivative, 1 to 3 parts of a foaming agent, 1 to 2 parts of polyurethane and 25 to 35 parts of water. The invention further discloses a preparation method of the external wall heat-insulation material for the constructional engineering. The external wall heat-insulation material for the constructional engineering, disclosed by the inventionhas excellent comprehensive performance, remarkable heat-insulation effect and strong flame-retarding performance, heat insulation and coagulation performance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

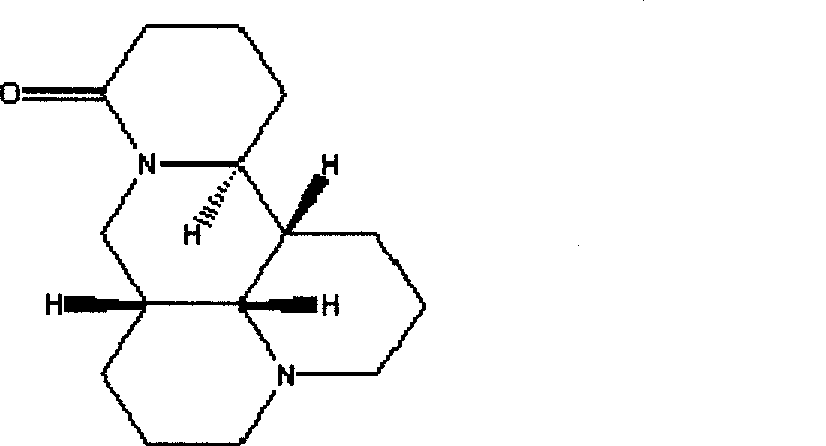

Berberine avermectin water agent

The invention relates to a berberine abamectin aqua which is characterized in that abamectin and berberine plant extract are composed into the aqua, wherein, the content of the abamectin is 1mg / L to 2mg / L and the content of the berberine plant extract is 45mg / L to 55mg / L. The berberine abamectin aqua, by composing two kinds of pesticides with different mechanisms of action, not only can be favorable to solving the drug resistance of pests but also can improve the property of each drug, i.e. the content of the abamectin is greatly reduced, while the toxicity of the abamectin against the pests and the control of the berberine plant extract over the pests are improved; simultaneously, the aqua takes water as basic material, thus solving the problems of flammability and hazard caused by organic solvents and avoiding poisoning people and livestock and polluting environment.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Process for preparing environmental protection soft polyurethane foam plastics

This invention is an environment protection soft quality polyurethane foam plastic generation method; it belongs to precision chemical industry field. It mainly solves the environment protection problem of soft quality polyurethane foam plastic in generation process. Toluene diisocynate and low unsaturated degree polyether glycol do one-step reaction to generate the soft quality polyurethane foam plastic. The feature lies in that foaming agent is cyclopentane, main reactant is modifying polyether glycol and nitrogen gas is added during the generation. The soft quality polyurethane foam plastic generated by this method can solve ozone consumption problem, and the generation process is safe, product quality is good.

Owner:张修景

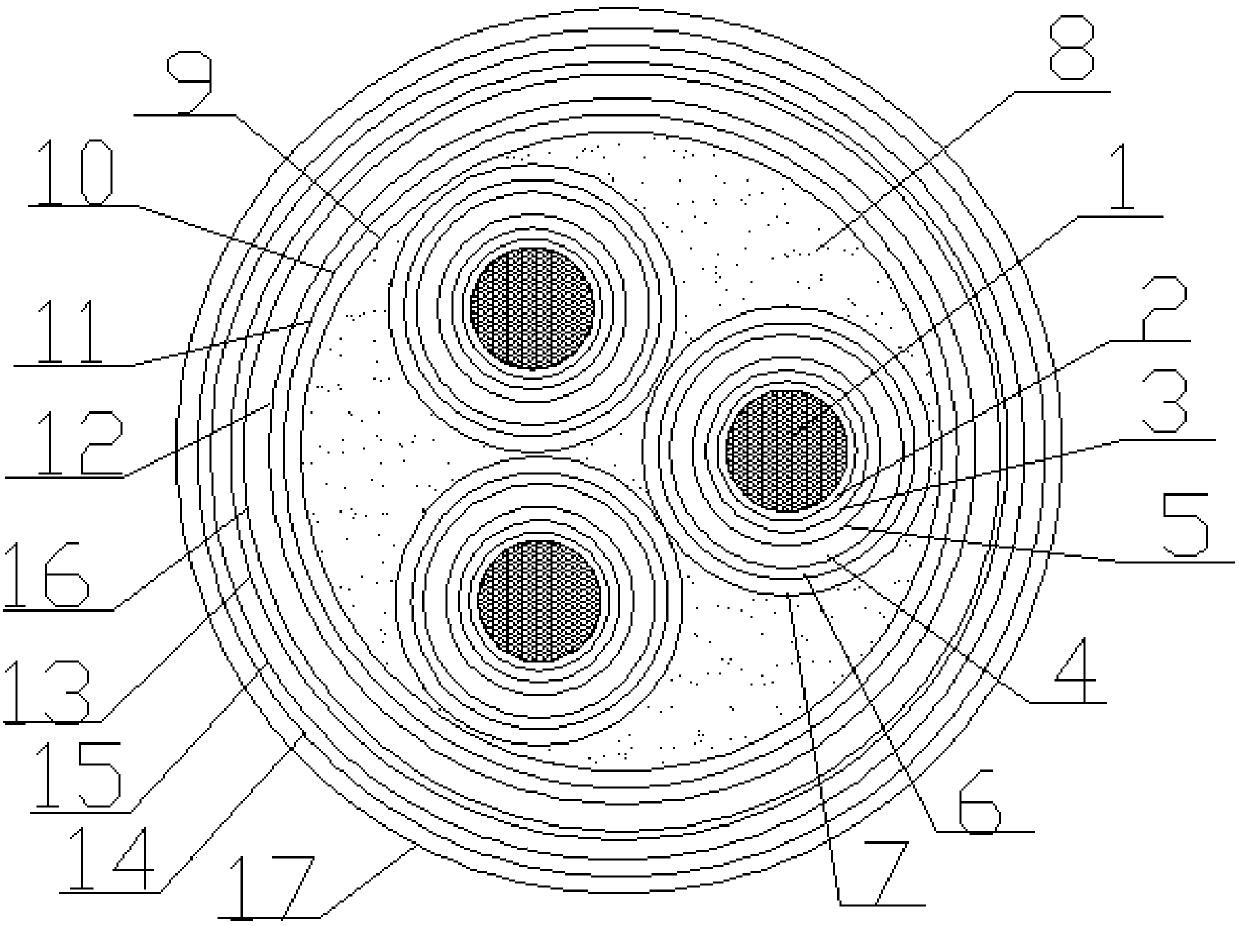

Pumped vacuum system and die casting method of magnesium alloy vacuum high-pressure die casting mould

The invention provides a pumped vacuum system and a die casting method of a magnesium alloy vacuum high-pressure die casting mould. Castings are better produced under vacuum state in order to have higher quality and meet the requirement of high cutting-edge technology occasions, therefore the mould has to undergo vacuum high-pressure die casting in order to solve the problem of flammability of magnesium alloys and overcome the pore defect and improve the quality of the castings and the productivity of the finished product. The pumped vacuum system comprises a gating system, wherein the gating system is connected with a labyrinth system (2) by an exhaust duct (1) and comprises a pressure chamber (3); the pressure chamber is connected with a sprue (4) of the labyrinth system; the sprue is connected with a runner (5); the runner is connected with inner casting gates (6) which are connected with the exhaust duct; the inner casting gates comprise overflow systems (7); and the labyrinth system is connected with vacuum valves (8). The invention is used for magnesium alloy die casting.

Owner:HARBIN UNIV OF SCI & TECH

Manufacturing method for crop straw building external wall heat insulation plate

ActiveCN105382911AEfficient use ofReduce energy consumptionFlat articlesDomestic articlesMildewEngineering

The invention provides a manufacturing method for a crop straw building external wall heat insulation plate. The method includes the steps that wheat straw, rice straw, cotton stalks and other agricultural leftovers are used as the raw materials; the technological processes of chopping smashing, mixing opening, airflow laying, acupuncturing felt forming, gluing sizing and curing, inflaming retarding, corrosion and mildew preventing treating, dicing molding and the like are conducted; and finally the light and durable building external wall heat insulation plate with the inflaming retarding and sound insulating functions is manufactured. Development of green buildings of our country is facilitated, energy consumption of buildings is greatly lowered, and efficient and high-additive value recycling of crop straw is achieved.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

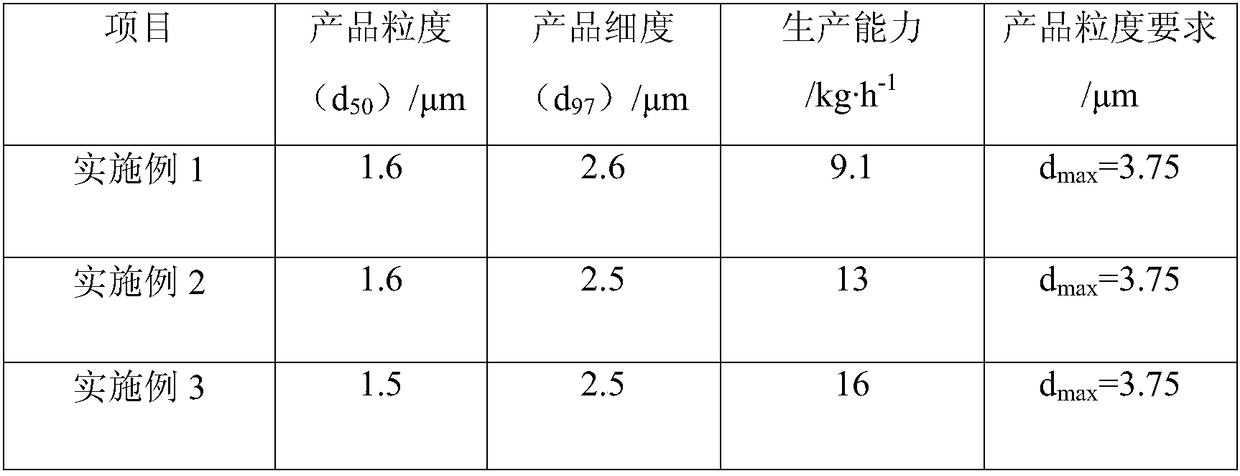

Preparation method of superfine lignin

ActiveCN108503862AUltra-fine crushing achievedReduce crushing energy consumptionGranularityHeat stability

The invention relates to superfine lignin and a preparation method thereof. The superfine lignin is lignin with granularity of 4000 to 10000 meshes. The preparation method comprises the following steps of feeding the lignin and a grinding additive, crushing by air flow, grading in a superfine way, returning back the coarse grains after grading to crush again, and collecting the product. The preparation method has the advantages that the grinding additive is added in the air flow crushing technology of the lignin, the grinding assisting effect is utilized, the superfine crushing of the lignin is realized, the crushing energy consumption is decreased, and the production efficiency is improved; because the crushing granularity of the grinding additive is smaller than the granularity of the lignin, the grinding additive is attached to the surface of the lignin to coat the lignin, and the good flame-retardant function is realized; by adopting the superfine lignin-filled plastic, foam and other materials, while the cost is reduced and the flame-retardant property is improved, the better mechanical property, heat stability and anti-ultraviolet aging property are realized, and the market requirements can be met.

Owner:NANJING UNIV OF TECH

Fiber-toughened wear-resistant cable material and preparation method thereof

The invention discloses a fiber-toughened wear-resistant cable material and a preparation method thereof. The material is characterized by being prepared from the following raw materials by weight: 90 to 100 parts of polyethylene, 10 to 15 parts of red phosphorus, 3 to 5 parts of paraffin, 0.5 to 1 part of a silane coupling agent kh570, 15 to 25 parts of nanometer calcium carbonate, 0.8 to 1.6 part of polyvinyl alcohol, 2 to 4 parts of copper powder, 5 to 8 parts of polystyrene resin, 1 to 3 parts of zinc borate, 5 to 10 parts of pentaerythritol stearamide, 2 to 3 parts of ethylenethiourea, 3 to 5 parts of glass fiber, 2 to 4 parts of oxidized polyethlene wax, 3 to 4 parts of reinforcing carbon black and a proper amount of absolute ethanol. According to the invention, the preparation method is simple; material sources are extensive; the prepared cable material has good comprehensive performances and long service life, and is worth popularization.

Owner:HEFEISHI SHENZHAO ELECTRONICS

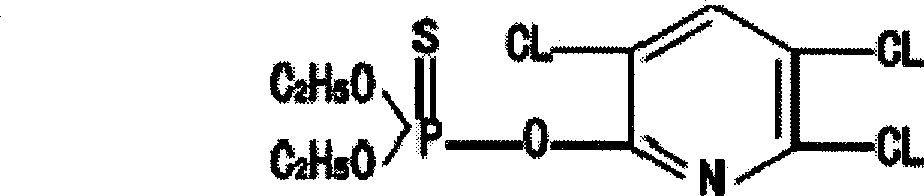

Matrine chlorpyrifos water agent

InactiveCN101422177AOvercome the problem of poor quick effectLong-lasting effectBiocideArthropodicidesChlorpyrifosOrganic solvent

The invention relates to a matrine chlorpyrifos aqua which is characterized in that chlorpyrifos and matrine plant extract are composed into the aqua, wherein, the content of the chlorpyrifos is 1mg / L to 2mg / L and the content of the matrine plant extract is 2mg / L to 5mg / L. The matrine chlorpyrifos aqua, by composing two kinds of pesticides with different mechanisms of action, not only can be favorable to solving the drug resistance of pests but also can improve the property of each drug, i.e. the dosage of the chlorpyrifos is greatly reduced, while the toxicity of the chlorpyrifos against the pests and the control of the matrine plant extract over the pests are improved; simultaneously, the aqua takes water as basic material, thus solving the problems of flammability and hazard caused by organic solvents and avoiding poisoning people and livestock and polluting environment.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Natural environmental-protective detergent

InactiveCN1818046AHigh removal rateIncrease costSurface-active detergent compositionsDetergent dyesSurface-active agentsSoy bean

The invention opened a natural abluent whose batch formula includes furfur, the sodium alkyl benzene sulfonate, the soy bean powder, the surface active agent, the whitener and so on. The main material of the invention is the natural furfur, so it has no corrosivity. The decontamination ratio can reach above 97%, so it can be used for the service profession and the undurable goods.

Owner:李阳林

Household socket and flame-retardant treatment process thereof

InactiveCN107868577AHigh affinityPrevent flocculationFireproof paintsContact member cases/bases manufactureEpoxyEmulsion

The invention discloses a household socket. The household socket comprises a socket box, wherein an insertion surface butted with a plug is arranged on the socket box; a cover body is also arranged onthe socket box; a protection layer is arranged on the inner wall of the cover body. The protection layer is prepared from the following components in parts by mass: 20-30 parts of organosilicone modified epoxy resin, 10-15 parts of a polyvinyl acetate emulsion, 0-15 parts of a plasticizer, 2-4 parts of a flame retardant, 5-8 parts of diatomite, 1-3 parts of pigments and fillers, 5-7 parts of a silane coupling agent, 4-6 parts of a curing agent, 0.5-1 part of a flame-retardant synergist, 0.1-0.5 part of an antioxidant and 0.2-0.4 part of composite rare earth. The flame-retardant treatment process is simple and is easy to operate; the treated socket has extremely high flame resistance; the service life of the socket is prolonged; and the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Building energy-saving thermal insulation material and preparation method thereof

The invention discloses a building energy-saving thermal insulation material, which is characterized being prepared from the following raw materials by weight: 15-25 parts of cement, 15-20 parts of blast furnace water granulated slag, 35-40 parts of volcanic ash, 5-8 parts of surface function modified porous hollow aluminum oxide nanofibers, 2-4 parts of rare earth fluoride hollow nano ions, 3-6 parts of Lambda-cyhalothric acid modified aminated beta-cyclodextrin and 1-3 parts of a coupling agent. The invention also discloses a preparation method of the building energy-saving thermal insulation material. The building energy-saving thermal insulation material disclosed by the invention is excellent in comprehensive performance, strong in thermal insulation property, good in aging resistance, weather resistance and flame retardance, excellent in performance stability and mechanical property, green and environment-friendly in use, high in durability, weather resistance, corrosion resistance, freeze thawing resistance and reliability, and wide in application range.

Owner:康亚男

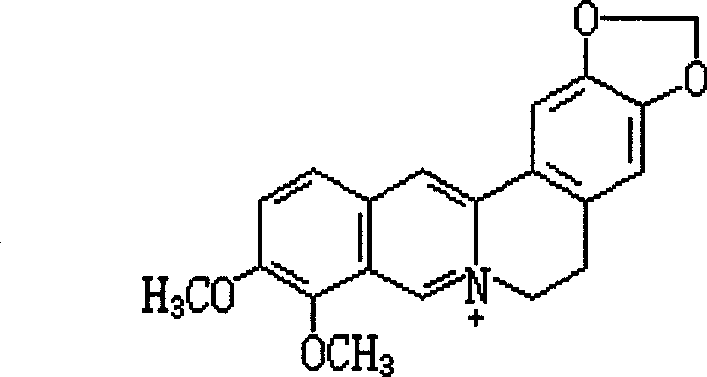

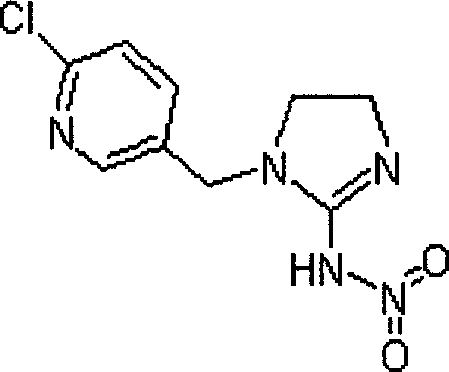

Berberine imidacloprid water agent

The invention relates to a berberine imidacloprid aqua which is characterized in that imidacloprid and berberine plant extract are composed into the aqua, wherein, the content of the imidacloprid is 1mg / L to 2mg / L and the content of the berberine plant extract is 15mg / L to 20mg / L. The berberine imidacloprid aqua, by composing two types of pesticides with different mechanisms of action, not only can be favorable to solving the drug resistance of pests but also can improve the property of each drug, i.e. the dosage of the imidacloprid is greatly reduced, while the toxicity of the imidacloprid against the pests and the control of the berberine plant extract over the pests are improved; simultaneously, the aqua takes water as basic material, thus solving the problems of flammability and hazard caused by organic solvents and avoiding poisoning people and livestock and polluting environment.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Medium-voltage fire-resistant power cable

InactiveCN107564612AExcellent flame retardantImprove fire resistancePlastic/resin/waxes insulatorsInsulated cablesFiberFirestop

The invention discloses a medium-voltage fire-resistant power cable, which comprises a cable core, wherein the cable core is formed by twisting a plurality of wire cores; each wire core comprises a conductor, a shielding layer, an insulating layer and an insulating shielding layer; the shielding layers, insulating layers and the insulating shielding layer are arranged outside the corresponding conductors; each conductor is formed by twisting a plurality of copper core conductors; a thermal insulating layer is also arranged outside each insulating layer; one insulating shielding layer is arranged outside each thermal insulating layer; a metal shielding layer wraps the outside of each insulating shielding layer; a fire-resistant layer is arranged outside each metal shielding layer; the partsamong the plurality of wire cores are filled with fillers; a ceramic fiber tape, an adiabatic cooling layer, a steel tape firestop layer, an oxygen barrier layer, an inner sheath and an outer sheathwrap the outside of the cable core; and the outer sheath wraps the inner sheath through a lubricating layer. The medium-voltage fire-resistant power cable is simple in structure, and has good flame retardant property and fire resistance; the voltage level of the cable is improved on the basis of ensuring the flexibility and the large-length processing performance of the cable; and safe and reliable operation of a power system is ensured.

Owner:JIANGSU PUCAO TECH CO LTD

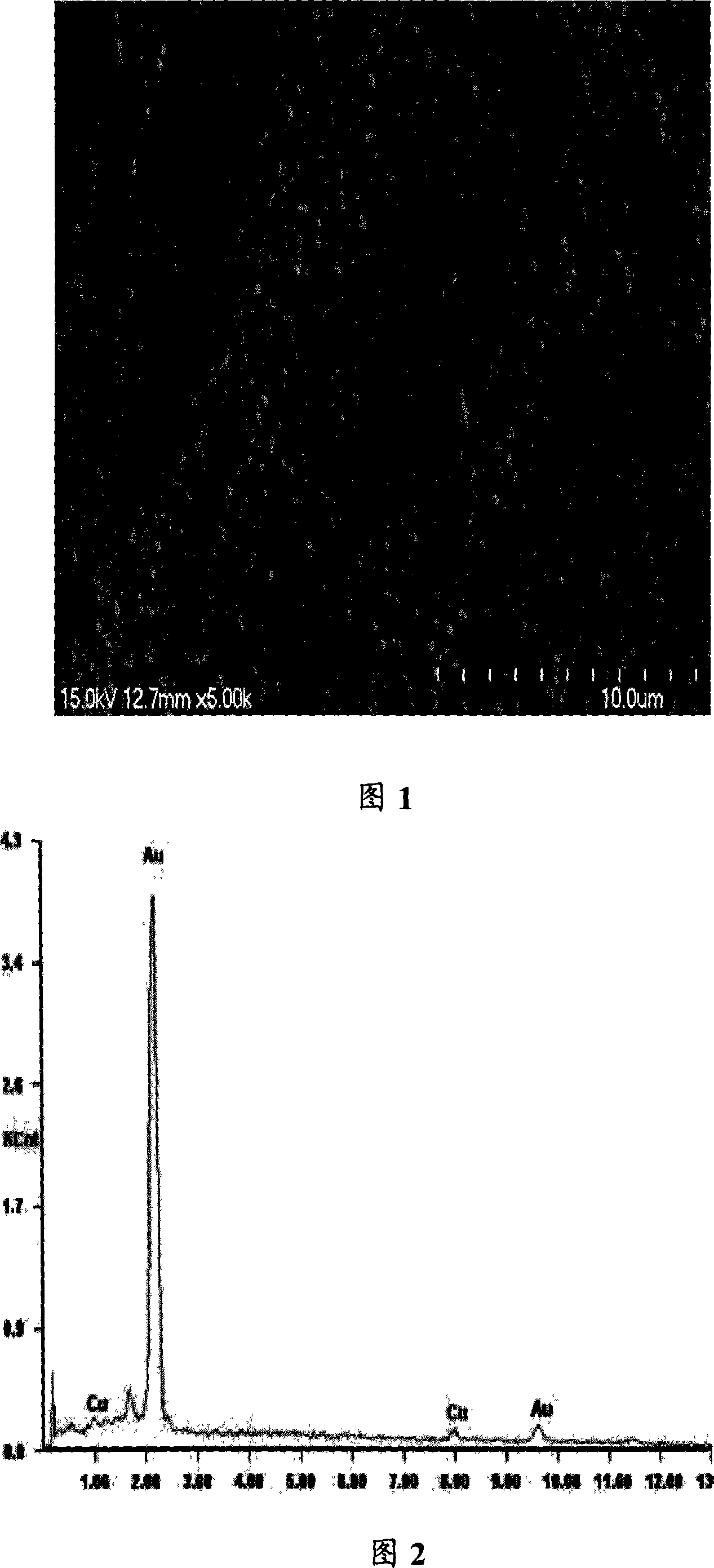

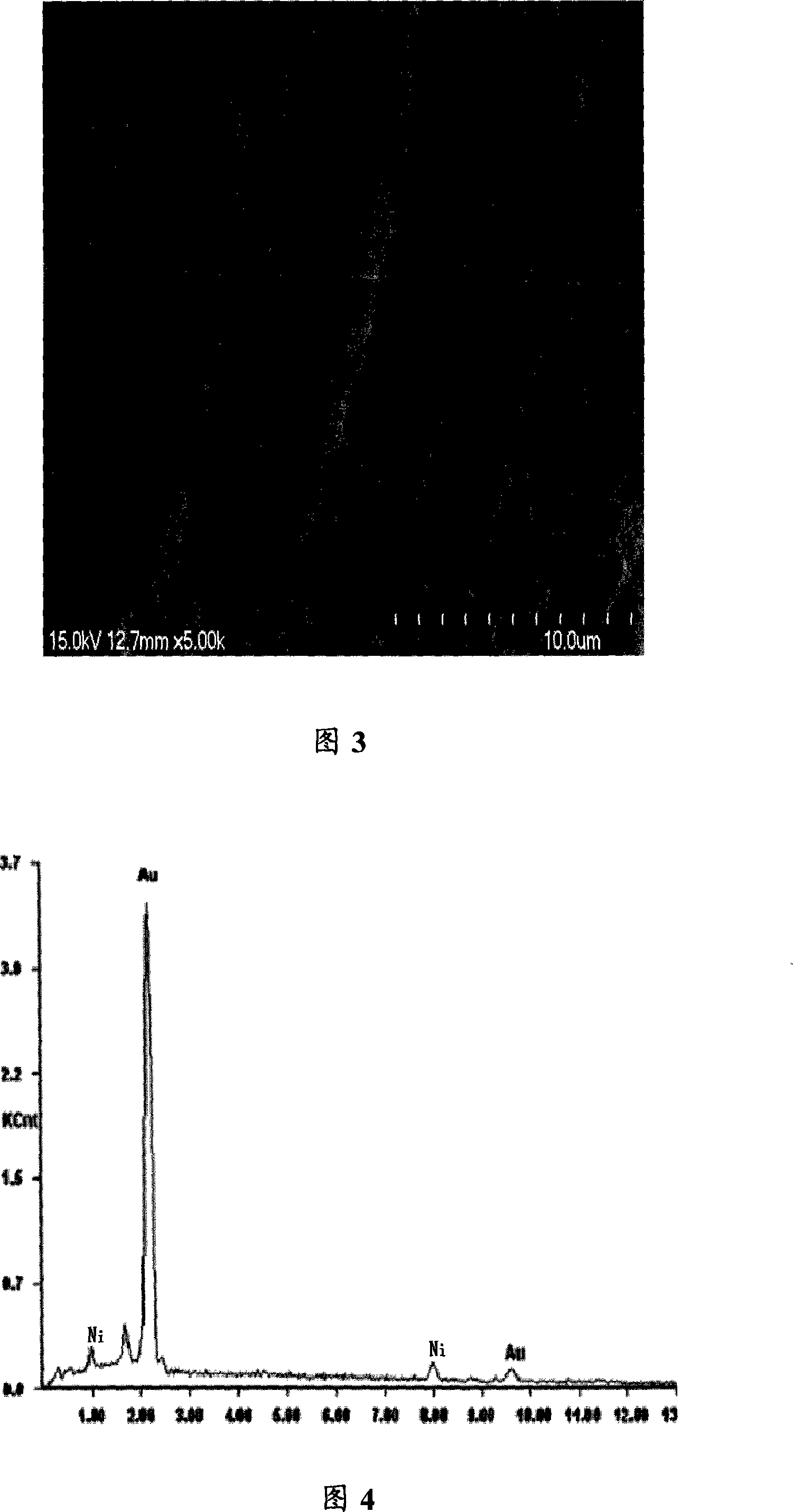

Gold plating solution, and method for plating gold

This invention discloses a gold-plating solution and gold-plating method. The method comprises: utilizing gold salt-containing room temperature ionic liquid as the gold-plating solution, gold as the anode, and material to be plated as the cathode, and performing DC electrolysis to reduce the cathode and obtain a shinning gold plating layer. The gold salt is Au (PPh3) Cl or Au (PPh3) Br; the room temperature ionic liquid is [bmim] BF4 or [bmim] PF6; the concentration of the gold salt in the ionic liquid is 0.005 mol / L to saturation concentration. The gold-plating solution does not contain hypertoxic cyanide, and has such advantages as high stability in air and water, no volatility, low flammability, and no harm to environment or operators.

Owner:SUZHOU UNIV +1

Preparation method for building thermal insulation particles

The invention discloses a preparation method for building thermal insulation particles. The method comprises the following steps: firstly, weighing thermal insulation particles, dipping the thermal insulation particles in hydrofluoric acid solution, and filtering out the thermal insulation particles, secondly, dipping filtered matter in dodecyl sodium sulfate solution, and then filtering out the thermal insulation particles, thirdly, mixing and grinding aerogel and alumina silicate micro powder, fourthly, mixing the mixed powder in the third step into the filtered matter in the second step, and stirring and stirring the mixed powder and the filtered matter till the mixed powder completely packages the surface of the filtered matter, and fifthly, drying, so as to obtain the building thermal insulation particles. The method solves the problem that the conventional thermal insulation material is easy to burn, modifies traditional organic thermal insulation material, reduces the heat-transfer coefficient of the traditional organic thermal insulation material, and changes the combustion performance of the traditional organic thermal insulation material at the same time, so as to ensurethat the traditional organic thermal insulation material becomes incombustible thermal insulation material meeting the requirement of building thermal insulation material.

Owner:陕西盟创纳米新型材料有限责任公司

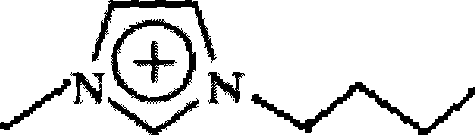

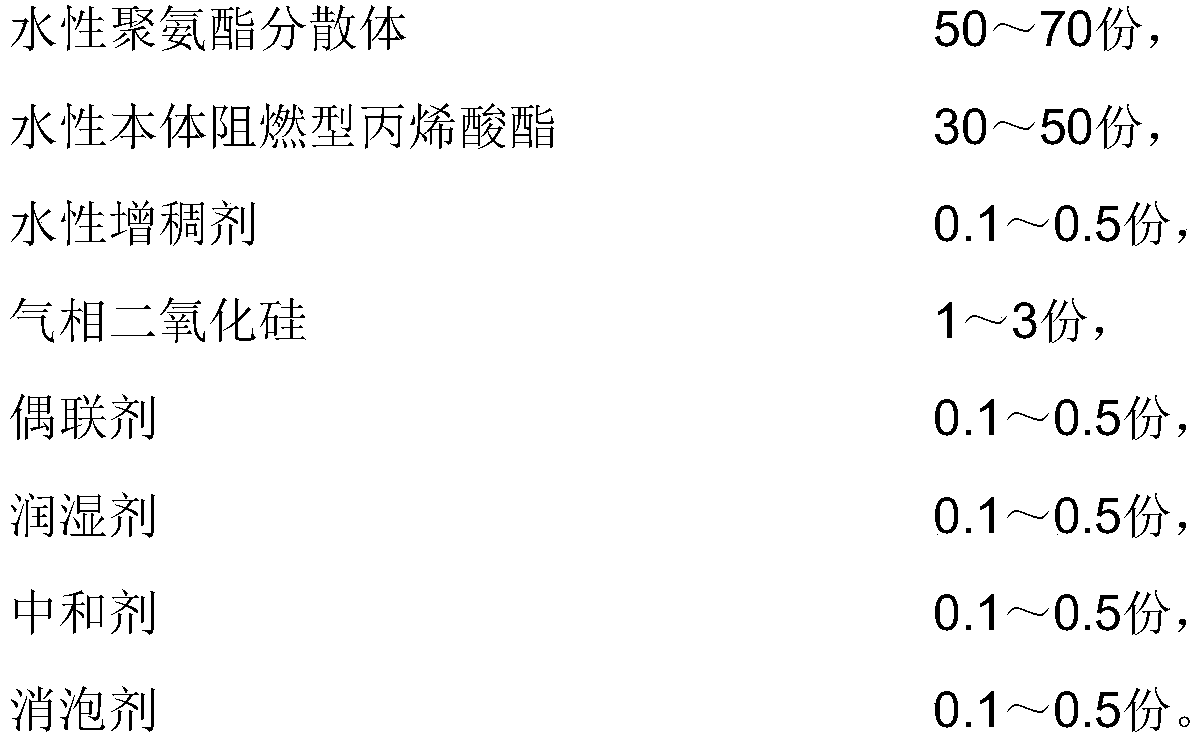

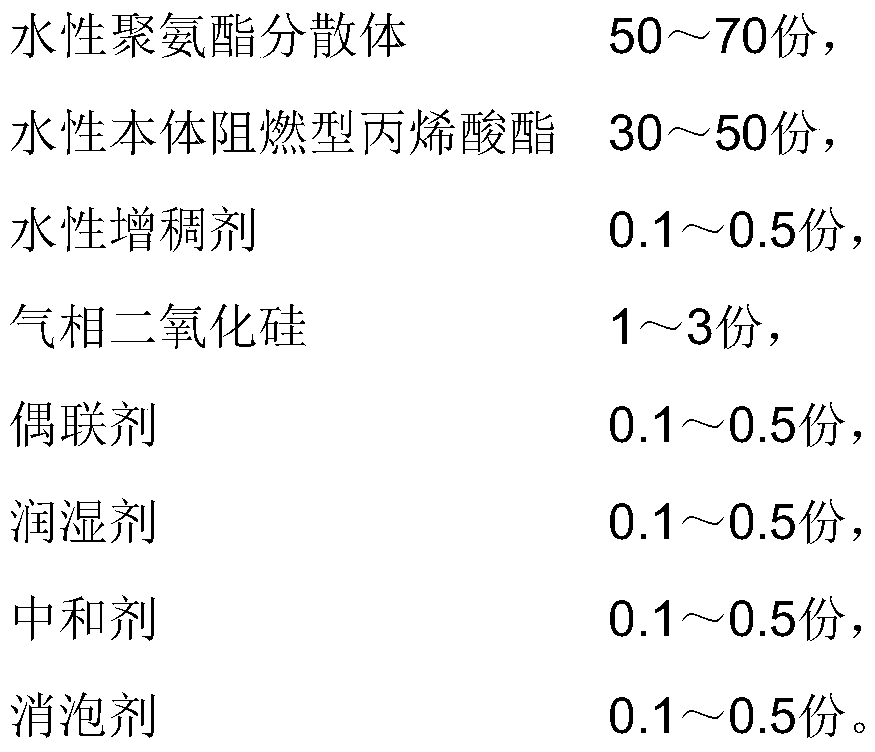

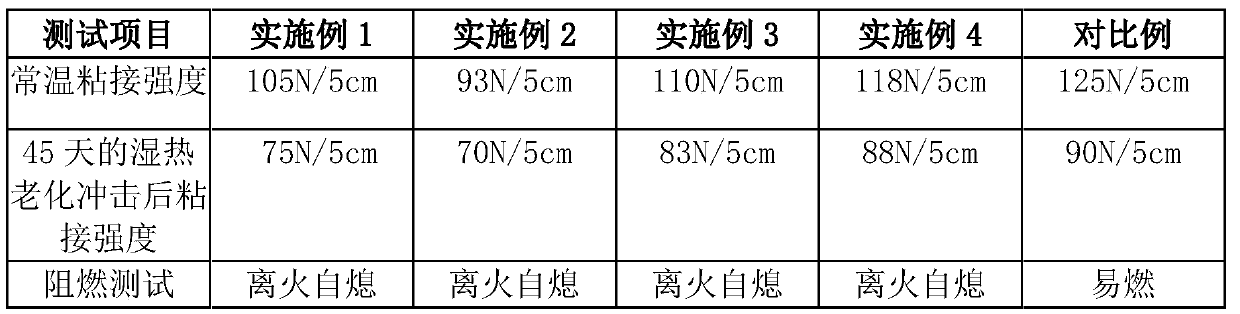

Flame-retardant waterborne polyurethane adhesive and preparation method thereof

InactiveCN111303817ALow VOC emissionSmall smellNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyurethane adhesive

The invention discloses a flame-retardant waterborne polyurethane adhesive and a preparation method thereof, the flame-retardant waterborne polyurethane adhesive is composed of a main adhesive and a waterborne isocyanate curing agent, and the main adhesive and the waterborne isocyanate curing agent are cooperatively used according to a weight ratio of 100: 2-10, wherein the main adhesive is prepared from the following raw materials in parts by weight: 50 to 70 parts of a waterborne polyurethane dispersion, 30 to 50 parts of waterborne body flame-retardant acrylate, 0.1 to 0.5 part of a waterborne thickener, 1 to 3 parts of fumed silica, 0.1 to 0.5 part of a coupling agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.5 part of a neutralizer and 0.1 to 0.5 part of a defoaming agent. The adhesive is environmentally friendly, non-toxic, low in VOC, low in odor and excellent in bonding strength, the flame retardant capacity of the adhesive after film formation is remarkably improved, and the adhesive can be widely applied to the fields of automobiles, high-speed rails, furniture, shoemaking, textiles and the like.

Owner:BEIJING COMENS NEW MATERIALS

Inorganic flame-retardant intelligent temperature regulation cellulose fiber and preparation method thereof

ActiveCN109576808AImprove flame retardant performanceSolve flammable,Artificial filaments from viscoseLimiting oxygen indexCrystallization temperature

The invention provides an inorganic flame-retardant intelligent temperature regulation cellulose fiber. For the fiber, the melting enthalpy value is 24-25 J / g, the melting temperature is 29-33 DEG C,the crystallization enthalpy value is 22.5-23.0 J / g, and the crystallization temperature is 18-21 DEG C. The invention also provides a preparation method of the fiber. In the phase-change temperatureregulation cellulose fiber prepared by the method, the content of phase-change material microcapsules is 10.4-10.6%; the limiting oxygen index of the inorganic flame-retardant temperature regulation fiber prepared by the method reaches 35% or above, and the flame retardancy is excellent.

Owner:邦特云纤(青岛)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com