Reaction kettle bottom agitation system

A reaction kettle and bottom stirring technology, applied in the field of homogenization, shearing and emulsification, can solve the problems of increased weight, processing cost, and excessively long stirring shaft, and achieve the effect of shortened length, stable operation and efficient shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

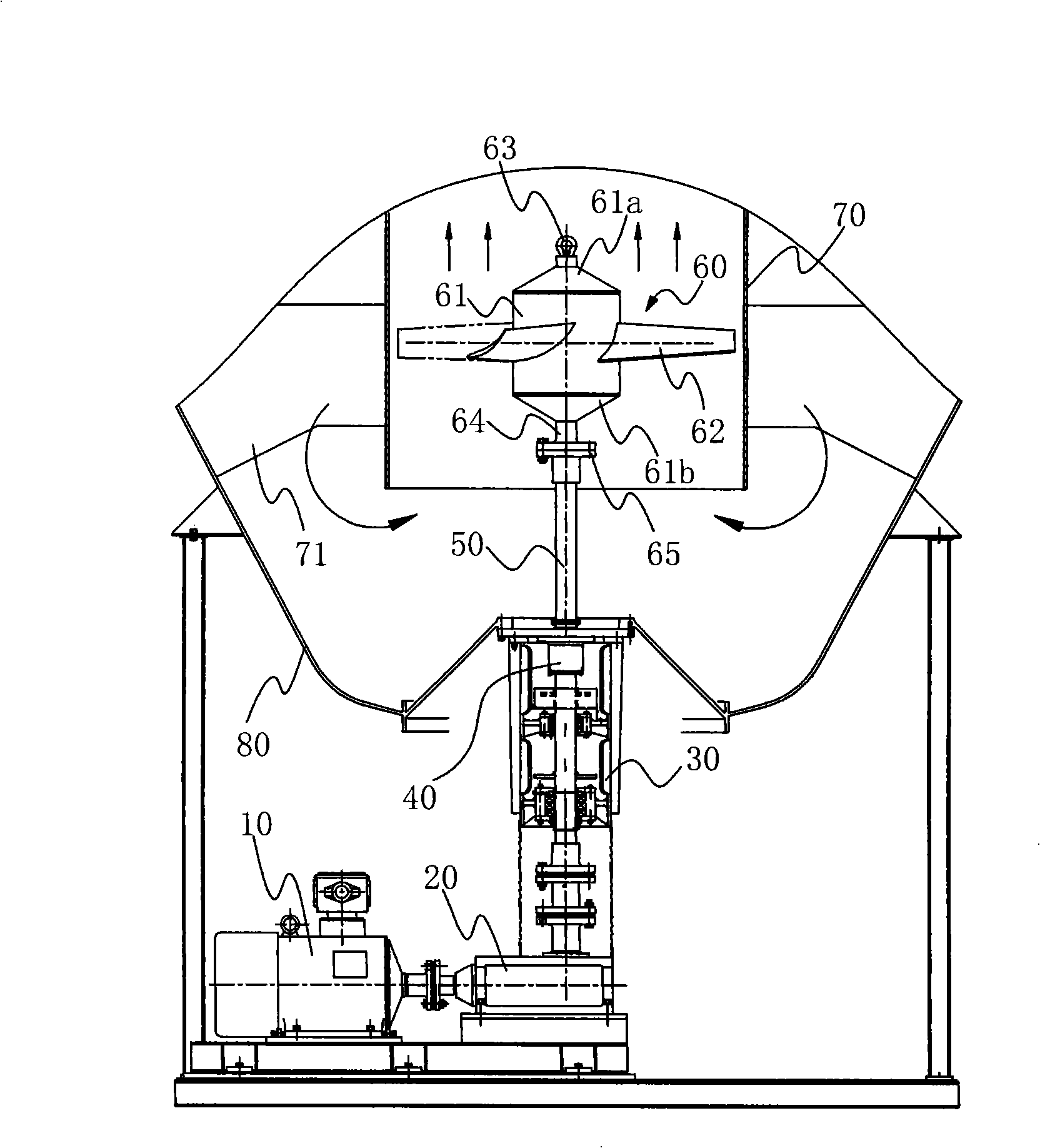

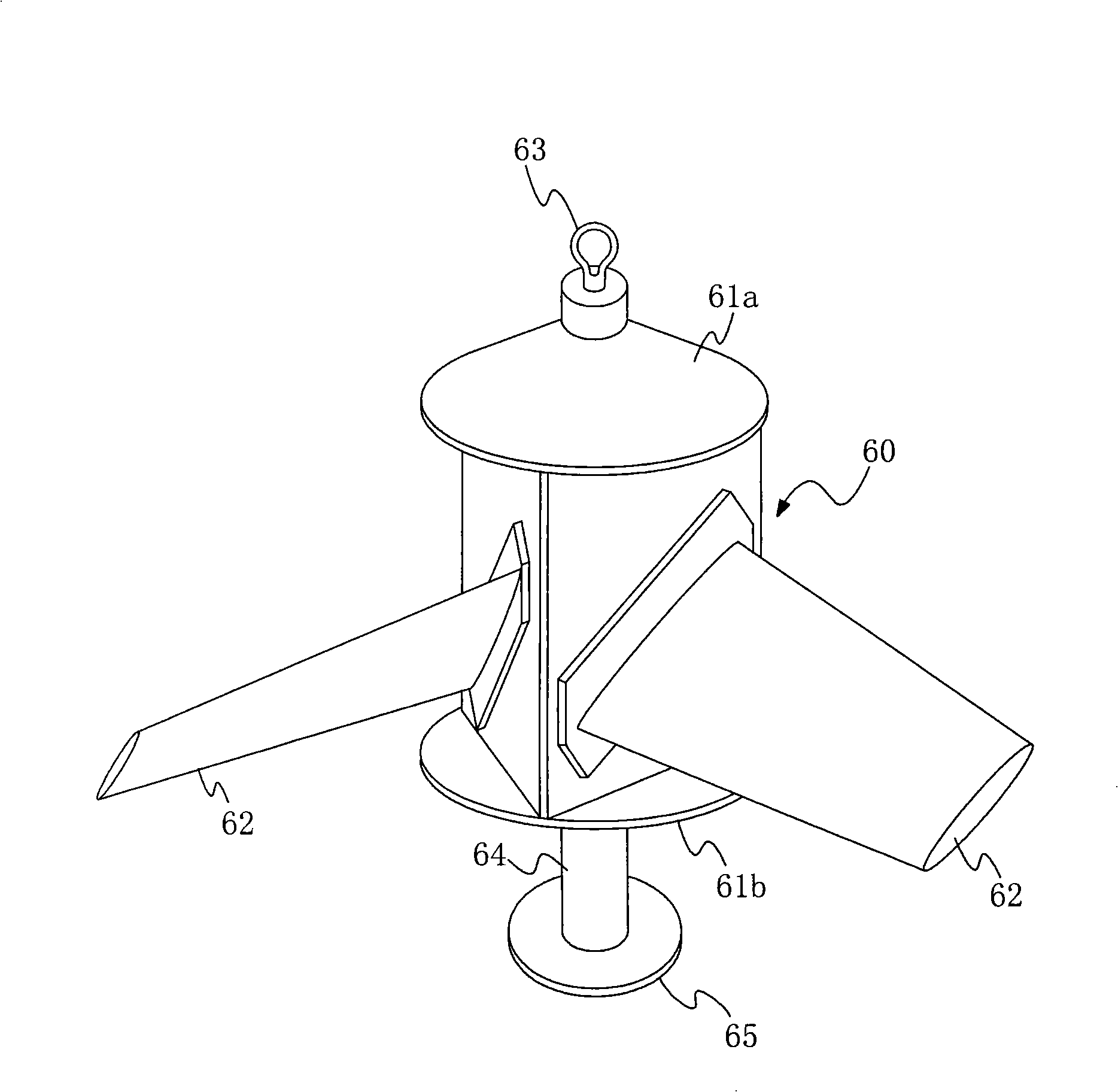

[0008] see figure 1 , the stirring system at the bottom of the reaction kettle includes that the interior of the reaction kettle 80 is equipped with a shroud 70, the upper and lower ends of the shroud 70 are open, the stirring device 60 is located in the shroud 70, and the lower part of the stirring device 60 has a transmission device 30 fixed on it. At the bottom of the reaction kettle 80, a cartridge type combined mechanical seal 40 is arranged between the transmission device 30 and the bottom of the reaction kettle 80, the transmission device 30 is connected with the power output shaft of the reducer 20, and the reducer 20 The power input shaft is connected with the motor 10 .

[0009] The invention is suitable for the axial-flow wing-type blade type and the assembled combined mechanical seal bottom stirring device of various reactors, and is used for the reactor stirring system with the bottom stirring structure. The cartridge combined mechanical seal 40 is installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com