A kind of preparation method of early-strength polycarboxylate water reducer

A polycarboxylic acid and early-strength technology, which is applied in the field of preparation of early-strength polycarboxylate water-reducing agents, can solve the problems of high equipment requirements, complicated processes, unfavorable environmental protection, etc., and achieves simple preparation process and wide dosage range. , the effect of small loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

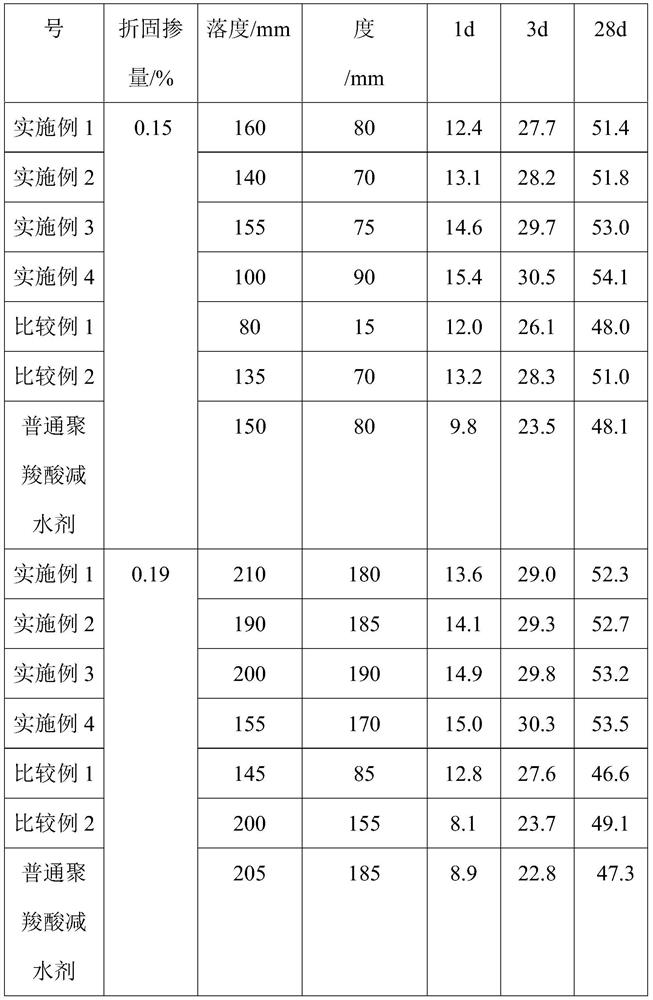

Examples

Embodiment 1

[0037] A preparation method of early-strength polycarboxylate water reducer, comprising the following steps:

[0038] (1) Put 260g of HPEG-2400, 100g of HPEG-3000 and 200g of deionized water into a four-necked flask, stir evenly, heat up to 30°C, add 1g of potassium persulfate and 1.98g of tert-butyl hydroperoxide;

[0039] (2) Stir 0.475g L-ascorbic acid, 0.0912g ferrous sulfate, 0.7g mercaptopropionic acid, 0.66g dodecyl mercaptan, 38g acrylic acid, 20g fumaric acid alcohol amine ester and 250g deionized water to form Mix the solution, and add the mixed solution dropwise to step (1), control the rate of addition, and drop it within 3h;

[0040] (3) After the dropwise addition, continue to heat-preserve and stir the reaction at 30° C. for 2 h, and add 184 g of water to obtain an early-strength polycarboxylate superplasticizer with 40% solid content.

[0041] The preparation method of the alcohol amine fumarate is: mix fumaric acid, monoethanolamine, diethanol monoisopropanol...

Embodiment 2

[0043] A preparation method of early-strength polycarboxylate water reducer, comprising the following steps:

[0044] (1) Put 250g of HPEG-2400, 110g of HPEG-5000 and 200g of deionized water into a four-necked flask, stir evenly, heat up to 30°C, add 1.4g of ammonium persulfate and 2.76g of hydrogen peroxide;

[0045] (2) Stir 0.74g sodium thiosulfate, 0.142g ferrous sulfate, 1.0g mercaptopropionic acid, 0.95g mercaptoacetic acid, 30g acrylic acid, 28g alcohol amine fumarate and 250g deionized water to form a mixed solution , and drop the mixed solution into step (1), control the rate of addition, and drop it within 3h;

[0046] (3) After the dropwise addition, continue to heat-preserve and stir the reaction at 30° C. for 2 hours, and then add 187.5 g of water to obtain an early-strength polycarboxylate superplasticizer with 40% solid content.

[0047] The preparation method of the alcohol amine fumarate is: mix fumaric acid, monoethanolamine, diethanol monoisopropanolamine a...

Embodiment 3

[0049] A preparation method of early-strength polycarboxylate water reducer, comprising the following steps:

[0050] (1) Put 360g of HPEG-3000 and 200g of deionized water into a four-necked flask, stir evenly, heat up to 30°C, add 1.75g of ammonium persulfate and 3.45g of tert-butyl hydroperoxide;

[0051](2) Stir 0.38g L-ascorbic acid, 0.1g sodium hypophosphite, 1.4g thioglycolic acid, 1.33g dodecyl mercaptan, 35g acrylic acid, 35g fumaric acid alcohol amine ester and 250g deionized water, and prepare into a mixed solution, and drop the mixed solution into step (1), control the rate of addition, and drop it within 3h;

[0052] (3) After the dropwise addition, continue to insulate and stir the reaction at 30° C. for 2 h, then add 207.5 g of water to obtain a 40% solid early-strength polycarboxylate water reducer.

[0053] The preparation method of the alcohol amine fumarate is: mix fumaric acid, monoethanolamine, diethanol monoisopropanolamine according to the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com