Method for preparing anti-freeze type high-performance polycarboxylate water reducer by utilizing amino resin waste liquid

A technology of amino resin and water reducer, which is applied in the field of preparing polycarboxylate water reducer, which can solve the problems of high alkali content, waste of resources, poor environmental protection, etc., to increase the internal liquid phase, accelerate hydration, and improve compactness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

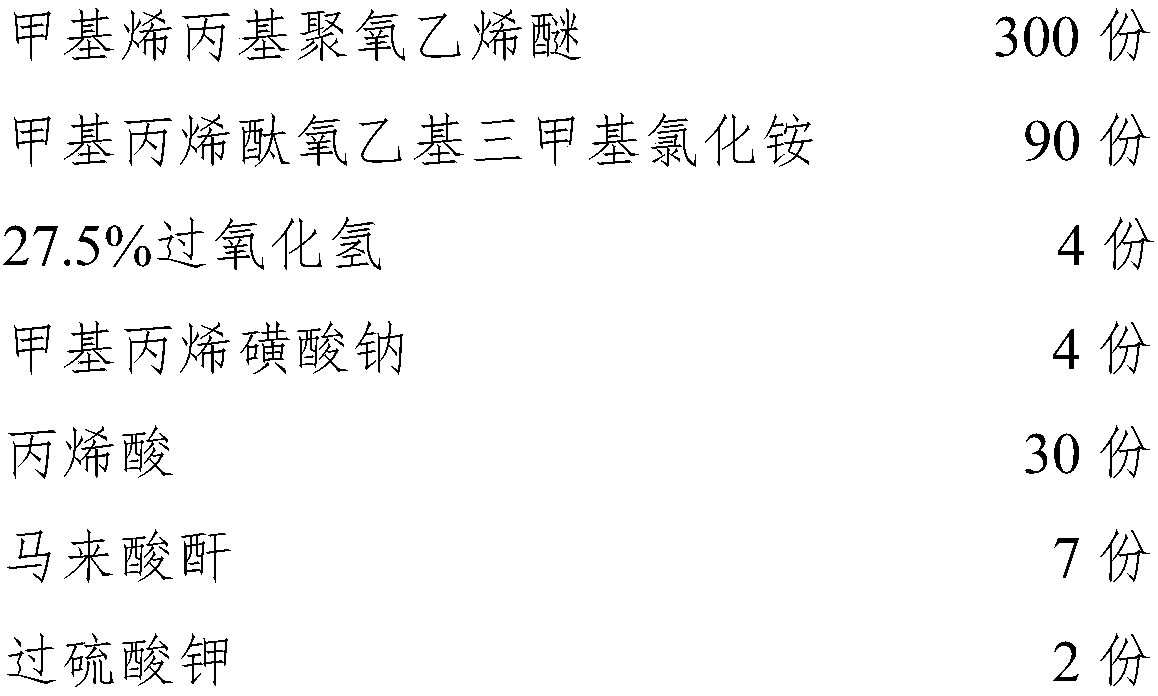

Embodiment 1

[0024] Utilize amino resin waste liquid to prepare the method for antifreeze type high-performance polycarboxylate water reducer, the steps are as follows:

[0025] a. Put methallyl polyoxyethylene ether, methacryloyloxyethyltrimethylammonium chloride, maleic anhydride, 27.5% hydrogen peroxide and appropriate amount of deionized water into the reaction kettle as base material, Stir until completely dissolved, and adjust the temperature to 50°C;

[0026] b. Mix acrylic acid, sodium methacryl sulfonate and deionized water to prepare solution A for use, mix potassium persulfate and deionized water to prepare solution B for use, and drop the primer at the same time after dissolving in step a Add solution A and solution B, solution A is added dropwise after 2 hours, solution B is added dropwise after 2.5 hours, after solution B is added dropwise, continue to stir and react for 50 minutes;

[0027] c. Adjust the pH value of the above mixed solution to 6 with a reagent, and continue...

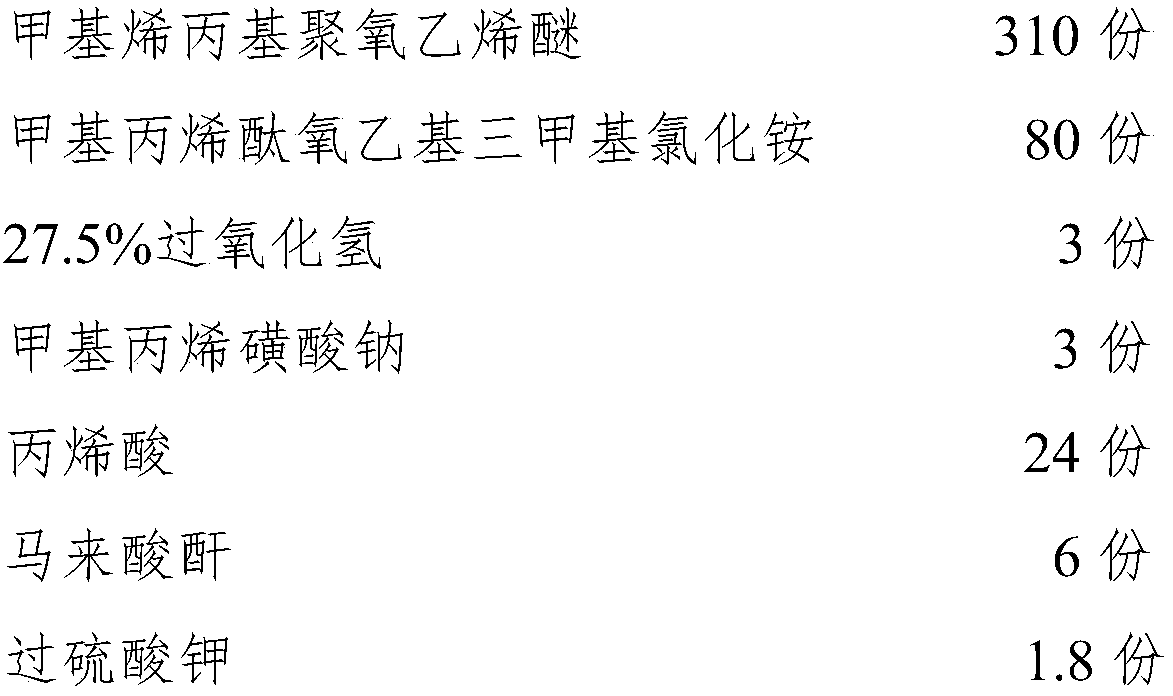

Embodiment 2

[0032] Utilize amino resin waste liquid to prepare the method for antifreeze type high-performance polycarboxylate water reducer, the steps are as follows:

[0033] a. Put methallyl polyoxyethylene ether, methacryloyloxyethyltrimethylammonium chloride, maleic anhydride, 27.5% hydrogen peroxide and appropriate amount of deionized water into the reaction kettle as base material, Stir until completely dissolved, and adjust the temperature to 50°C;

[0034] b. Mix acrylic acid, sodium methacryl sulfonate and deionized water to prepare solution A for use, mix potassium persulfate and deionized water to prepare solution B for use, and drop the primer at the same time after dissolving in step a Add solution A and solution B, solution A is added dropwise after 2 hours, solution B is added dropwise after 2.5 hours, after solution B is added dropwise, continue to stir and react for 50 minutes;

[0035] c. Adjust the pH value of the above mixed solution to 6.5 with a reagent, and contin...

Embodiment 3

[0040] a. Put methallyl polyoxyethylene ether, methacryloyloxyethyltrimethylammonium chloride, maleic anhydride, 27.5% hydrogen peroxide and appropriate amount of deionized water into the reaction kettle as base material, Stir until completely dissolved, and adjust the temperature to 50°C;

[0041] b. Mix acrylic acid, sodium methacryl sulfonate and deionized water to prepare solution A for use, mix potassium persulfate and deionized water to prepare solution B for use, and drop the primer at the same time after dissolving in step a Add solution A and solution B, solution A is added dropwise after 2 hours, solution B is added dropwise after 2.5 hours, after solution B is added dropwise, continue to stir and react for 50 minutes;

[0042] c. Adjust the pH value of the above mixed solution to 7 with a reagent, and continue to stir for 30 minutes to obtain a polycarboxylate superplasticizer;

[0043] d. Take the polycarboxylate superplasticizer and amino resin waste liquid in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com