Light filled structure and its construction process

A technology of light-weight soil filling and construction method, applied in the direction of filling and other directions, can solve the problems such as the inability to fundamentally eliminate post-construction settlement, the large volume of fly ash soil, and the increase of construction costs, so as to improve stability and buoyancy resistance. , Good buoyancy resistance, saving expensive land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

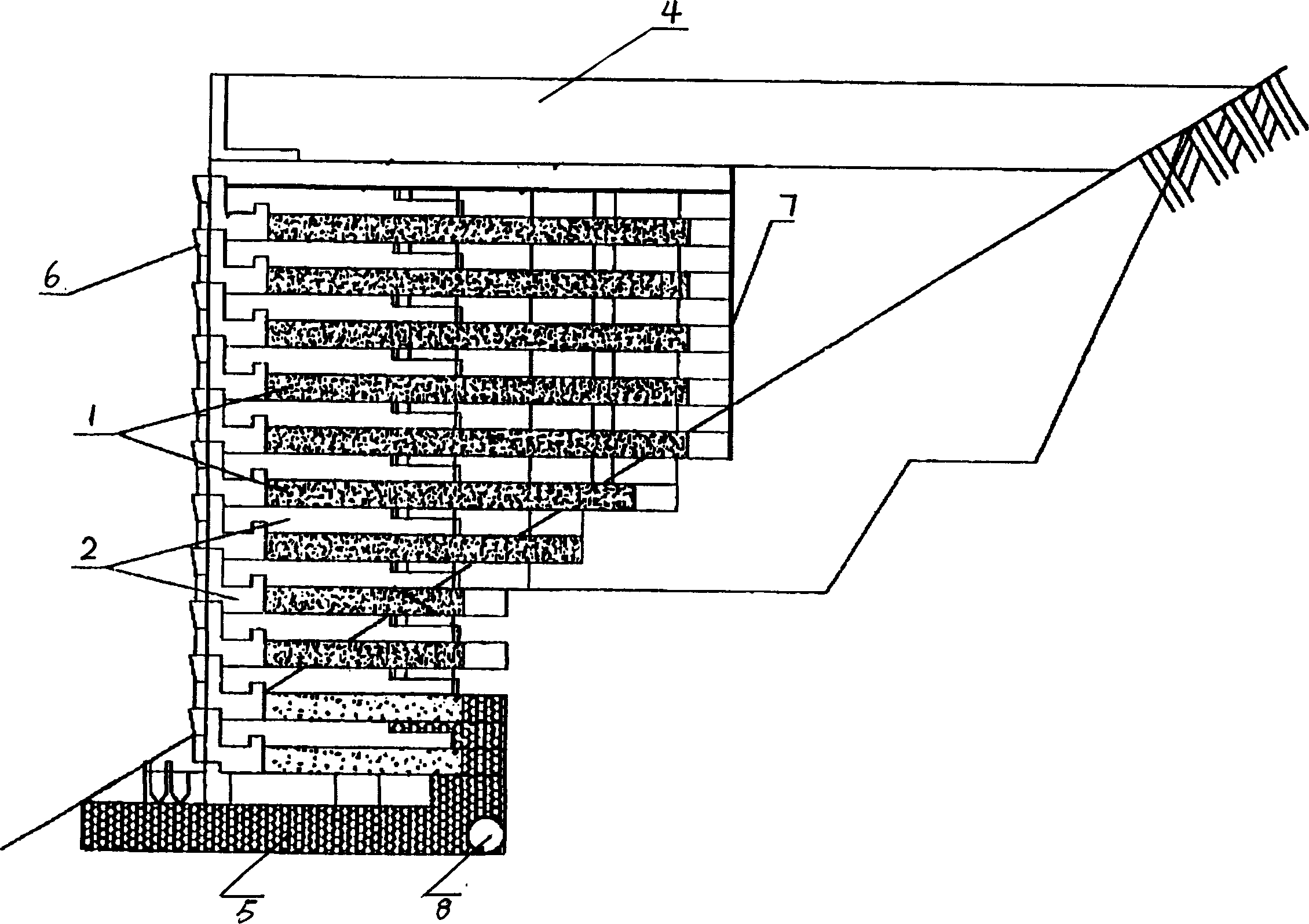

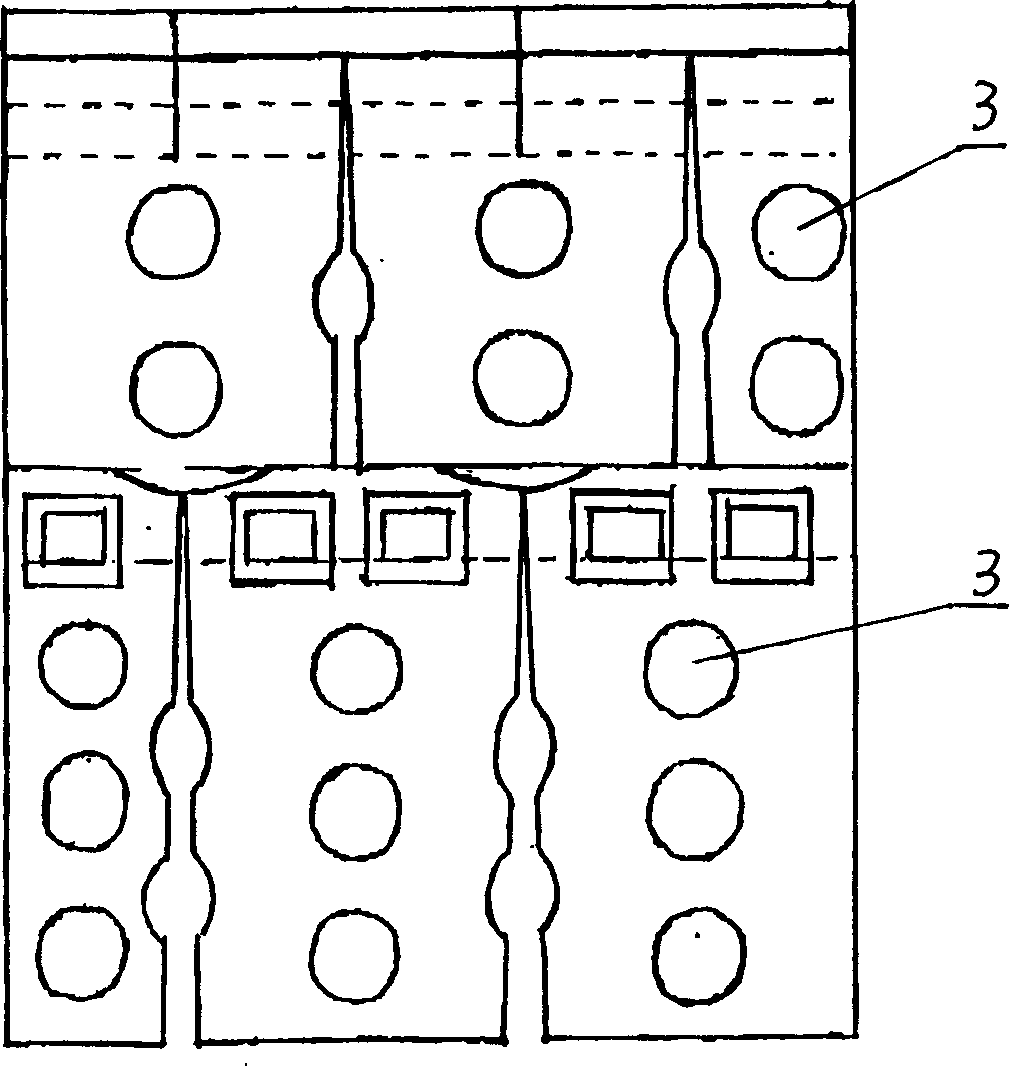

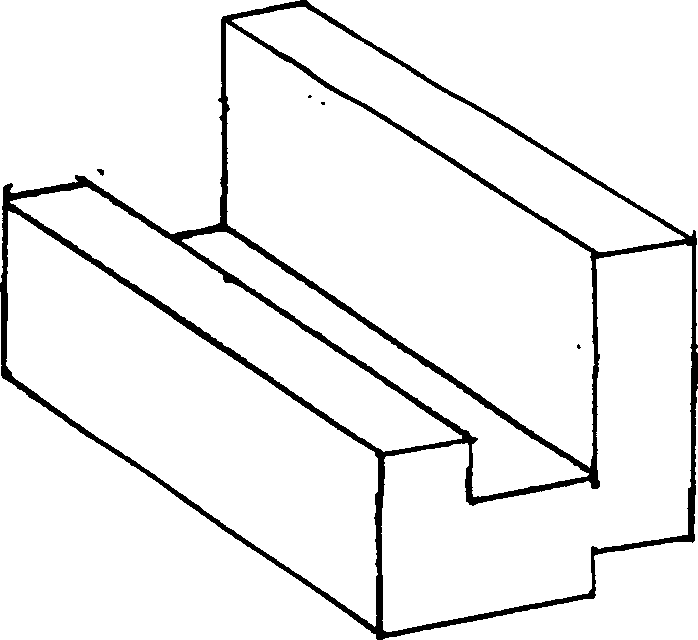

[0017] Such as figure 1 As shown, the present embodiment includes a soil layer 1 and a polystyrene foam block layer 2, and the soil layer and the polystyrene foam block layer are stacked at intervals to form a filling body, and the thickness of the polystyrene foam block layer is 10 to 80 cm, and the thickness of the soil layer is 20-100 cm. A plurality of soil column holes 3 are arranged on each layer of polystyrene foam plastic blocks, and the top and bottom layers of the filling body are all polystyrene foam block layers 2, and the top layer of the filling soil body is laid with a concrete sealing layer 4, and the filling soil body A gravel cushion 5 is laid on the bottom of the ground; a permeable hose 8 is laid on the gravel cushion, a retaining wall 6 is provided on one side of the filling body, and a geotextile 7 is wrapped on the other side. Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the foamed plastic block layer in this embodiment is formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com