Method for using thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel

A thin-slab continuous casting and thin-gauge technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of excessive thickness, wear, and adverse effects on the mechanical properties of strip steel, so as to reduce production costs and improve dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

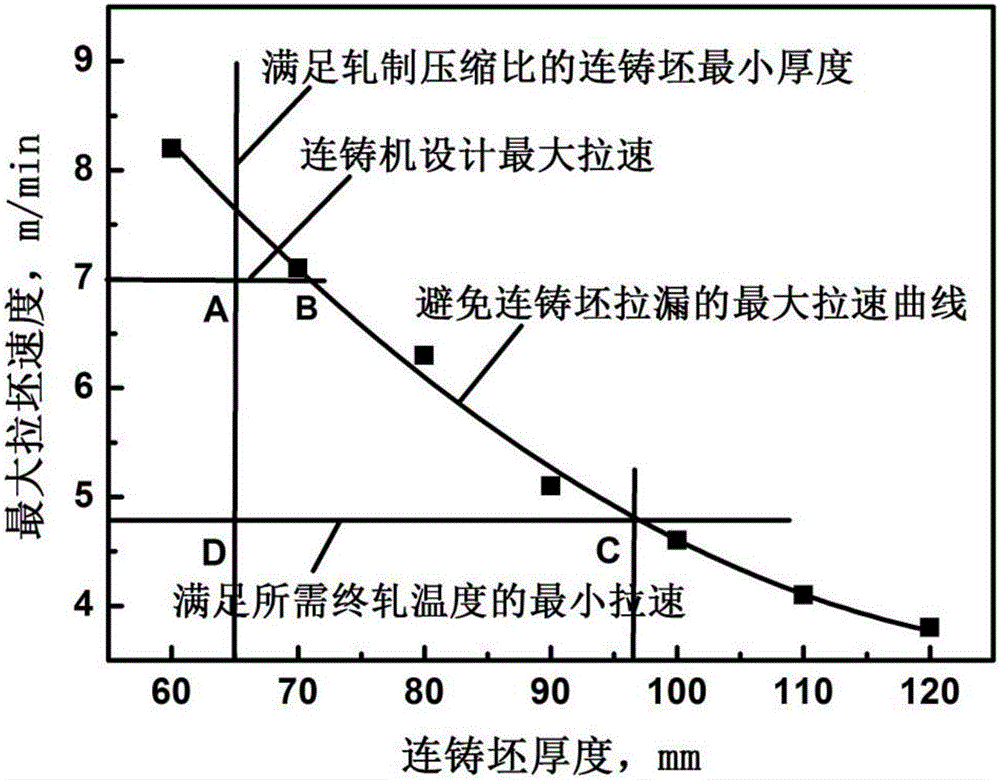

[0050] This embodiment provides a method for producing thin-gauge low-alloy high-strength steel by applying thin slab continuous casting and rolling technology. The process route is as follows: figure 1 As shown, the molten steel was first continuously cast into a continuous casting billet with a width of 1300-1600 mm and a thickness of 65-96 mm, and then rough rolling, heat preservation by a heat preservation cover, induction heating, high-pressure water descaling and finishing rolling were performed in sequence to obtain a width of 1300- The ultra-thin strip steel with a thickness of 1.3 to 1.6 mm is 1600mm, and finally it is cooled by control, cut into coils, and coiled into coils. The main process steps and process parameters are as follows:

[0051] (1) Continuous casting

[0052] The chemical composition of the molten steel is: C 0.04%-0.08%, Si 0.1%-0.2%, Mn 0.3%-0.5%, Al 0.02%-0.04%, P≤0.015%, S≤0.012%, N ≤0.008%, Ca≤0.002%, Cu≤0.15%, Sn≤0.02%, Ni≤0.2%, Cr≤0.12%, Mo≤...

Embodiment 2

[0078] This embodiment provides a more detailed and optimized process scheme on the basis of the first embodiment, which can make the longitudinal thickness accuracy, shape accuracy and surface quality of the finished strip steel better, and obtain the equivalent of the cold-rolled strip steel of the same specification. Comprehensive mechanical properties.

[0079] The thickness of the continuous casting billet is 72-82 mm, and the billet drawing speed is 5.9-6.5 m / min.

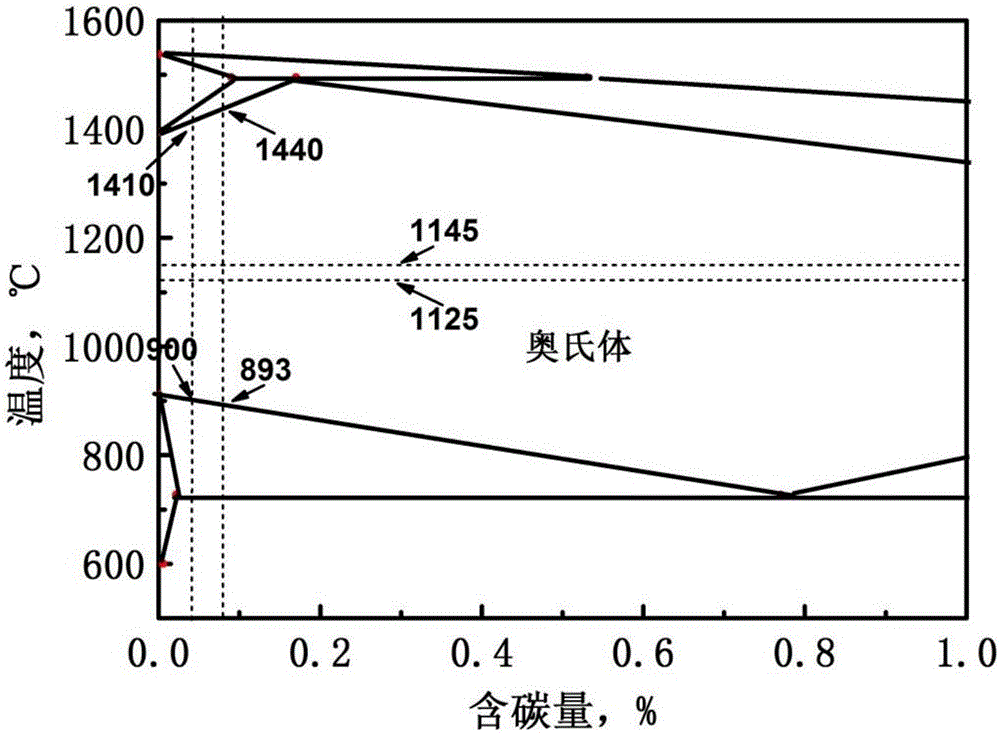

[0080] The reduction ratio of the first rough rolling mill of the rough rolling group is 50% to 55%, the rolling temperature is controlled at 1125 to 1145° C., and the rolling pressure per unit width is 13 to 15KN / mm; the reduction ratio of the second rough rolling mill is 40%~45%, the rolling temperature is controlled at 1060~1080℃, the rolling pressure per unit width is 13.5~14.5KN / mm; the reduction rate of the third roughing mill is 35%~40%, and the rolling temperature is controlled at 1000~ 1020℃, the ro...

Embodiment 3

[0090] In this embodiment, the production of finished strip steel with a carbon content of 0.06%, a width of 1300 mm and a thickness of 1.5 mm is taken as an example, and the specific process is as follows.

[0091] The molten steel is continuously cast into a continuous casting billet with a width of 1300mm and a thickness of 80mm, and then rough rolling, thermal insulation cover insulation, induction heating, high-pressure water descaling and finishing rolling are performed in sequence to obtain an ultra-thin strip with a width of 1300mm and a thickness of 1.5mm. , and finally controlled cooling, sub-coil shearing and coiling into rolls. The main process steps and process parameters are as follows:

[0092] (1) Continuous casting

[0093] The chemical composition of the molten steel is: C 0.04%-0.08%, Si 0.1%-0.2%, Mn 0.3%-0.5%, Al 0.02%-0.04%, P≤0.015%, S≤0.012%, N ≤0.008%, Ca≤0.002%, Cu≤0.15%, Sn≤0.02%, Ni≤0.2%, Cr≤0.12%, Mo≤0.05%, V≤0.02%, Nb≤0.025%, the rest are Fe and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com