X80 level large-deformation resistance pipe line steel medium and heavy plate production method

A technology of anti-large deformation and pipeline steel, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of insufficient plasticity and low deformation ability, reduce production costs, and refine austenite grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

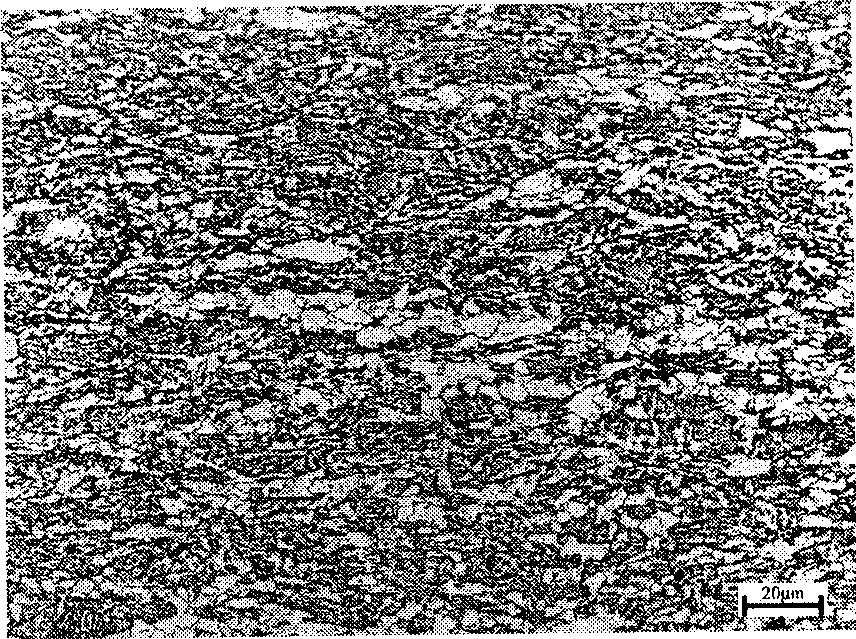

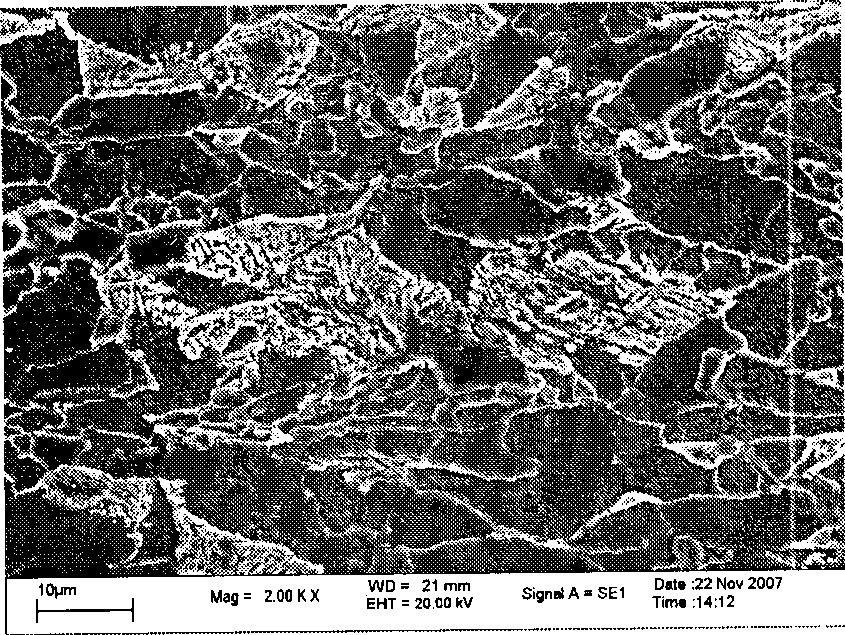

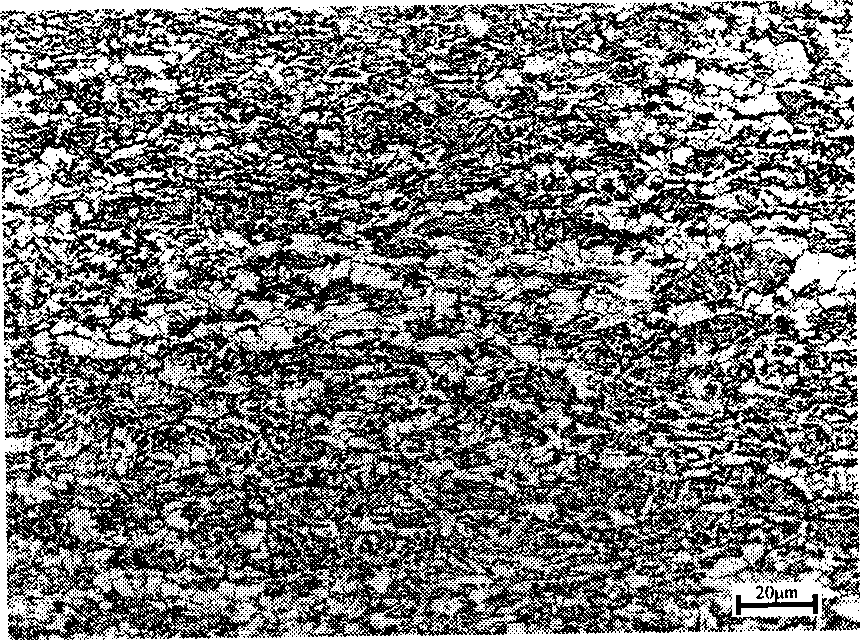

Image

Examples

Embodiment 1

[0032] The molten steel is continuously cast into a billet with a thickness of 230mm, and its chemical composition is calculated by weight percentage: C accounts for 0.037%, Si accounts for 0.20%, Mn accounts for 1.50%, Ti accounts for 0.012%, Ni accounts for 0.22%, Cr accounts for 0.22%, Nb accounts for 0.06%, P accounts for 0.005%, S accounts for 0.003%, H accounts for 0.00018%, N accounts for 0.0015%, O accounts for 0.0013%, and the balance is Fe.

[0033] The billets are soaked at 1200°C and kept for 120 minutes, followed by high-pressure water dephosphorization and two-stage controlled rolling. The starting rolling temperature in the recrystallization zone is 1190°C. After multi-pass rolling, the final rolling temperature in the recrystallization zone is 1040°C, the deformation is 67%, and the thickness of the intermediate billet is 75mm.

[0034] After the intermediate billet is air-cooled and warmed, the rolling start temperature in the non-recrystallized area is 910°C....

Embodiment 2

[0038] The molten steel is continuously cast into a billet with a thickness of 230mm, and its chemical composition is calculated by weight percentage: C accounts for 0.027%, Si accounts for 0.19%, Mn accounts for 1.27%, Ti accounts for 0.012%, Ni accounts for 0.25%, Cr accounts for 0.22%, Nb accounts for 0.06%, P accounts for 0.005%, S accounts for 0.003%, H accounts for 0.00016%, N accounts for 0.0015%, 0 accounts for 0.0015%, and the balance is Fe.

[0039] The billets are soaked at 1200°C and kept for 120 minutes, followed by high-pressure water dephosphorization and two-stage controlled rolling. The starting rolling temperature in the recrystallization zone is 1180°C. After multi-pass rolling, the final rolling temperature in the recrystallization zone is 1030°C, the deformation is 67%, and the thickness of the intermediate billet is 75mm.

[0040] After the intermediate billet is air-cooled and warmed, the rolling start temperature in the non-recrystallized area is 890°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com