All-solid-state polyelectrolyte film, its preparation and application method

A polyelectrolyte, all-solid-state technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as the preparation method of all-solid-state polyelectrolyte films, and achieve excellent film-forming properties, improve safety performance, and thermal stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

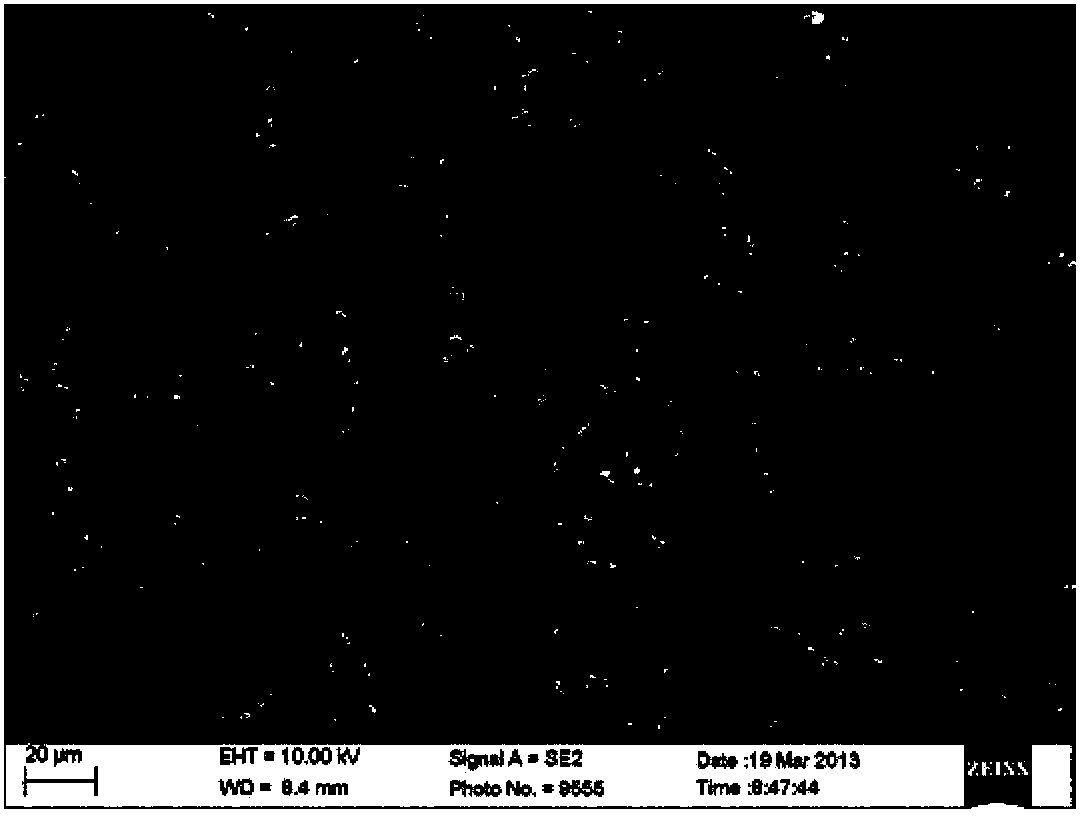

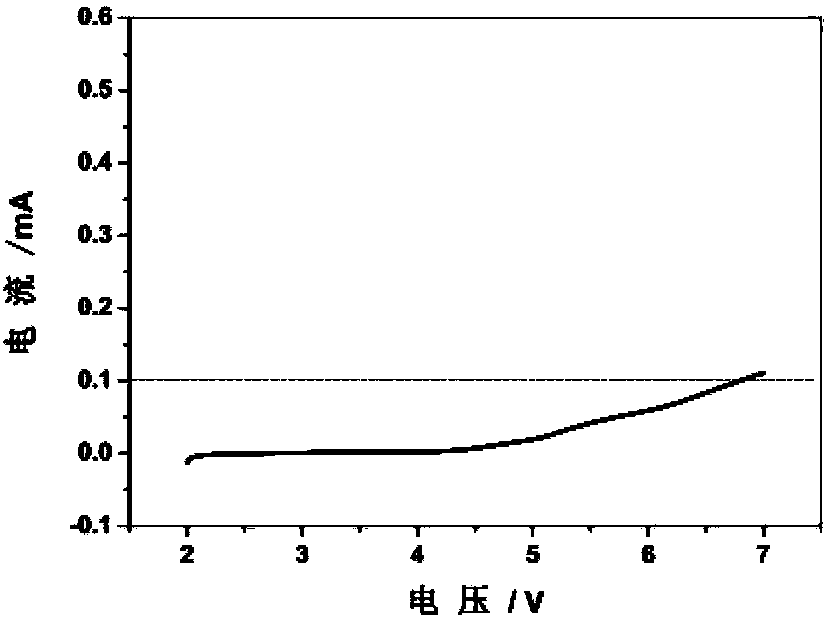

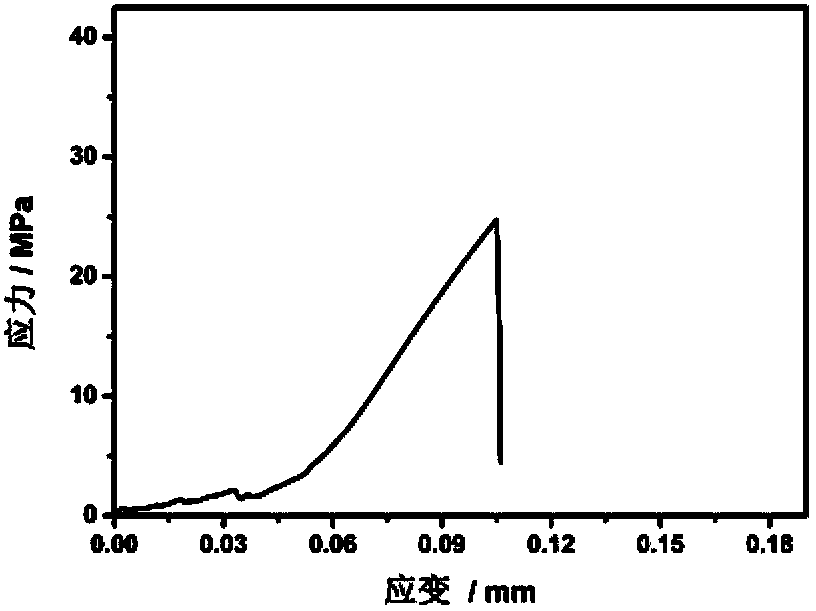

Embodiment 1

[0045] Take 0.8631g polyvinyl formal (molecular weight 60000-80000, degree of alcoholysis 79%) and dissolve it in 5.7344g dimethyl sulfoxide, fully stir to dissolve completely, and prepare a homogeneous and clear transparent solution. The organic solvent used here can be, but not limited to, dimethyl sulfoxide, and the organic solvent is preferably at least one of N-methylpyrrolidone, N,N-dimethylformamide, chloroform, dimethyl sulfoxide, tetrahydrofuran A sort of. Add 0.0284g of boric acid to the above solution, (equivalent to a molar ratio of hydroxyl and boron atoms of 2:1), stir magnetically at 70°C for 5 hours, then add 0.0187g of lithium carbonate and 0.0114g of oxalic acid (boron atom: lithium atom: The molar ratio of oxalic acid is 2:1:2), stirred in a water bath at 90°C for 24 hours, coated on a clean glass plate with a coating machine, and dried to obtain a polyelectrolyte membrane. The lithium salt used here can be but not limited to lithium carbonate. The method ...

Embodiment 2

[0047] Take 0.8594g polyvinyl formal (molecular weight 60000-80000, degree of alcoholysis 79%) and dissolve it in 5.7344g N,N-dimethylformamide, stir well to dissolve completely, and prepare homogeneous transparent solution. The organic solvent used here can be, but not limited to N,N-dimethylformamide, the organic solvent is preferably N-methylpyrrolidone, N,N-dimethylformamide, chloroform, dimethyl sulfoxide, At least one of tetrahydrofuran and the like. Add 0.1237g of boric acid to the above solution (equivalent to a molar ratio of hydroxyl and boron atoms of 1:2), stir magnetically at 80°C for 5 hours, then add 0.048g of lithium hydroxide and 0.1801g of oxalic acid (boron atom: lithium atom: The molar ratio of oxalic acid is 2:1:2), and after stirring in an oil bath at 120°C for 24 hours, it was coated on a clean glass plate with a coating machine, and the polyelectrolyte membrane was obtained after air drying. The lithium salt used here may be but not limited to lithium...

Embodiment 3

[0049] Take 0.8597g of polyvinyl butyral (molecular weight is about 70000) and dissolve it in 5.7344g of N,N-dimethylformamide, stir well to dissolve completely, and prepare a homogeneous transparent solution. The organic solvent used here can be, but not limited to N,N-dimethylformamide, the organic solvent is preferably N-methylpyrrolidone, N,N-dimethylformamide, chloroform, dimethyl sulfoxide, At least one of tetrahydrofuran and the like. In the above solution, 0.0124g of boric acid (equivalent to a molar ratio of hydroxyl to boron atom of 5:1), magnetically stirred at 60°C for 5 hours, then added 0.0044g of methyllithium and 0.0180g of oxalic acid (boron atom: lithium atom: oxalic acid The molar ratio is 2:1:2), and after stirring in an oil bath at 110°C for 24 hours, it was coated on a clean glass plate with a coating machine, and the polyelectrolyte membrane was obtained after air drying. The lithium salt used here may be but not limited to methyllithium. The method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com