Embedded device for electrochemically detecting or repairing reinforcing bars in concrete

A kind of concrete and electrochemical technology, applied in the direction of material electrochemical variables, etc., can solve the problems of promoting external corrosive medium erosion, unfavorable structural stress, difficult to control construction quality, etc., to save later inspection costs, simple and fast operation process, rich Effect of Electrochemical Parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

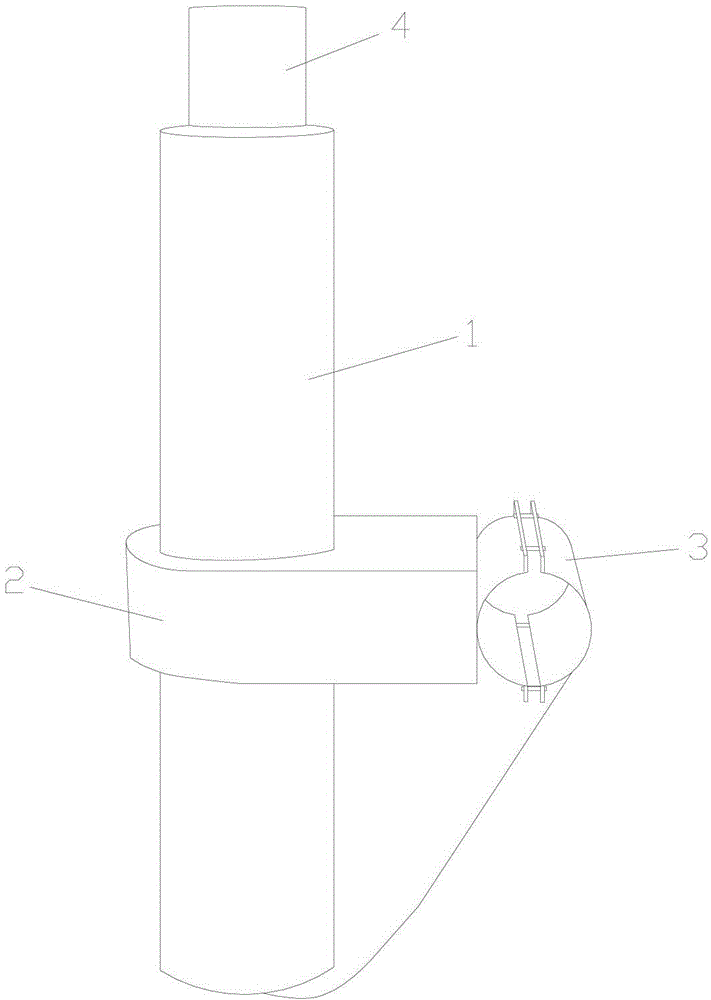

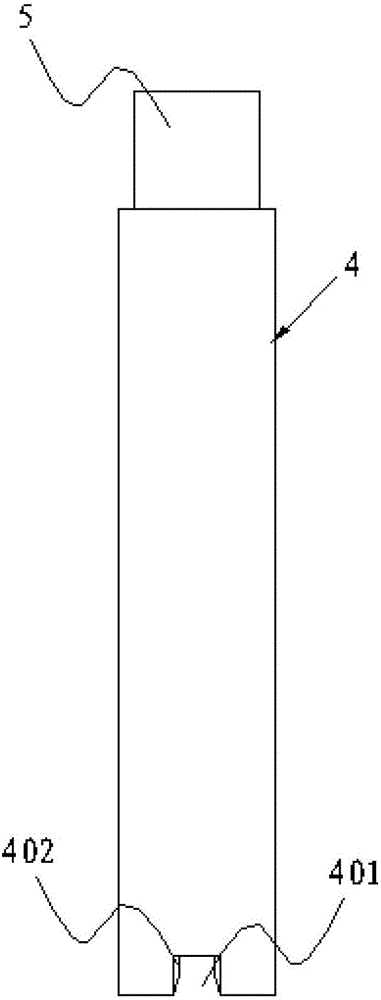

[0033] Such asfigure 1 As shown, the pre-embedded device for electrochemical detection or repair of steel bars in concrete in this embodiment includes a joint 1, a locator 2, a fixture 3 and a conductive rod 4. The shape of the joint 1 is a straight rod, and its outer wall is fixedly connected to the locator 2. , the locator 2 is used to fix the joint 1, and one end of the locator 2 is connected with the clamp 3; one end of the joint 1 is electrically connected to the conductive rod 4.

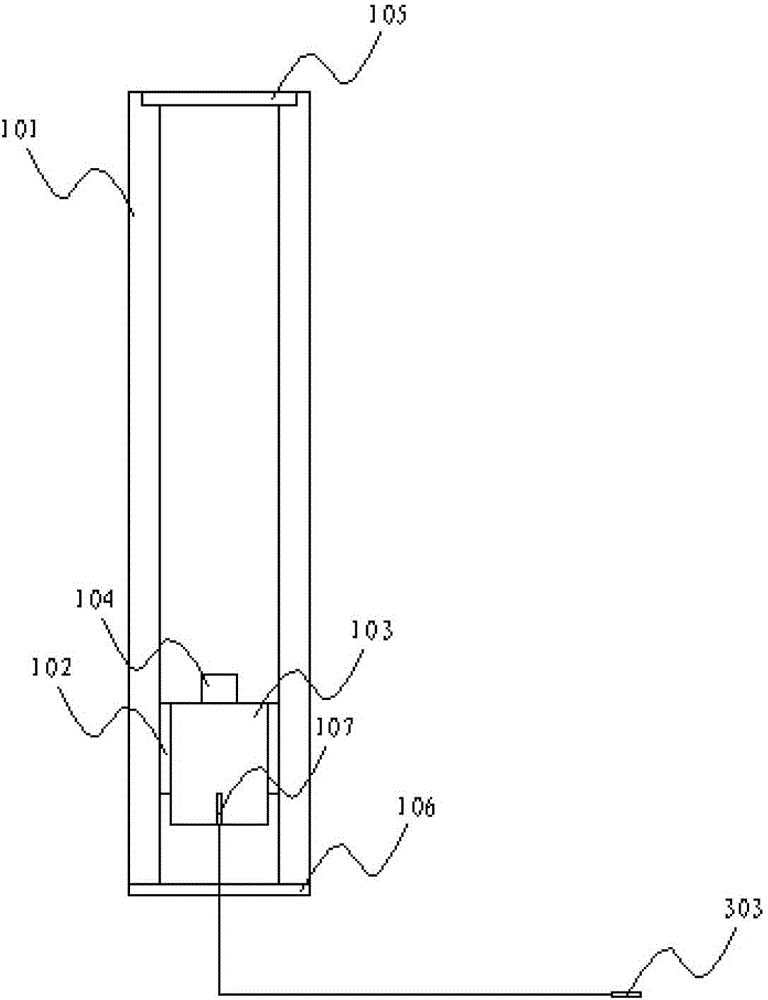

[0034] Such as figure 2 As shown, the joint 1 includes an outer sleeve 101, an insulating cushion layer 102, a conductive block 103, a conductive head 104, a first sealing cover 105 and a second sealing cover 106, wherein the outer sleeve 101 is in the shape of a middle tube, and its outer wall is processed There are rib-shaped lines; the insulating pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com