Tire tread pattern structure of all-terrain vehicle pneumatic tire

A pneumatic tire and tread pattern technology, which is applied to tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problem of light control response of the front wheel, difficulty in tire assembly, and inability of pattern blocks to be fast and effective Cut into problems such as sandy ground to achieve the effect of improving handling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

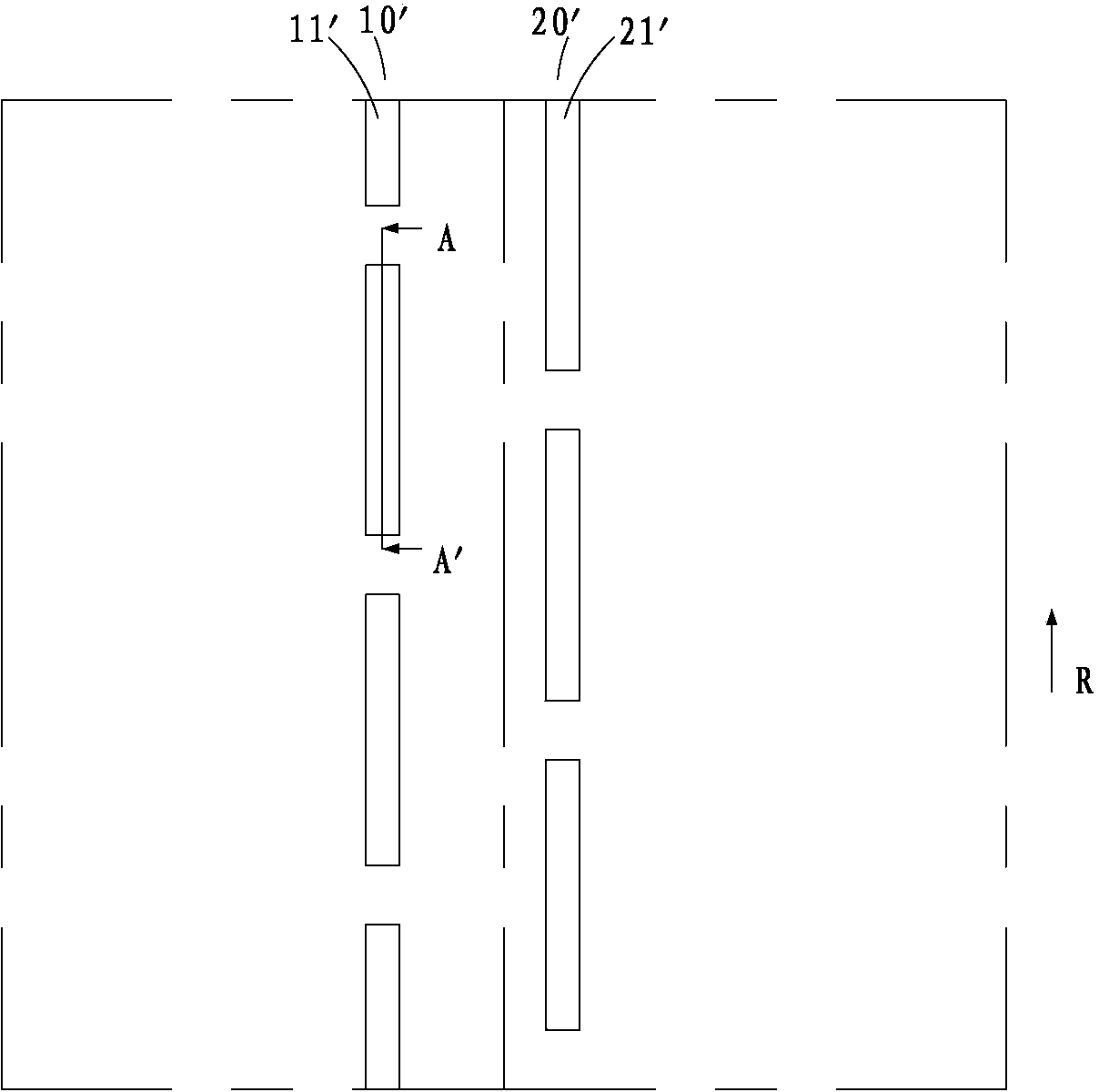

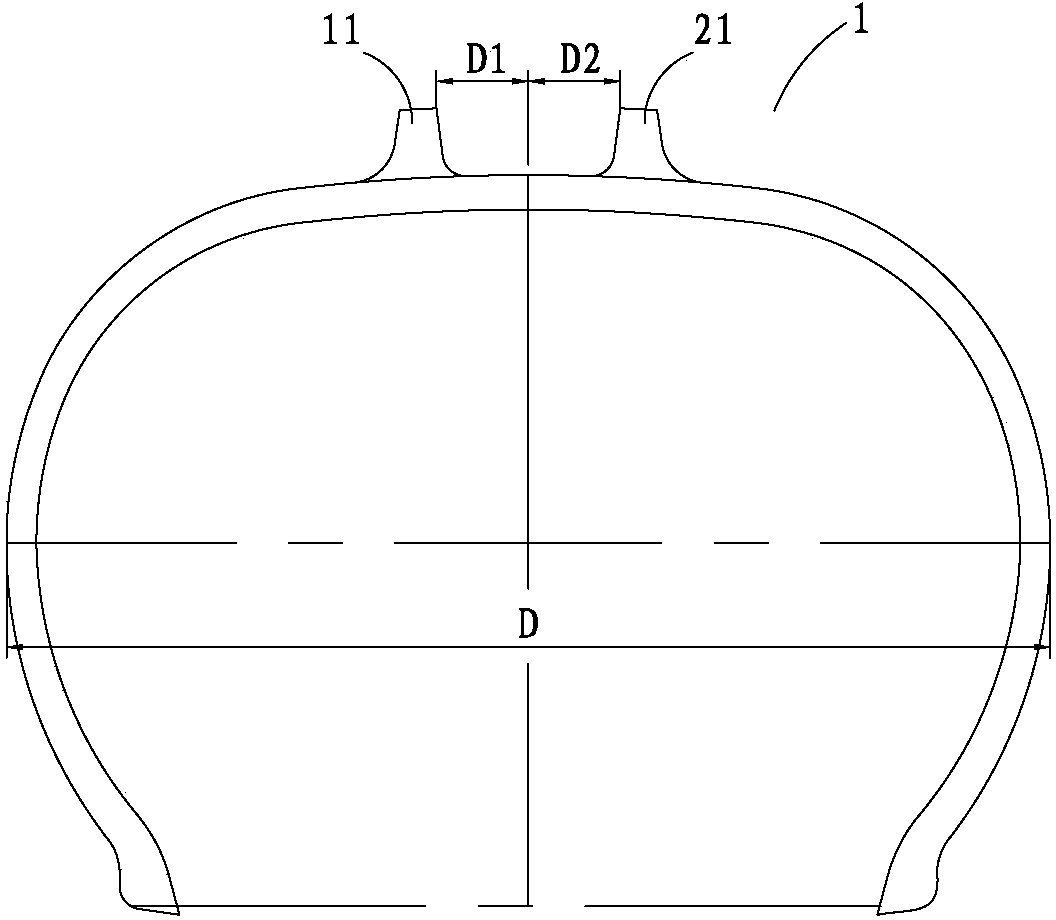

[0019] Such as Figure 3 to Figure 6 As shown, the present invention discloses a tread pattern structure of an all-terrain vehicle pneumatic tire. The tire tread 1 includes a left rib row 10 along the tire circumferential direction and a right rib row 20 along the tire circumferential direction. The circumferential striped left pattern row 10 and the circumferential striped right pattern row 20 are designed symmetrically along the center plane of the tire, and the circumferential striped left pattern row 10 is formed by circumferentially arranging discontinuous left pattern blocks 11, and the circumferential direction The striped right pattern row 20 is formed by discontinuous right pattern blocks 21 circumferentially arranged, and the left pattern blocks 11 and the right pattern blocks 21 are arranged alternately;

[0020] Such as image 3 As shown, the distance D1 between the left pattern block 11 and the center plane of the tire is 7% to 15% of the tire section width D, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com