Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Reduce additional stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

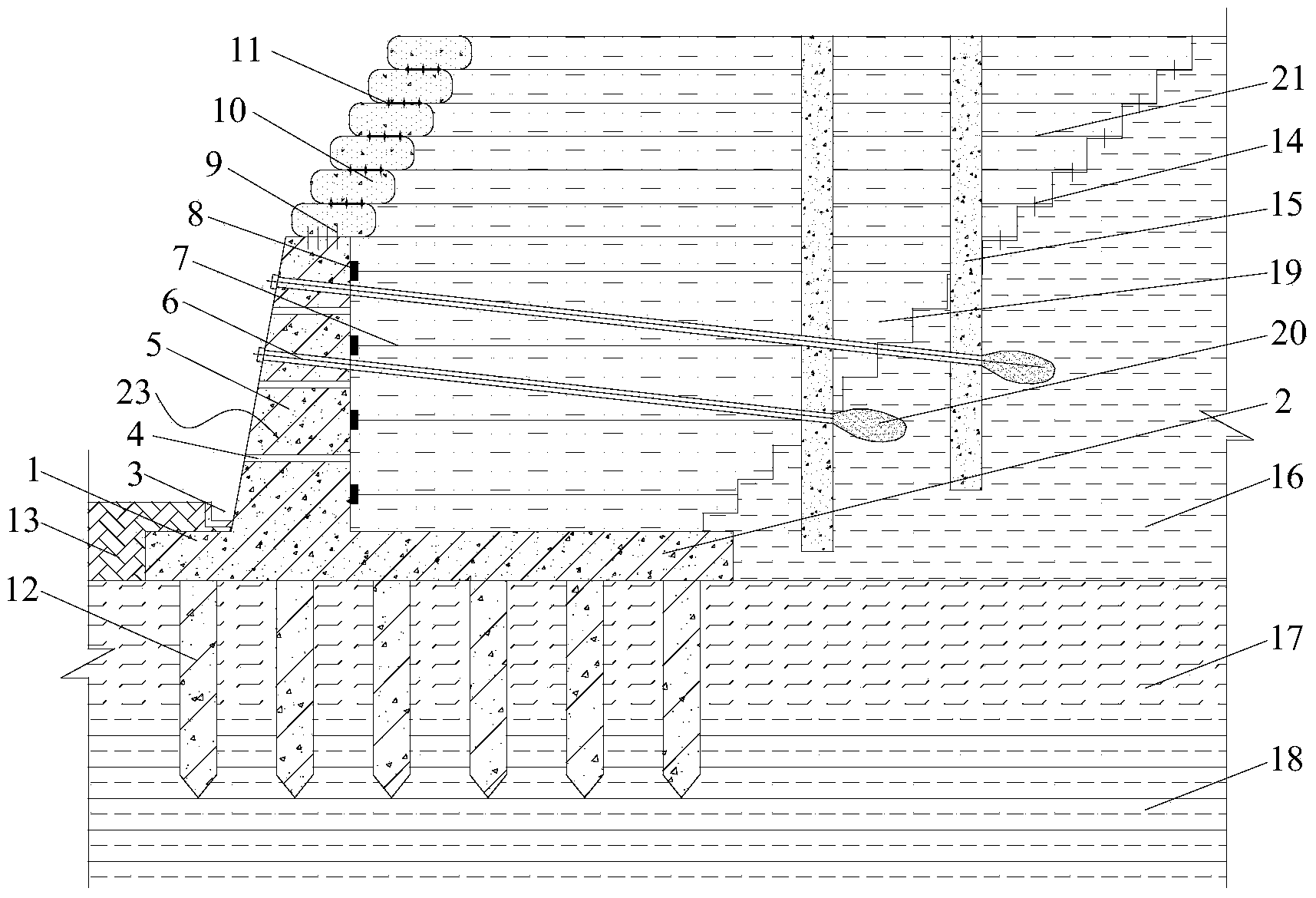

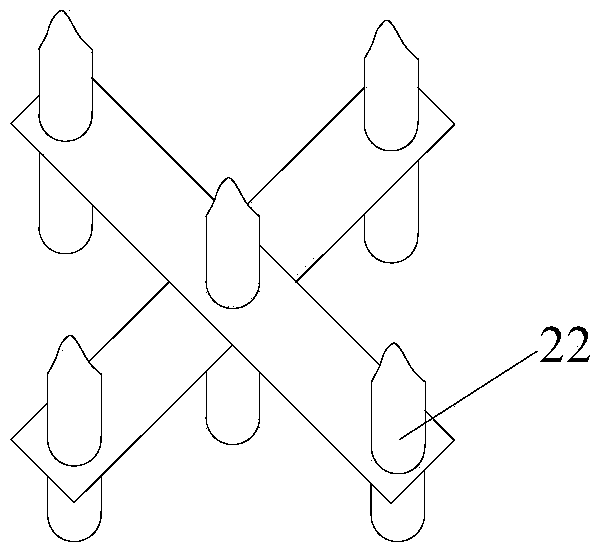

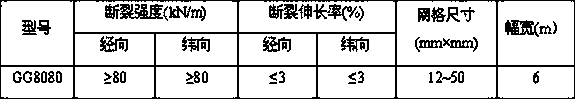

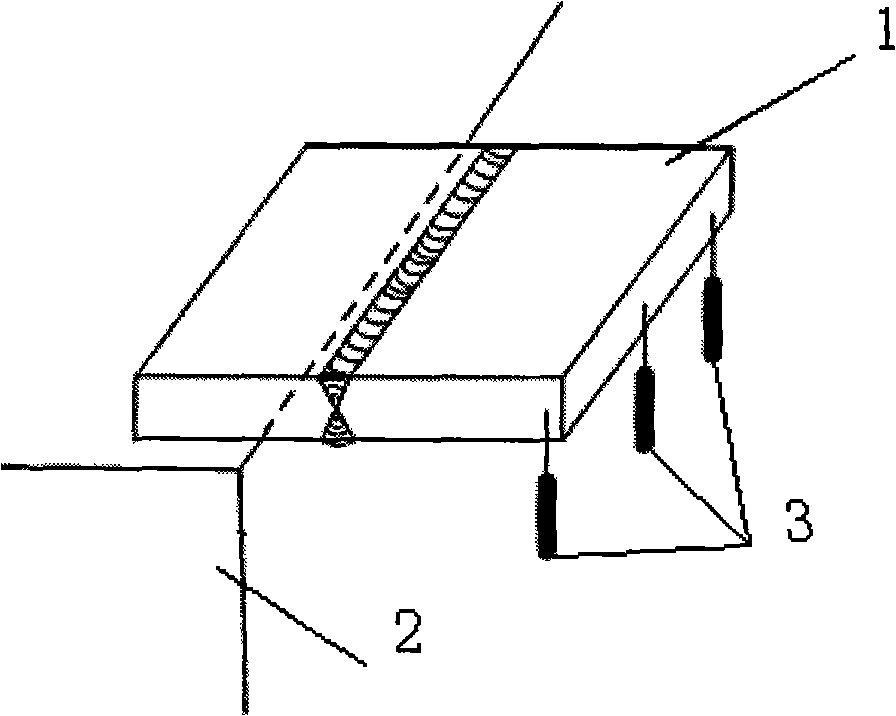

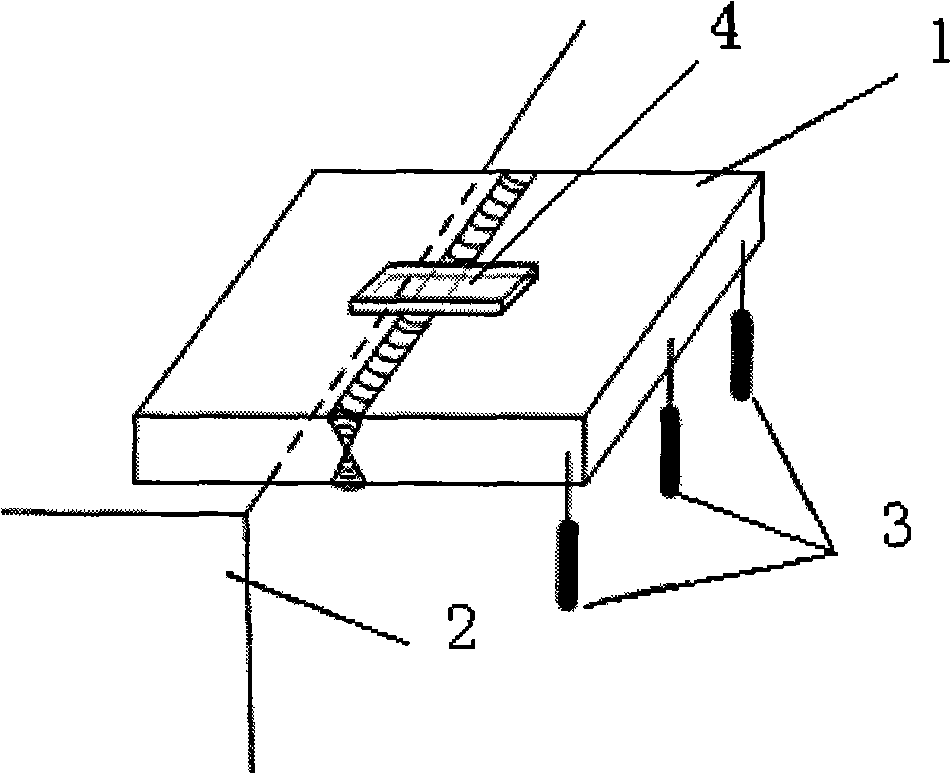

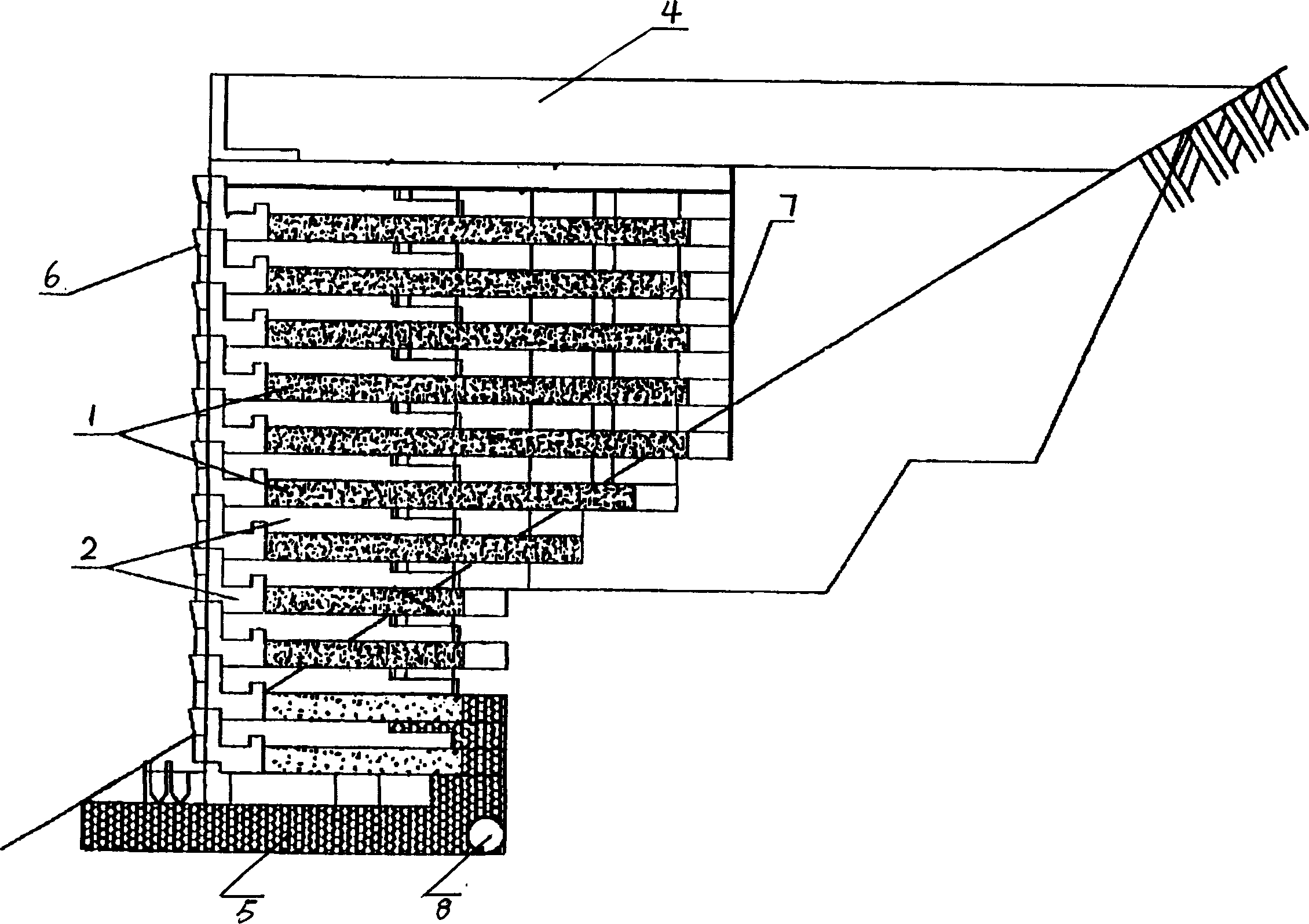

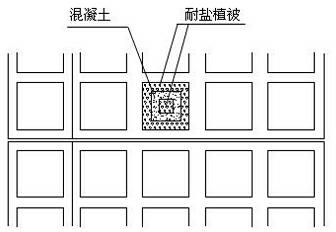

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167AHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsEngineering

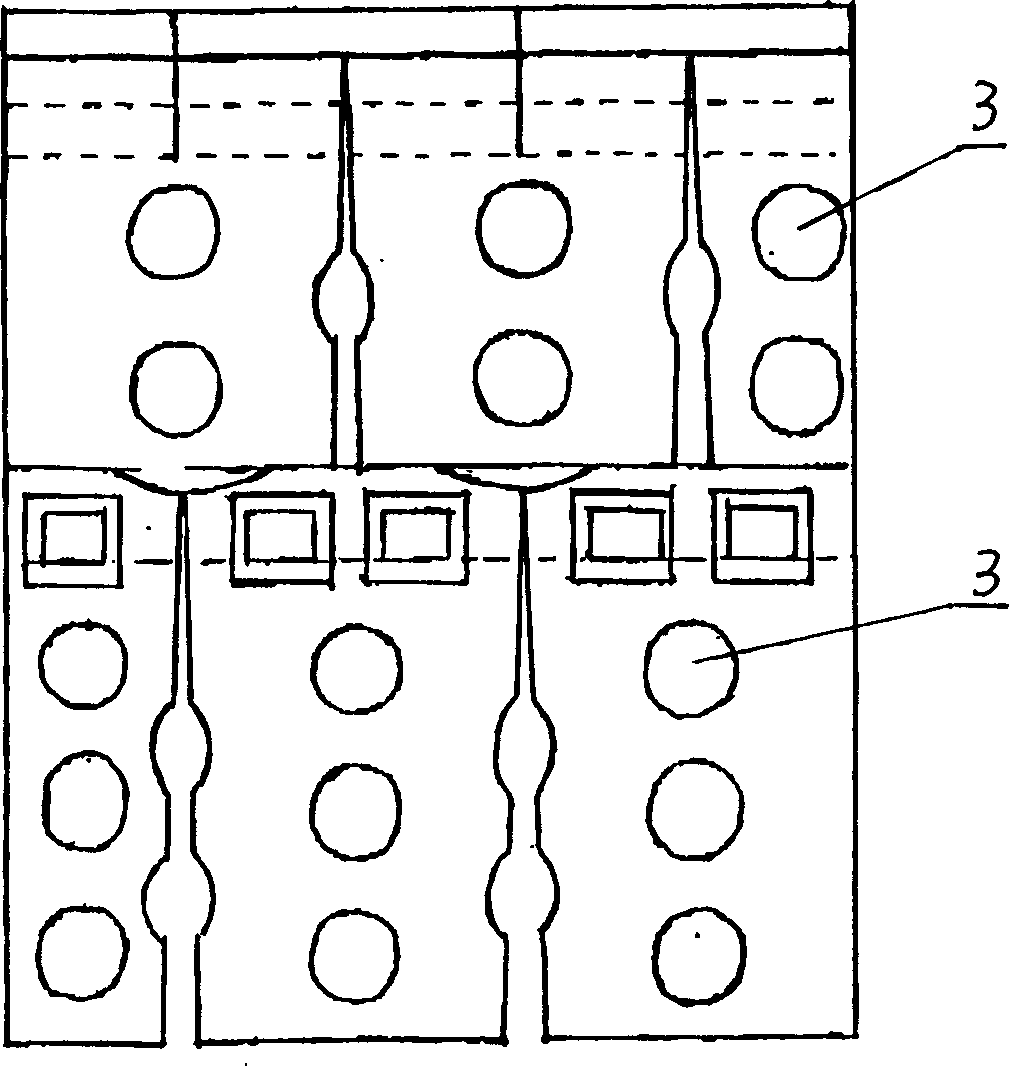

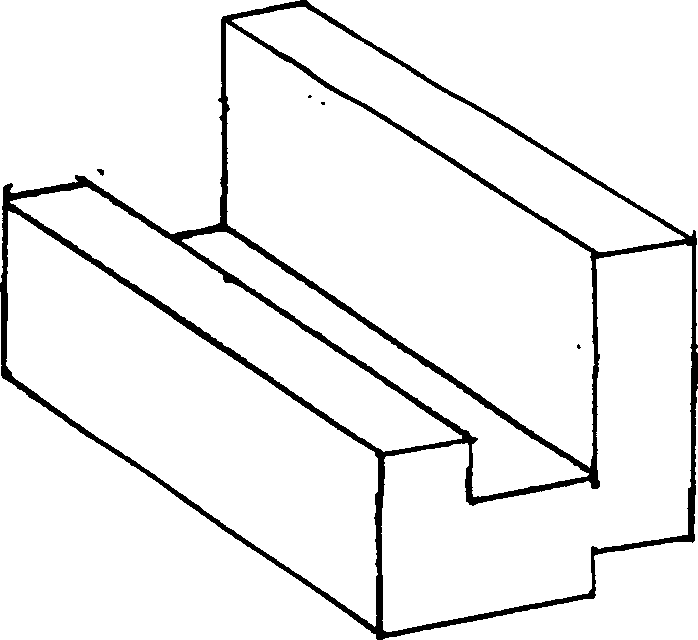

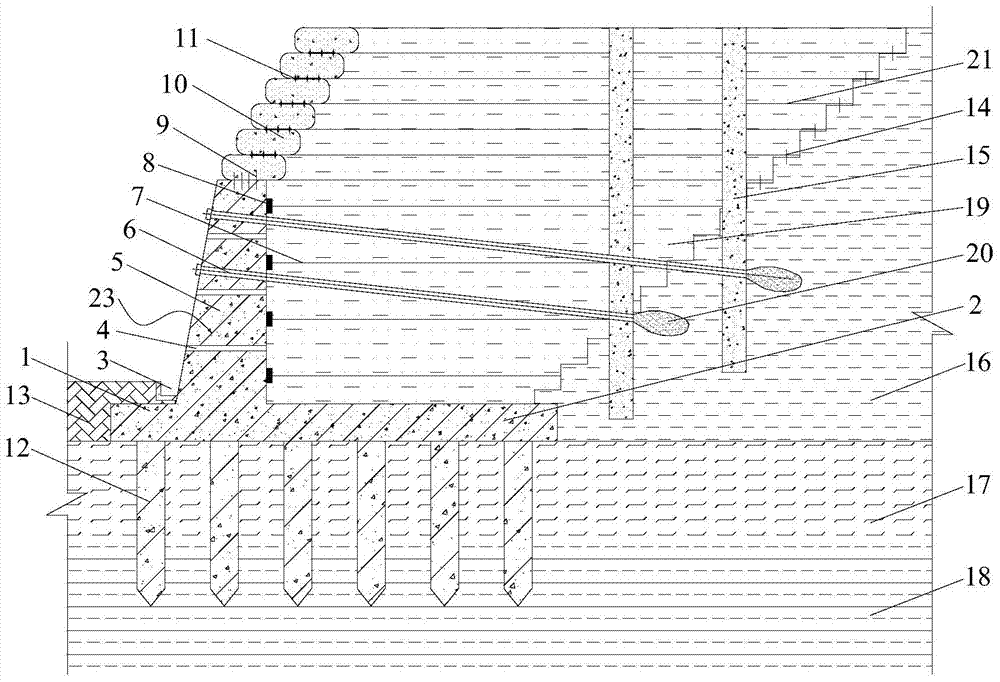

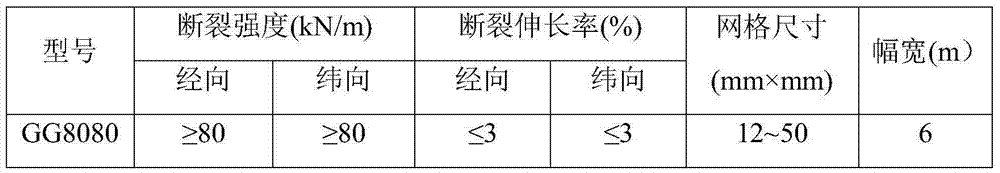

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

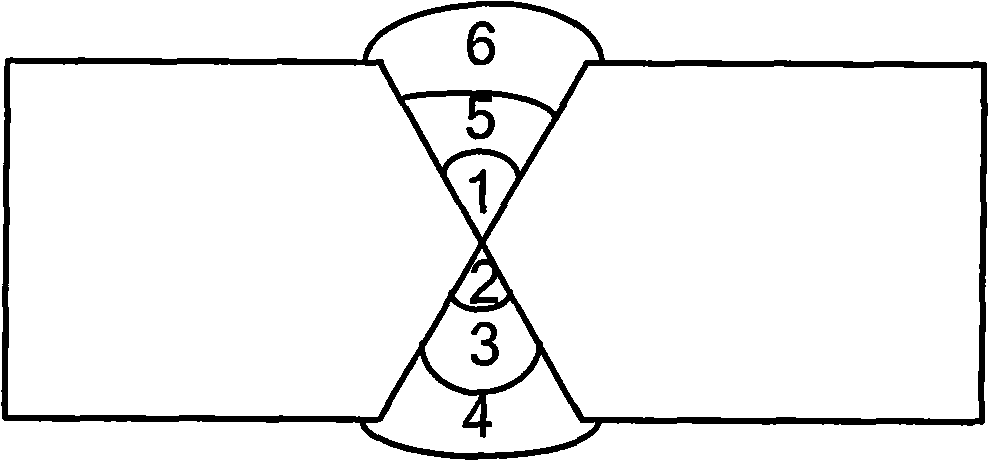

Method for measuring welding residual stress

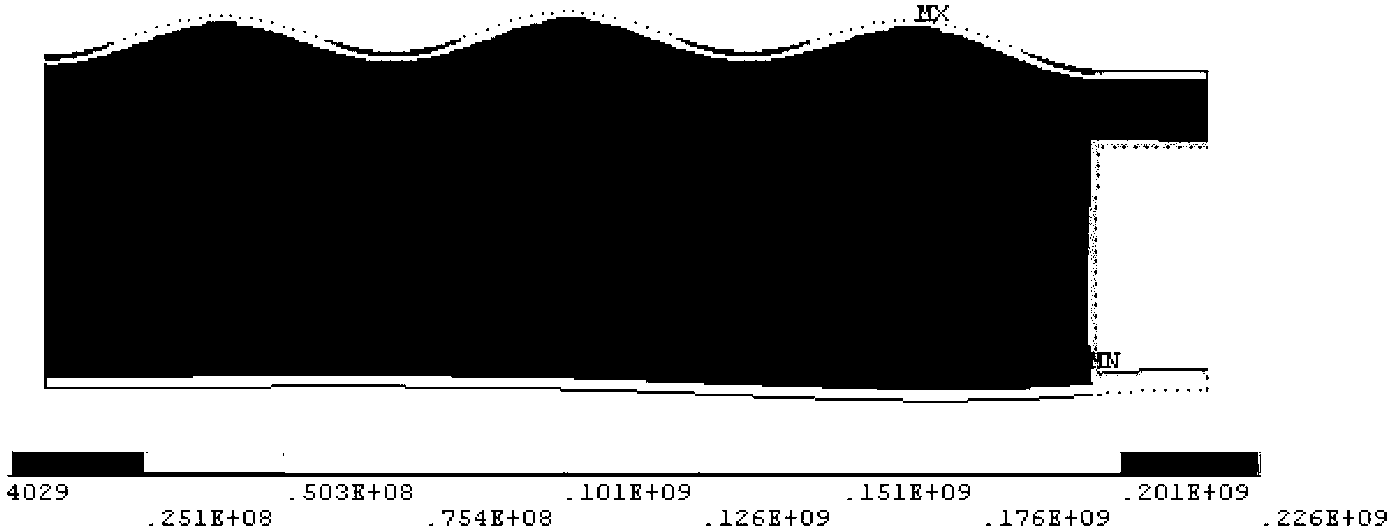

InactiveCN101539506AReduce additional stressIntegrity guaranteedUsing mechanical meansMaterial analysisThick plateWelding residual stress

The invention relates to a method for measuring welding residual stress-a partial layer-by-layer blind hole removing method for measuring the residual stress on the basis of a blind hole method, which proposes to measure the residual stress in a component by using the partial layer-by-layer blind hole removing method. After materials of certain depth on both the front side and the opposite side of a component to be measured are partially removed, the blind hole method is used for measuring the residual stress. The method is a semi-destructive residual stress measuring method, can be used for carrying out multi-point measurement and measuring the residual stress in the component with severe stress change and has convenient operation and high measuring efficiency. Proved by a thick plate carbon steel welding residual stress measuring test, the method has more accurate measuring results.

Owner:XI AN JIAOTONG UNIV

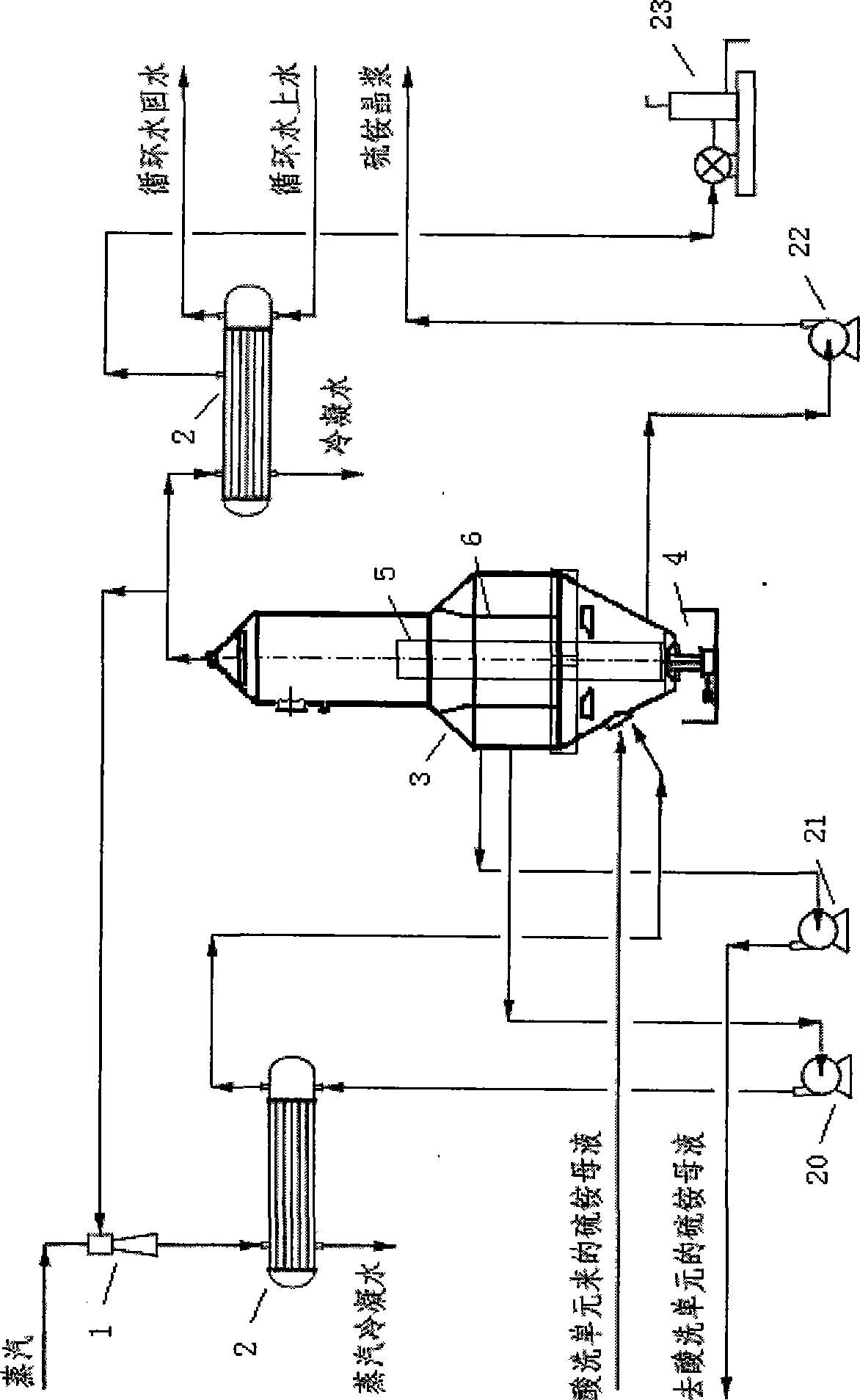

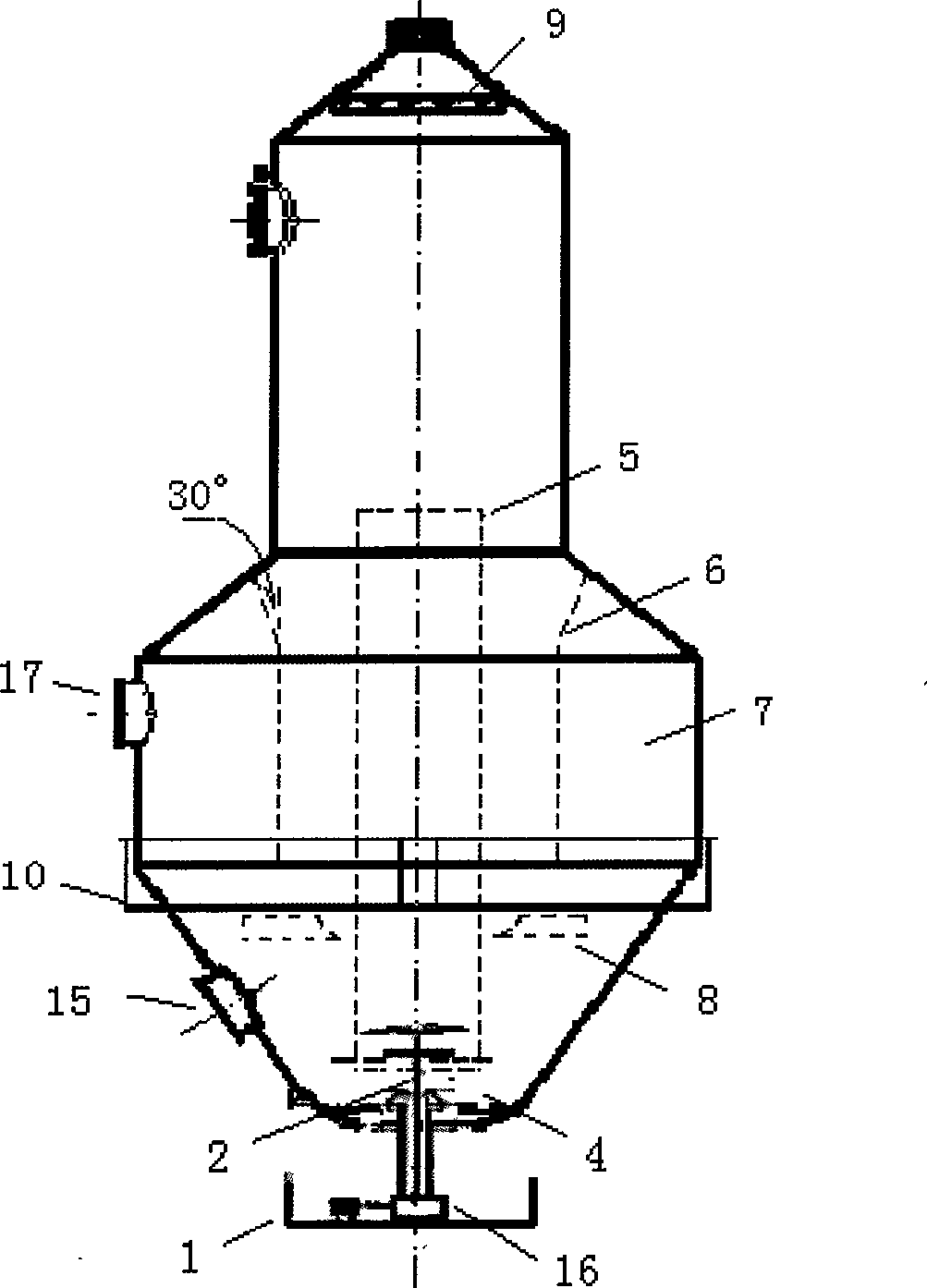

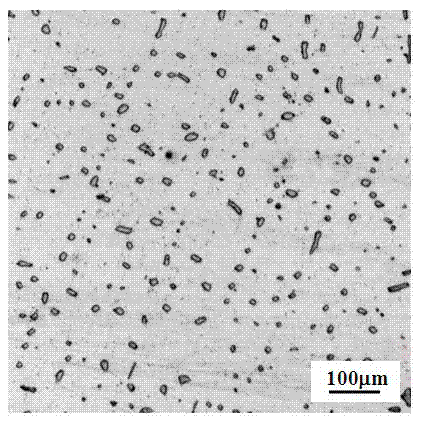

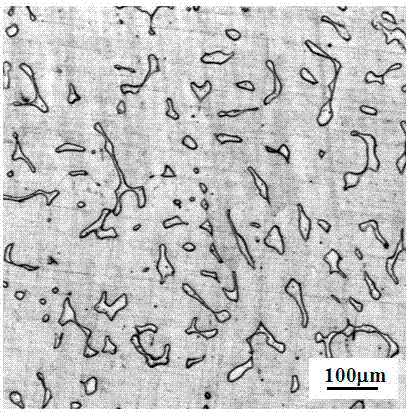

Production process and crystallization device for large-particle ammonium sulfate

ActiveCN101531382AReduced circulation of mother liquorReduce energy consumptionAmmonium sulfatesGranularitySupersaturation

The invention relates to a production process and a crystallization device for large-particle ammonium sulfate. 30-50 percent unsaturated ammonium sulfate solution from an acid-cleaning unit enters a crystallizer and then is evaporated in vacuum at an operation temperature of between 40 and 70 DEG C so as to evaporate moisture and obtain ammonium sulfate crystals; during crystallization, ammonium sulfate mother solution is subjected to heat exchange in an outer circulation channel, and excessive fine crystals are eliminated; and the circulating mother solution entering the outer circulation channel is heated by use of part of low-pressure steam from the crystallizer, so that energy consumption is reduced by 20 to 40 percent. The crystallization device adopts an optimized flow-guiding crystallizer (DTB), and a blender perpendicularly stretches into a flow-guiding cylinder from the bottom of the crystallizer. Because the production process effectively controls the supersaturation degree of the ammonium sulfate mother solution inside the crystallizer, large-particle ammonium sulfate crystals can be obtained, and the quality of ammonium sulfate is improved. The crystallizer is not easy to form crystal scabs inside, has reasonable structure and high production capability, can ensure the production of the crystal products with narrow particle-size range, and can meet the requirements of users on different particle size of the crystal products.

Owner:天津天达联合工程技术有限公司

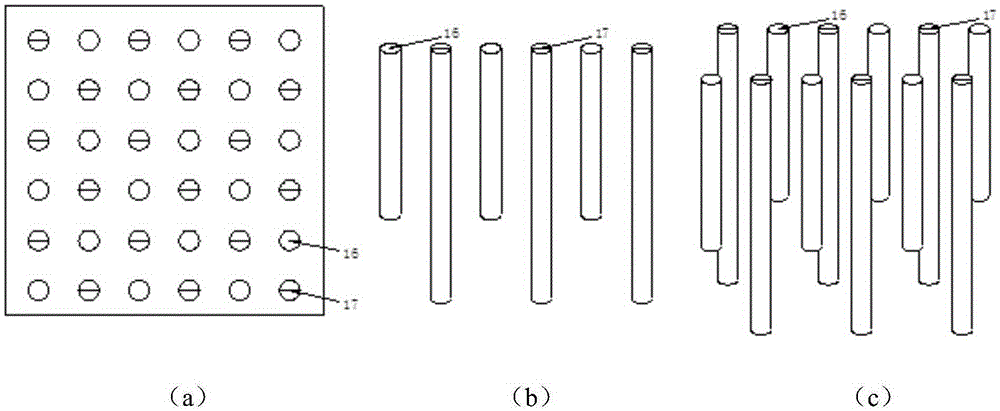

Method for processing vehicle bump at bridge head of existing highway

InactiveCN102409598AReduce post-construction settlementSolve the jumpRoads maintainenceArchitectural engineeringStructural engineering

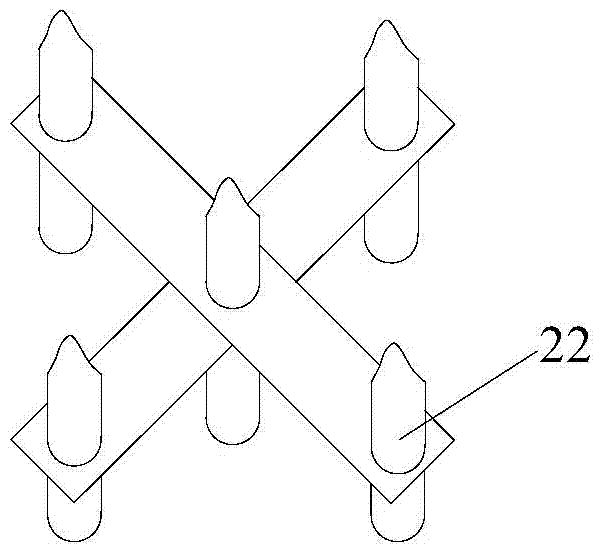

The invention discloses a method for processing vehicle bump at a bridge head of an existing highway, and the method comprises the following steps: mixing lightweight materials at a construction site; drilling holes from embankment slopes on both sides of the highway, and automatically discharging soil outward from a threaded opening while rotatably drilling holes; after a designed depth reaches, rotatably and slowly pulling out a drill rod, and starting a booster pump so as to pump the lightweight materials into the obtained drill holes by virtue of a central tube of the drill rod; and jetting the lightweight materials from the central hole of the drill rod so as to gradually fill the hole from bottom to top, thereby replacing the filled soil of an embankment. The drill holes are arranged squarely or quincuncially on the side slope of the embankment, a certain included angle is formed between each drill hole and a horizontal plane, and the elevation of the opening of each hole is positioned below a pavement structure layer and above the underside of the filled soil of the embankment. By using the method disclosed by the invention, the weight of the embankment is greatly reduced, thereby reducing the settlement after construction caused by embankment loads and then effectively solving the problem of vehicle bump at bridge heads. During the construction period, the highway is not required to be closed, therefore, the normal traffic of the highway is not affected. The method disclosed by the invention is simple in construction process, convenient to operate, simple in equipment, economical, and high in efficiency.

Owner:HOHAI UNIV

Method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil

ActiveCN102505598ASuppression uniformityInhibition of lateral movementRoadwaysLateral displacementUnderground pipeline

The invention discloses a method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil. The method adopts high-strength foam lightweight soil as filler for foundation pits. Due to pumping construction, the construction of a construction road is omitted, the construction floor occupation is small, the construction difficulty is reduced greatly while the construction period is shortened, the post-construction settlement of the filler is eliminated effectively, the additional pressure of foundation to underground pipelines is decreased, the nonuniform settlement and lateral displacement of foundation are suppressed, and the stability of roadbed is improved. Therefore, the method can ensure safety of underground pipelines, but also meet the bearing capacity requirement of foundation.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

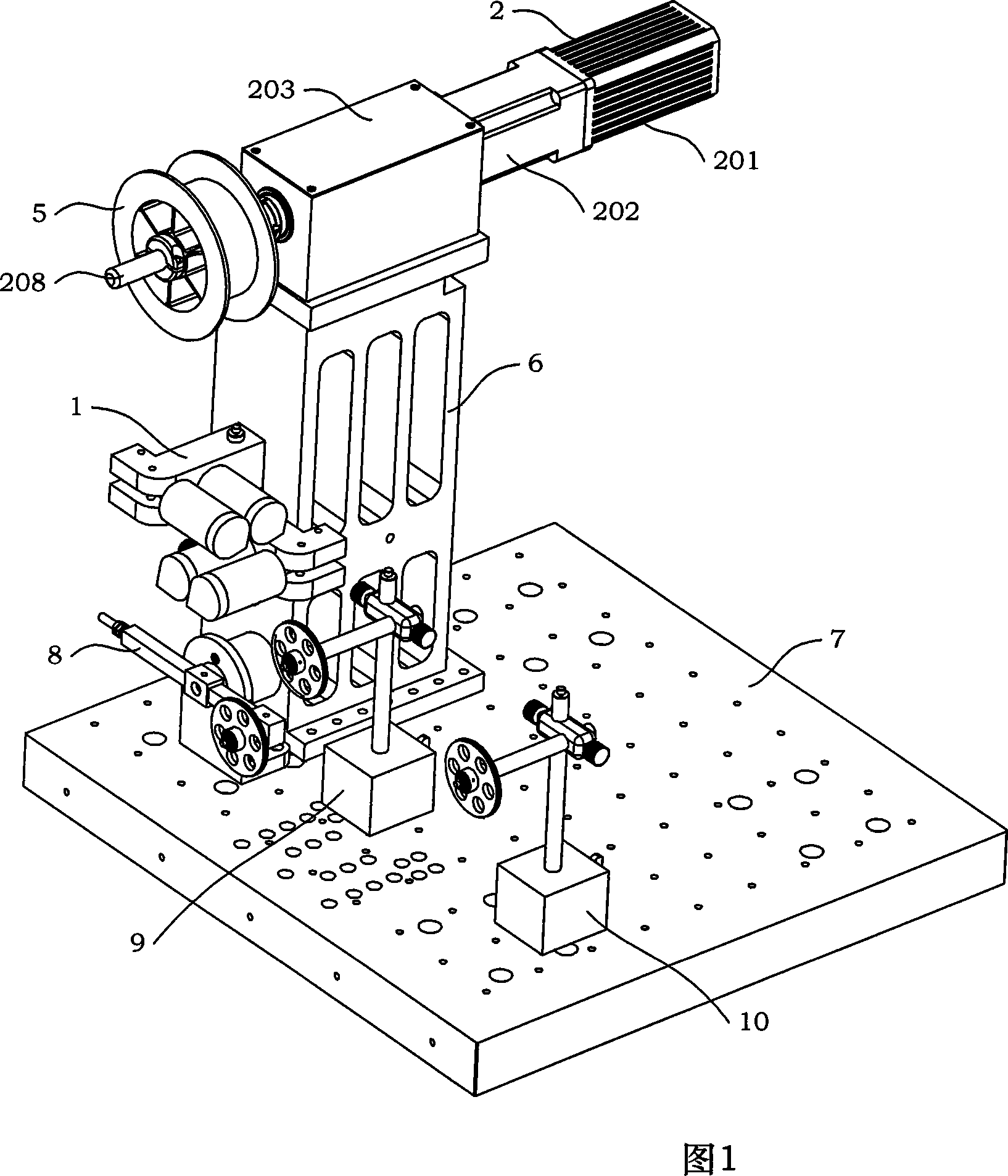

Tension mechanism adapted for automatic optical fiber winding machine

InactiveCN101059582ACompact designNo reverse dead zoneFilament handlingSagnac effect gyrometersWinding machineFiber

The invention discloses a tension structure used in automatic fiber coiler, composed of a fiber collector, a driver, a transmit box, a fiber discharge wheel, a support base, and a sliding table tension element, a first fiber guider and a second fiber guider, wherein the lower end of the support base via nut and screw is mounted on the sliding table, while the upper end is mounted with the transmit box, the driver is on the transmit box, while a motor and a speed reducer are mounted at the outer back of the transmit box, the accurate shaft of the driver is suspended at the outer front of the transmit box, which is mounted with the fiber discharge wheel, the fiber collector is at one side of the support base, vertically with the fiber discharge wheel, the sliding table is arranged with a plurality of mounting holes for fixing and mounting devices, the tension element, the first and the second fiber guiders via nut and screw are fixed on the sliding table, which guide grooves are in one plane. The inventive tension device has reasonable, compact and simple structure, without reverse dead area, but with stable transmission control, accurate tension control, non-zero-bias in force measurement, digit and closed tension control.

Owner:BEIHANG UNIV

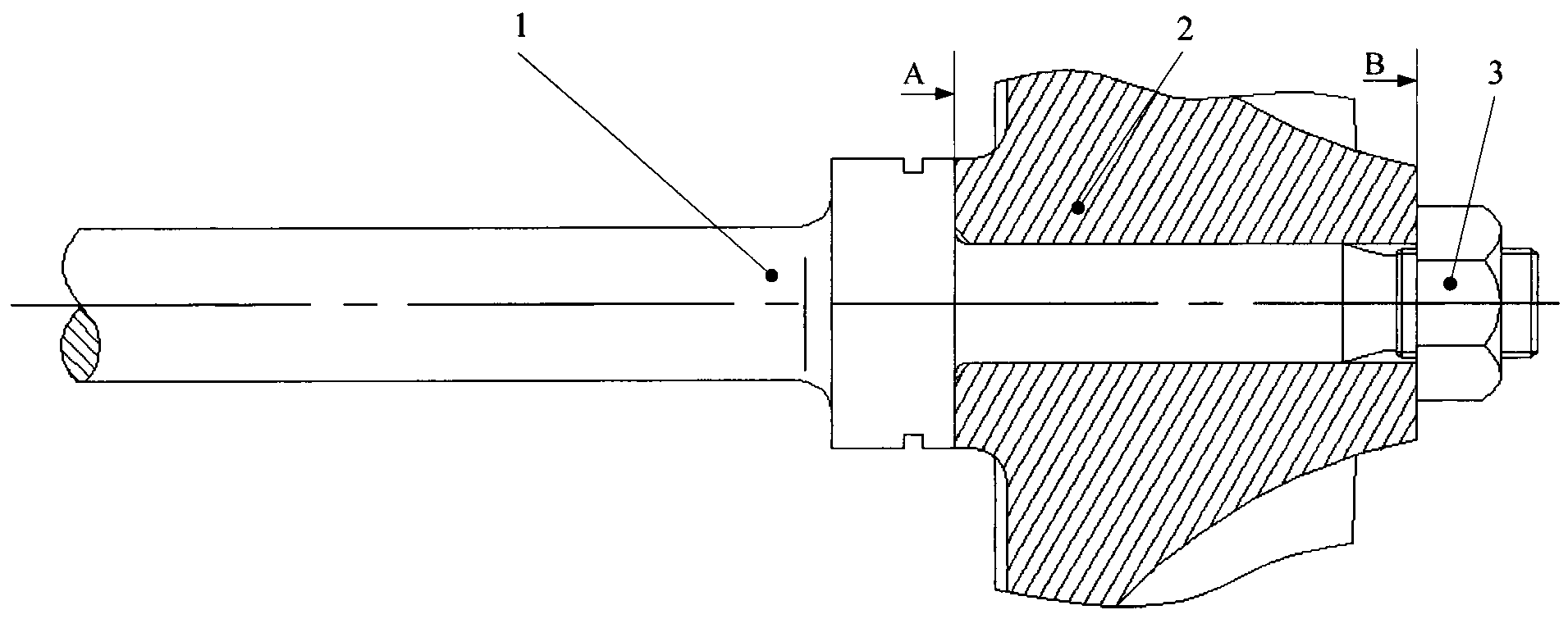

Through-hole connection method and connection structure of titanium aluminum turbine impeller and rotating shaft

ActiveCN103321685AMeet the needs of engineering applicationsGuaranteed connection strengthBlade accessoriesMachines/enginesInterference fitImpeller

The invention relates to a through-hole connection structure and connection method of a titanium aluminum supercharger turbine impeller and a rotating shaft. The connection structure comprises the rotating shaft, the titanium aluminum turbine impeller and a shaft end locking nut. A through hole is formed in the center of the titanium aluminum turbine impeller. A thread is arranged at the end portion of the rotating shaft. Seen from the end of a turbine, the rotating direction of the thread is the same as the rotating direction of the turbine rotating shaft during working. The lower portion of the thread is the rotating shaft connection portion. The rotating shaft connection portion penetrates through the through hole of the turbine impeller. The rotating shaft connection portion and the turbine impeller through hole are in transition fit or interference fit. The shaft end locking nut is installed on the thread of the end portion of the rotating shaft. As for the connection problem of the titanium aluminum turbine impeller and the rotating shaft, the through-hole connection and threaded locking structure are adopted, the durable and reliable connection between the titanium aluminum turbine impeller and the 42CrMo rotating shaft can be achieved, the requirements for the connection strength of the supercharger turbine impeller and the rotating shaft are met, and meanwhile the connection structure has the advantages of being simple in structure, easy to machine and the like.

Owner:CHINA NORTH ENGINE INST TIANJIN

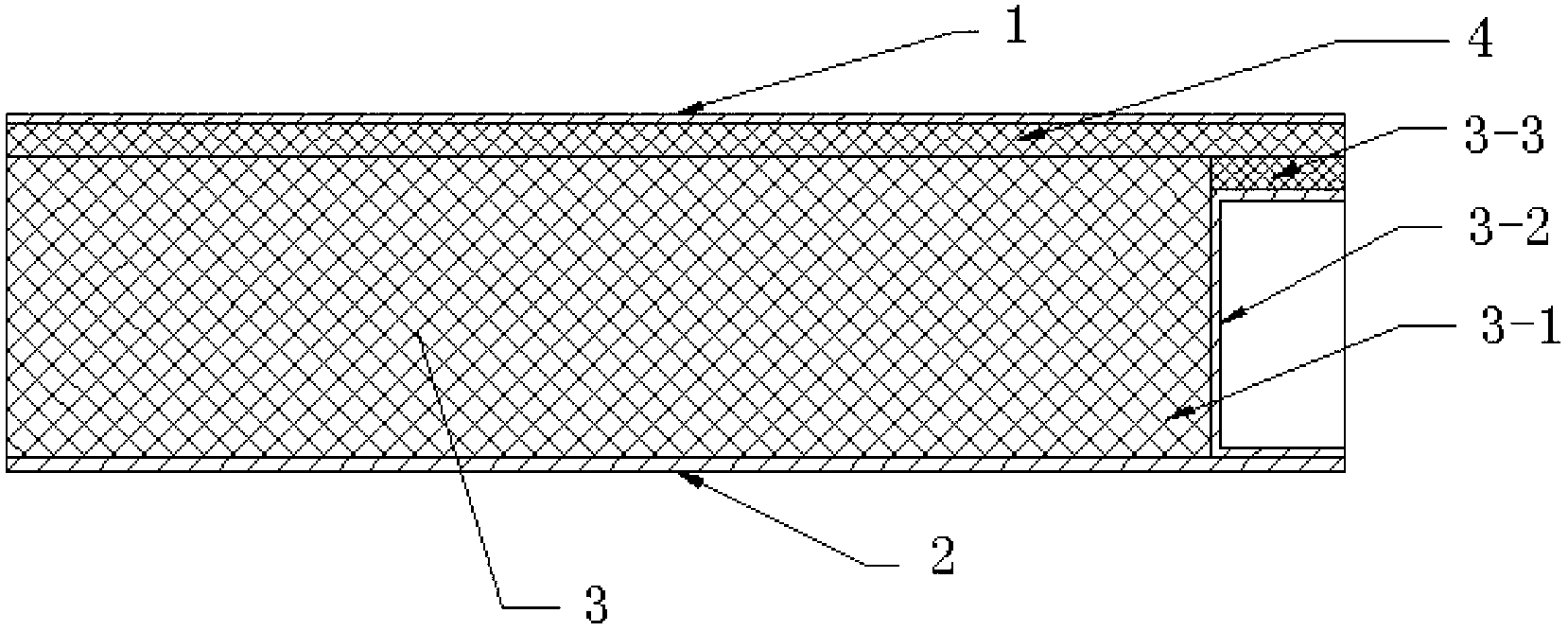

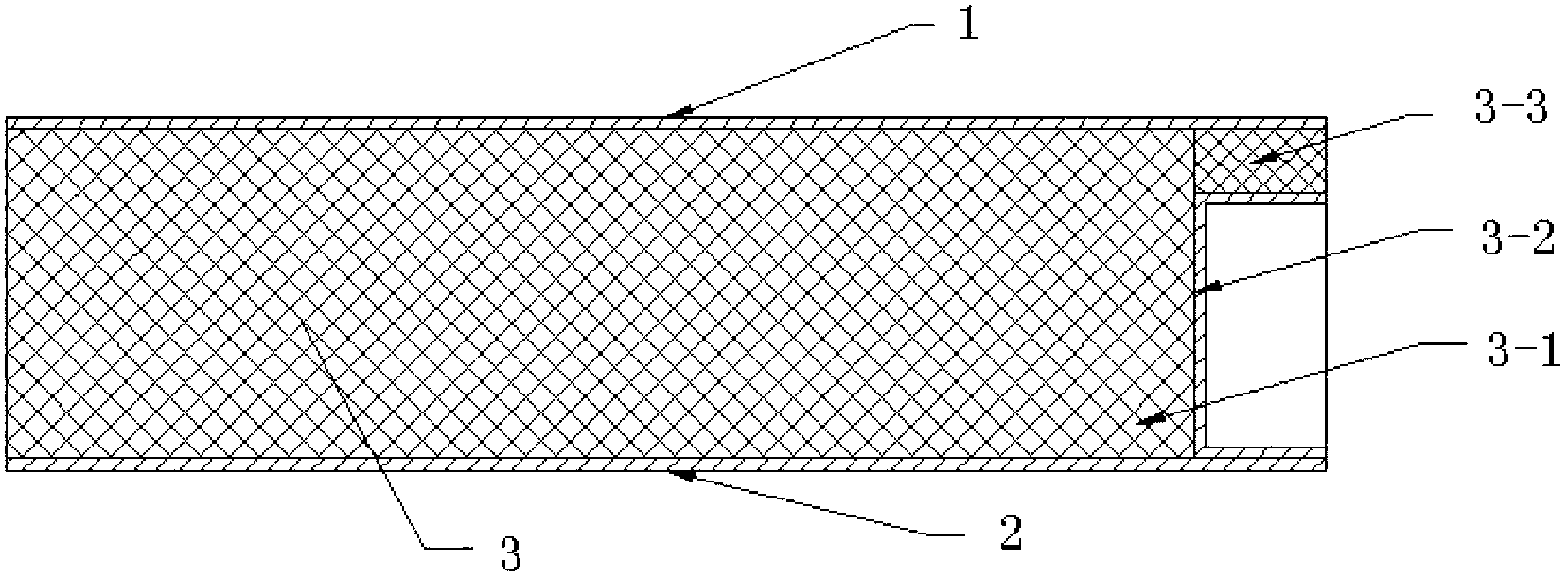

Square cabin composite plate

InactiveCN102704615AReduce thermal stressNot easy to debondBuilding componentsEngineeringComposite plate

The invention relates to a square cabin composite plate, which comprises an outer skin, an inner skin and a middle sandwich layer, wherein a rubber layer is arranged between the outer skin and the middle sandwich layer. The rubber layer is arranged between the outer skin and the middle sandwich layer, the elasticity modulus of the rubber is much smaller than the elasticity modulus of polyurethane foam and basswood, so the heat stress between the outer skin and the rubber is small, the heat deformation phenomenon is reduced, the debonding problem of the existing square cabin caused by heat deformation at high temperature is solved, meanwhile, the rubber layer, the outer skin, the foam and the basswood are bonded through bonding agents, vibration reduction and buffer effects can be realized between the outer skin and the inner layer framework, the additional stress between the outer skin and the inner layer structure caused by impact and vibration in the transportation process is reduced, and the debonding problem in the transportation process is reduced.

Owner:XIAN UNIV OF TECH

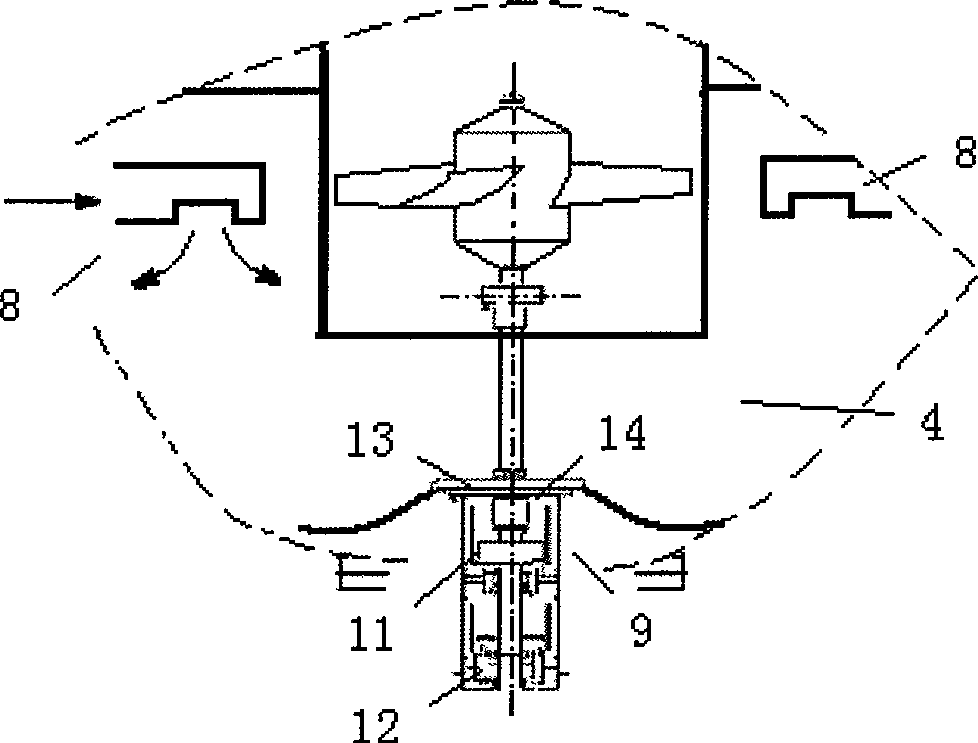

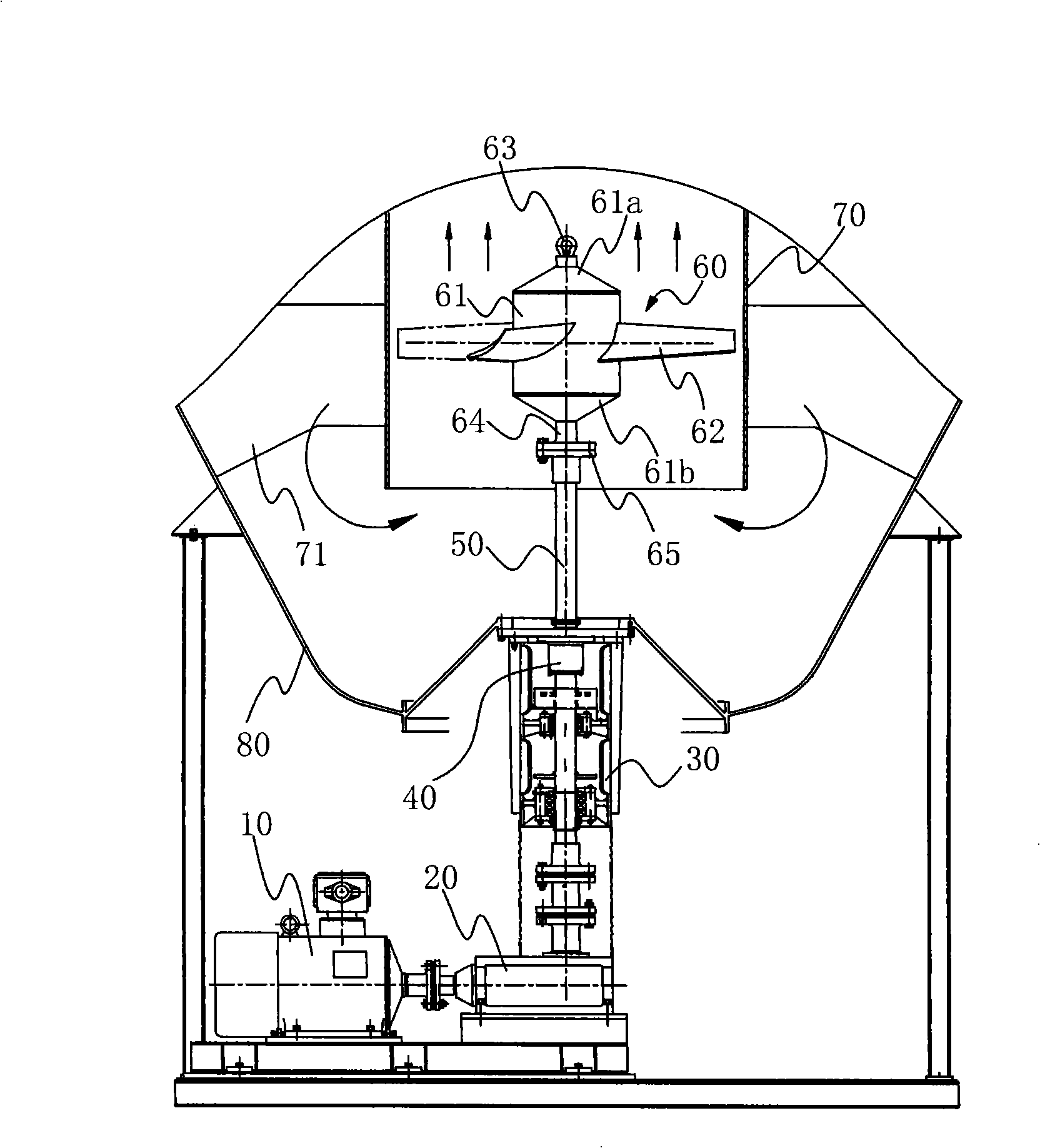

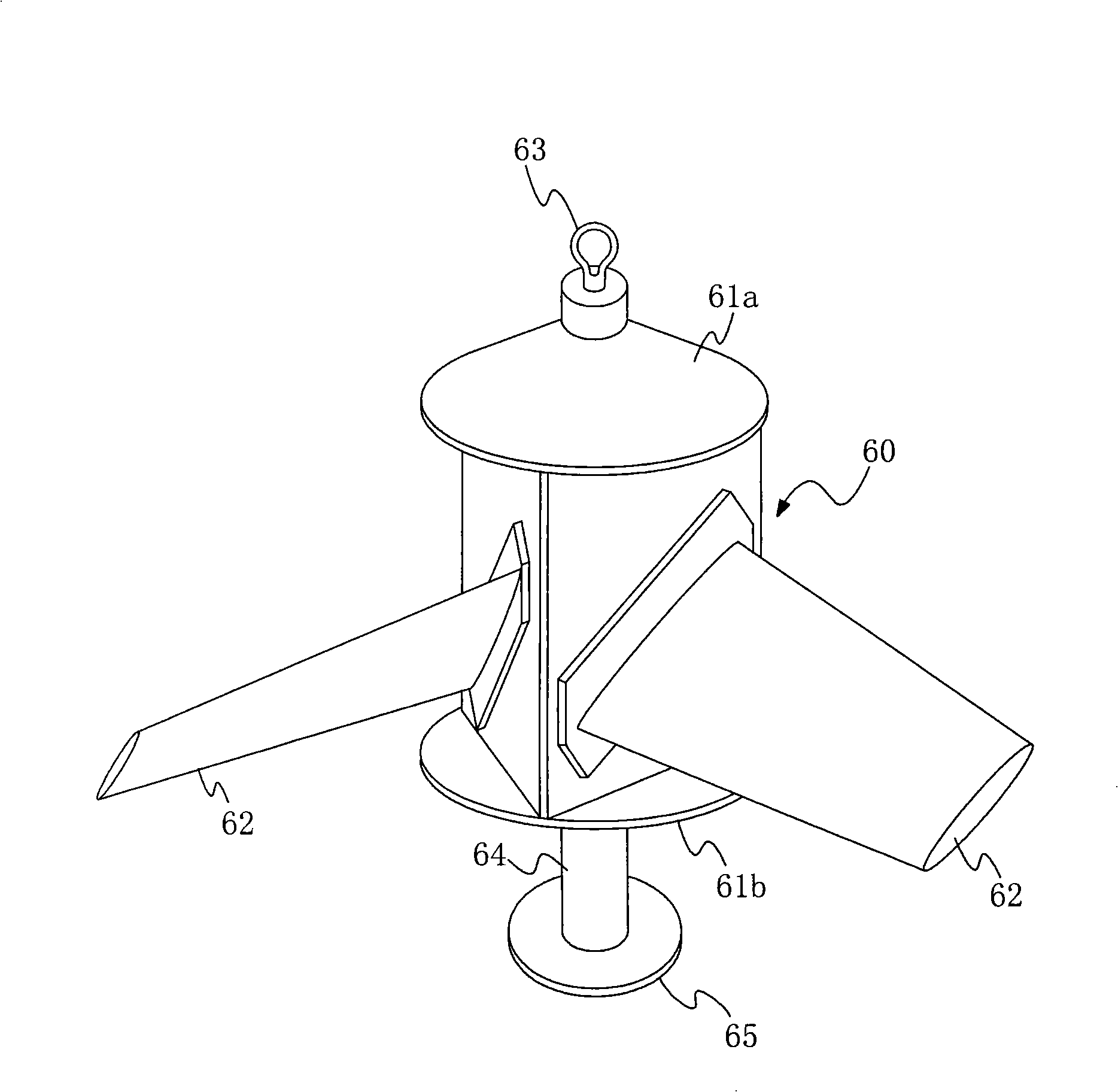

Reaction kettle bottom agitation system

ActiveCN101310843AShorten the lengthEasy to operateRotary stirring mixersChemical/physical/physico-chemical stationary reactorsChemical industryPharmaceutical industry

The invention discloses a stirring system at the bottom of a reaction kettle, which can be widely applied to the processes of shearing, emulsification and homogenizing in media of petroleum trade, chemical industry, pharmaceuticals industry, food service industry, etc. The reaction kettle is internally provided with an air guide sleeve the upper end and the lower end of which are both open. The lower part of a stirring device in the air guide sleeve is provided with a transmission device which is fixed at the bottom of the reaction kettle. Cartridge and combined mechanical seals are arranged between the bottoms of the transmission device and the reaction kettle, and the transmission device is connected with a power output shaft of a speed reducer while a power input shaft of the speed reducer is connected with a motor. With the respect to the problem of the over-length of stirring shafts in the general jacking structure adopted, the stirring system of the invention can greatly shorten the length of the stirring shaft and ensure the stable operation and that a rotating shaft bears small subsidiary stress, thus providing comparatively favorable application environment for sealing.

Owner:合肥华升泵阀股份有限公司

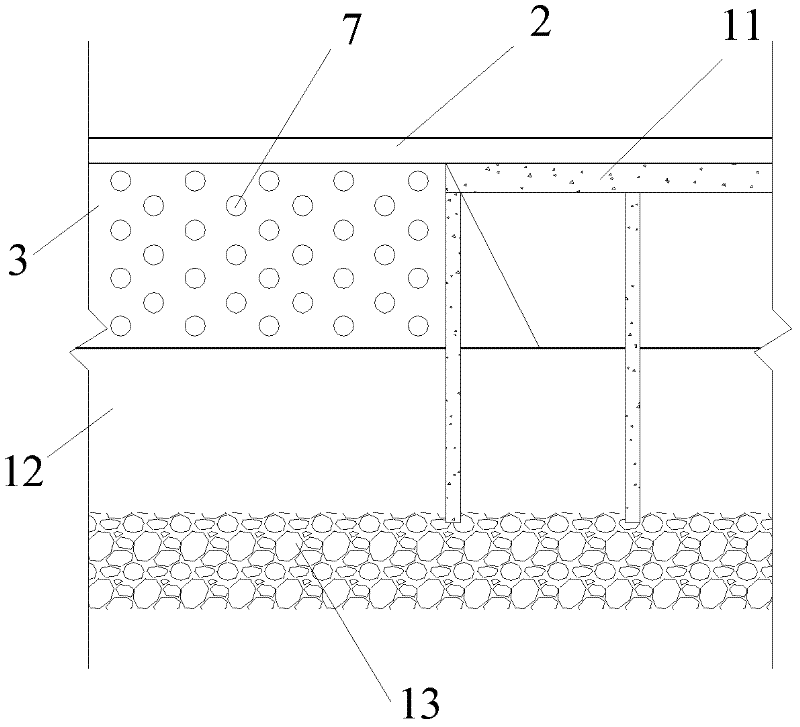

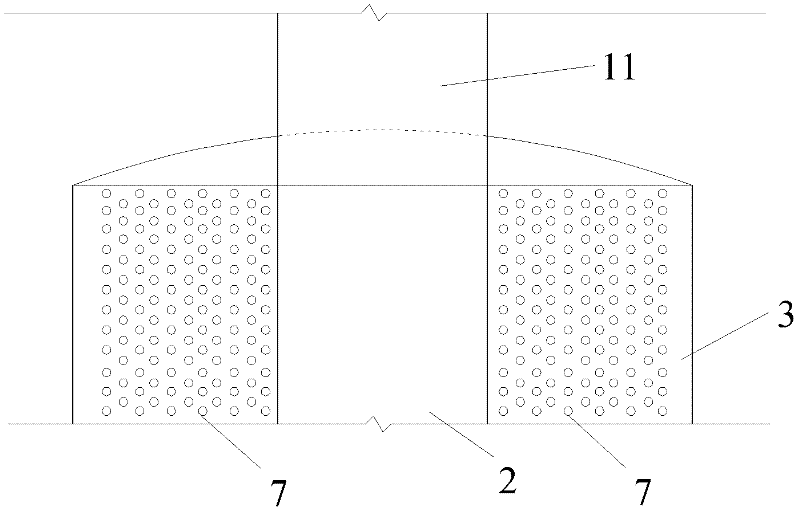

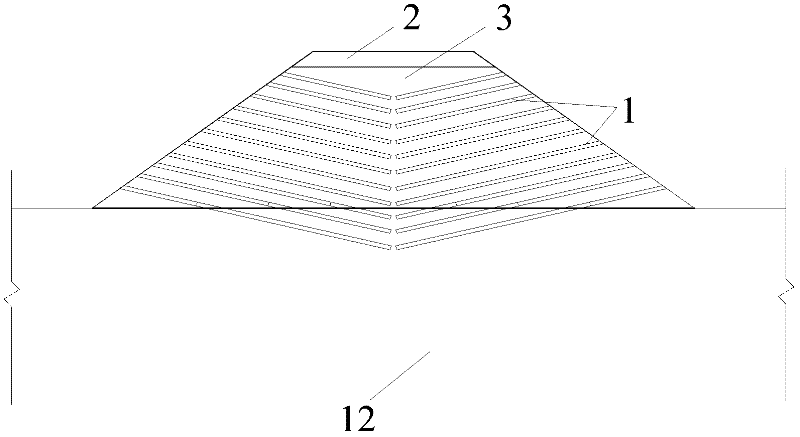

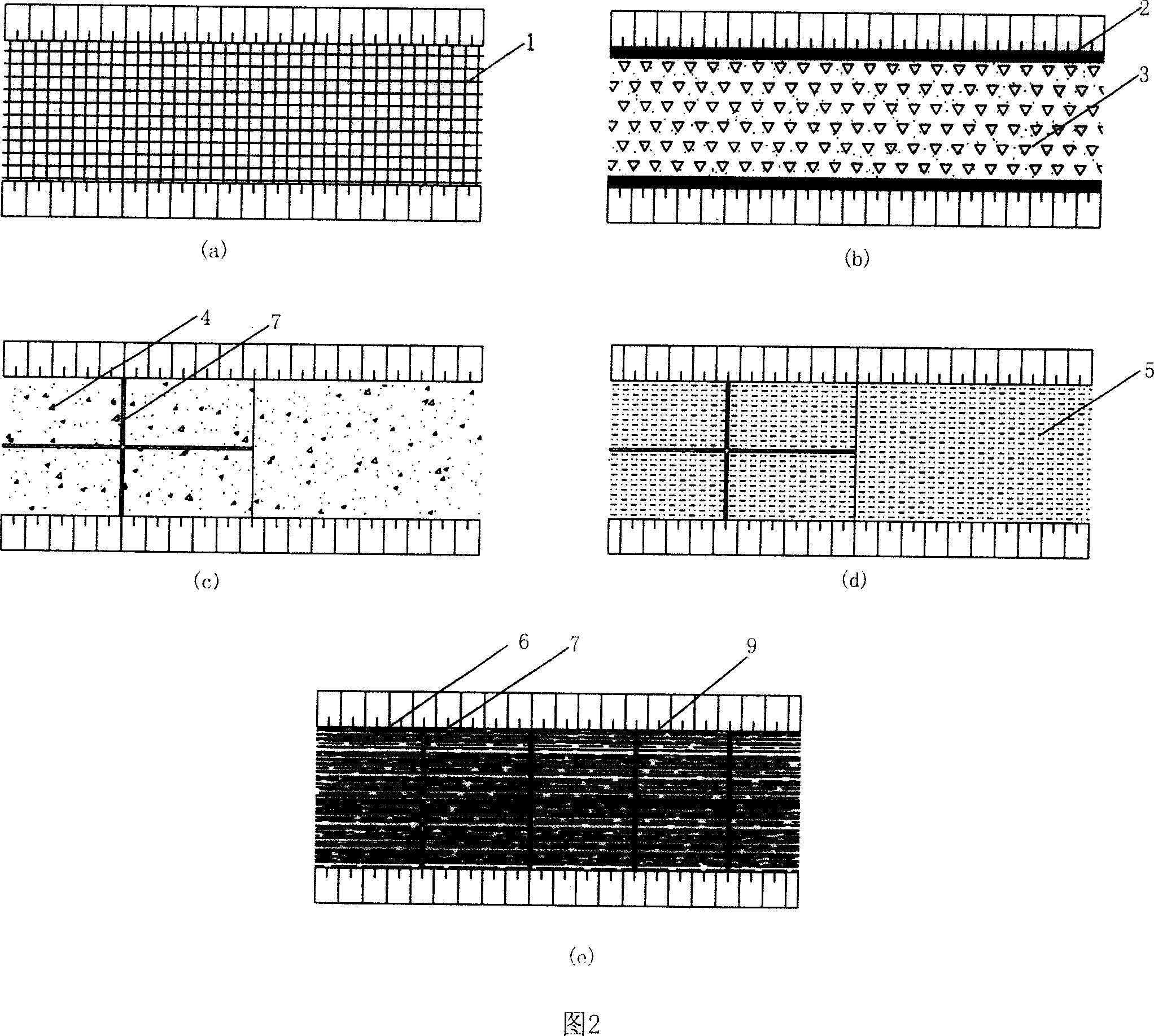

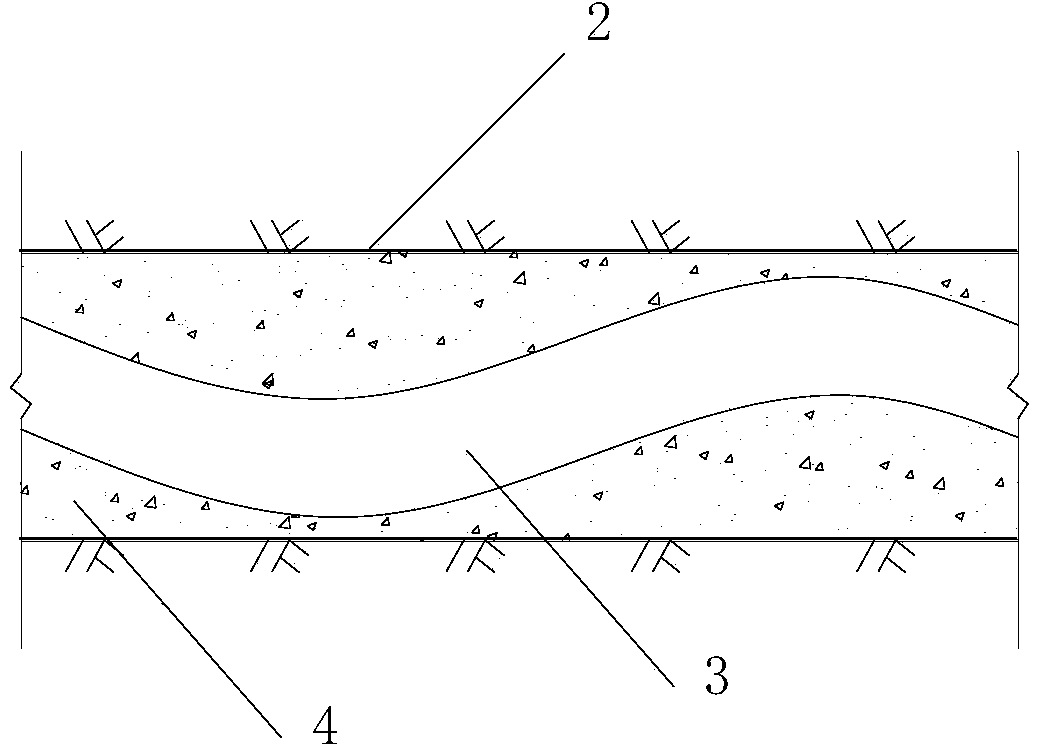

Light filled structure and its construction process

The light fill body structure includes soil layers and foamed plastic block layers superposed alternately. In all the foamed plastic block layers, there are drilled soil column holes. There are also concrete layer over the top foamed plastic block layer, bottom crushed stone layer below the lowest foamed plastic block layer, and retaining wall to the sides of the fill body structure. The present invention is easy to construct, and has density lower than common soil, adjustable strength, light pressure to soil, and less deposit and side flow. The present invention makes it possible to refill soil vertically.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

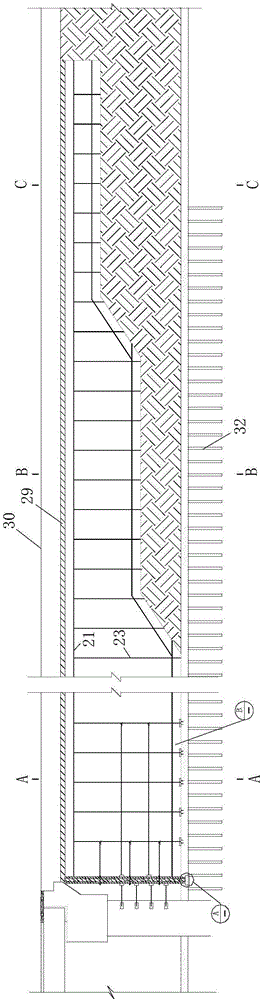

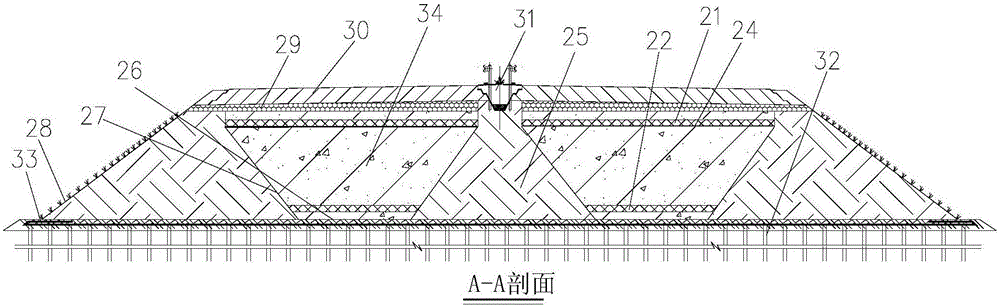

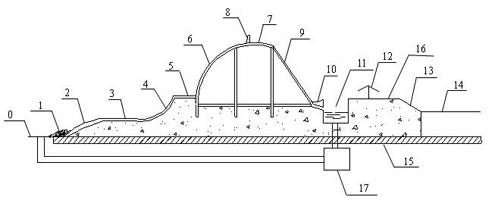

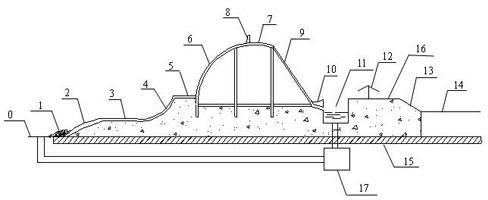

Non-bridgehead-conical-slope cast-in-situ baffle foam concrete light embankment structure and construction method

The invention relates to a non-bridgehead-conical-slope cast-in-situ baffle foam concrete light embankment structure and a construction method. The structure mainly comprises an upright, a cast-in-situ concrete baffle, a baffle foundation, a cover beam, embedded thread sleeves, template stay bars, template guide fixing plates, a side die, opposite-pull screws, template fixing plates, baffle connecting reinforcing steel bars, template fixing screws, connecting keys, fastening nuts, transverse connecting ribs, transverse connecting rib end plates, anti-shearing ribs, vertical connecting ribs, reinforcing steel bar fixing plates, V-shaped pulling pieces, an upper layer reinforcing mesh, transitional section foam concrete and joint section foam concrete. The method includes the main construction steps of firstly, ground stabilization, secondly, embedment of embedding parts, thirdly, reinforced cushion layer construction, fourthly, baffle foundation construction, fifthly, baffle construction, sixthly, reinforcing mesh laying construction, seventhly, foam concrete filling, eighthly, water permeating layer laying, and ninthly, road surface laying. By the adoption of the construction method, construction of the embankment structure can be achieved under the condition that no bridgehead conical slope is arranged, and the economic and technical benefits are relatively good.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

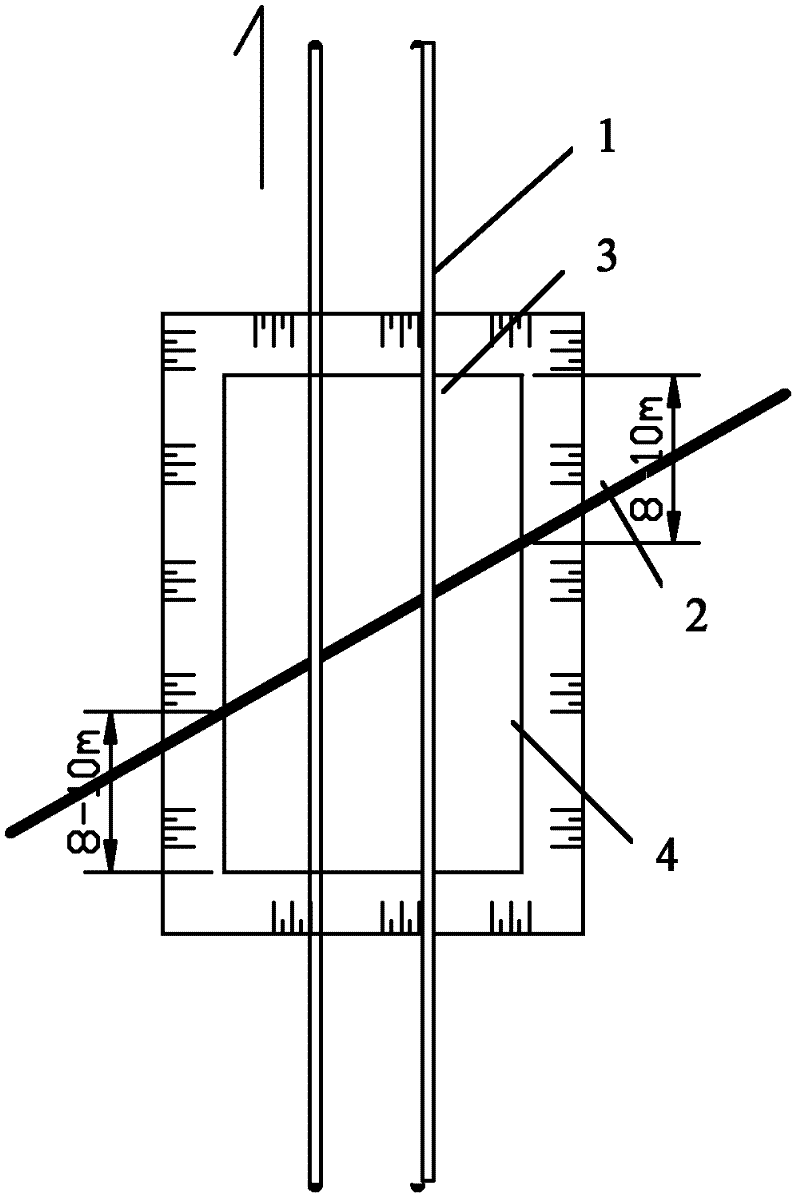

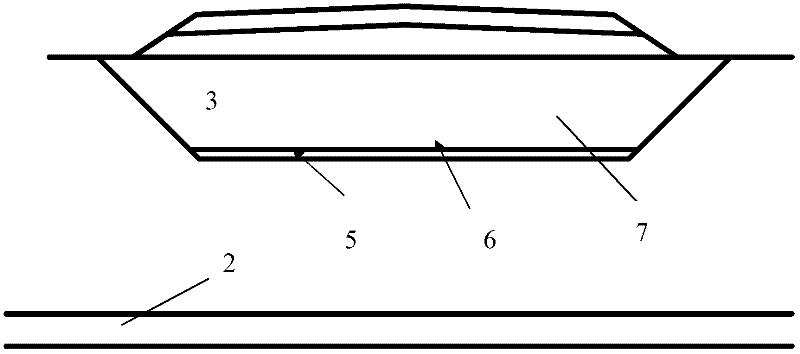

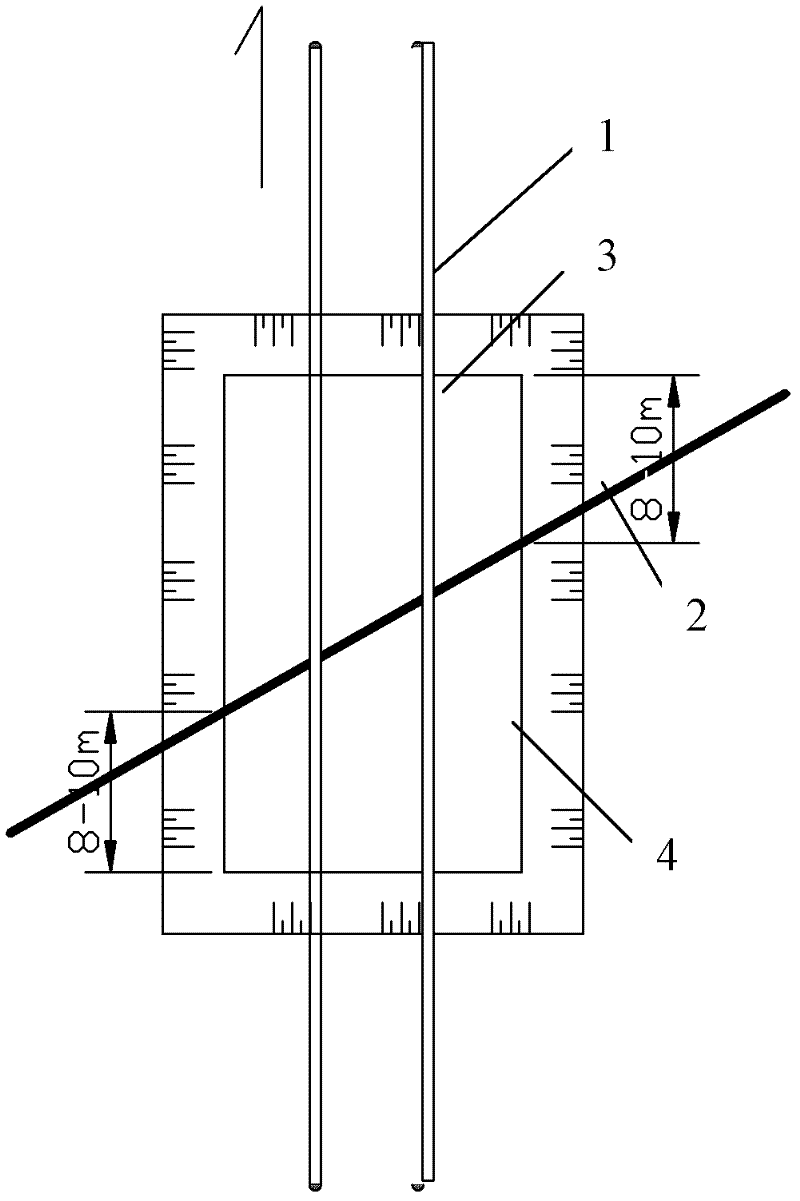

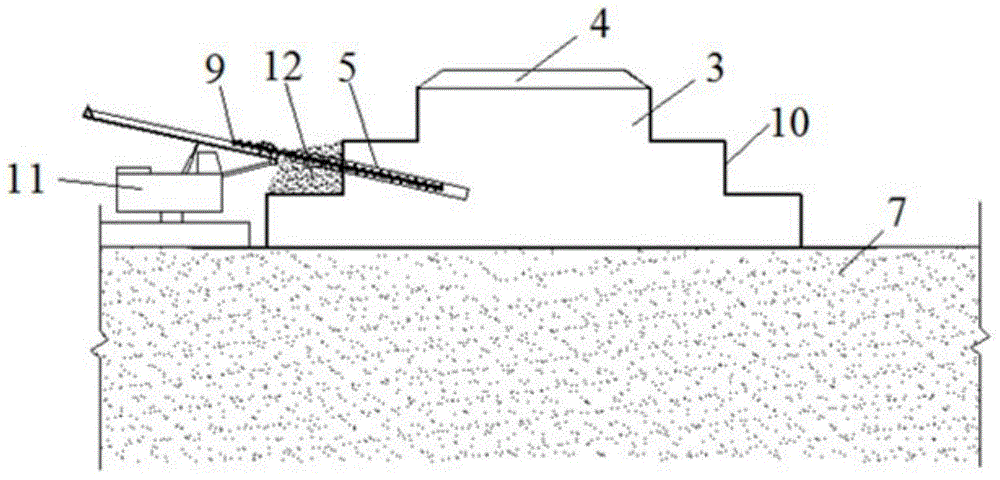

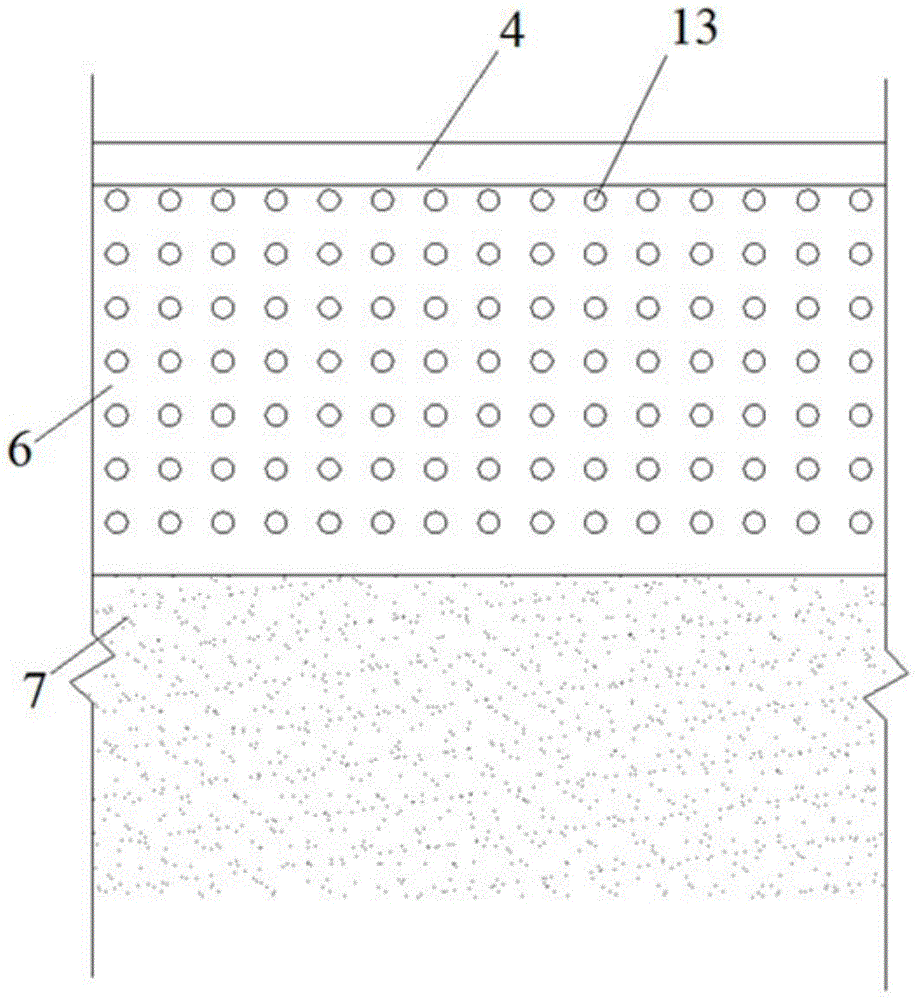

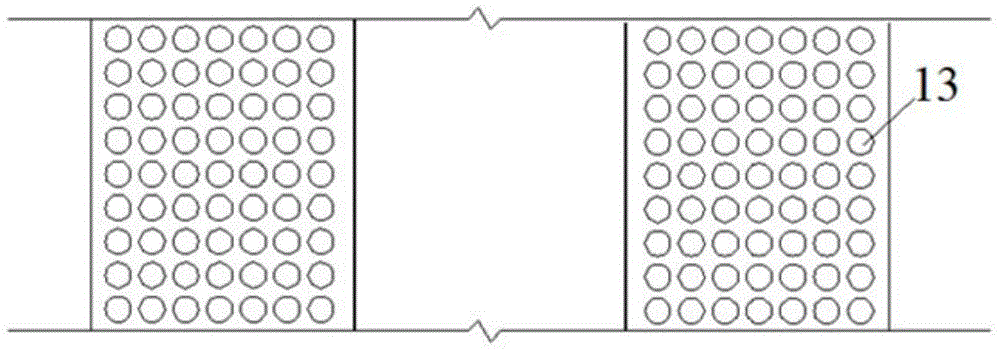

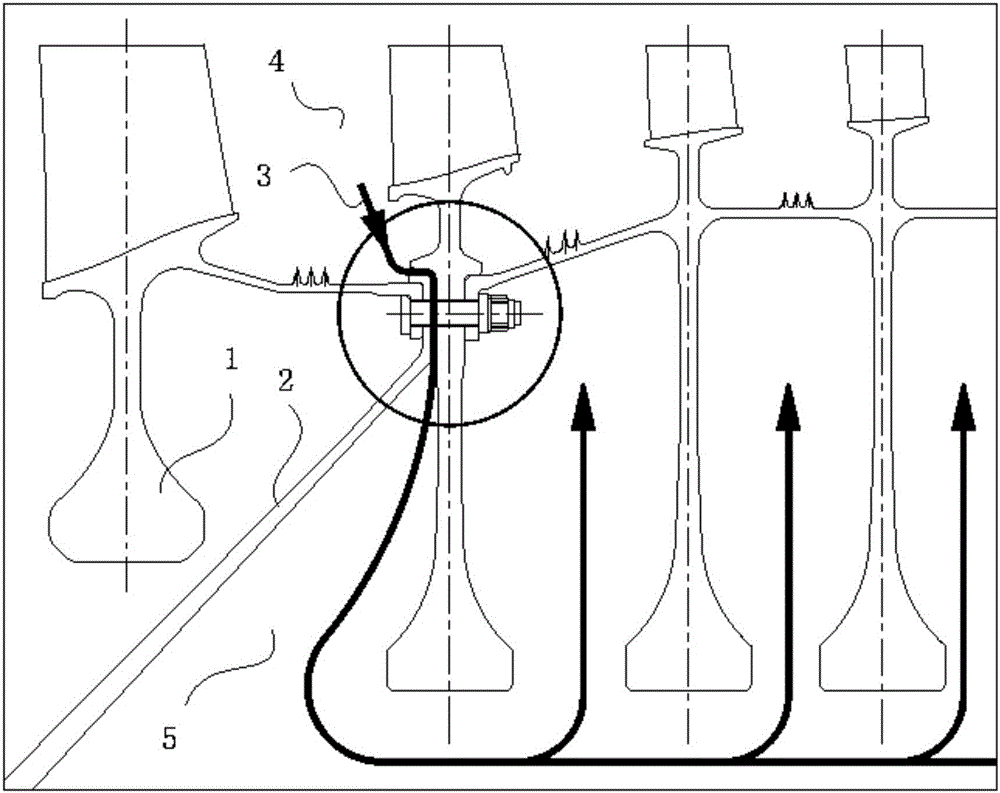

Existing expressway (railway) embankment lightening settlement control method

The invention discloses an existing expressway (railway) embankment lightening settlement control method. Steps are dig in slopes at two sides of a road as construction platforms; drilling holes are arranged in construction areas; the drilling holes are dripped into embankments according to certain inclined dip angles; in the drilling process, soil is automatically discharged from spiral drill rods; after the drilling is finished, PVC pipes are inserted in; bagged sands are filled into the PVC pipes, and the exposed ends are added with PVC pipe sealing covers; the replacement of the drilling holes in whole construction sections is finished; the slopes are backfilled by light soils for protecting the slopes again; and the backfilled sands filled in the PVC pipes are taken out every period of time according to actual conditions of highway differential settlement so as to achieve the settlement control effect. The traffic is normal in construction; the drilling holes little damage pavement structure layers; and the PVC pipes replace the embankment backfilled soils to achieve the effect of lightening the weight of the embankments, so that the roadbed post-construction settlement is largely reduced. The method is simple and clear in construction procedures, convenient for construction, economic, efficient and excellent in implementation effect.

Owner:CHONGQING UNIV

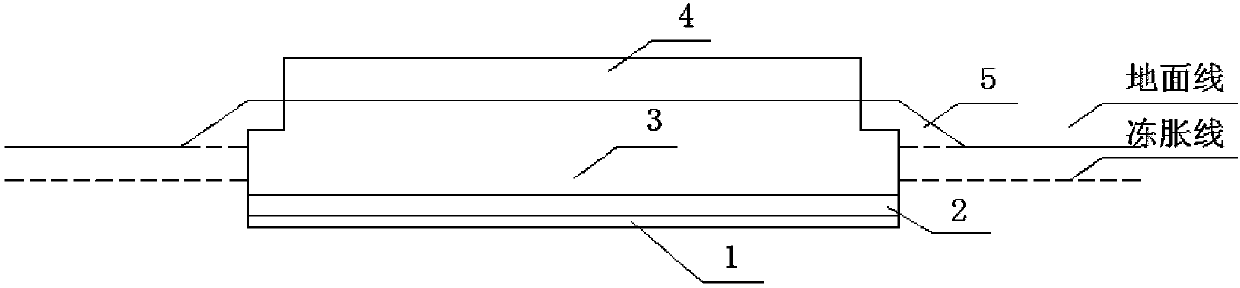

Novel soft soil quality seasonal frozen soil area highway subgrade structure and construction method

PendingCN107747261AStrong freeze-thaw resistanceGood stress structure layerRoadwaysClimate change adaptationAnti freezingEngineering

The invention discloses a novel soft soil quality seasonal frozen soil area highway subgrade structure and a construction method, which can be used for solving problems of frost heaving and sedimentation of building highway subgrades in soft soil areas. The novel soft soil quality seasonal frozen soil area highway subgrade structure mainly comprises a waterproof layer, a rubble layer, a lightweight concrete layer, a pavement structure layer and a backfill soil slope layer as a main body structure. The novel soft soil quality seasonal frozen soil area highway subgrade structure not only can utilize characteristics of low heat conduction, anti-freezing property, light weight and so on of a lightweight concrete material but also can use the rubble layer as a drainage layer and waterproof geotextile as a water-resisting layer to form an integral structure; good freeze-melt resistance during a low temperature effect is guaranteed; and moreover, as the lightweight concrete layer and the pavement structure layer form a good integral stressed structural layer, the additional stress is reduced and the sedimentation problem is weakened.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

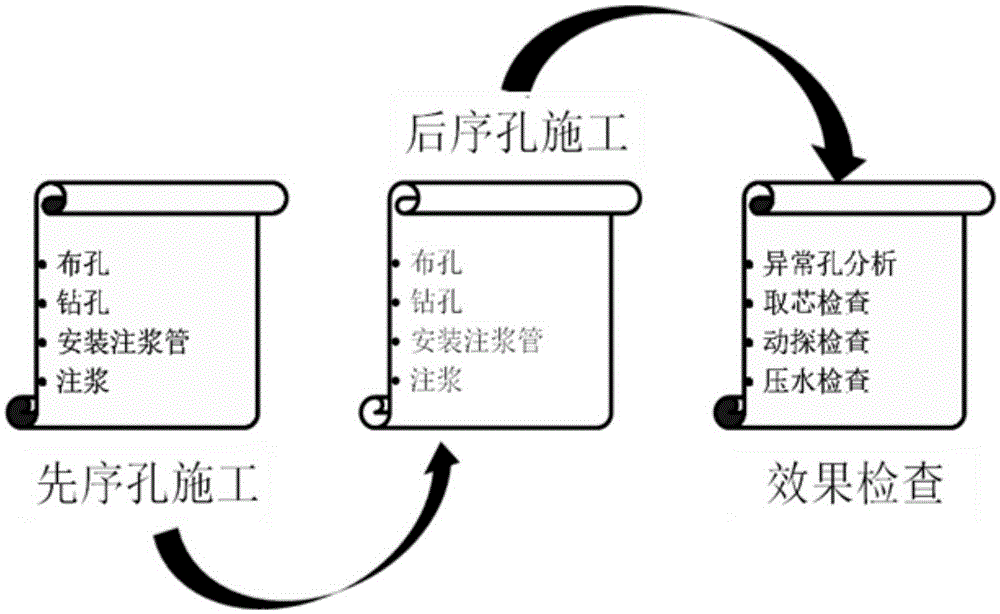

Sequential deepening grouting construction technology and device for soil covering layer on karst cave in karst area

The invention discloses a sequential deepening grouting construction technology and device for a soil covering layer on a karst cave in a karst area. The technology comprises two sequences, namely a front sequence and a rear sequence. Rear sequential holes are distributed among front sequential holes, and the hole depth of the rear sequential holes is increased on the basis of the front sequential holes. The front sequential holes mainly perform a function of reducing the permeability of the superficial strata, and the hole depth of the rear sequential holes is further increased than that of the front sequential holes. In this way, the sequential deepening process realizes an effect similar to that of sectional grouting, realizes emphasis reinforcing on a soil layer near a top plate of the karst cave, is as convenient as through grouting, does not need to bury orifice pipes or floral pipes, and does not need to carry out repeated drilling. The workload is greatly reduced, and the construction period is greatly shortened.

Owner:CHANGAN UNIV +1

Method for forming pavement of highway resisting large deformation of ground

InactiveCN101003963AGuaranteed normal operationFunction increaseIn situ pavingsPaving detailsSurface layerCrushed stone

The present invention relates to a highway road surface forming method capable of resisting ground surface large-deformation. Said method includes the following steps: firstly, laying a layer tension-resisting geotechnical material on the top layer of roadbed, making edge-covering treatment of roadbed two sides whose width range is 30-50 cm on the geotechnical material, then laying broken stone hardcore whose thickness is 10 cm-15 cm on the geotechnical material, according to different non-uniform settlements respectively further laying road surface base layer and surface layer with different sizes, and between the road surface structure plate blocks of every layer filling flexible material with different widths.

Owner:CHINA UNIV OF MINING & TECH

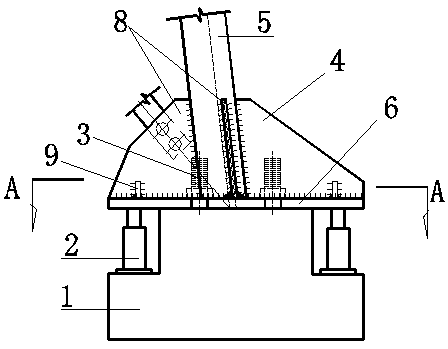

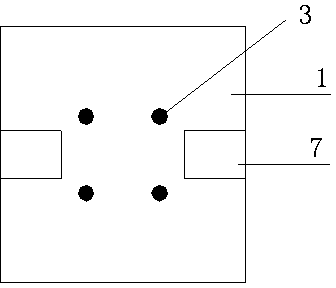

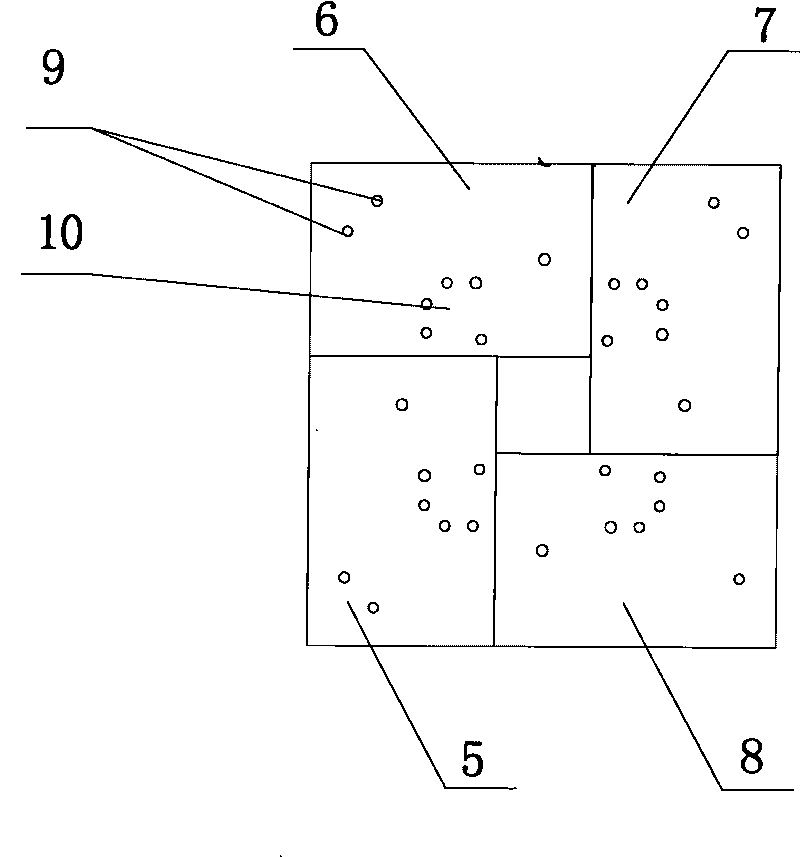

Jacking device for deviation rectification of steel pylon in mining area of coal mine

InactiveCN103669432ASafety CorrectionReliable CorrectionFoundation engineeringScrew threadStructural system

The invention discloses a deviation rectification device for a steel pylon, and particularly relates to a jacking device for deviation rectification of the steel pylon in a mining area of a coal mine. The jacking device for deviation rectification of the steel pylon in the mining area of the coal mine comprises an independent long-column concrete foundation (1), foundation bolts (3) and a pylon leg plate (4) capable of being jacked, wherein the pylon leg plate capable of being jacked (4) comprises a base plate (6) and a steel pylon principle material connecting plate (8) welded to the base plate (6), the steel pylon principle material connecting plate (8) is welded to a steel pylon principle material (5) along the edge, the base plate (6) of the pylon leg plate capable of being jacked (4) is connected with the independent long-column concrete foundation (1) through the foundation bolts (3), loading holes (7) used for installation of jacks (2) are formed in the independent long-column concrete foundation (1), and the length of exposed screw threads of each foundation bolt (3) is no smaller than 150mm. According to the structural system, the jacking device for deviation rectification of the steel pylon in the mining area of the coal mine is simple in structure, when the steel pylon inclines, the foundation bolts (3) are loosened, the jacks can be used for directly jacking the pylon leg plate capable of being jacked, and deviation rectification can be carried out.

Owner:STATE GRID CORP OF CHINA +2

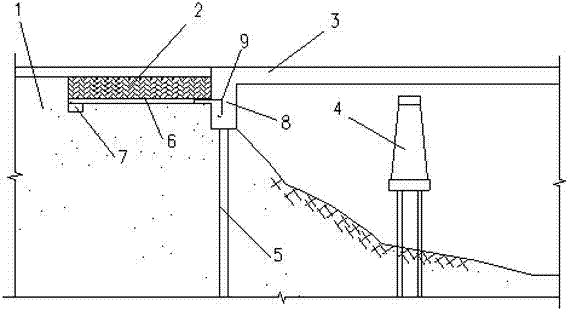

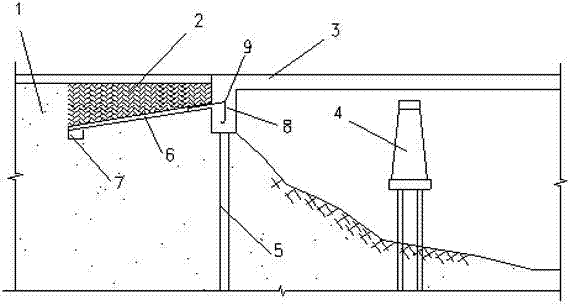

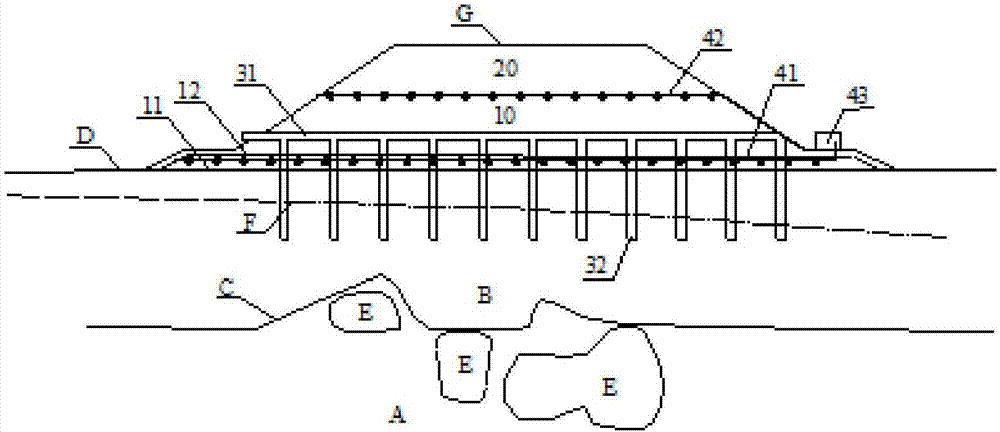

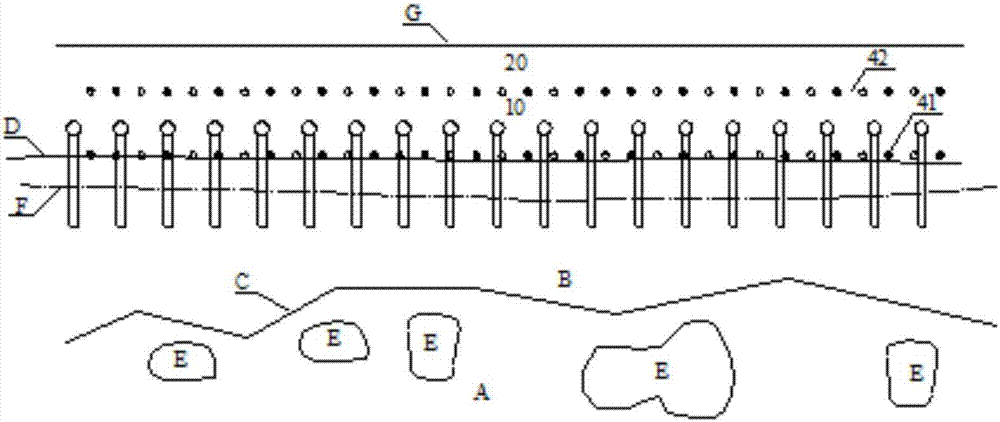

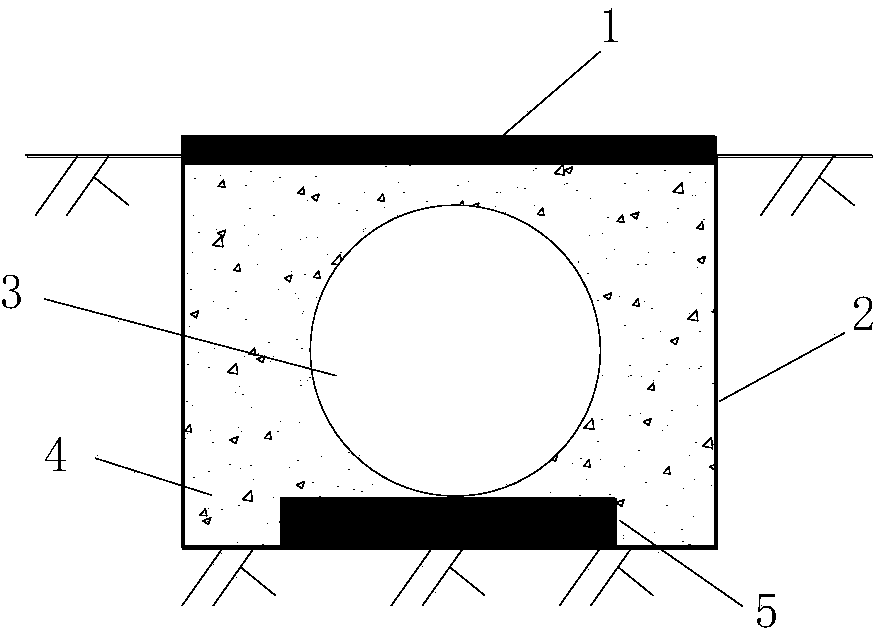

Structure and construction process for reducing power impact response at back of seamless bridge abutment

InactiveCN104499425AReduce additional stressReduce post-construction settlementBridge structural detailsBridge erection/assemblyDirect effectsAbutment

The invention discloses a structure and a construction process for reducing power impact response at the back of a seamless bridge abutment. A slab is buried in the filling at the back of an abutment and is integrally connected with a back wall. The top part of the buried slab is provided with a back filling layer to distribute part of impact load and reduce the impact effect on the slab. Cover soil in the length range of the buried slab and a soil body at the end of the slab together form a thick and long elastic body to absorb the expansion deformation of a girder body. By the structure and construction process for reducing power impact response at the back of the seamless bridge abutment, load of vehicles on the bridge is distributed, the direct effect impact of vehicles on the slab is decreased, and the slab can be prevented from breaking down. Because the slab bears part of overburden load, subsidiary stress on a lower soil matrix is reduced, post-construction settlement of the soil matrix is decreased, large bridge settlement difference of the bridge is avoided, the settlement of the transaction section of the seamless bridge is transformed from a sharp change to a gradual change, and bumping at bridgehead is avoided. Moreover, the seismic performance of the seamless bridge is improved. Therefore, the structure and the construction process for reducing power impact response at the back of the seamless bridge abutment are particularly applicable to integral seamless bridges.

Owner:FUZHOU UNIV

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167BHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsRebar

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

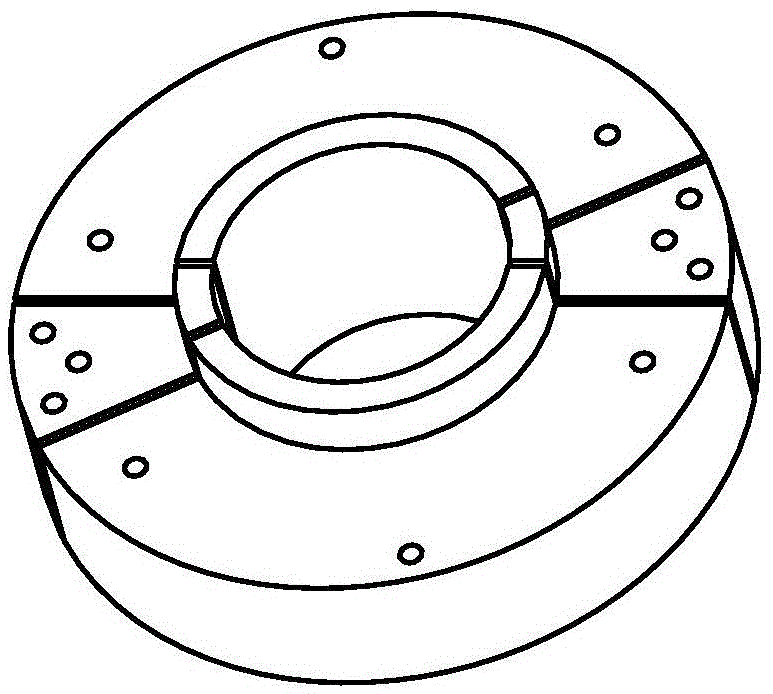

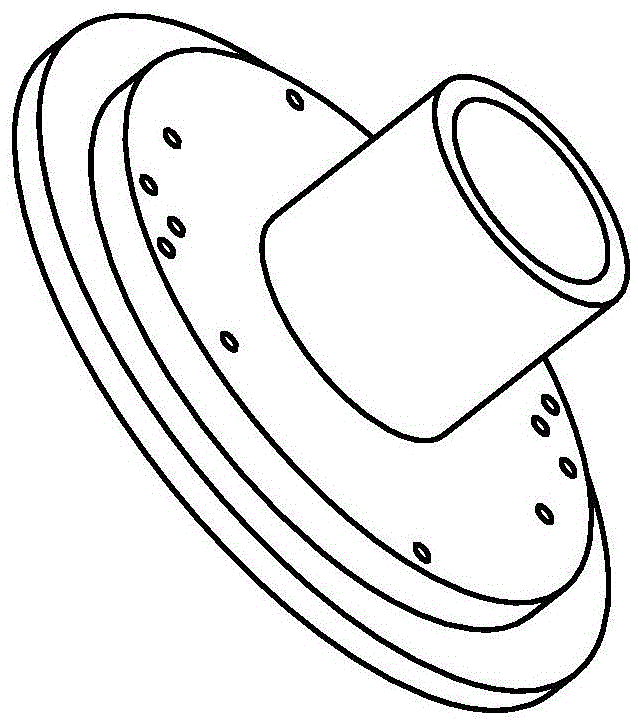

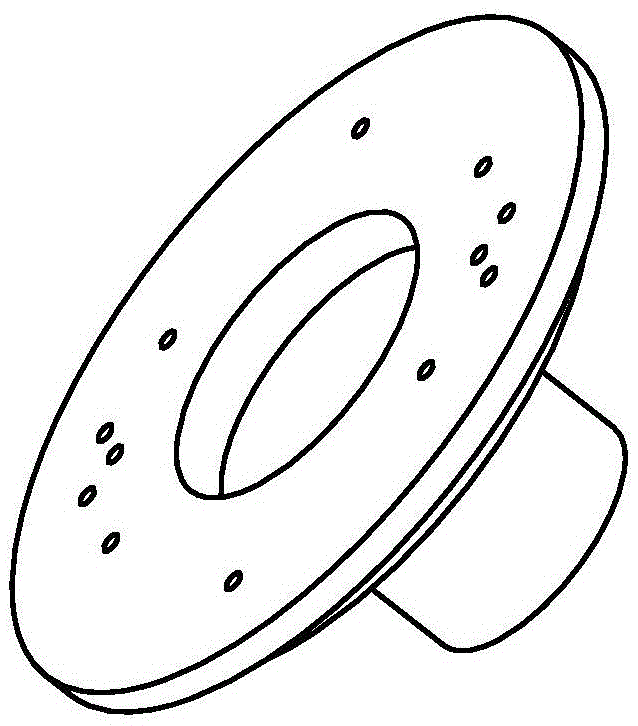

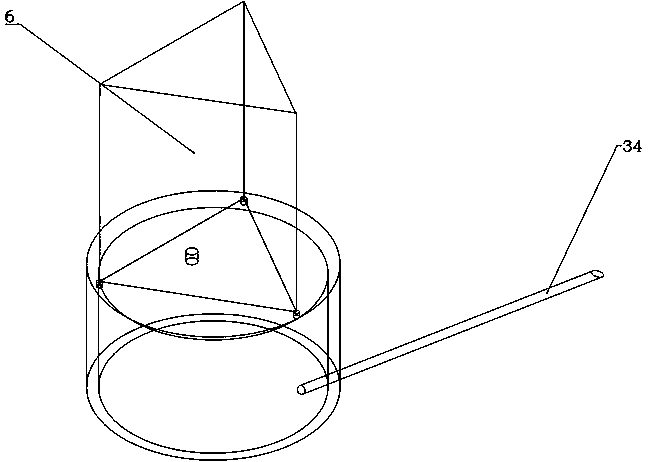

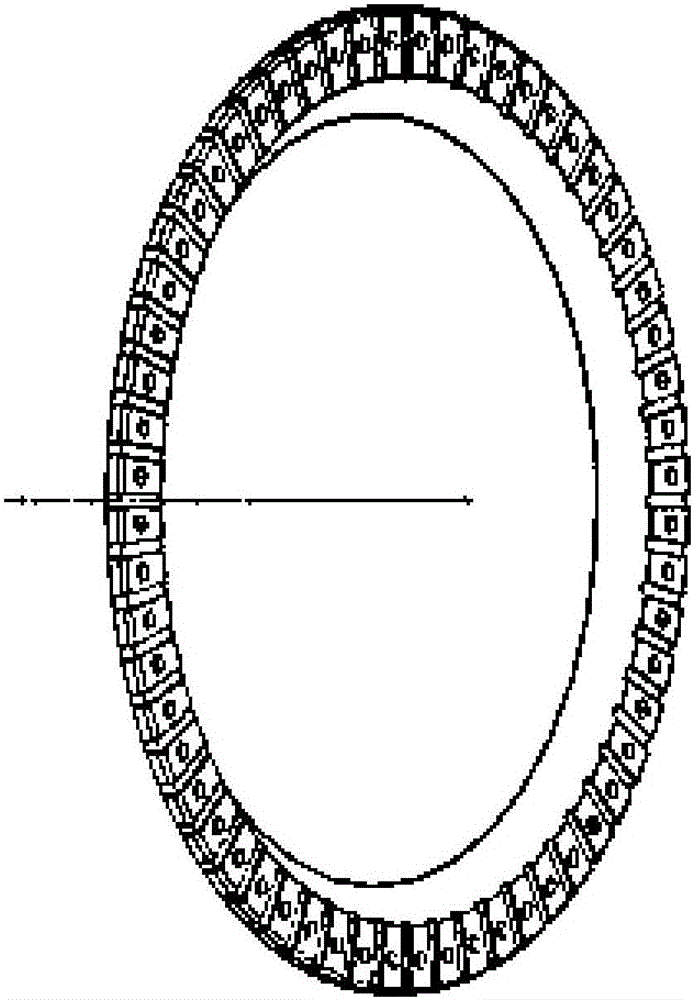

Frameless optical fiber ring demoulding frame and demoulding method

ActiveCN105571616AAccuracy consistency is smallGood consistency of precisionGyroscopes/turn-sensitive devicesEngineeringConductor Coil

The invention belongs to the field of machine manufacturing and particularly relates to a frameless optical fiber ring demoulding frame and a demoulding method. The frame comprises a retaining collar, a ring winding body and a transitional body which are sequentially assembled in a sleeved mode. The demoulding method based on the frameless optical fiber ring demoulding frame includes the steps of demoulding frame assembly, ring winding and solidifying, disassembly of an optical fiber ring from the frame and demoulding. The demoulding frame is easy to install and convenient to detach; after the frame is repeatedly assembled and disassembled, precision is high and uniformity is good; the quality of the frameless optical fiber ring is improved, production efficiency of products is improved, the unqualified rate of the products is reduced, and production cost is reduced.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

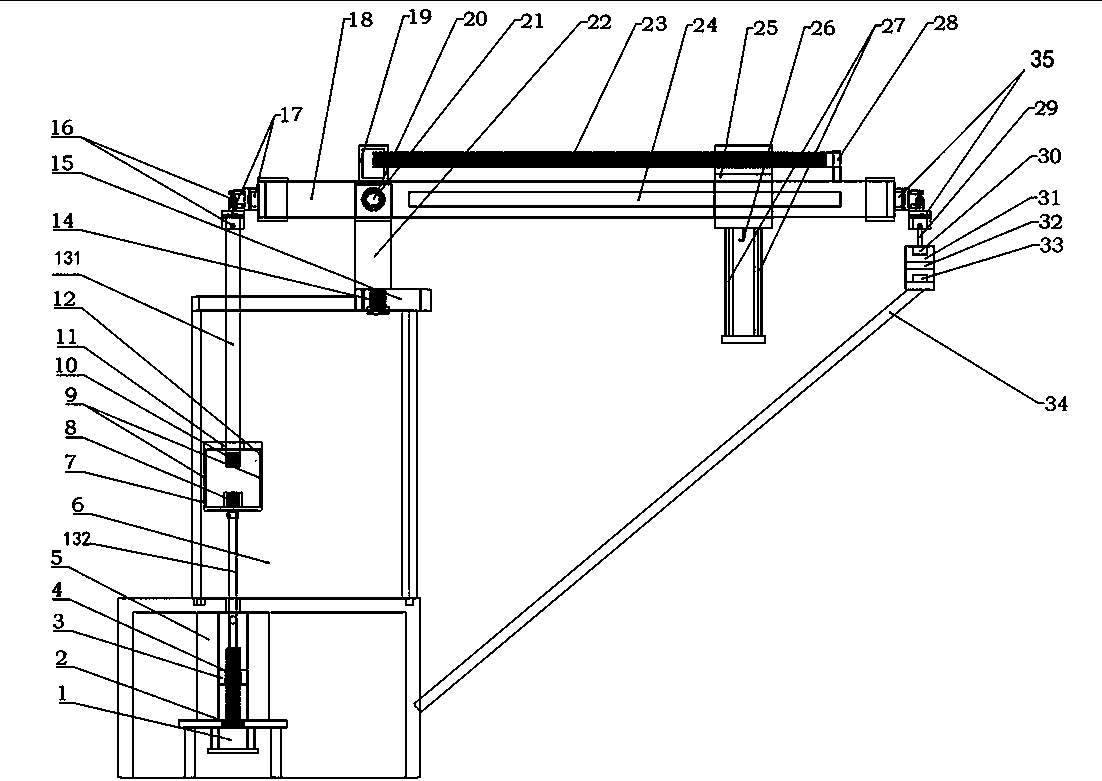

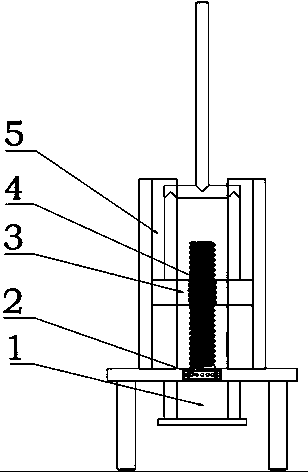

Lever-based slow tensile stress corrosion experimental device

ActiveCN109827897AReduce additional stressContinuous constant outputWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCreep stressElectricity

The invention discloses a lever-based slow tensile stress corrosion experimental device. The device comprises a lever balance system, a corrosion test system and a feedback adjustment system; the lever balance system comprises a lever and a lever bracket for supporting the lever; the left end of the lever is connected with the corrosion test system; the right end of the lever is provided with a weight device; the corrosion test system includes an electrochemical corrosion tank; the electrochemical corrosion tank is used for simulating a corrosive environment and fixing a sample; the electrochemical corrosion tank is connected with the left end of the lever; the feedback adjustment system is connected between the lever balance system and the corrosion test system; and the feedback adjustment system is used for adjusting the balance of the lever. According to the lever-based slow tensile stress corrosion experimental device of the invention, the load of the weight can be amplified by thelever structure, and therefore, additional stress on a rod can be reduced; before an experiment is performed, different loads can be loaded or the position of the weight can be moved, and therefore,a variety of creep stress stretching conditions can be provided. The device has the advantages of simplicity and accurate measurement. With the device adopted, the real-time monitoring of creep stressand displacement under a constant force can be realized.

Owner:NANJING INST OF TECH

Air entraining structure used for inner rotor cavity of compressor

InactiveCN106194828AReduce additional stressReduce temperature gradientPump componentsPumpsEngineeringLimited structures

The invention relates to an air entraining structure used for an inner rotor cavity of a compressor. Multiple air entraining grooves are formed in the rotor installation edge of the compressor. Air entraining air flow communicates with the rotor inner cavity and an outer rotor cavity through the air entraining grooves. A compressor rotor, the rotor installation edge and a next level of compressor rotor are fixedly connected through a connecting piece. According to the air entraining structure used for the inner rotor cavity of the compressor, the air entraining air flow is entrained into the inner rotor cavity for heating a post level of inner rotor cavity of the compressor, the temperature gradient of a rotor disc is reduced, and therefore rotor additional stress brought by the temperature gradient is reduced; and in a limited structural space, safe and reliable connection of the rotor is not affected, air entraining of the inner rotor cavity is achieved while no extra structural part is arranged, the rotor additional stress, caused by the temperature gradient, on the rotor disc is reduced, the structure is safe, and reliability is high.

Owner:AECC SHENYANG ENGINE RES INST

Environmental hydrophilic composite seawall

InactiveCN102286957AReduce additional stressReduce settlementDamsClimate change adaptationSea dikeEngineering

The invention discloses an environmental water-loving composite sea dike which is arranged between a fore beach and a back beach and comprises a foundation bed and a slope body ridgy on the foundation bed, wherein an upstream slope surface, a dike body and a downstream slope surface sequentially cover the outer surface of the slope body between the fore beach and the back beach; the dike body is set with an empty case structure and is made from transparent materials; the dike body is formed by sequentially connecting a circular arc shaped upstream surface, an arc-shaped dike crest and a slope downstream surface; and an arc-shaped sound deadening wave wall is arranged at the side of the dike crest, near the sea. Thus, the sea dike disclosed by the invention has good effects of damp proofing, wave prevention, erosion resistance, beach strengthening and shore protection; and the width of the dike body is smaller, the structural style is simple and stable and the foundation stress is small to ensure that the foundation settlement can be effectively decreased and the requirement on foundation bearing capacity is easily satisfied.

Owner:HOHAI UNIV

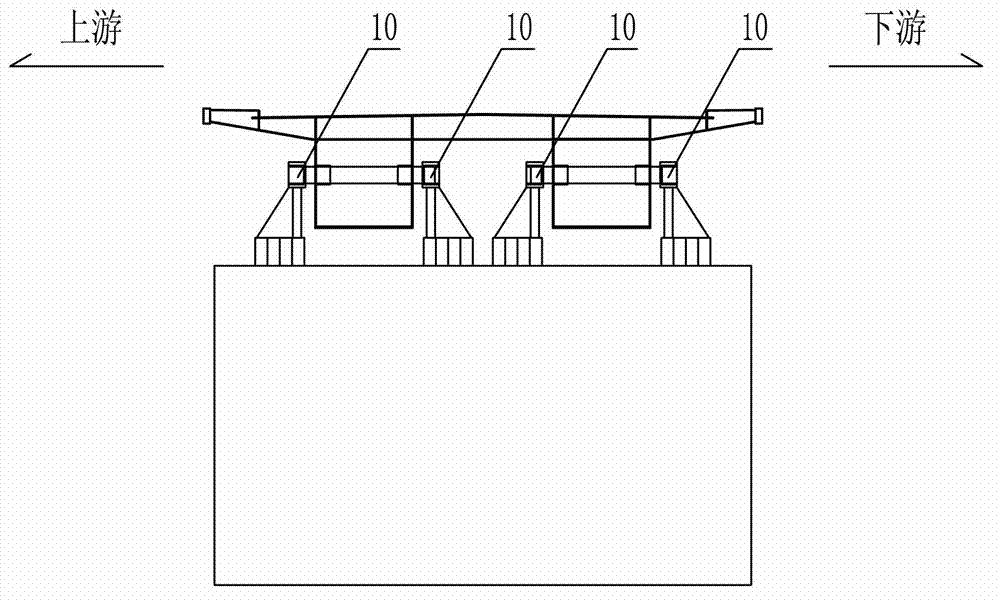

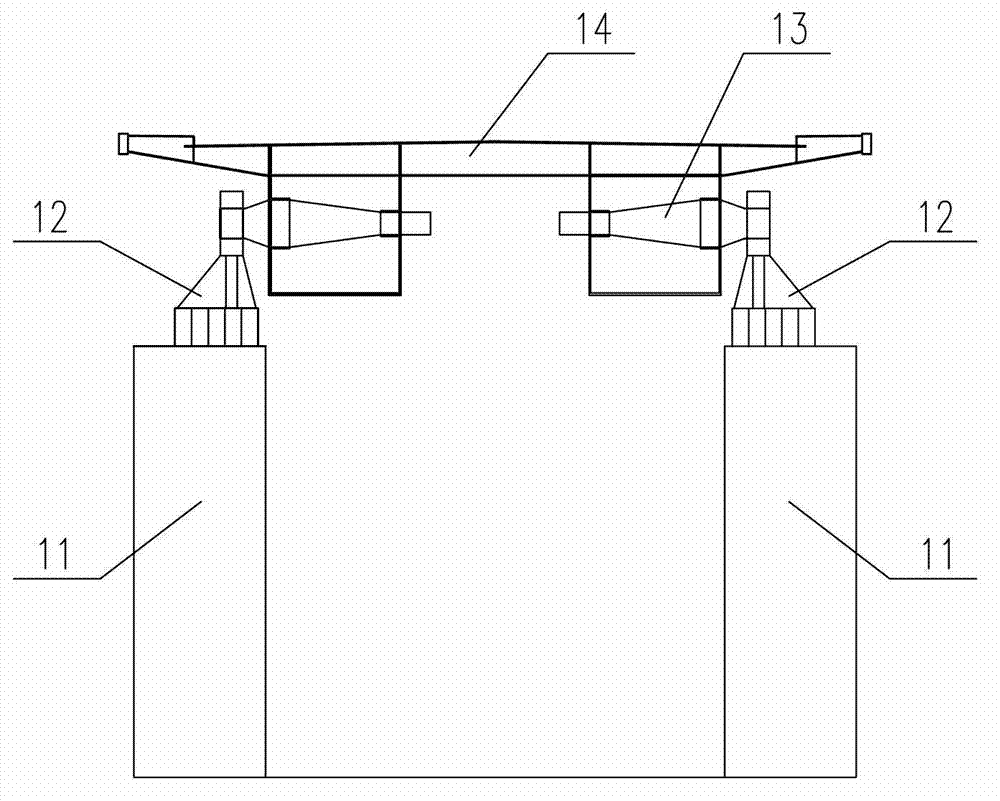

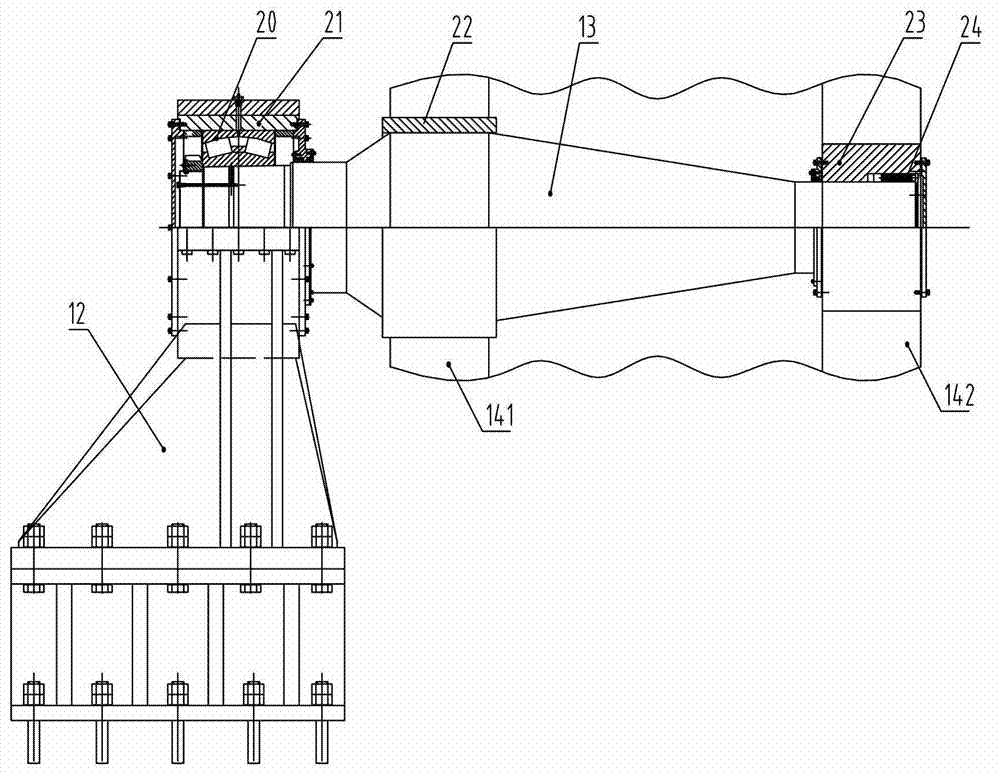

Single-cantilever supporting system for vertically-rotary movable bridge and installing method thereof

InactiveCN103031805AImprove reliabilityReduce additional stressBascule bridgesBridge erection/assemblySupporting systemStructural reliability

The invention discloses a single-cantilever supporting system for a vertically-rotary movable bridge. The single-cantilever supporting system for the vertically-rotary movable bridge comprises four sets of supporting devices which are symmetrically arranged on the two sides of a main bridge 0# node of the movable bridge, with two sets on each bank, wherein each supporting device comprises a base, a bearing pedestal, a bearing and a pivot; one end of the pivot is connected with the bearing pedestal through the bearing; the other end of the pivot is a cantilever end; a bearing sleeve C is arranged between the pivot and a web plate A of a main bridge 0# node steel box beam of the movable bridge; the cantilever end of the pivot and a web plate B of the main bridge 0# node steel box beam of the movable bridge are fixed through a bearing sleeve B and an expandable connecting sleeve; the two bearing pedestals on a same bank are symmetrically arranged along a central axis, with the positioning deviation of not more than 1-minus 1 mm; the difference between axis elevations of the two bearing pedestals on a same main pier is not more than 1 mm; and the coaxiality error of the two bearing pedestals on the same bank is not more than 0.6 mm. The single-cantilever supporting system for the vertically-rotary movable bridge can effectively reduce additional stress caused by an installing error, so that the structural reliability is further enhanced and the structure per se is more reasonable.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

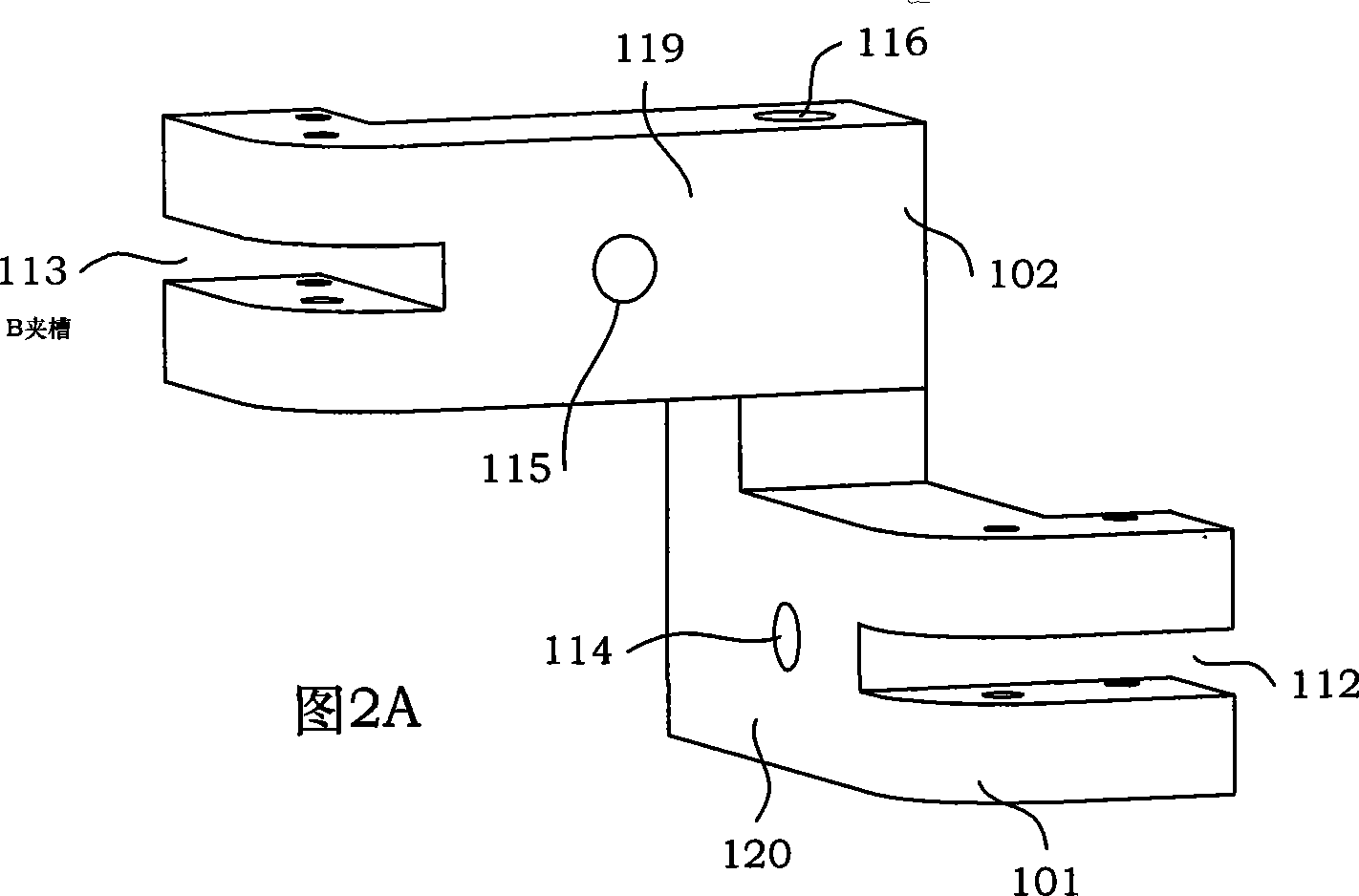

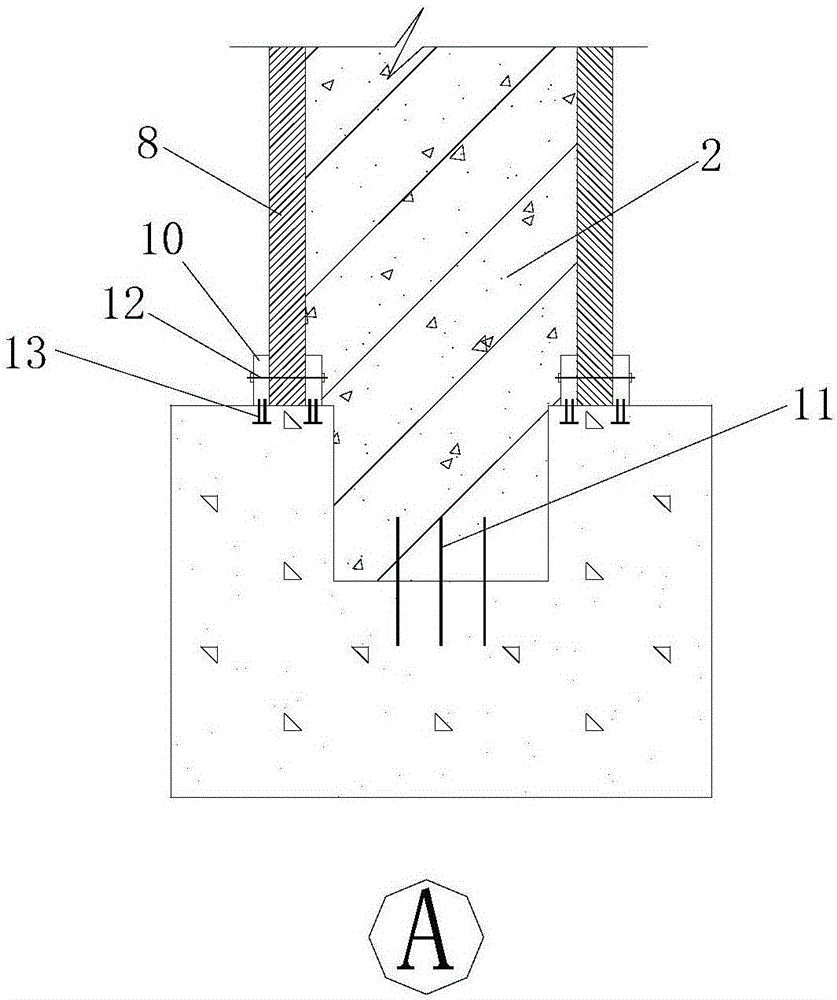

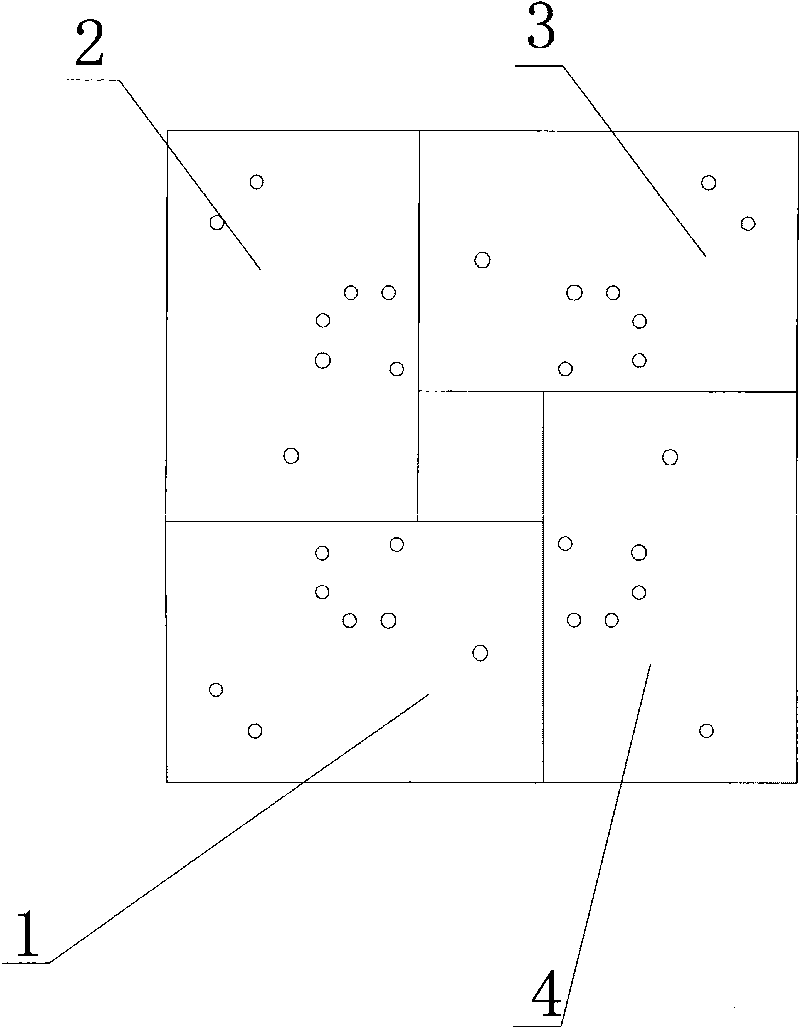

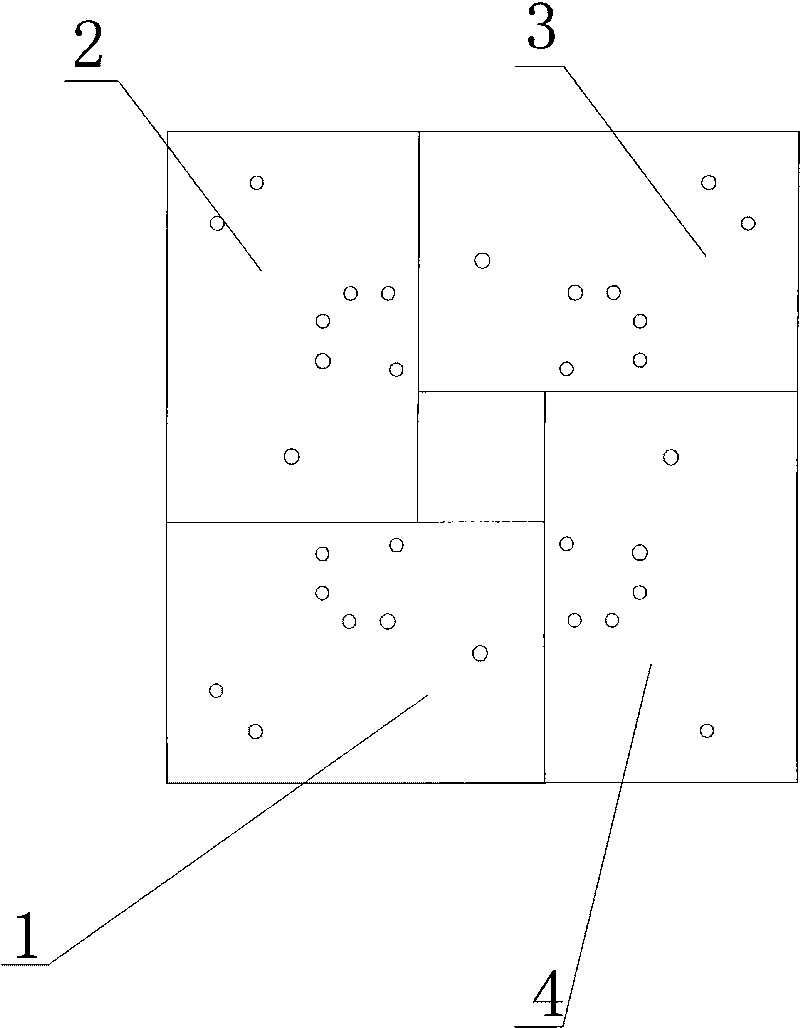

Reinforced concrete foundation for mounting assembled tower crane

ActiveCN101709584AShorten construction timeReduce use costFoundation engineeringReinforced concreteRebar

The invention relates to a reinforced concrete foundation for mounting an assembled tower crane, which is characterized by comprising eight rectangular reinforced concrete blocks of a completely identical shape and in a completely identical size, wherein every four rectangular reinforced concrete blocks are encircled into a rectangular-ambulatory-plane structure in an identical plane; the two rectangular-ambulatory-plane structures are superposed in a way that one is arranged above the other; every two adjacent rectangular reinforced concrete blocks are mutually staggered around the centre of the corresponding rectangular-ambulatory-plane structure for a phase angle of 90 degrees so that each rectangular reinforced concrete block of an upper layer presses the two rectangular reinforced concrete blocks of a lower layer; each rectangular reinforced concrete block is provided with a plurality of pre-embedded connecting holes; the rectangular reinforced concrete blocks of the upper and lower layers run through a part of the pre-embedded connecting holes through a bolt set to be connected into a whole; and the other pre-embedded connecting holes are connected with a tower body structure of a tower crane through the bolt set. The technical scheme has the characteristics of simple structure, good chemical property due to the rectangular-ambulatory-plane structures, quick and convenient mounting and disassembly and remarkable economical and social effect.

Owner:CHONGQING CONSTR ENG SECOND CONSTR CO LTD +1

Casting blank heat treatment method of stainless steel welding strip for nuclear power

The invention provides a casting blank heat treatment method of a stainless steel welding strip for nuclear power. The casting blank heat treatment method of the stainless steel welding strip for the nuclear power includes the steps: polishing the surface of a continuous casting blank prior to performing hot delivery of the continuous casting blank to a trolley type high-temperature annealing furnace; heating the continuous casting blank to an expected temperature in the high-temperature annealing furnace; holding the continuous casting blank at the expected temperature; cooling the continuous casting blank in air after completion of temperature holding; and conveying the air-cooled continuous casting blank to a walking-beam heating furnace and performing hot-rolling forming after soaking. The continuous casting blank subjected to heat treatment is good in high-temperature thermoplasticity at a hot rolling stage, and hot-rolling edge crack of the casting blank of the stainless steel welding strip for the nuclear power can be eliminated, so that the casting blank can go through hot-rolling forming smoothly, and domestication of stainless steel welding strips for the nuclear power is achieved.

Owner:TAIYUAN IRON & STEEL GROUP

High-speed-railway karst roadbed structure with pre-warning function and repairing method thereof

PendingCN107964843AHigh strengthReduce deformation effectsRoadwaysRailway tracksInsulation layerKarst

The invention provides a high-speed-railway karst roadbed structure with a pre-warning function and a repairing method thereof so as to effectively solve the technical difficult problems that as for atraditional high-speed-railway single karst roadbed, the collapse risk is high, the reinforcing effect is poor, karst caves cannot be accurately positioned, the engineering cost is high, and secondary repairing is difficult. The roadbed structure comprises a high-strength geotextile insulation layer, a light concrete filled-up body and a foundation bed, the first high-strength geotextile insulation layer is laid on a foundation, and the light concrete filled-up body is arranged on the first high-strength geotextile insulation layer in a filled-up mode. The foundation bed is arranged on the light concrete filled-up body in a filled-up mode, a first multi-point settlement observation system and a second multi-point settlement observation system are arranged on the bottom face and the top face of the light concrete filled-up body correspondingly, and a roadbed collapse pre-warning system is arranged nearby a roadbed basal slope and used for collecting and processing roadbed settlement data observed by the first multi-point settlement observation system and the second multi-point settlement observation system and conducting automatic pre-warning when deformation of a roadbed tends toexceed the limit. A reserved post grouting repairing system is arranged in the light concrete filled-up body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

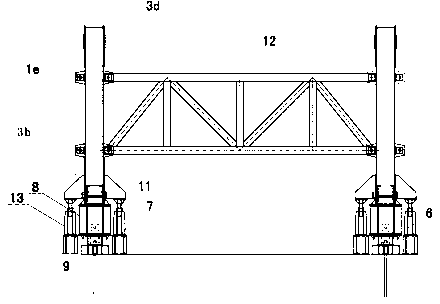

Cantilever hanging bracket and using method thereof

The invention relates to a cantilever hanging bracket and a using method thereof. The cantilever hanging bracket comprises a main truss, a traveling mechanism and an anchoring device. The main truss comprises two diamond-shaped truss bodies arranged symmetrically in a horizontal mode. Each diamond-shaped truss body comprises an upper chord, a lower chord, a front chord and a rear chord, wherein the front end of the upper chord and the upper end of the front chord are connected through a front pitch point, the rear end of the upper chord and the upper end of the rear chord are connected through an upper pitch point, the lower end of the rear chord and the rear end of the lower chord are connected through a rear pitch point, the front end of the lower chord and the lower end of the front chord are connected through a lower pitch point, and a column is connected between the upper pitch point and the lower pitch point. A rear horizontal truss sheet is connected between the columns of the two diamond-shaped truss bodies, a front upper cross beam is connected between the front pitch points of the two diamond-shaped truss bodies, the upper chords incline towards the front lower direction, and inclined angles of the upper chords are 15-25 degrees. The cantilever hanging bracket and the using method of the cantilever hanging bracket can achieve generality of a hanging basket main truss and the cantilever hanging bracket, and the cantilever hanging bracket is low in gravity center, good in stability and reasonable in stress.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

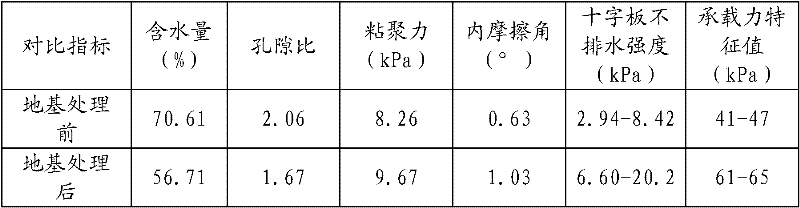

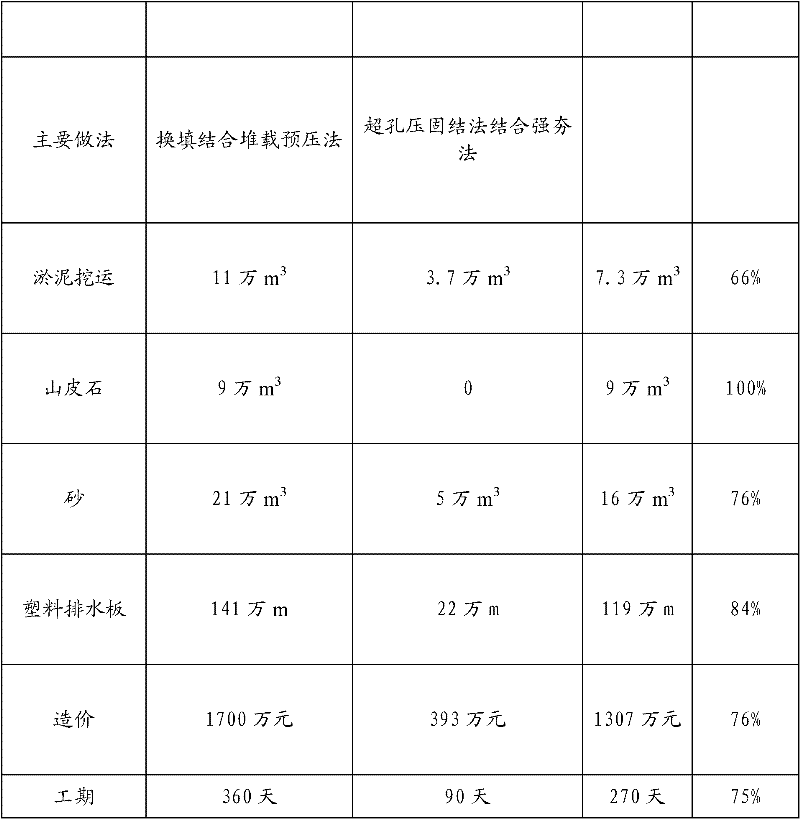

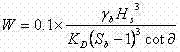

A rapid drainage consolidation treatment method for soft soil foundation

InactiveCN102296591AReduce differential settlementImprove bearing capacitySoil preservationMedicineCushion

The invention discloses a rapid drainage and consolidation treatment method for soft soil foundations, which comprises the following steps: (1) digging the silt to 2-3m below the delivery elevation, and backfilling the first layer of sand to 0.8-3m below the delivery elevation while digging 1.2m, insert the plastic drainage board to a depth of 8m below the handover elevation, cover the second sand cushion to 0.5-1.5m above the handover elevation, set up a drainage system to pump water continuously; (2) start the first dynamic load after 12-18 days after the backfill is in place , the energy is 500-650 kJ, and the depth of the ramming pit does not exceed 1.5m; (3) The second dynamic load after 5-8 days, the energy is 700-900 kJ, and the depth of the ramming pit does not exceed 1.5m, (4) 5-8 Start the third dynamic load after 5-8 days, the energy is 1100-1500 kJ, and the depth of the ramming pit does not exceed 1.5m; m; (6) After 5-8 days, excavate excess filler, perform 600 kilojoule full-field dynamic load once, and level and hand over the work twice. The invention can reduce the cost by 75%, and shorten the construction period from more than 360 days to about 90 days.

Owner:厦门地山建设发展有限公司

Pipe laying method for subsidence area of coal mine

Disclosed is a pipe laying method for a subsidence area of a coal mine. A high-density polyethylene pipe, which is good in flexibility, penetrates the coal mine subsidence area and is disposed in a cover plate pipe ditch, a pipe ditch top plate is 0.5m away from the ground, and the pipe ditch width is about 1m wider than the outer diameter of the pipe. The pipe is laid in the pipe ditch in a curved S shape, two sides of the pipe are filled with cushioning materials such as yellow sand and saw powder, and rubber supports which are about 20cm are arranged for every 30m to 50m at the bottom of the pipe. According to the method, the pipe can resist effects of large deformation of the ground surface such as mining area uneven settlement and buckling deformation, the normal operation of the pipe during the ground surface subsidence can be guaranteed, damage to the pipe due to additional internal force caused by ground surface settlement can be effectively prevented, relocation land resources are greatly saved, the structure is simple, implementation is convenient, investment is small, the effect is good, and wide practicality is provided.

Owner:CHINA UNIV OF MINING & TECH

Novel breakwater and design method thereof

InactiveCN102191759BReduce climbingReduce the amount of overshootBreakwatersQuaysEngineeringLow altitude

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com