Jacking device for deviation rectification of steel pylon in mining area of coal mine

A technology for transmission towers and jacking devices, applied in construction, infrastructure engineering and other directions, can solve the problems of large amount of tools and tools, complex on-site layout, high workload and labor intensity of workers, etc. The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

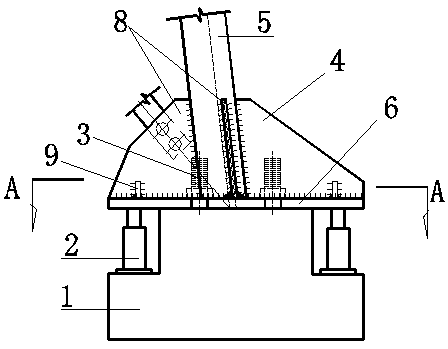

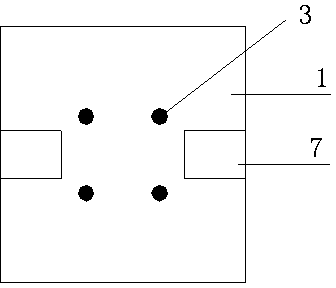

[0016] Such as Figure 1 to Figure 4 Shown: the present invention includes concrete long column independent foundation 1, anchor bolt 3 and jacking tower foot board 4; The material connecting plate 8 is welded with the main material 5 of the iron tower along the edge, and the bottom plate 6 of the tower foot plate 4 is connected to the independent foundation 1 of the long concrete column through the anchor bolt 3; the independent foundation 1 of the long concrete column is provided with a jack 2 The loading hole 7 is reserved; the length of the exposed thread of the anchor bolt 3 is not less than 150mm.

[0017] A stiffening plate 9 is welded on the bottom plate 6, and the stiffening plate 9 is vertically welded to the connecting plate 8 of the main material of the iron tower. Due to the setting of the stiffening plate 9, the bearing capacity of the device can be effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com