Sandwich structural fiber board

A sandwich structure and fiberboard technology, applied in the field of boards, can solve the problems of unfavorable interior panels such as thermal insulation and sound insulation, and achieve the effects of reducing the use of non-renewable resources, good thermal insulation, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

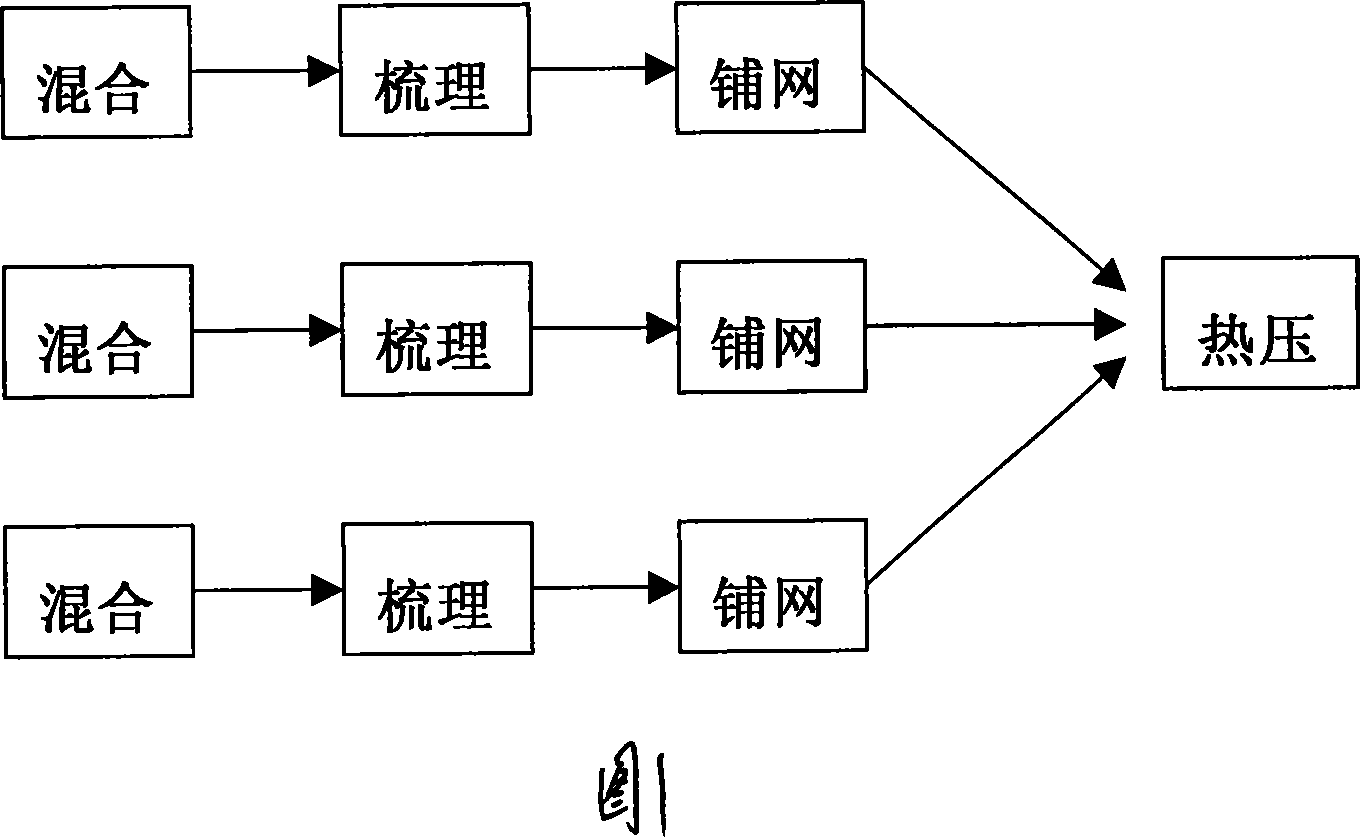

Embodiment 1

[0025] The hemp fiber and the low-melting point polyester are opened separately, and then fed to three carding machines according to different ratios. Among them, the ratio of low-melting point polyester and hemp fiber fed to the carding machines on both sides is the same, which is 90:10, and the carding machine in the middle is fed to three carding machines. The ratio of imported low-melting point polyester and hemp fiber is 20:80. The fiber web formed by the carding machine is laminated by the web-laying machine to form a certain amount of fiber web, and the three web-laying machines respectively form the upper skin layer, core layer, and lower skin layer fiber web of the board, and the core layer accounts for 30% of the total fiber web weight. . Spray and apply flame retardant FPK8001 to each fiber web, which is a phosphorus-containing compound provided by Hong Kong Hutt International Group, and the flame retardant accounts for 4 to 8% of the weight of the fiber web. The w...

Embodiment 2

[0027] The ratio of low-melting point polyester and hemp fibers fed to the carding machines on both sides is 80:20, the ratio of low-melting point polyester and hemp fibers to the middle carding machine is 30:70, and the core layer accounts for 40% of the total fiber web weight. Quantitative 3300g / m 2 , the hot pressing pressure is 2 MPa, and the temperature is 180°C. All the other are with embodiment 1.

Embodiment 3

[0029] The ratio of low-melting point polyester and hemp fibers fed to the carding machines on both sides is 70:30, and the ratio of low-melting point polyester and hemp fibers to the middle carding machine is 35:65. The core layer accounts for 50% of the total fiber web weight. Quantitative 3100g / m 2 , the hot pressing pressure is 4MPa, and the temperature is 175°C. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com