Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Good consistency of precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

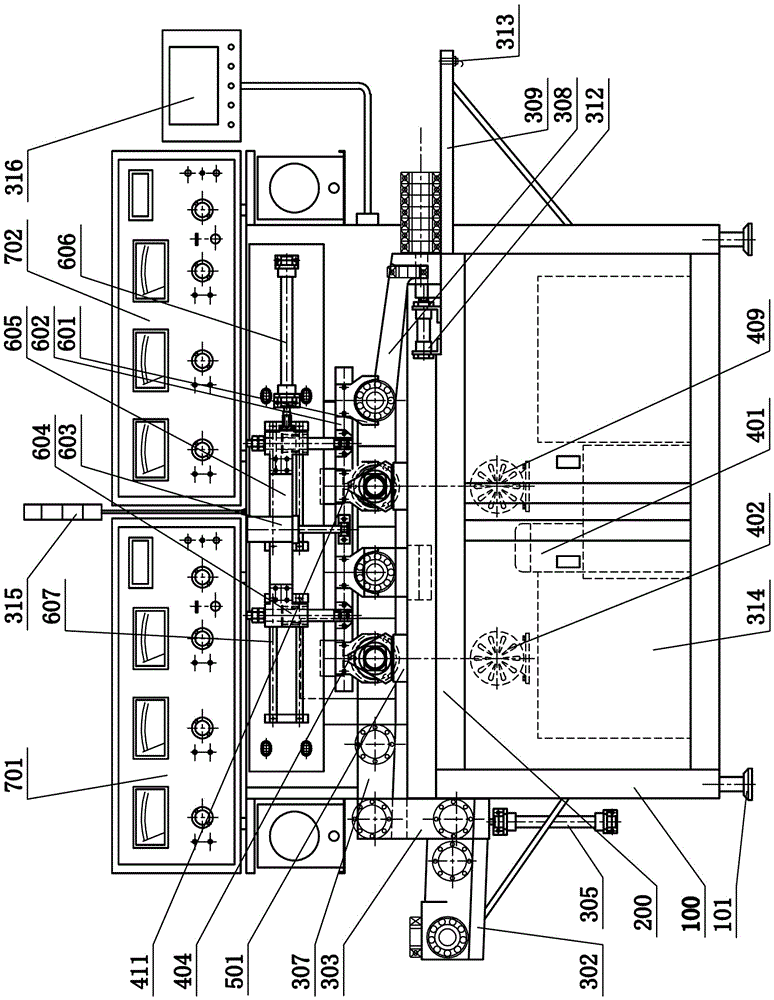

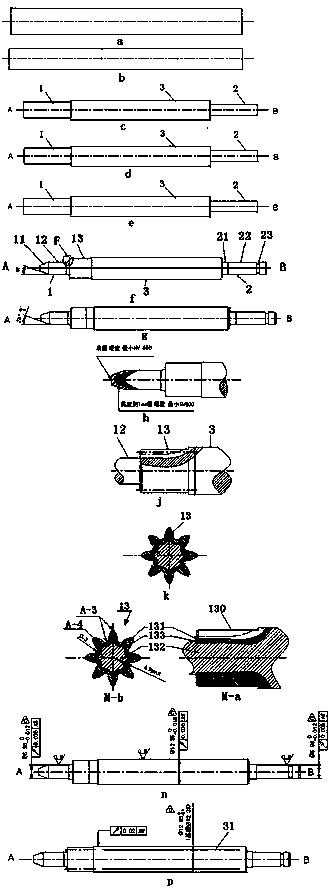

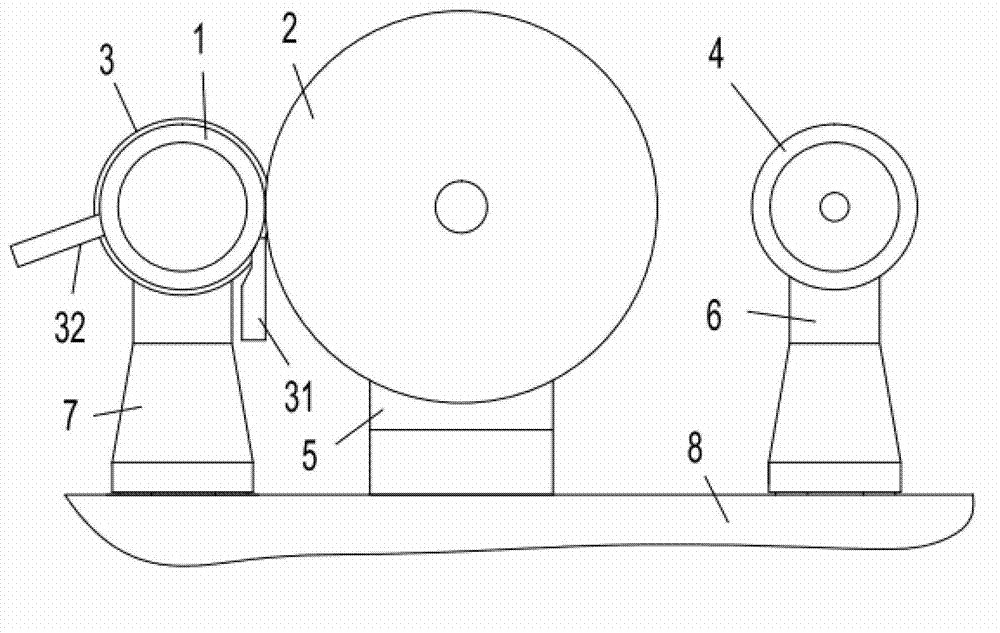

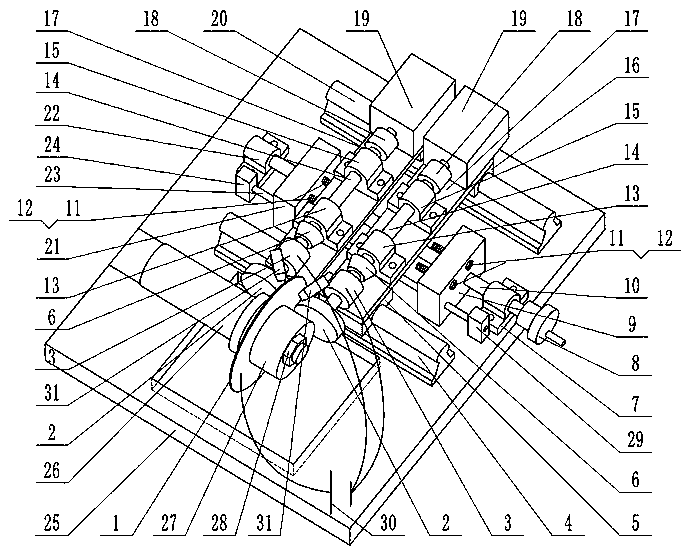

Automatic bearing sound inspection machine

InactiveCN105537147AEasy to operateLow technical requirementsSortingManufacturing cost reductionNoise detection

The invention discloses an automatic bearing sound inspection machine, and belongs to the technical field of rolling bearing vibration, noise detection and sorting technologies. The automatic bearing sound inspection machine comprises a feeding module, a rotating module, a loading module and a locating module. The feeding module comprises a working material channel. The rotating module comprises an A-axis motor, an A-axis spindle, a B-axis motor and a B-axis spindle, wherein the A-axis spindle and the B-axis spindle are installed behind the working material channel; the A-axis motor is connected with the A-axis spindle through a conveying belt; the B-axis motor is connected with the B-axis spindle through a conveying belt; a face turning device is arranged between the A-axis spindle and the B-axis spindle. The automatic bearing sound inspection machine has the advantages that operation is facilitated, the technical requirement for operators is not high, precision consistency of detected products is good, quality is stable, production efficiency and product quality can be remarkably improved, and manufacturing cost is reduced; besides, through the automatic line connection of bearing assembly, automatic detection of bearing vibration and noise detection is achieved.

Owner:HANGZHOU ANDELON EQUIP PROD

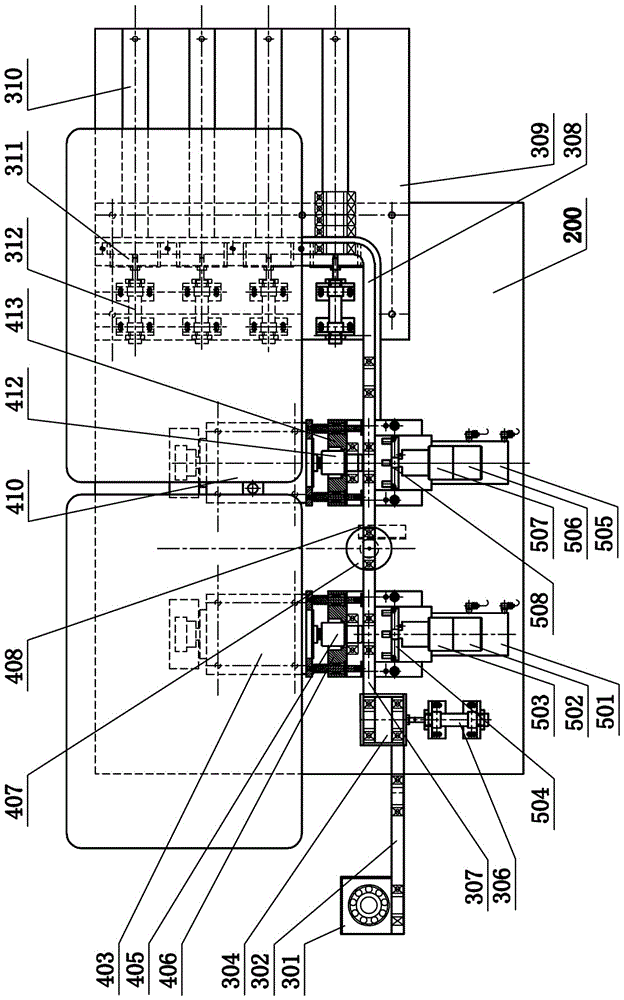

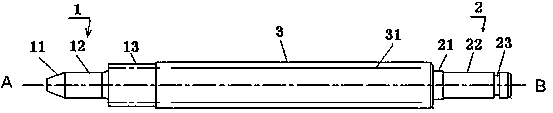

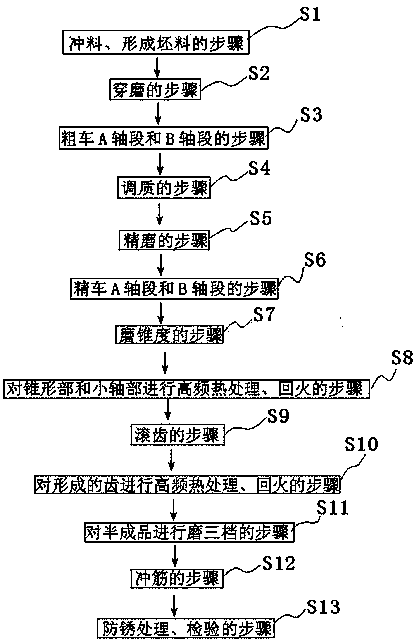

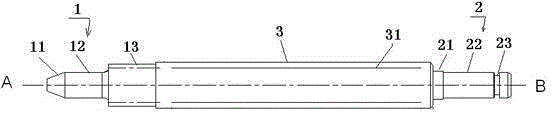

Rotor shaft processing technic and rotor shaft thereof

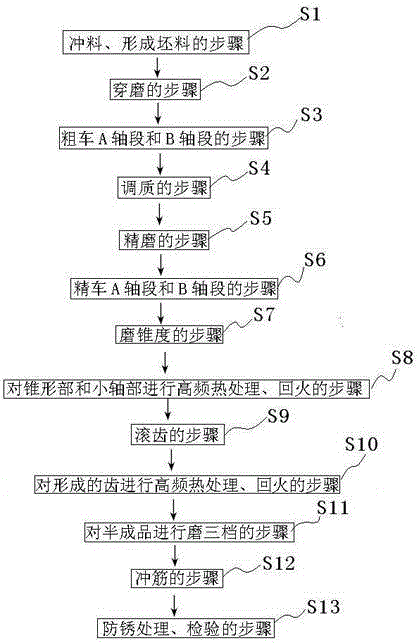

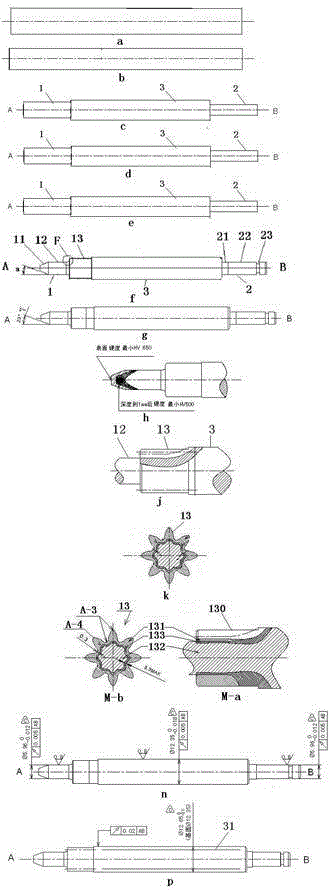

The invention discloses a rotor shaft processing technic, which is characterized by the following steps of punching to form a blank; roughly grinding: roughly turning a shaft section A and a shaft section B; hardening and tempering; finely grinding; finely turning the shaft section A and the shaft section B; grinding tapers; performing high-frequency thermal treatment on a conical part and a small-shaft part, and tempering; hobbing; performing high-frequency thermal treatment on formed teeth and tempering to form a semi-finished product; grinding the semi-finished product at three stages; screeding; and performing rust prevention treatment and inspecting. The invention further discloses a rotor shaft. Most equipment are operated automatically, so that the production efficiency is increased, high production safety, high quality of the produced rotor shaft and high product accuracy consistence are achieved, and waste products are reduced by over 60 percent in comparison to an original process; and the rotor shaft processing technic has the advantages of saving raw materials, reducing production cost and saving energy consumption.

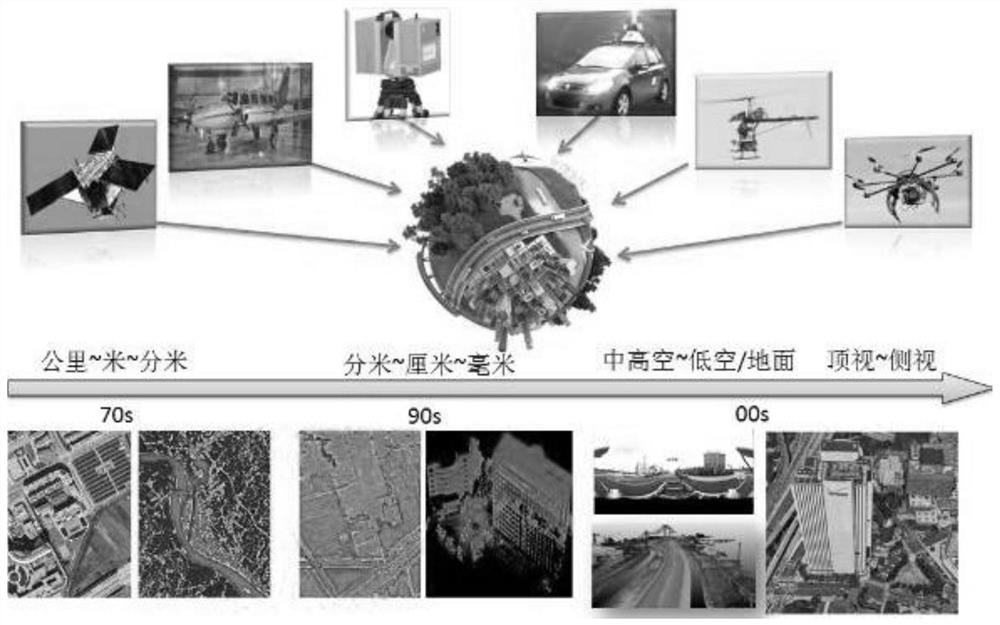

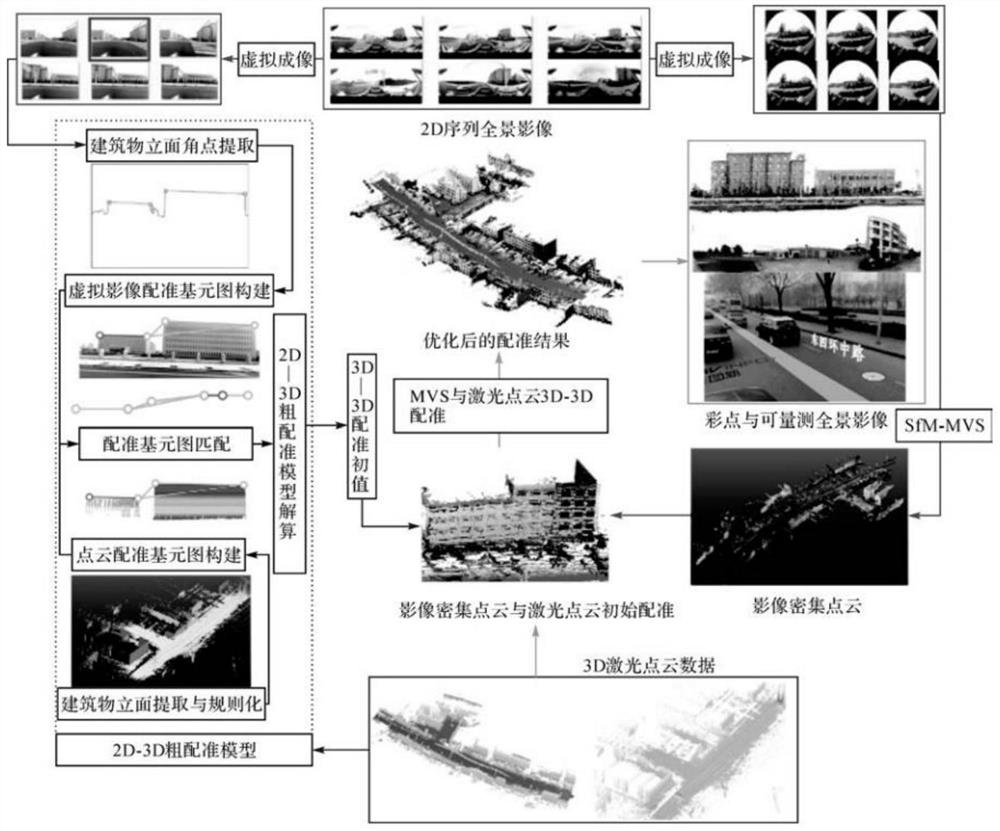

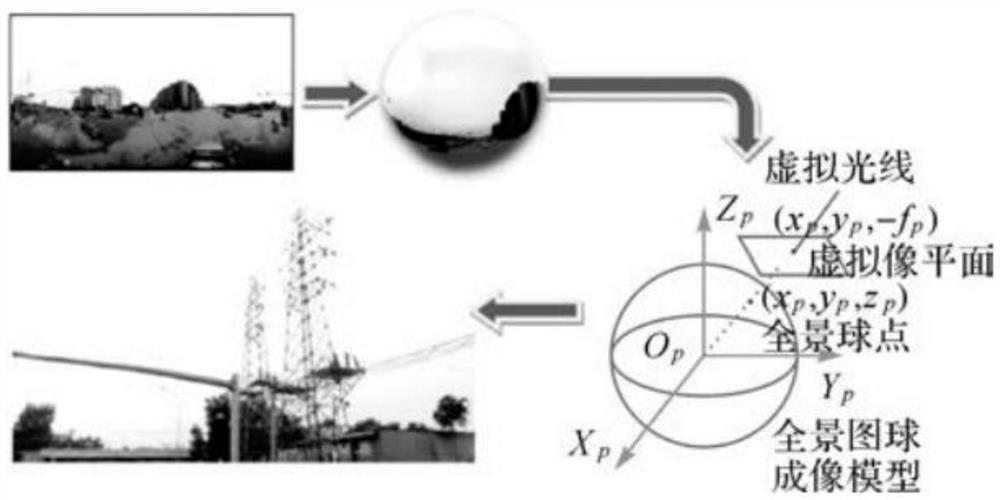

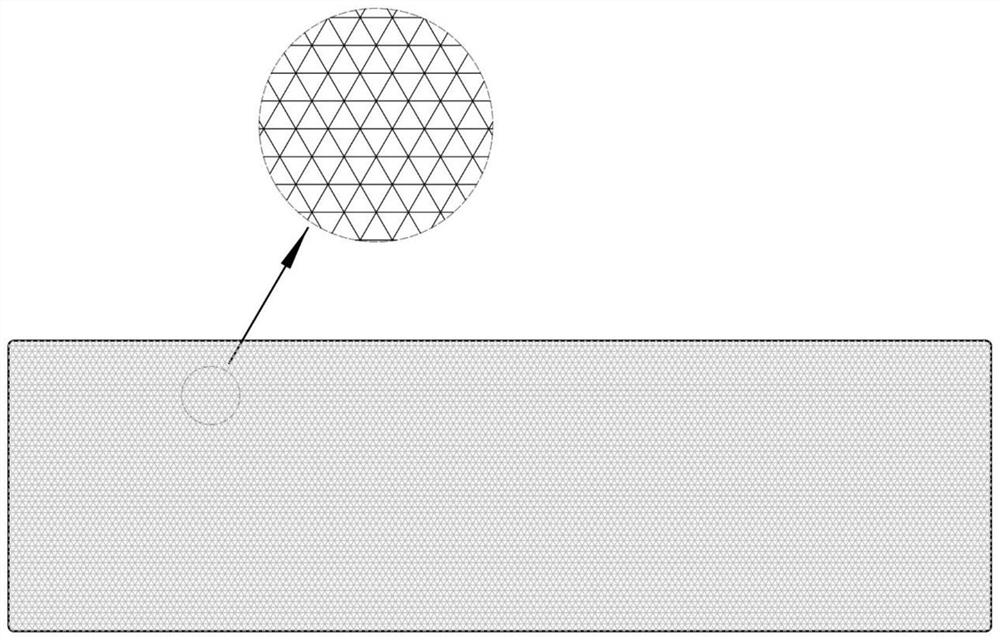

Vehicle-mounted laser point cloud and sequence panoramic image registration method

InactiveCN112465732AHigh precisionGood consistency of precisionImage enhancementImage analysisPoint cloudComputer graphics (images)

The invention belongs to the technical field of surveying and mapping, and discloses a vehicle-mounted laser point cloud and sequence panoramic image registration method, which comprises the steps ofobtaining vehicle-mounted laser point cloud data and sequence panoramic image data, and obtaining a first skyline vector and a second skyline vector; respectively constructing a laser point cloud registration primitive graph and an image registration primitive graph; forming a conjugate registration primitive pair; resolving a pre-established 2D-3D coarse registration model by using the conjugateregistration primitive pair to obtain space coordinate initial conversion parameter information between a photogrammetric coordinate system and a LiDAR reference coordinate system, and completing 2D-3D coarse registration; generating an MVS image dense point cloud based on the sequence panoramic image data; and taking the space coordinate initial conversion parameter information as an initial value, and performing optimal registration between the MVS image dense point cloud and the vehicle-mounted laser point cloud data to complete 3D-3D accurate registration. According to the invention, the registration result precision is high, and the precision consistency is good.

Owner:WUHAN UNIV

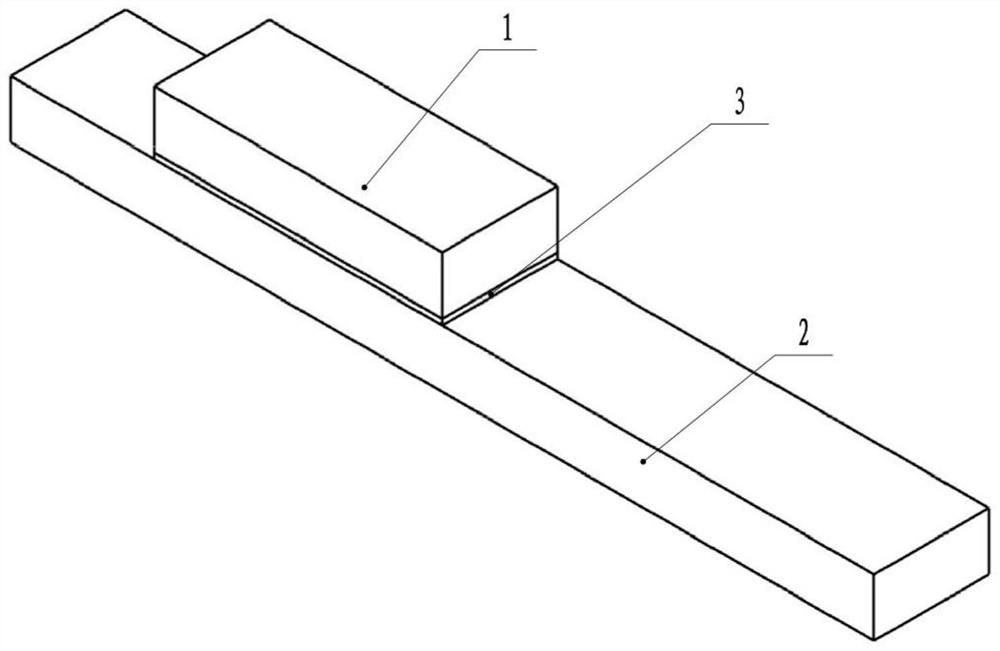

Three-dimensional digital laser repairing device and method of steel rail

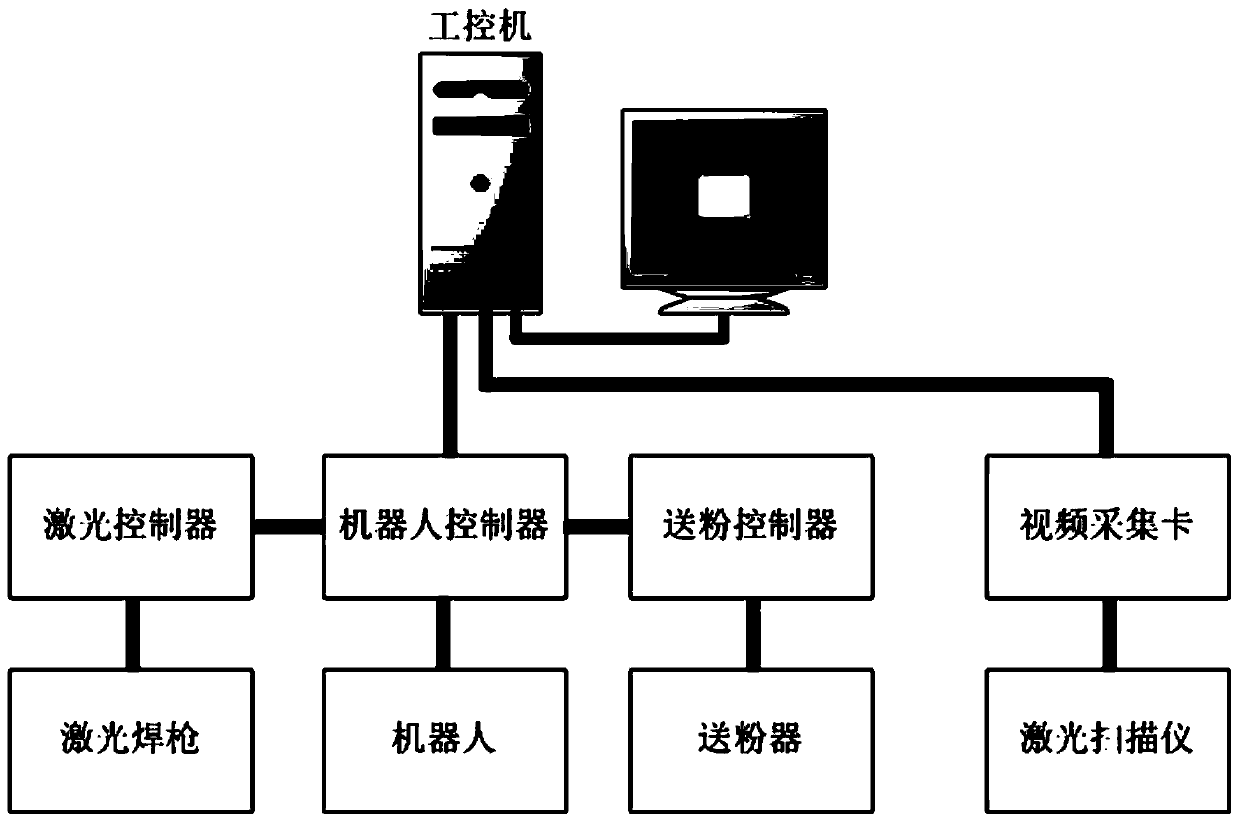

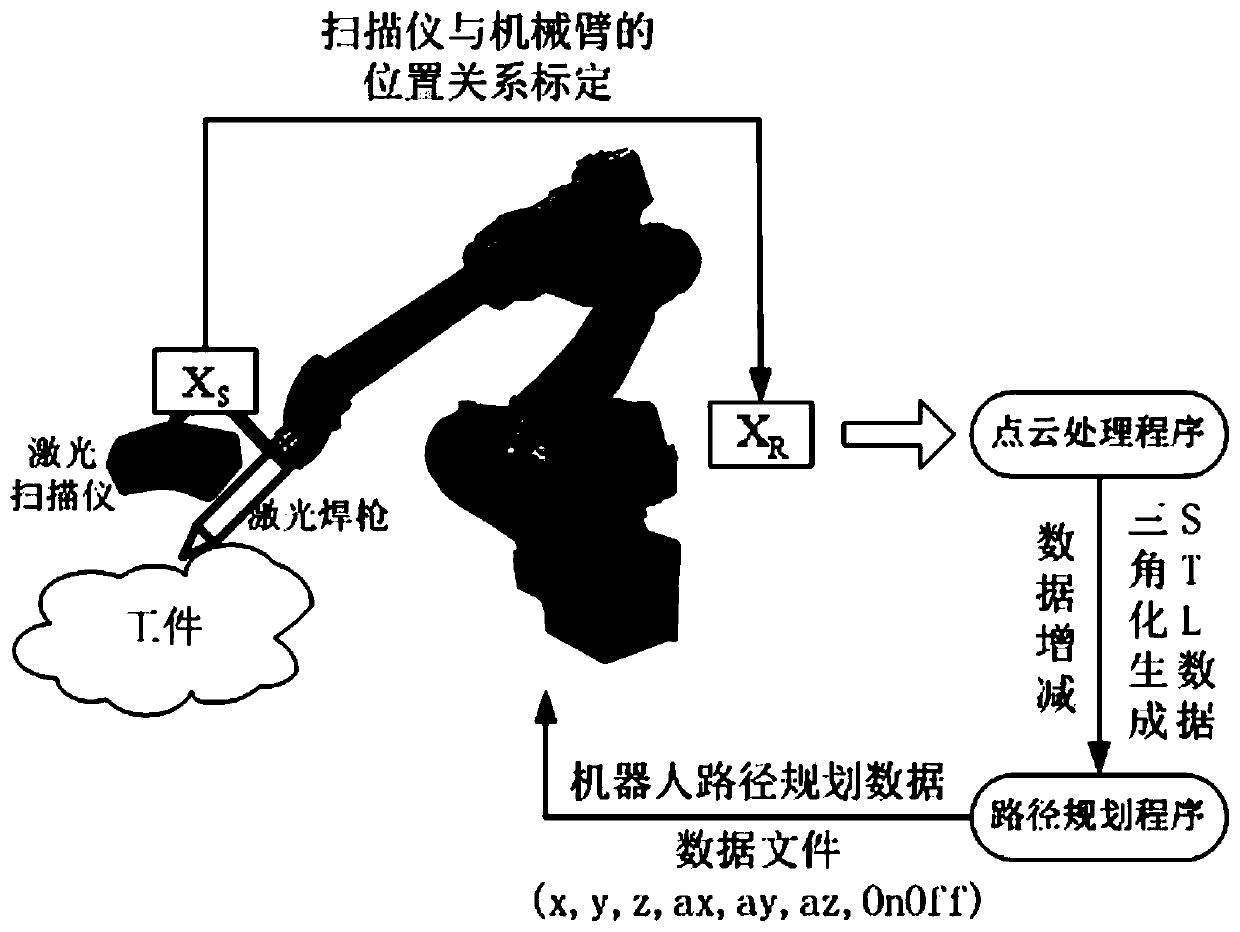

PendingCN110369874ARealize automatic positioningHigh degree of automationLaser beam welding apparatusRobotic systemsLaser scanning

The invention discloses a three-dimensional digital laser repairing device of a steel rail. The device comprises a laser cladding robot system and a three-dimensional model rebuilding system, whereinthe robot system comprises an industrial personal computer, a robot, a robot controller, a laser generator, a laser welding gun, a metal powder conveyor and a spray head; the three-dimensional model rebuilding system comprises a laser scanning instrument and a video acquiring card; the video acquiring card is connected to the industrial personal computer; and the laser scanning instrument is connected to the video acquiring card. According to the three-dimensional digital laser repairing device and method of the steel rail, the steel rail can be automatically positioned, and a three-dimensional model of a broken part can be rebuilt, so that the robot moving route can be automatically planned and a laser switch can be automatically controlled through the three-dimensional model, and as a result, the broken part can be automatically repaired. With the adoption of the device and the method, the automation degree and the production capacity can be improved; and the processing accuracy andthe quality consistency can be improved.

Owner:BEIJING TUOBOER TRACK MAINTENANCE TECH CO LTD

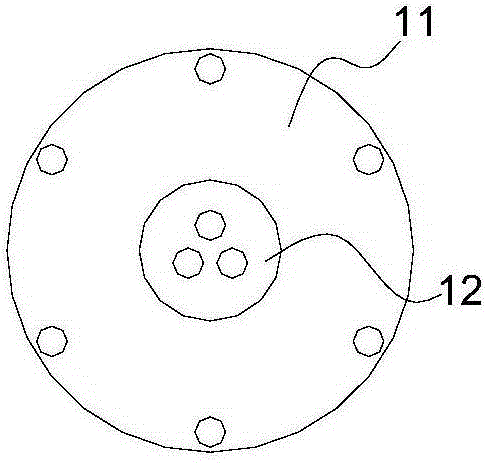

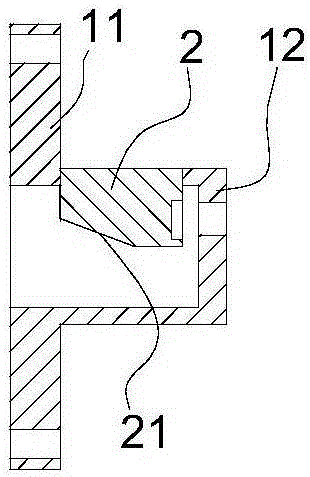

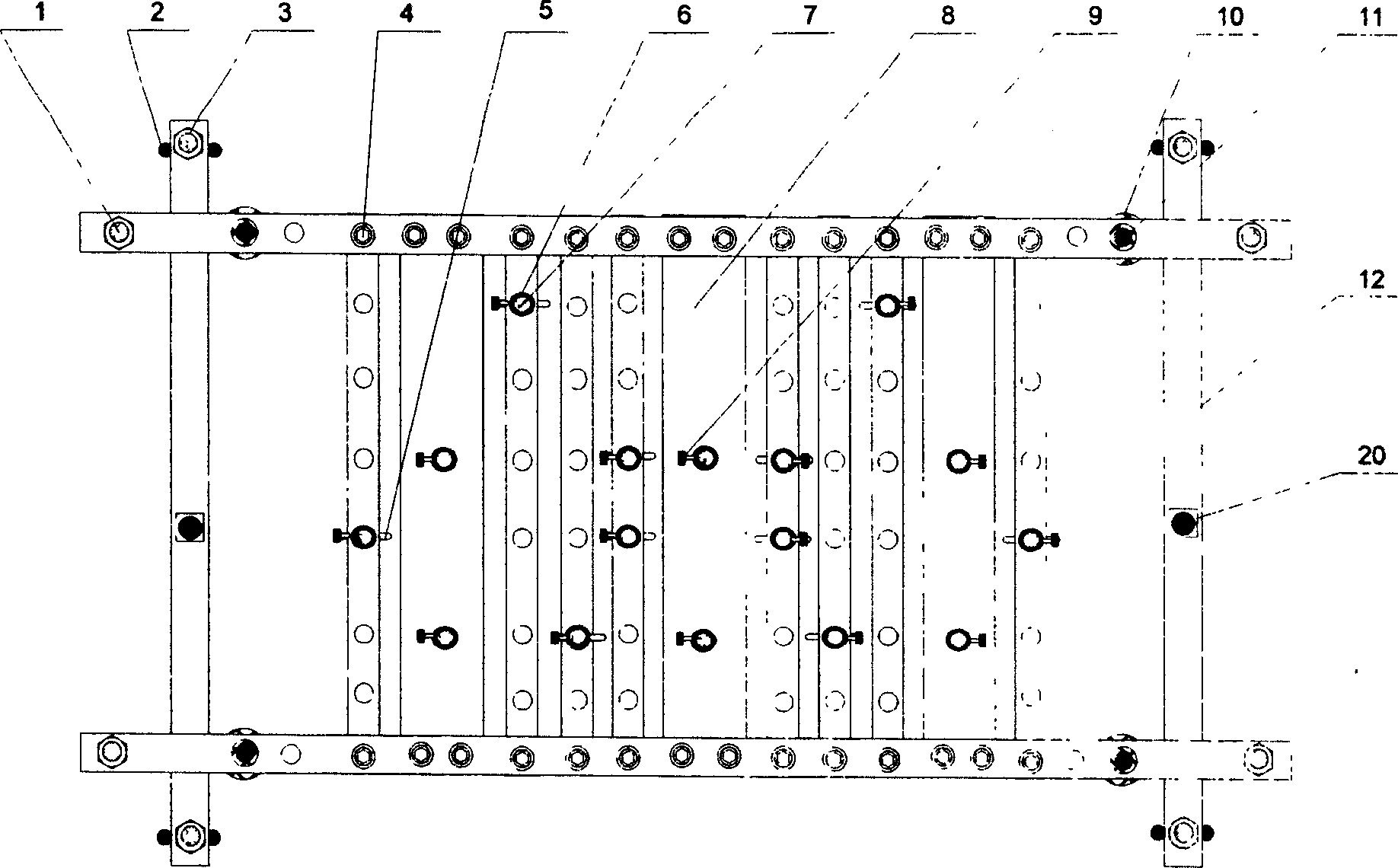

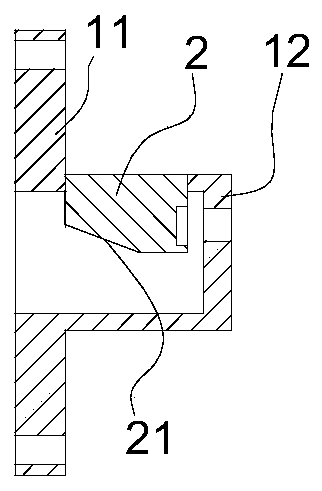

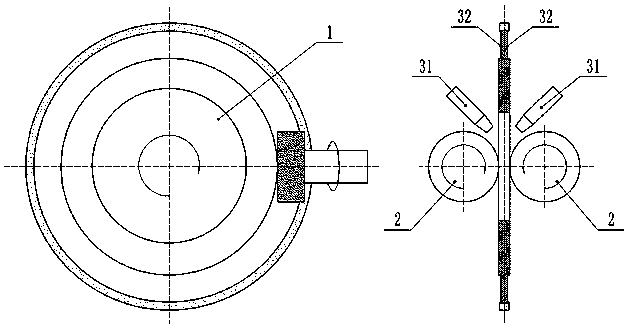

Frameless optical fiber ring demoulding frame and demoulding method

ActiveCN105571616AAccuracy consistency is smallGood consistency of precisionGyroscopes/turn-sensitive devicesEngineeringConductor Coil

The invention belongs to the field of machine manufacturing and particularly relates to a frameless optical fiber ring demoulding frame and a demoulding method. The frame comprises a retaining collar, a ring winding body and a transitional body which are sequentially assembled in a sleeved mode. The demoulding method based on the frameless optical fiber ring demoulding frame includes the steps of demoulding frame assembly, ring winding and solidifying, disassembly of an optical fiber ring from the frame and demoulding. The demoulding frame is easy to install and convenient to detach; after the frame is repeatedly assembled and disassembled, precision is high and uniformity is good; the quality of the frameless optical fiber ring is improved, production efficiency of products is improved, the unqualified rate of the products is reduced, and production cost is reduced.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Leakage current detection circuit

ActiveCN105652140AImprove detection accuracyHigh precisionElectrical testingElectrical resistance and conductanceIntegrator

The invention provides a leakage current detection circuit which is designed based on the closed loop flux gate principle for exciting coil current mean value detection. The leakage current detection circuit comprises a self-excitation square wave oscillating circuit, an active filtering integrator circuit, a feedback resistor, a first filtering circuit and a current detection resistor, wherein the self-excitation square wave oscillating circuit is connected with the first filtering circuit, the active filtering integrator circuit, the current detection resistor and the feedback resistor respectively, the first filtering circuit is connected with the feedback resistor and the current detection resistor respectively, the active filtering integrator circuit is connected with the feedback resistor which is connected with the current detection resistor, the current detection resistor is grounded, and the self-excitation square wave oscillating circuit comprises an exciting coil. The leakage current detection circuit can improve the leakage current detection precision, is simple, and is not influenced by the magnetic conductivity of a magnetic core, the product precision consistency is good and the cost is reduced.

Owner:深圳市艾华迪技术有限公司

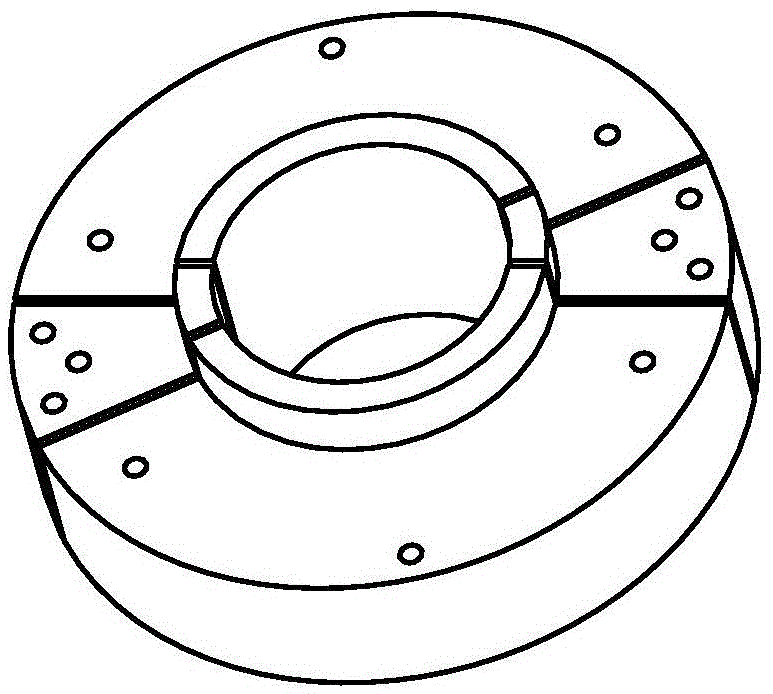

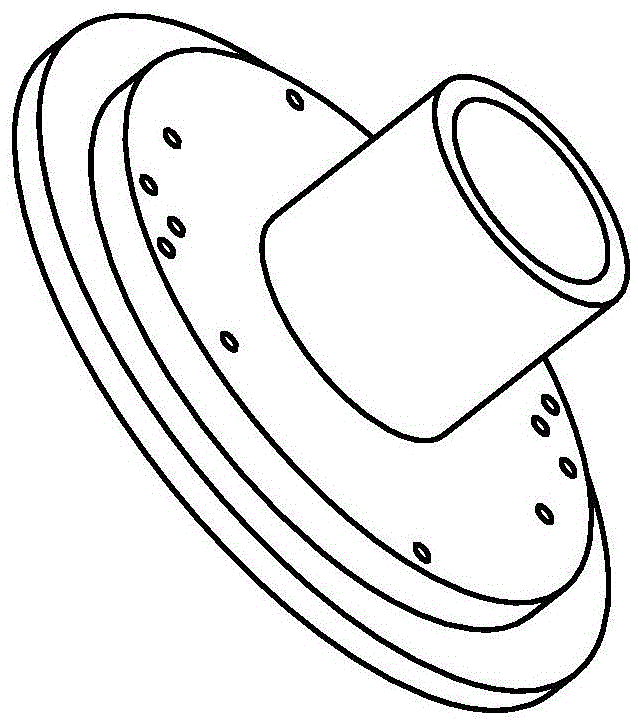

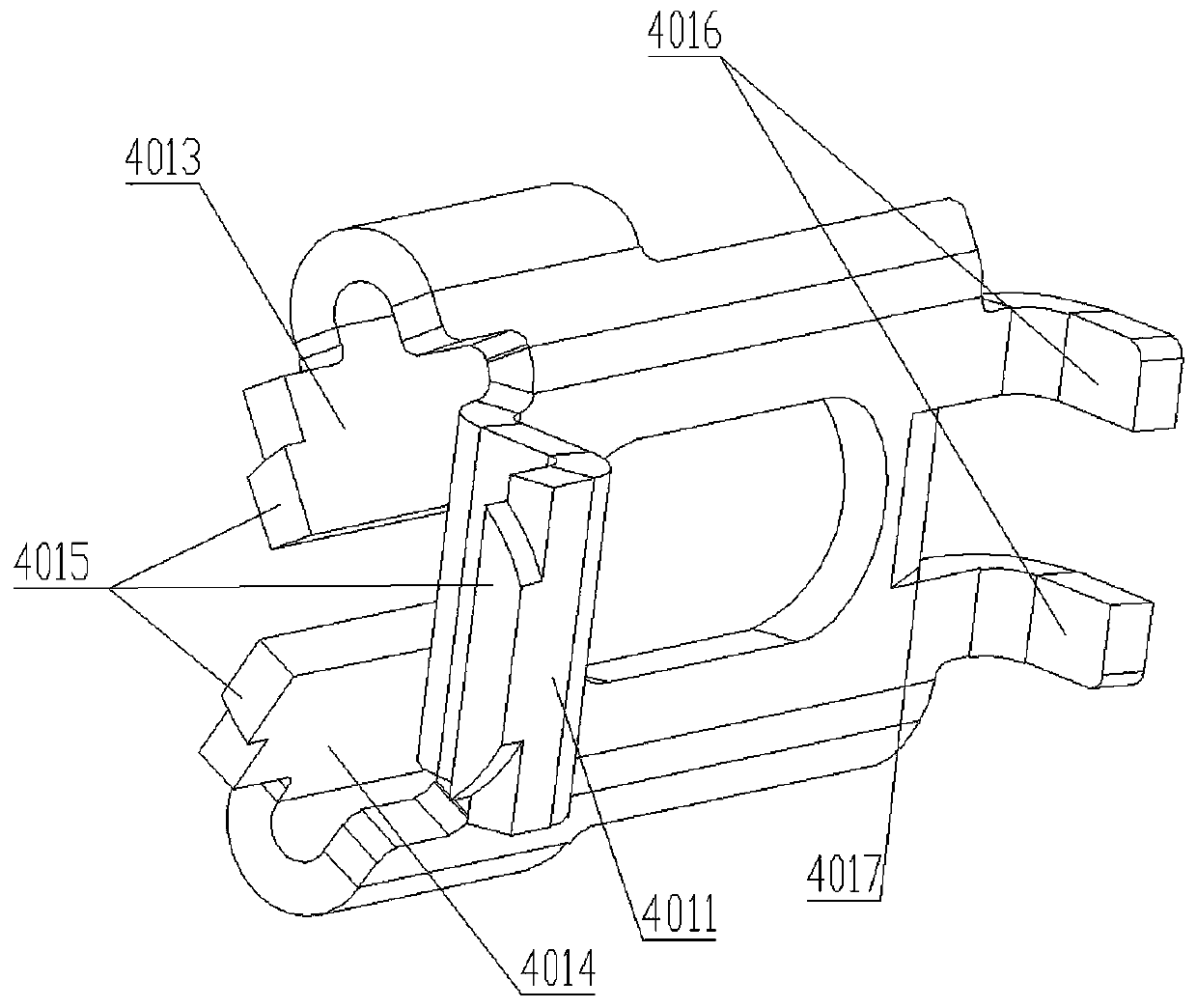

Sloping cover sleeve product machining clamp

ActiveCN105171486AAffects mass accuracyAffects dimensional accuracyWork clamping meansPositioning apparatusArchitectural engineeringEconomic benefits

The invention discloses a sloping cover sleeve product machining clamp. The sloping cover sleeve product machining clamp comprises a locating block, locating clamping jaws, a guide rod and a base, wherein the locating block comprises a lug boss raised in the middle and a supporting platform arranged on the edge; the locating block and the base are fixedly arranged, and center shafts of the locating block and the base are intersected; the base is fixedly connected to a machine tool; the lug boss is of a hollow structure, and through holes are formed in the side surfaces of the lug boss in directions vertical to the center shaft; the locating clamping jaws are arranged in the through holes, and first wedge-shaped surfaces are formed at one sides, which face to the center shaft of the lug boss, of the locating clamping jaws; and the guide rod is arranged in the hollow structure of the lug boss, the top of the guide rod is supported against the first wedge-shaped surfaces, and the bottom of the guide rod is connected to a feed shaft of the machine tool. The sloping cover sleeve product machining clamp has the advantages of good repeatability and accuracy consistency, high machining efficiency and reliability, good appearance quality of product surfaces, high size accuracy, good machining stability, high degree of automation, low cost, and easy maintenance and assembly and has good economic benefits.

Owner:武汉泛洲中越合金有限公司

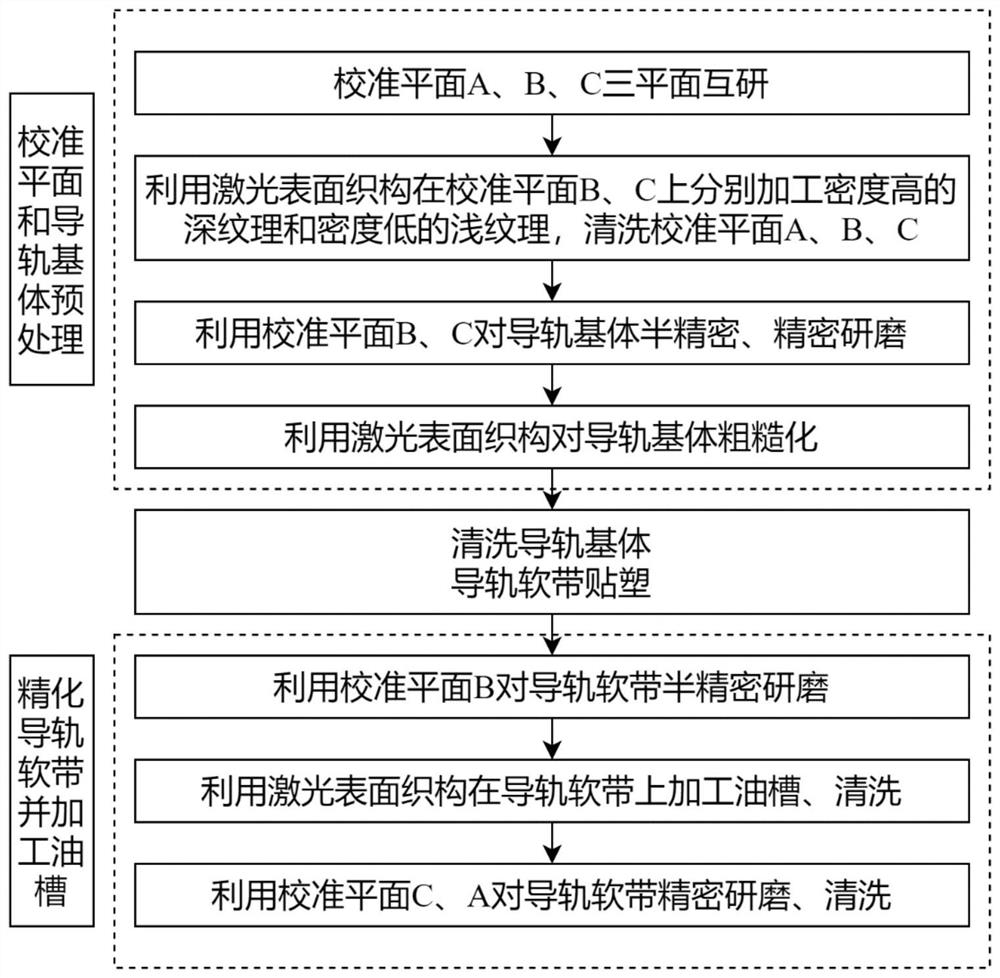

Sliding guide rail plastic-pasting process method

The invention belongs to the technical field of precision machining and testing, and relates to a sliding guide rail plastic-pasting process method, which comprises the following steps of: machining a high-flatness calibration plane by utilizing a three-plane mutual grinding method to grind and refine a guide rail base body, roughening the guide rail base body by utilizing a laser surface texture, and after the guide rail base body is subjected to plastic pasting, matching the laser surface texture with the calibration plane for grinding to refine a guide rail soft belt and machine an oil groove. The method can replace manual scraping to machine the guide rail base body and the guide rail soft belt, so that the machining efficiency is higher, the labor intensity is lower, and the precision consistency is better; the sliding guide rail can be subjected to high-precision plastic pasting machining without more scraping experience, so that the processing cost is lower; and complex oil grooves with different shapes and depths can be designed, so that flowing of lubricating oil and antifriction of the sliding guide rail are facilitated, the using performance of a sliding pair is improved, the service life of the sliding pair is prolonged, and the good market application prospect and popularization value are achieved.

Owner:DALIAN UNIV OF TECH

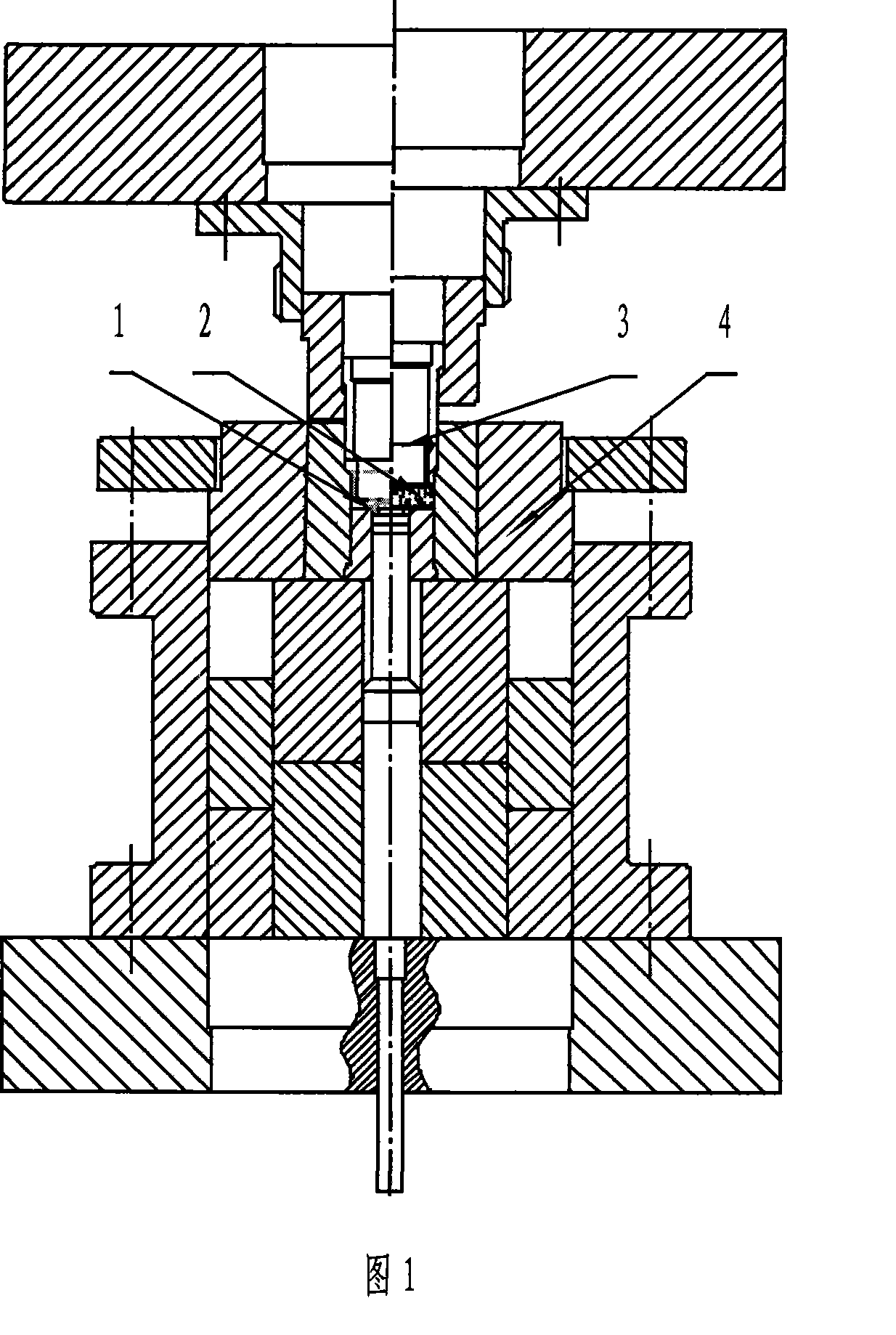

Blind hole internal gear precision forming method and internal tooth forming mold

InactiveCN101214510BGood consistency of precisionSave materialExtrusion diesHeat treatment process controlEntrance angleRough surface

The invention provides a blind hole internal gear fine forming method and an internal gear forming die relating to the metal machinery processing and metal pressing fields of no cutting. The technical steps includes: computer simulation analyzing to study out a process forming scheme-baiting to manufacture roughs-surface intenerating and lubricating processing-fine forming-cutting off redundant part. A convex die profile of an internal gear forming die is corrected according to a gear precision grade tolerance belt and the gear precision is 6 to 5 grade. The surface roughness of the convex die is smaller than 0.5 micron. The thickness of a surface nanometer coat is 0.002 to 0.004 millimeter. A die entrance angle of at end surface of the gear is transited by a semi-arc. An effective width of a minor first flank is between 1.5 and 3 millimeter. A double surface back gap of the minor first flank is 0.3 millimeter smaller than the minor first flank by average. The transition cone angle between the minor first flank of the convex die and a basic die is 3 to 6 degrees. A concave die is formed through interference pressure distribution by adopting 2 to 3 layers of compound dies. The magnitude of interference is 0.4 to 0.5 percent of a matched dimension of a die. The invention has the advantages of short technique line, high manufacture efficiency, good consistence of the gear precision and high intensity.

Owner:JIANGSU SUN WAY GRP FEIDA CO LTD

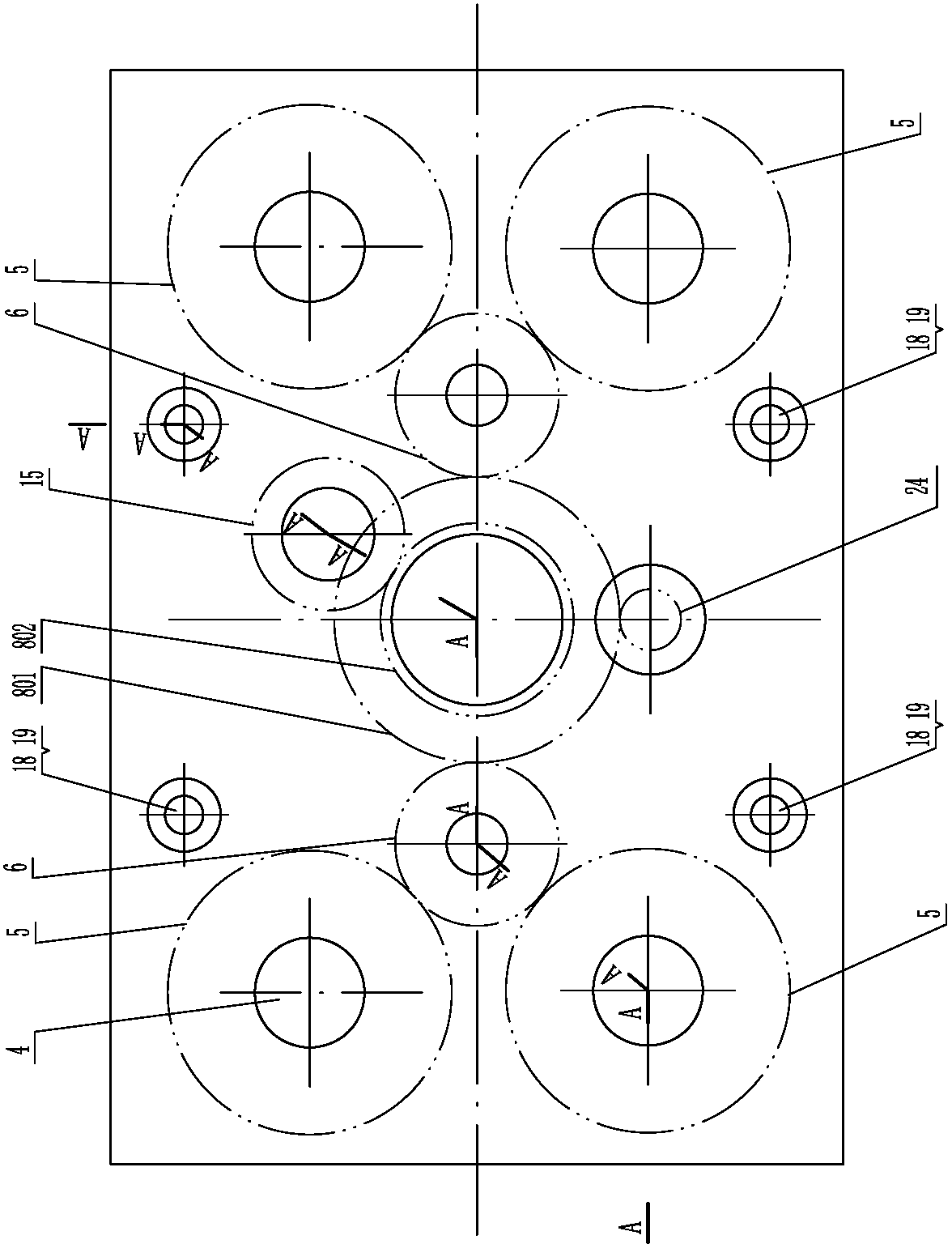

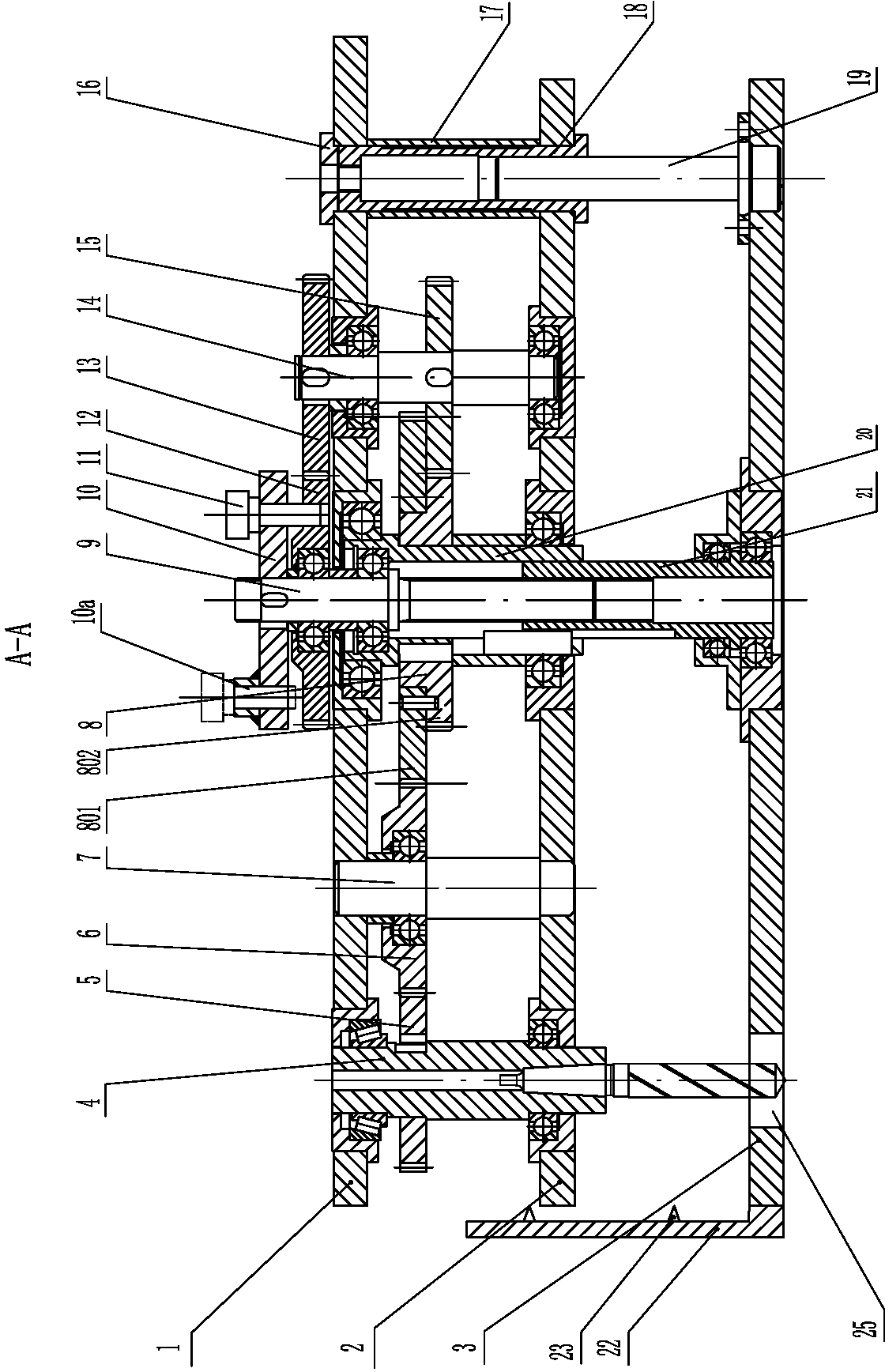

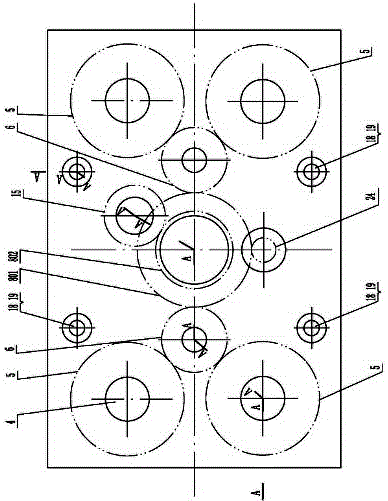

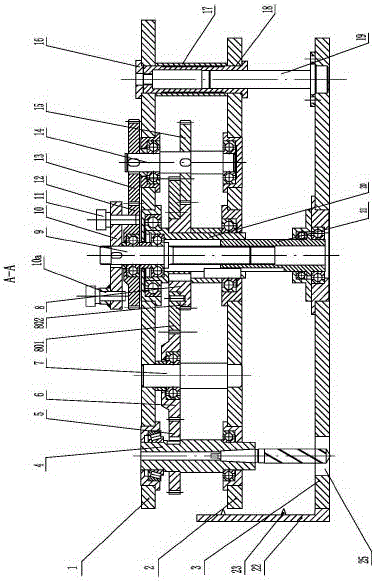

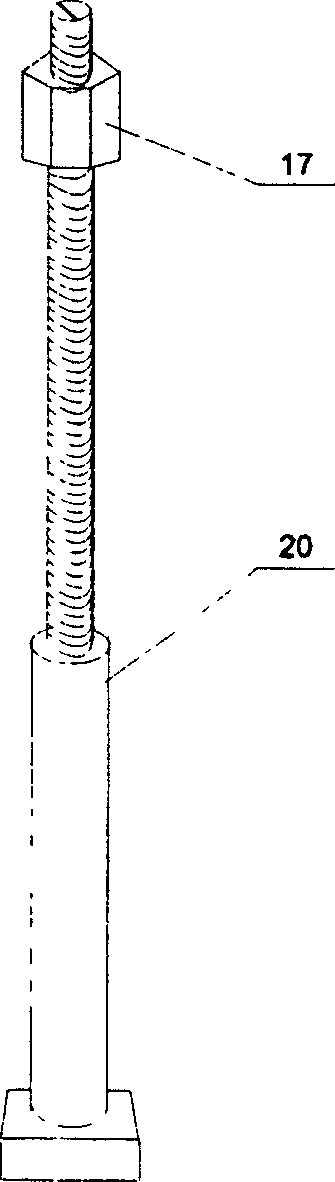

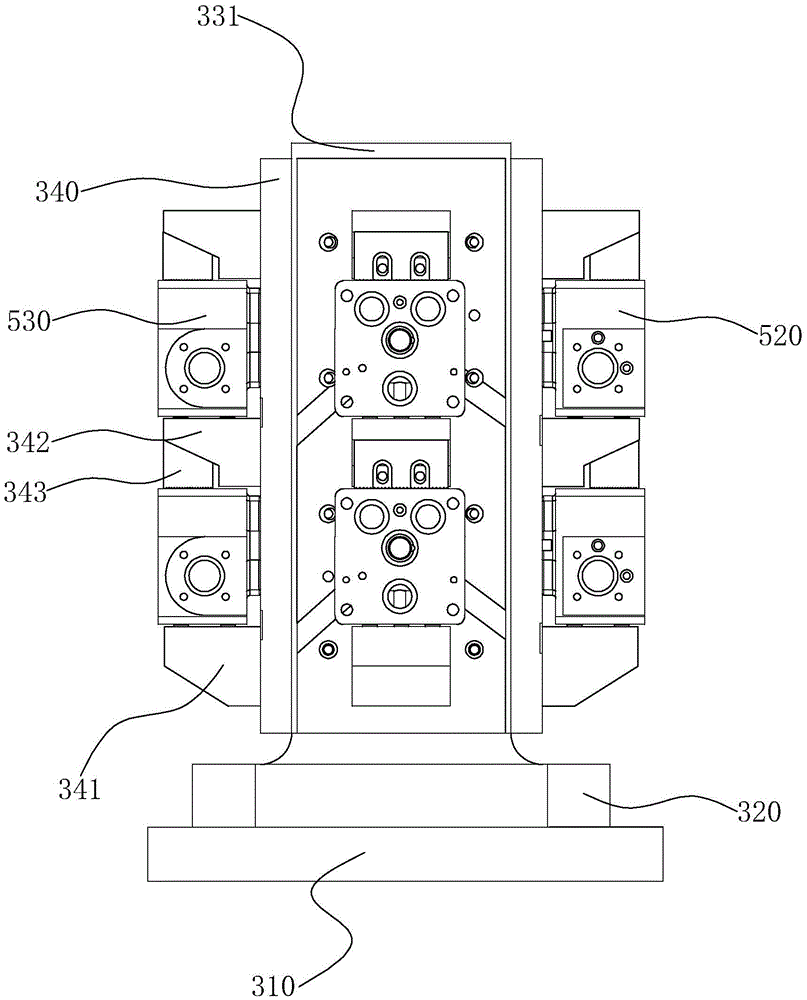

Multi-hole drilling transmission mechanism

ActiveCN103182551AShorten the timeImprove processing efficiencyBoring/drilling componentsScrew threadMachining

The invention relates to a multi-hole drilling transmission mechanism which can be used for processing a plurality of holes at the same time, belonging to the technical field of machining; the multi-hole drilling transmission mechanism comprises an upper plate, a middle plate and a lower plate, wherein a plurality of drilling rod shafts are respectively and rotatablely supported on the middle plate and the upper plate; the drilling rod shafts are respectively and fixedly provided with a drill bit; the lower plate is provided with drilling rod holes, and the drill bits can respectively and conveniently pass through the drilling rod holes in a corresponding way; the middle plate and the upper plate are also respectively provided with a plurality of support sleeve mechanisms which are used for relatively fixing the upper plate and the middle plate; the lower plate is provided with a plurality of guide pillars which are respectively and correspondingly matched with inner holes of the support sleeve mechanism up and down in a sliding way; two hollow shaft sleeves are respectively and rotatablely supported at the centers of the middle plate and the upper plate; two thread guide sleeves which are respectively sheathed in the hollow shaft sleeves in a matching way and can synchronously rotate together with the hollow shaft sleeves are rotatablely supported on the lower plate; a lifting screw rod shaft matched with the thread in each thread guide sleeve passes through each hollow shaft sleeve; the upper ends of the lifting screw rod shafts are connected with the upper plate in a rotary support way; the hollow shaft sleeves are connected with the drilling rod shafts by a main transmission mechanism in a transmission way; and hollow shaft sleeves are connected with the lifting screw rod shafts by a feeding mechanism in a transmission way.

Owner:YANGLI GRP CORP LTD

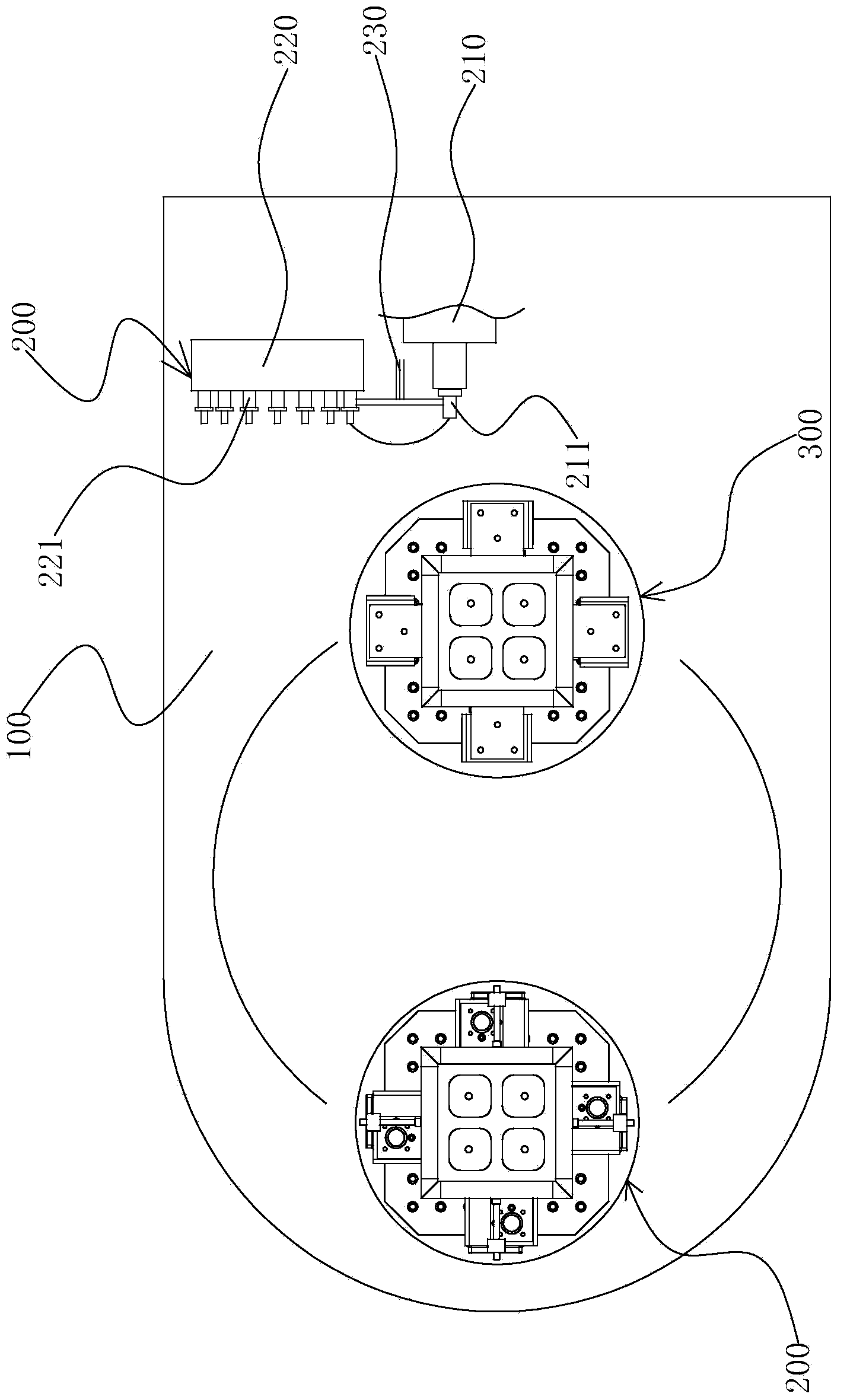

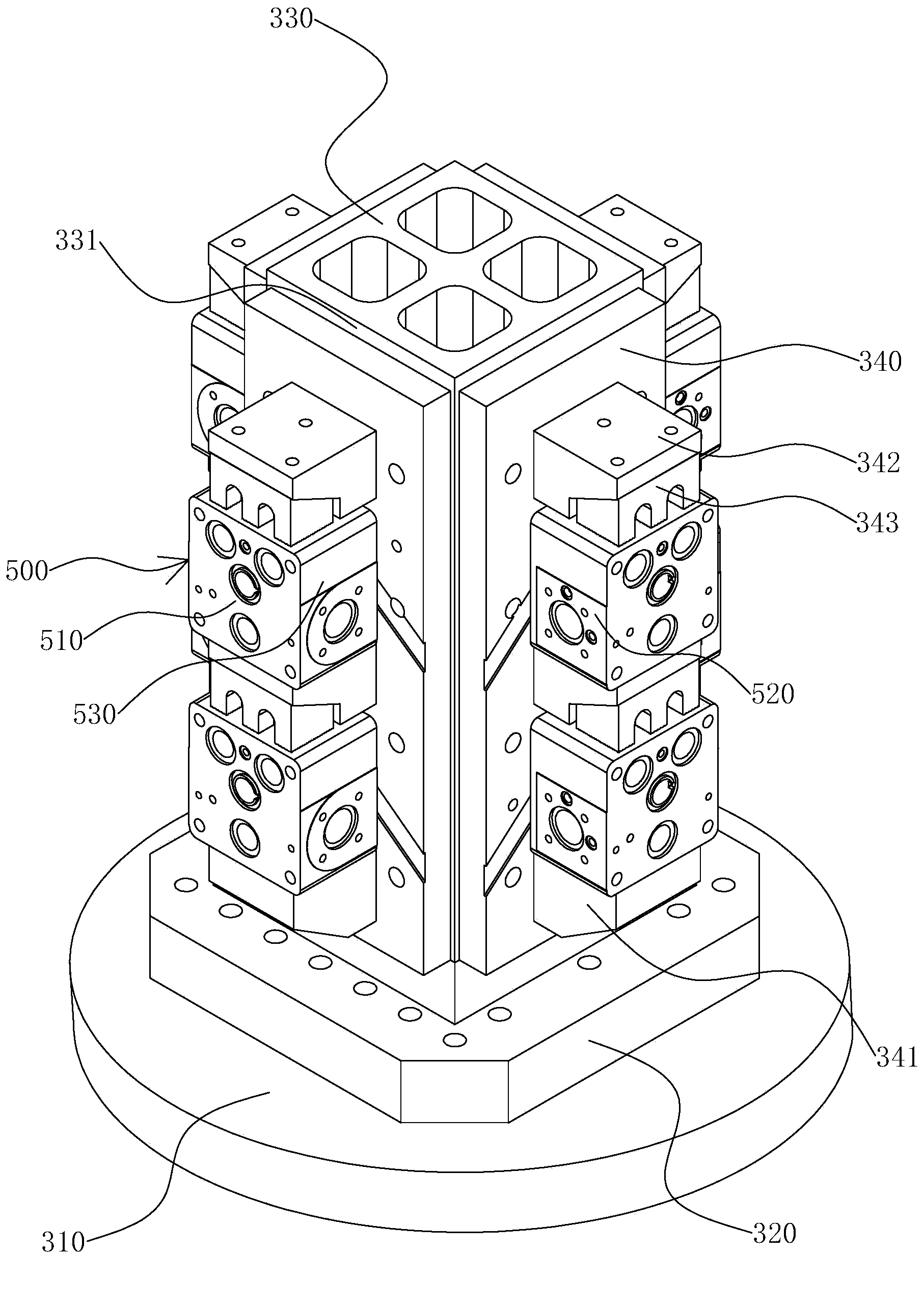

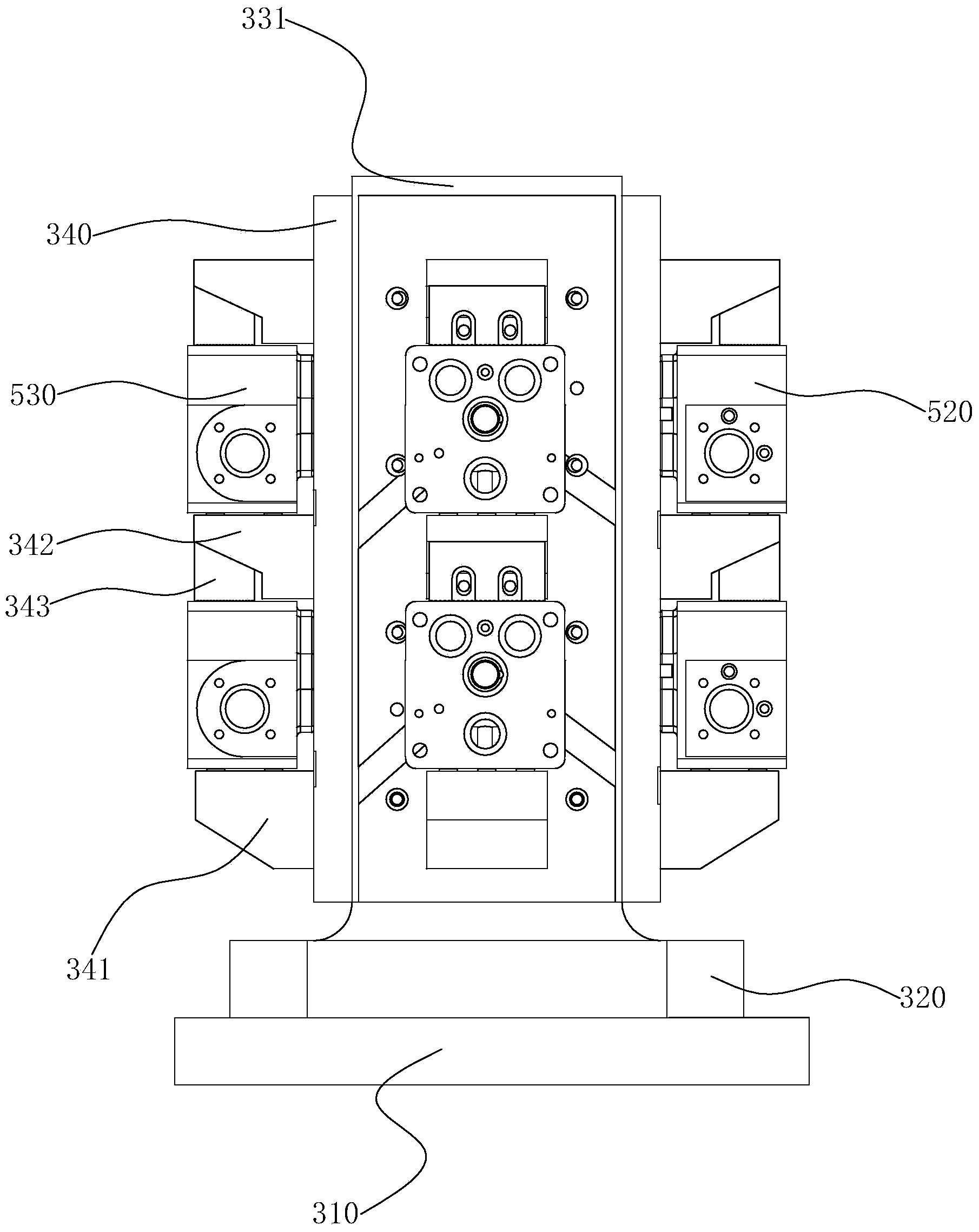

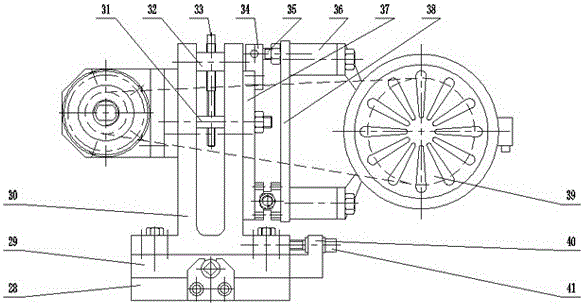

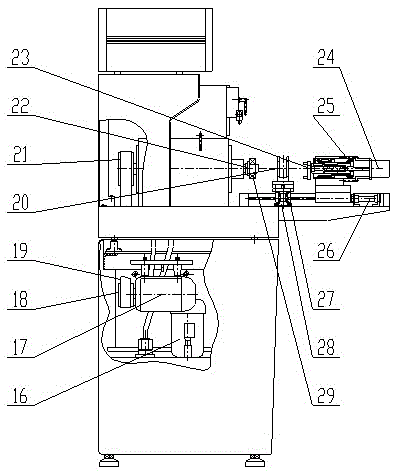

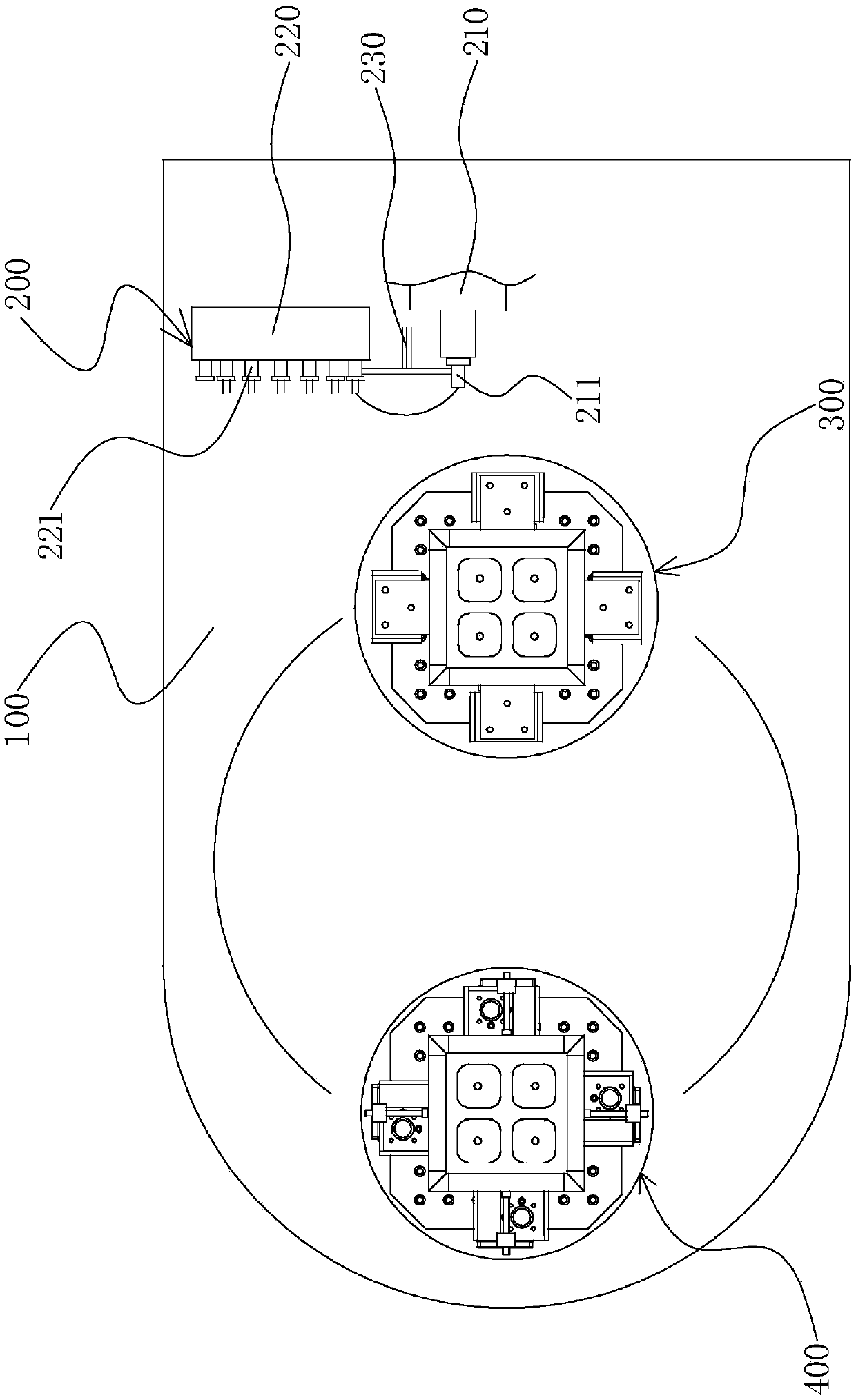

Machining device for proportional pressure control valve special for injection machine

ActiveCN103706810AHigh positioning accuracyThe overall accuracy is consistentTurning machinesMachine controlInjection molding machine

The invention provides a machining device for a proportional pressure control valve special for an injection machine, and belongs to the technical field of lathe machining. The machining device solves the technical problems that an existing control valve is complex in machining technology, low in production efficiency and poor in accuracy. The machining device for the proportional pressure control valve special for the injection machine comprises a fixed platform, an annular guide rail and a machining unit are arranged on the fixed platform, and a first installing unit and a second installing unit are arranged on the annular guide rail and respectively provided with a plurality of control valves; each control valve is provided with six faces, wherein three adjacent faces form a first set of machining faces, the other three faces form a second set of machining faces, the first installing unit and the second installing unit respectively revolve on the annular guide rail, and the first set of machining faces of the control valves in the first installing unit and the second set of machining faces of the control valves in the second installing unit are respectively machined through the machining unit. The machining device is high in production efficiency, simple in technology and accurate in positioning, and the machined control valves are good in uniformity of overall accuracy.

Owner:NINGBO HOYEA MACHINERY MFG

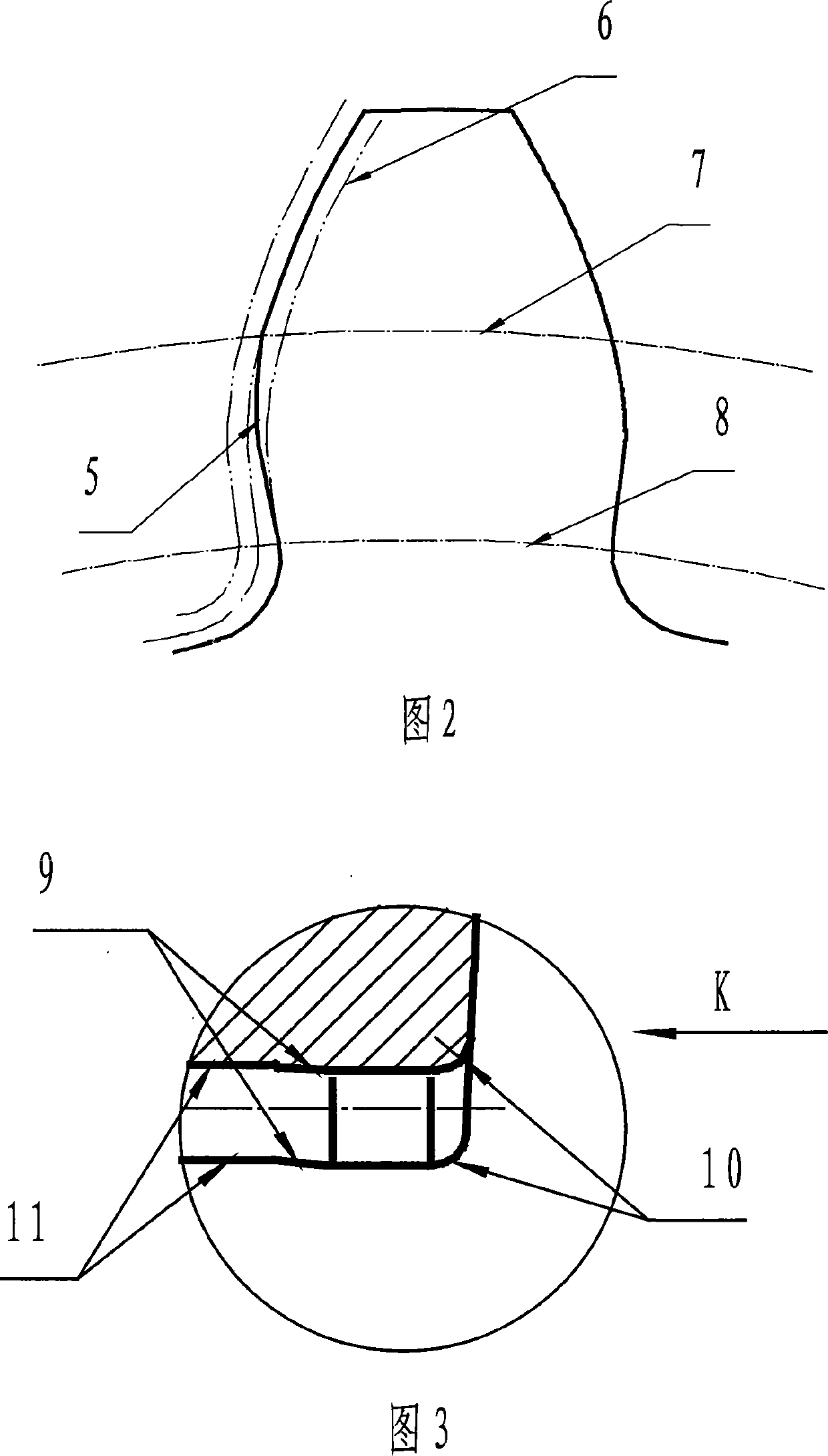

Bus section symmetric-convexity tapered roller and finish grinding method

InactiveCN102878206AImprove processing qualityReduce noiseRevolution surface grinding machinesBearing componentsCircular conePulp and paper industry

The invention relates to the field of manufacture of bearing rollers, and provides a bus section symmetric-convexity tapered roller and a finish grinding method. A bearing of the bus section symmetric-convexity tapered roller is low in temperature rise, vibration and noise and long in service life, requirements on processing quality can be met, and the processing quality can be improved. A bus of the bus section symmetric-convexity tapered roller comprises a middle convex wire and two end convex wires, wherein the curvature radius of each end convex wire is smaller than that of the middle convex wire; and two ends of the middle convex wire are smoothly connected with one ends of the end convex wires respectively. A grinding wheel with a trimmed recess corresponding to the bus is used for performing finish grinding on the bus section symmetric-convexity tapered roller. The pressure of the edge of the bus section symmetric-convexity tapered roller is dispersive, the dispersive pressure is beneficial to elastic fluid lubrication, the bearing is low in temperature rise, vibration and noise and long in service life, and by the finish grinding method, the requirements on the processing quality of the bus section symmetric-convexity tapered roller can be met, and the processing quality can be improved.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

Multihole drill transmission mechanism

InactiveCN106378470AShorten the timeImprove processing efficiencyBoring/drilling machinesPetroleum engineeringDrill bit

The invention relates to a multihole drill transmission mechanism capable of processing multiple holes in the technical field of mechanical processing. The multihole drill transmission mechanism comprises an upper plate, a middle plate and a lower plate; a plurality of drill rod shafts are rotatably supported on the middle plate and the upper plate, drill bits are fixedly mounted on the drill rod shafts respectively, the lower plate is correspondingly provided with drill rod holes convenient for the drill bits to penetrate through, the middle plate and the upper plate are further provided with a plurality of supporting sleeve mechanisms causing the upper plate and the middle plate to be relatively fixed, the lower plate is respectively correspondingly provided with a plurality of guide columns in upper and lower sliding match with inner holes of the supporting sleeve mechanisms, a hollow shaft sleeve is rotatably supported on the centers of the middle plate and the upper plate, a threaded guide sleeve sleeved in the hollow shaft sleeve and synchronously rotating with the hollow shaft sleeve is rotatably supported on the lower plate, a lifting screw rod shaft matched with internal threads of the threaded guide sleeve is arranged in the hollow shaft sleeve in a penetrating manner, the upper end of the lifting screw rod shaft is in rotation supporting connection with the upper plate, the hollow shaft sleeve and the drill rod shafts are in transmission connection by a main transmission mechanism, and the hollow shaft sleeve and the lifting screw rod shaft are in transmission connection through a feeding mechanism.

Owner:南通安洲制冷设备有限公司

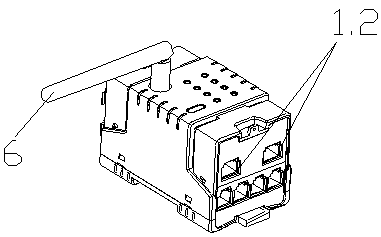

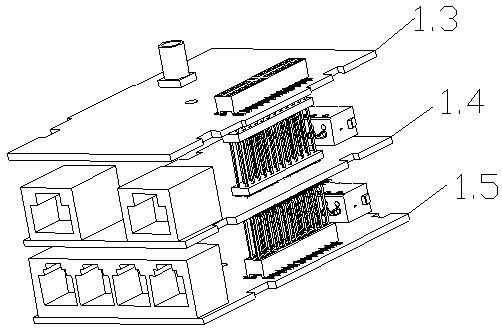

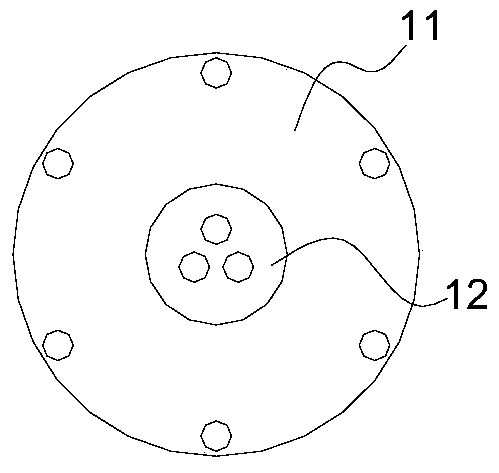

Intelligent multi-loop environmental protection monitoring device

PendingCN110426981ARealize terminal data collectionRapid positioningProgramme controlComputer controlIntelligent lightingElectricity

The invention relates to an intelligent multi-loop environmental protection monitoring device. The device comprises a main body module, a voltage taking device, an open type current transformer and anantenna; the main body module comprises a casing, a first circuit board, a second circuit board and a third circuit board, wherein the first circuit board, the second circuit board and the third circuit board are arranged inside the casing, the first circuit board comprises an MCU module, a Lora communication module, a power-down report module and an indicator light, the second circuit board comprises a voltage terminal and a 485 communication port, and the third circuit board comprises a current input interface and an active DI module; the voltage terminal is connected with the voltage taking device through a lead wire, and the current input interface is provided with a lead wire to be connected with the open type current transformer. The intelligent multi-loop environmental protection monitoring device is used for monitoring three-phase loops with 1-4 channels unequal, is capable of monitoring the operating conditions of a plurality of environmental protection devices, has real-timemonitoring and remote monitoring functions and meets the requirements of collection and reading.

Owner:JIANGYIN ACREL ELECTRICAL APPLIANCE MFGCO +1

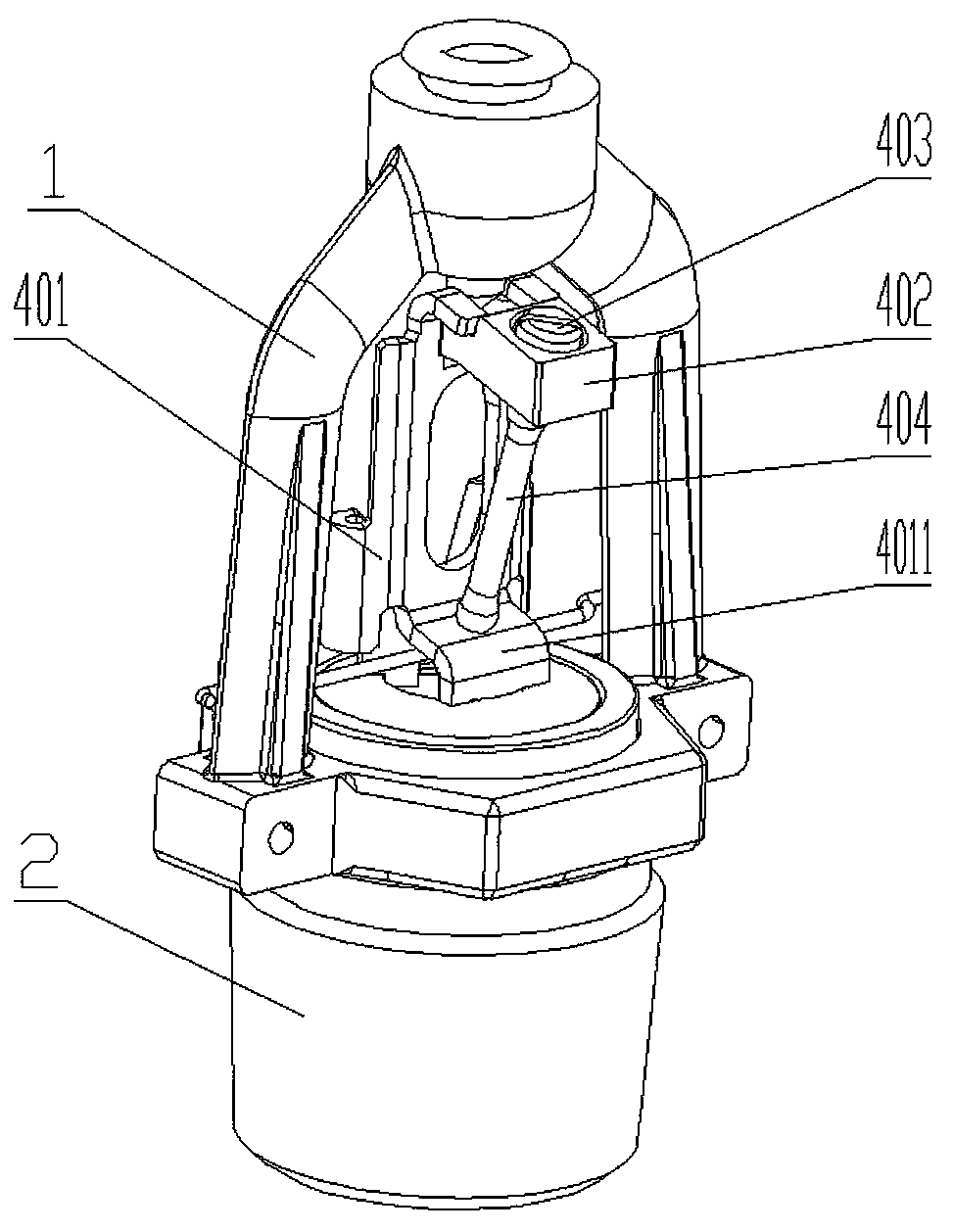

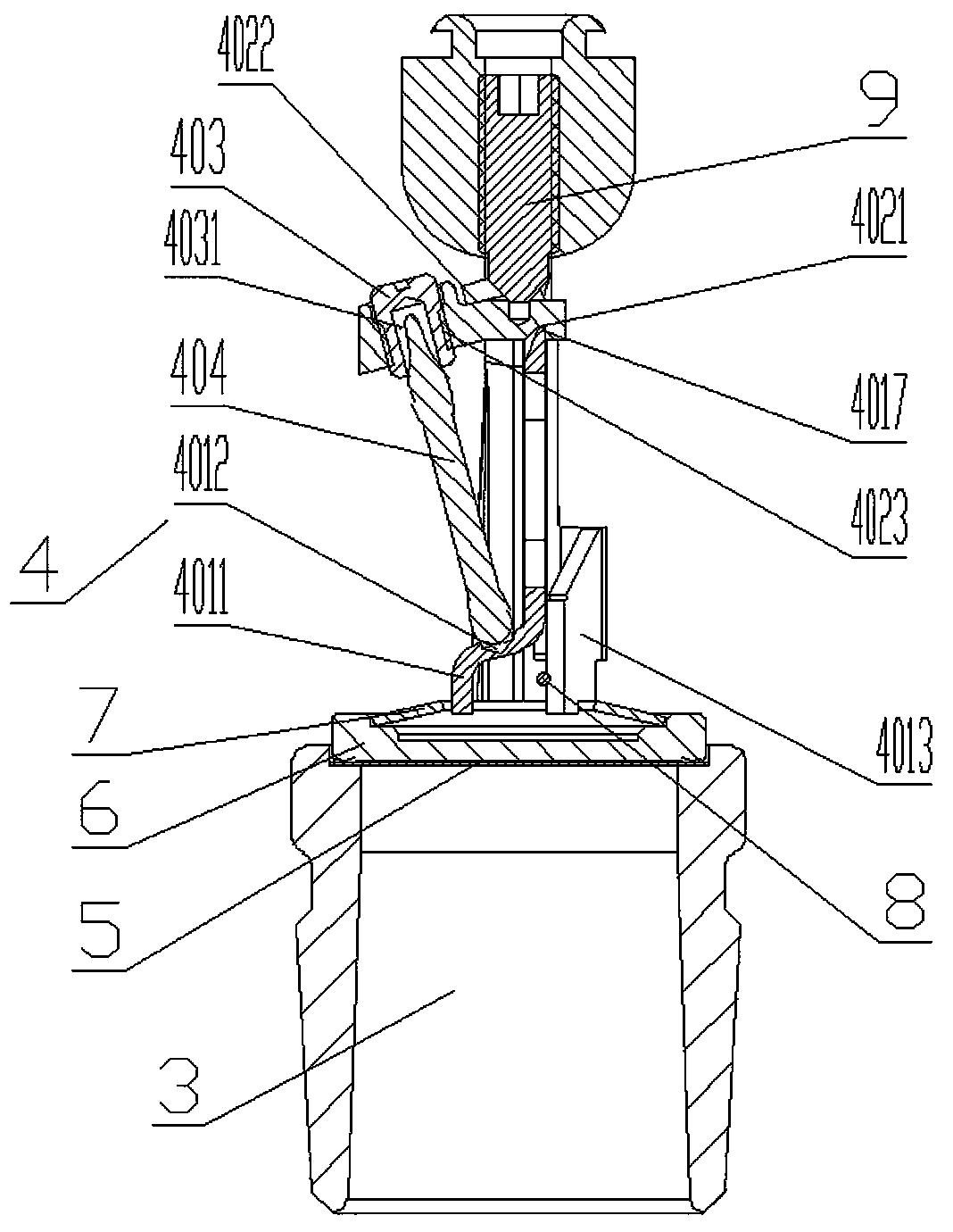

Temperature sensing mechanism of large-diameter spray nozzle, and large-diameter spray nozzle

The invention discloses a temperature sensing mechanism of a large-diameter spray nozzle. The mechanism comprises a temperature sensing trigger device, a first storage chamber, positioning stairs anda glass ball, wherein a first supporting leg, a second supporting leg, a third supporting leg and a supporting edge are disposed on a supporting frame, and stabilization tongues bent to the first supporting leg are symmetrically disposed on two ends of the supporting leg; a guide groove is formed in one end of a press block, a threaded hole is formed in the other end, and a shoulder part fitted with the stabilization tongues is disposed at the middle part; a second storage chamber is disposed on a glass ball screw; and the glass ball can sense temperatures, one end is mounted in the first storage chamber, and the other end is mounted in the second storage chamber. The large-diameter spray nozzle comprises a spray nozzle body, an end cap and a conical screw, wherein a water outlet channel and a spray nozzle frame are disposed on the spray nozzle body, the end cap is disposed on a water outlet end face of the water outlet channel, the conical screw is screwed on the spray nozzle frame and is coaxial with the end cap, and the large-diameter spray nozzle also comprises the temperature sensing mechanism.

Owner:SHANGHAI RUITAI FIRE FIGHTING EQUIP MFG CO LTD

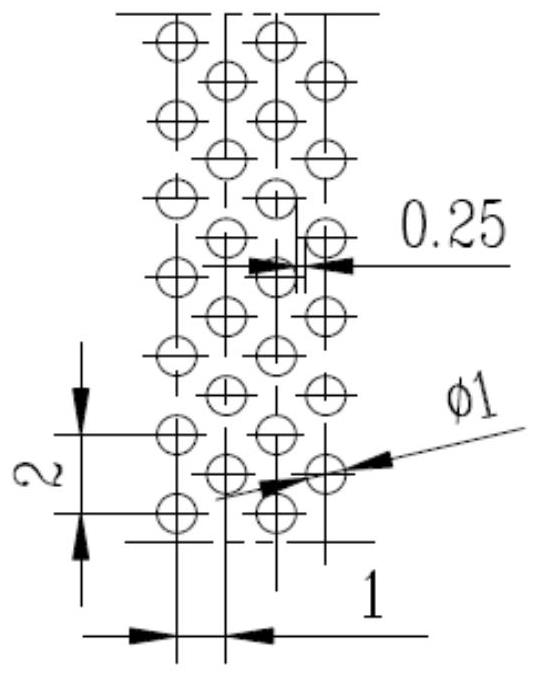

A hole-making method for ion propulsion carbon grid assembly

ActiveCN109227740BGuaranteed coaxial accuracyGuaranteed positioning accuracyMetal working apparatusMachine toolMachining

Owner:DALIAN UNIV OF TECH

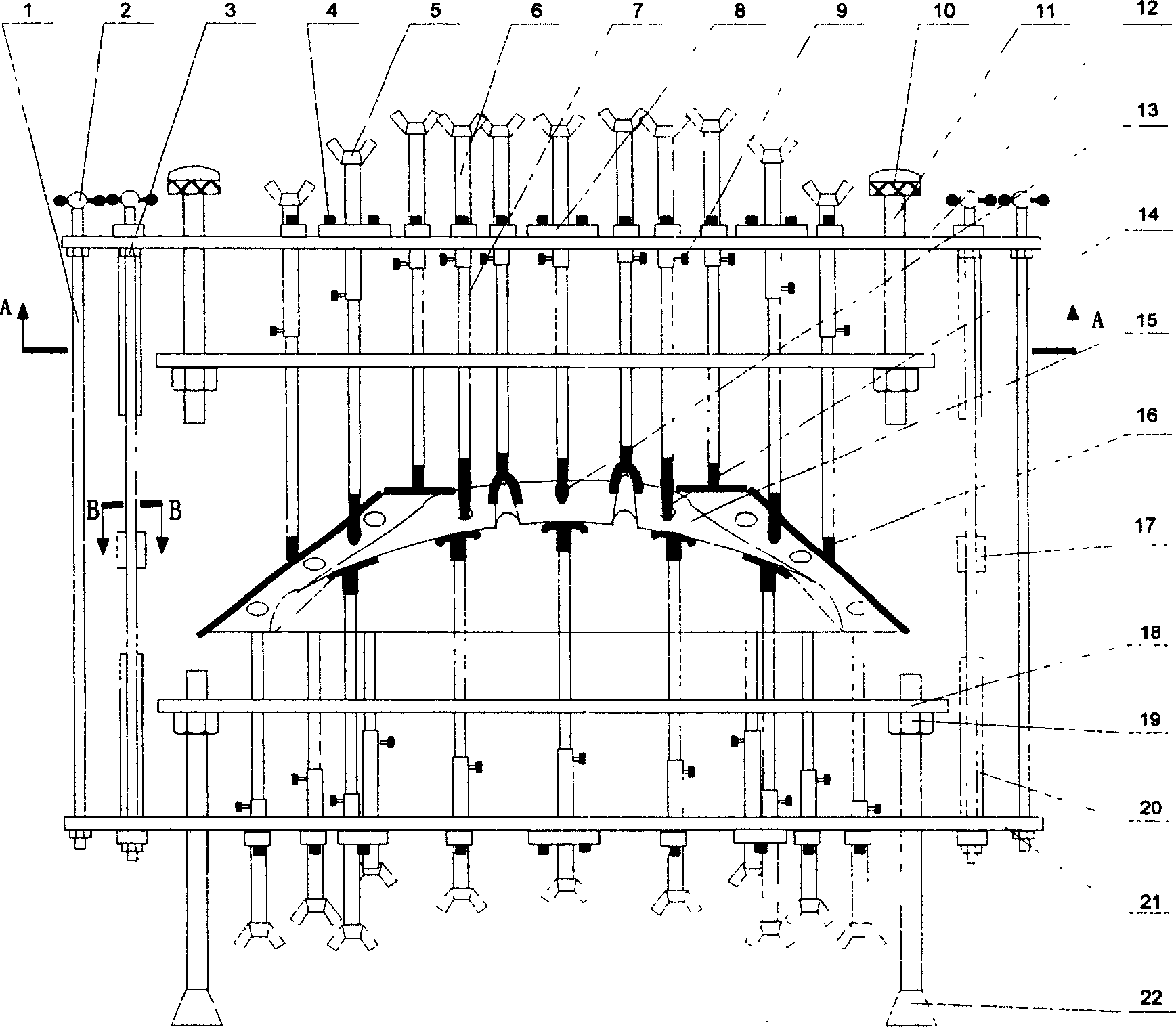

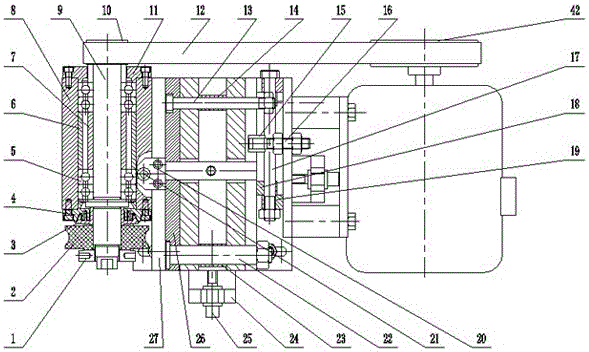

Flexible checking implement for large complicated carved punched thin-wall workpiece

InactiveCN1300545CIncrease flexibilityMeet process requirementsMechanical measuring arrangementsEngineeringBatten

A flexible detection tool of punching thin wall component with large complicated curve features including two sets of frames being arranged symmetrically and being connected by long foot screws , setting adjustable screw at four edges of frame , applying external through jacked with regulation screw at centre of width edge and a numbers of slats with replaceable scaled pin at length edge , setting two coordinate reference plates in parallel within frame for reading out coordinate value to check whether the value is in the tolerance or not and using filler gauge to check component size.

Owner:SHANGHAI JIAO TONG UNIV

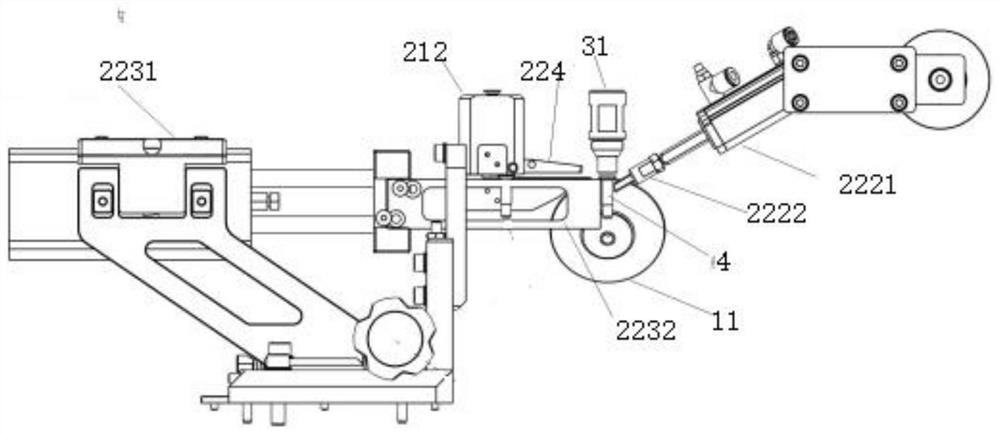

A diamond roller grinding wheel dresser device

ActiveCN103495933BReduce vibration effectsAvoid enteringAbrasive surface conditioning devicesManufacturing cost reductionHigh volume manufacturing

The invention provides a diamond roller grinding wheel dresser device which comprises a U-shaped support, a main shaft component, a roller driving motor component, a vertical adjusting plate, a horizontal adjusting plate, a height adjusting plate and an angle adjusting plate. A motor reduces the vibration influence of motor vibration on a diamond roller trimming wheel through a vibration reducer and the U-shaped support. The diamond roller grinding wheel dresser device is characterized in that the device is simple in operation and not high in requirement for the technology of workers, the precision consistency of processed products is good, quality is stable, production efficiency and product quality can be improved obviously, manufacturing cost can be lowered, and grinding machining automation can be achieved easily. Compared with traditional single-point diamond stylus trimming, the diamond roller grinding wheel dresser device enables production efficiency to be greatly improved, is higher in surface quality and precision of machined parts, and is especially suitable for high-precision and volume production.

Owner:杭州人本轴承有限公司

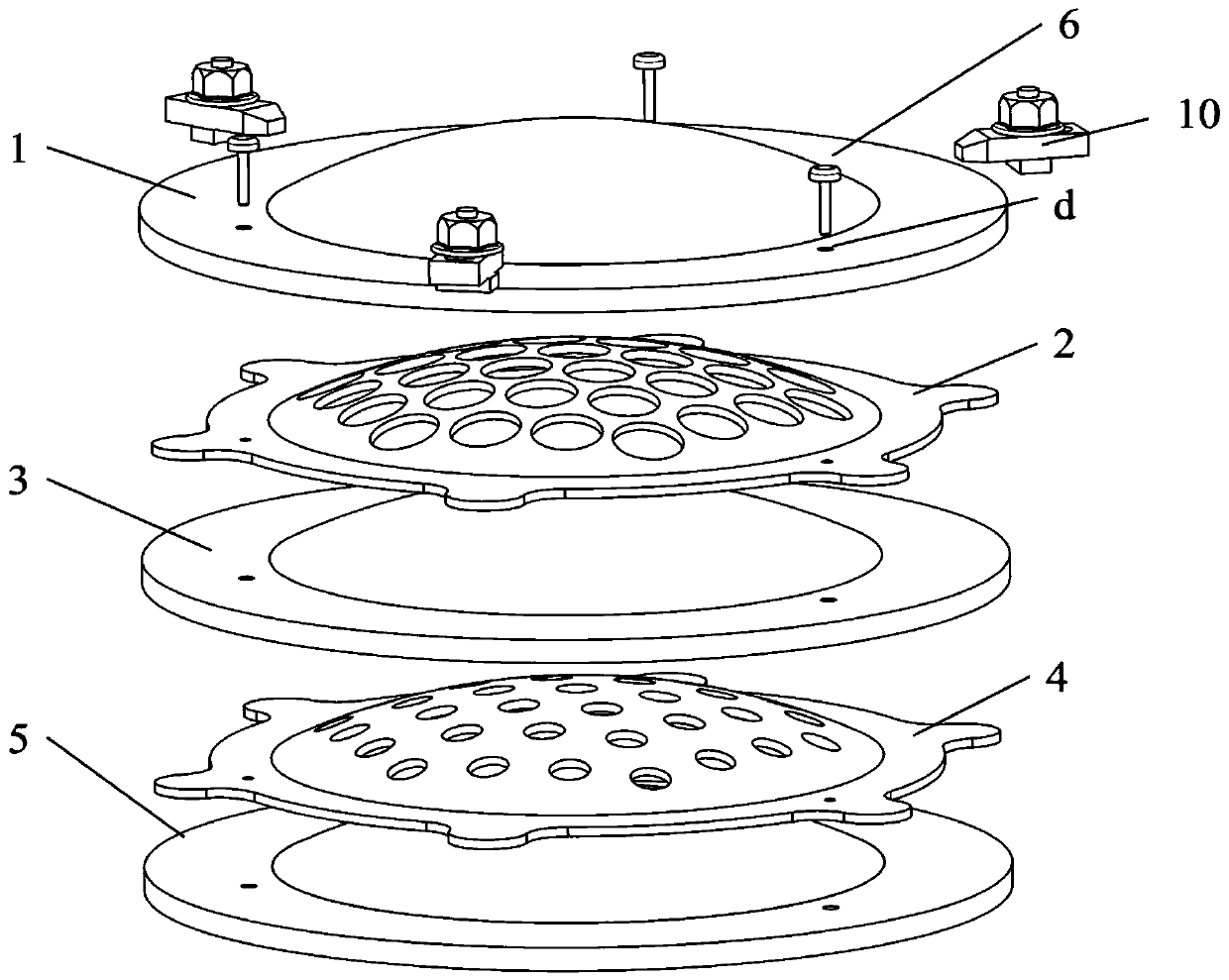

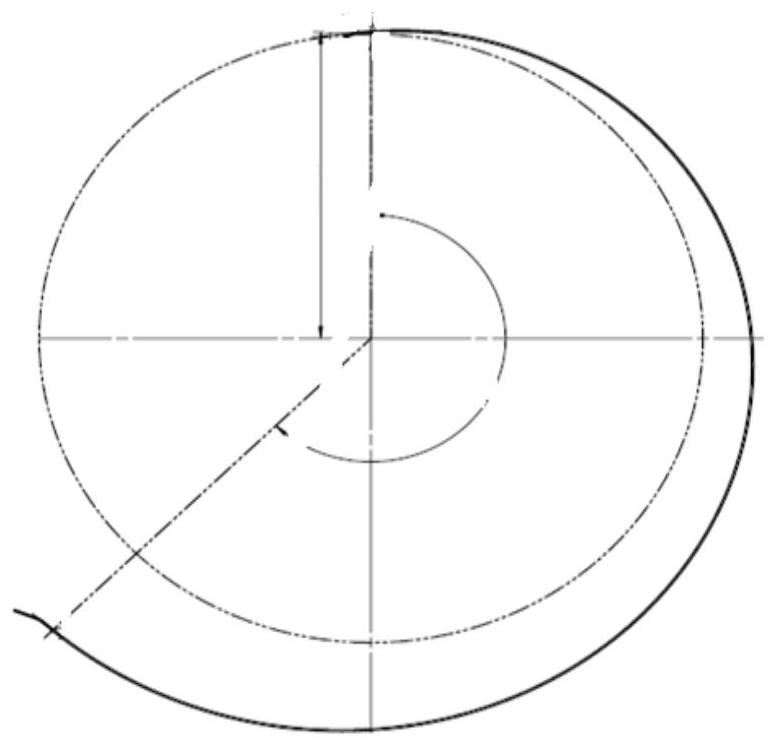

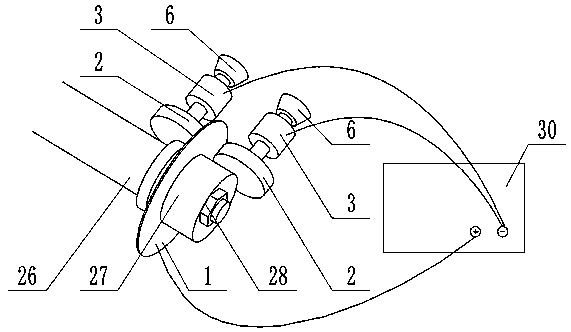

Microcapillary membrane assembling, positioning and welding tool based on C-shaped positioning wire

ActiveCN114473117AMeet the design requirementsPrecise positioningMetal working apparatusTubular articlesEngineeringMechanical engineering

The invention discloses a microcapillary membrane assembling, positioning and welding tool based on C-shaped positioning wires. The microcapillary membrane assembling, positioning and welding tool comprises an upper positioning mechanism, an upper positioning disc, a stand column, a lower positioning disc and a lower positioning mechanism. The upper positioning disc is supported on the lower positioning disc through three or more stand columns, and the three or more stand columns are evenly arranged in the circumferential direction of the disc body. An upper positioning mechanism and a lower positioning mechanism are installed on the upper positioning disc and the lower positioning disc respectively and used for being jointly connected with a plurality of C-shaped positioning wires and achieving tensioning of each C-shaped positioning wire. Wherein the C-shaped positioning wire is used for assembling, positioning and welding a microcapillary membrane, and the C-shaped positioning wire is formed by uniformly pressing a plurality of C-shaped grooves in the single side of a positioning wire blank along the axial direction through a C-shaped positioning wire forming tool.

Owner:BEIJING POWER MACHINERY INST

Bevel set product processing fixture

ActiveCN105171486BGood repeatabilityGood consistency of precisionWork clamping meansPositioning apparatusEconomic benefitsArchitectural engineering

The invention discloses a sloping cover sleeve product machining clamp. The sloping cover sleeve product machining clamp comprises a locating block, locating clamping jaws, a guide rod and a base, wherein the locating block comprises a lug boss raised in the middle and a supporting platform arranged on the edge; the locating block and the base are fixedly arranged, and center shafts of the locating block and the base are intersected; the base is fixedly connected to a machine tool; the lug boss is of a hollow structure, and through holes are formed in the side surfaces of the lug boss in directions vertical to the center shaft; the locating clamping jaws are arranged in the through holes, and first wedge-shaped surfaces are formed at one sides, which face to the center shaft of the lug boss, of the locating clamping jaws; and the guide rod is arranged in the hollow structure of the lug boss, the top of the guide rod is supported against the first wedge-shaped surfaces, and the bottom of the guide rod is connected to a feed shaft of the machine tool. The sloping cover sleeve product machining clamp has the advantages of good repeatability and accuracy consistency, high machining efficiency and reliability, good appearance quality of product surfaces, high size accuracy, good machining stability, high degree of automation, low cost, and easy maintenance and assembly and has good economic benefits.

Owner:武汉泛洲中越合金有限公司

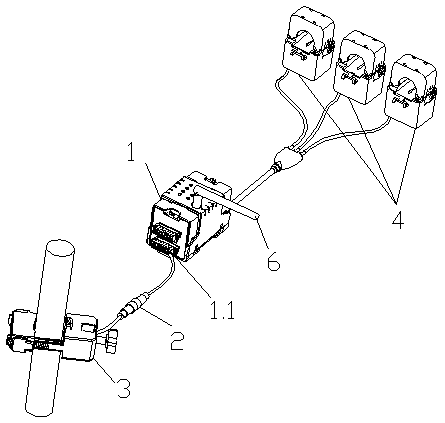

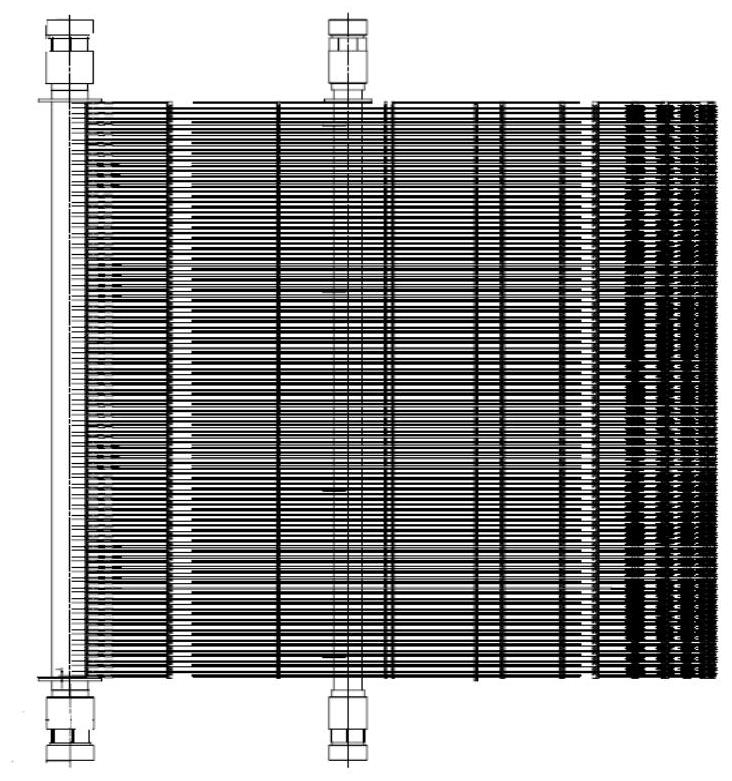

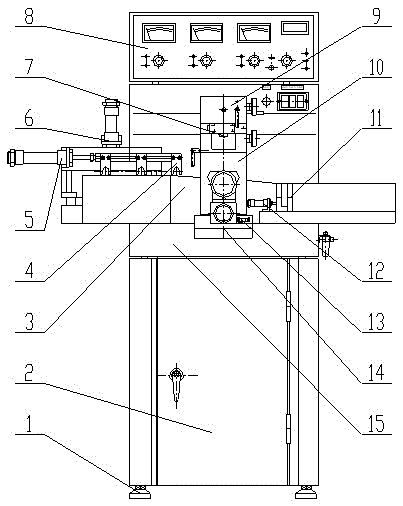

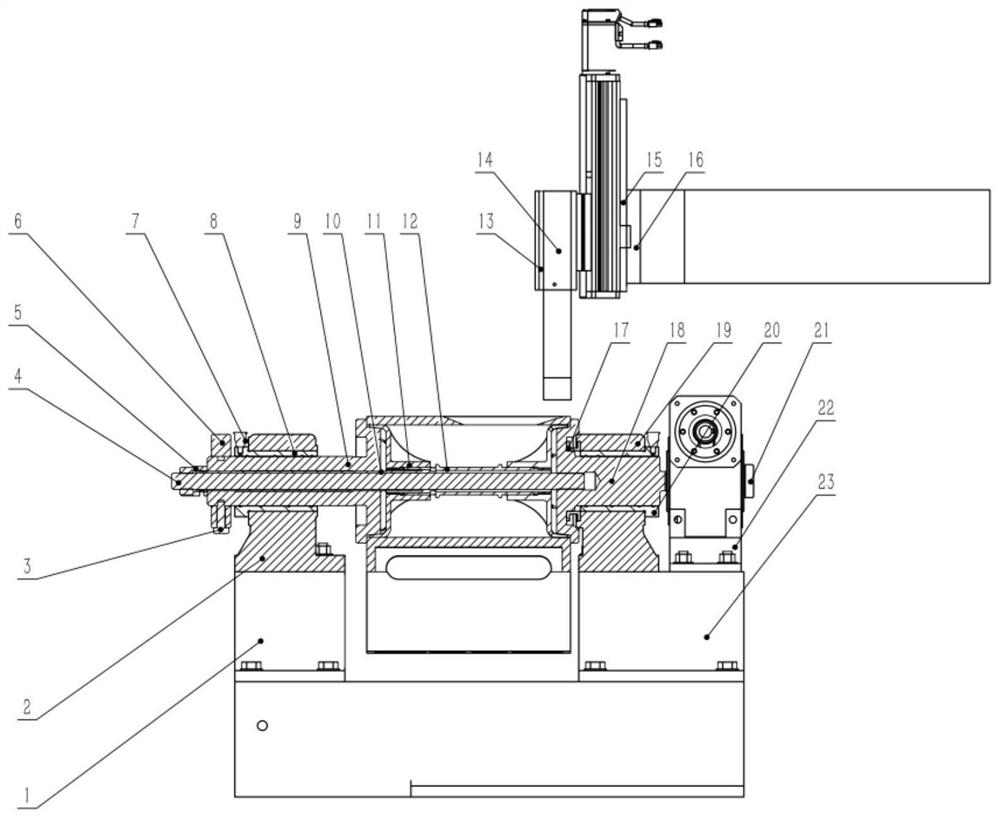

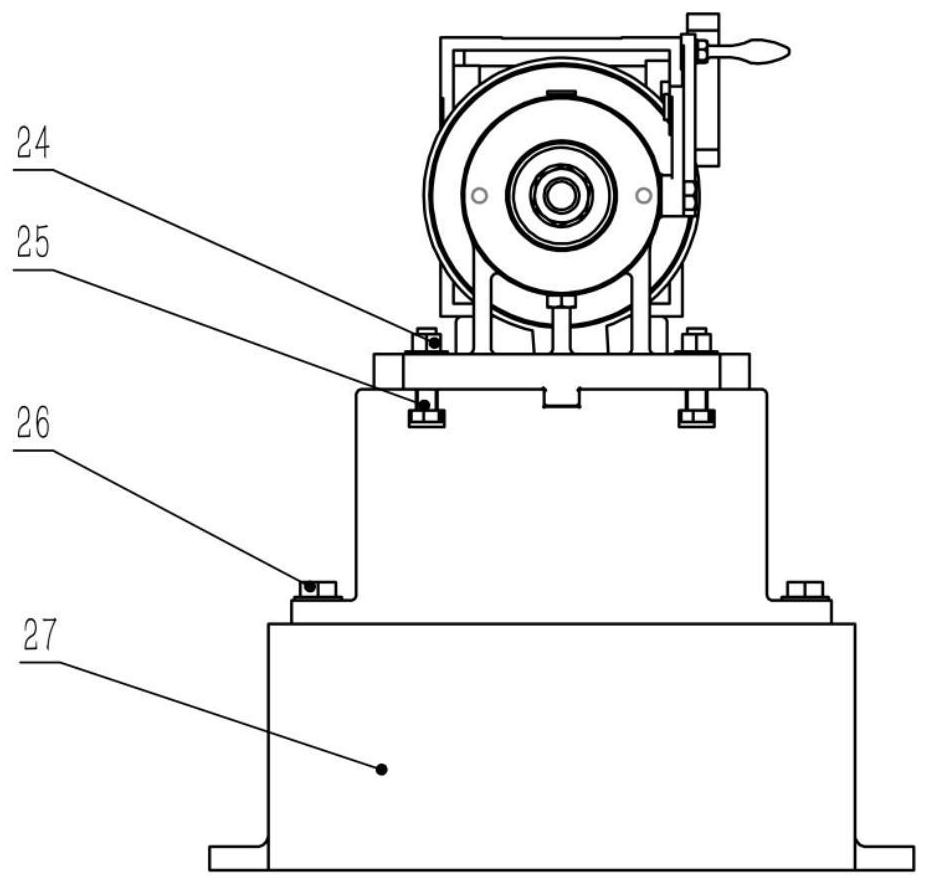

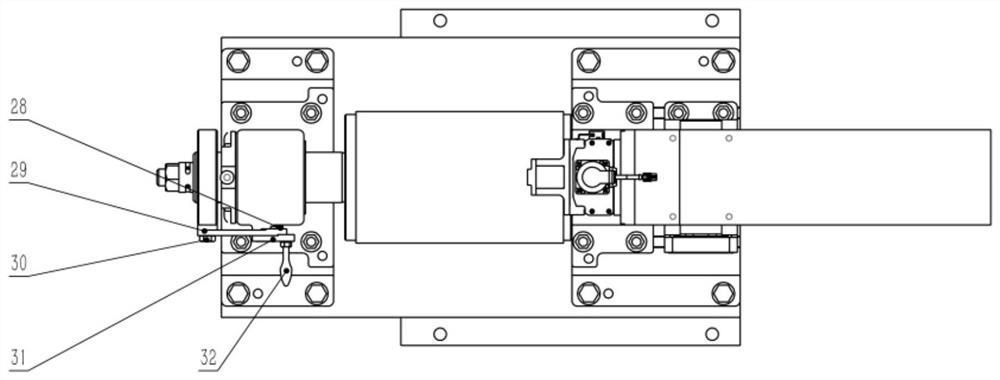

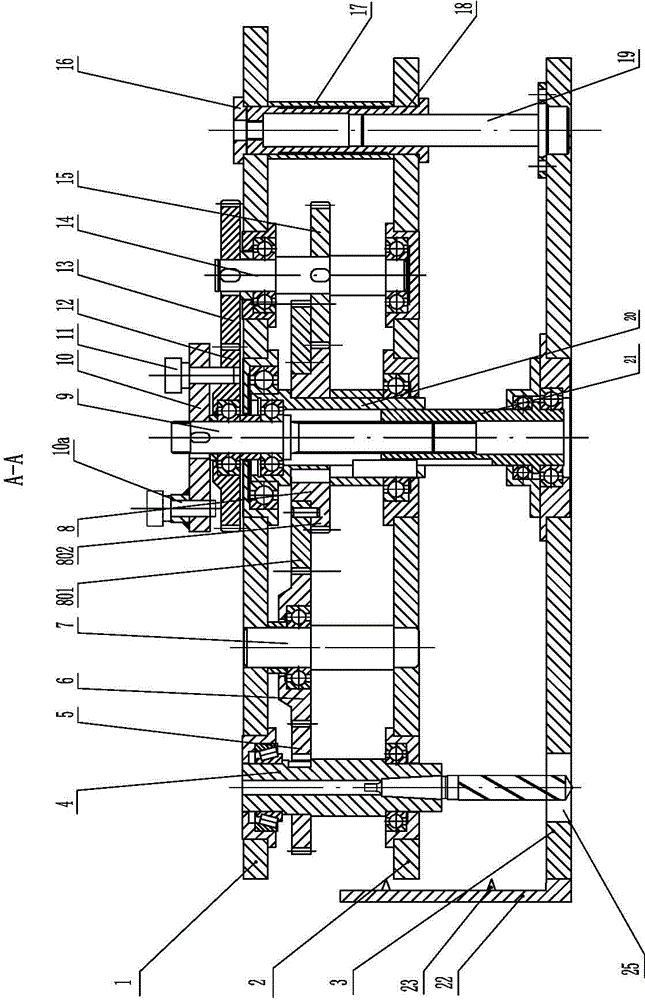

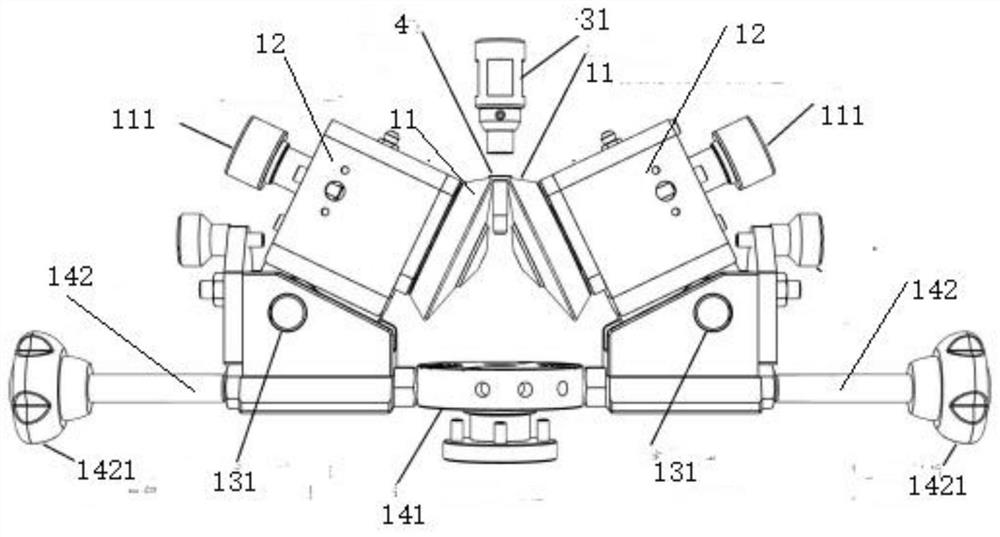

A bearing vibration and noise sorting machine

ActiveCN103934216BEasy to operateLow technical requirementsMachine bearings testingSortingManufacturing cost reductionHigh volume manufacturing

The invention provides a bearing vibrating noise sorting machine which comprises a machine body, wherein a base is arranged on the machine body; a main shaft oil supply device and a main shaft motor are arranged inside the machine body; a feeding channel and a discharging channel are formed on the base; a main shaft which is vertical to the feeding channel and the discharging channel is arranged between the feeding channel and the discharging channel and is connected with the main shaft motor; a sensor is arranged on the upper part of the main shaft; a loader base is arranged on the front part of the main shaft on the base; a turn-over device and a loader are arranged on the loader base; a measuring electric box is further arranged on the base. The bearing vibrating noise sorting machine is characterized in that operation is easy, the technical requirement on an operator is low, the product accuracy detection consistence is high, the quality is stable, the production efficiency and the product quality can be improved remarkably, the manufacturing cost is reduced, and automatic detection of bearing vibration and noise is realized through connection of an automatic bearing assembly line. Compared with the conventional vibration meter, the bearing vibrating noise sorting machine has the advantages that the production efficiency is improved greatly, and human interference factors are reduced. The bearing vibrating noise sorting machine is particularly suitable for high-accuracy large-scale production.

Owner:杭州人本轴承有限公司

A special proportional pressure control valve processing device for injection machine

ActiveCN103706810BHigh positioning accuracyGood consistency of precisionTurning machinesMachine controlEngineering

The invention provides a machining device for a proportional pressure control valve special for an injection machine, and belongs to the technical field of lathe machining. The machining device solves the technical problems that an existing control valve is complex in machining technology, low in production efficiency and poor in accuracy. The machining device for the proportional pressure control valve special for the injection machine comprises a fixed platform, an annular guide rail and a machining unit are arranged on the fixed platform, and a first installing unit and a second installing unit are arranged on the annular guide rail and respectively provided with a plurality of control valves; each control valve is provided with six faces, wherein three adjacent faces form a first set of machining faces, the other three faces form a second set of machining faces, the first installing unit and the second installing unit respectively revolve on the annular guide rail, and the first set of machining faces of the control valves in the first installing unit and the second set of machining faces of the control valves in the second installing unit are respectively machined through the machining unit. The machining device is high in production efficiency, simple in technology and accurate in positioning, and the machined control valves are good in uniformity of overall accuracy.

Owner:NINGBO HOYEA MACHINERY MFG

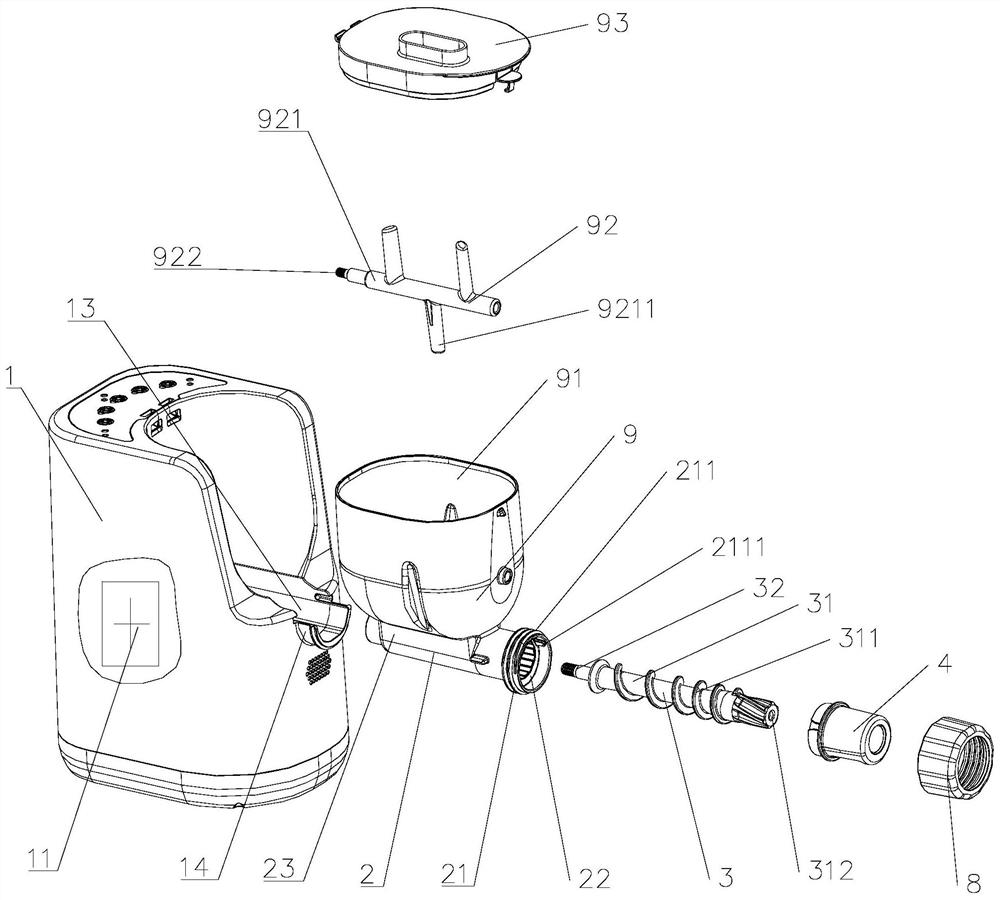

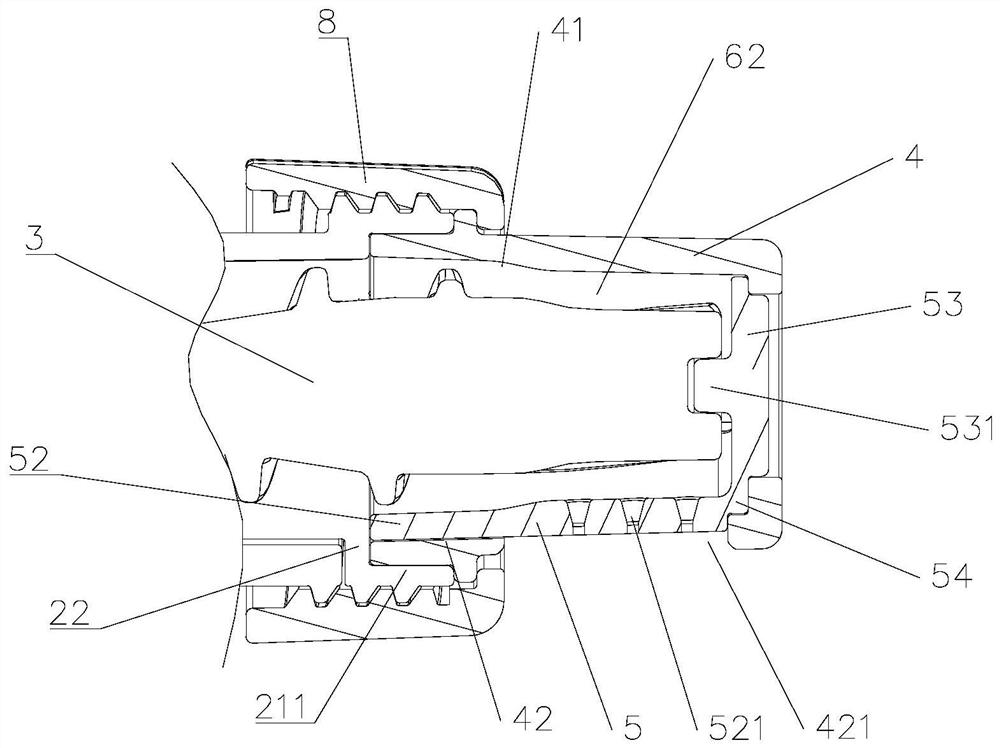

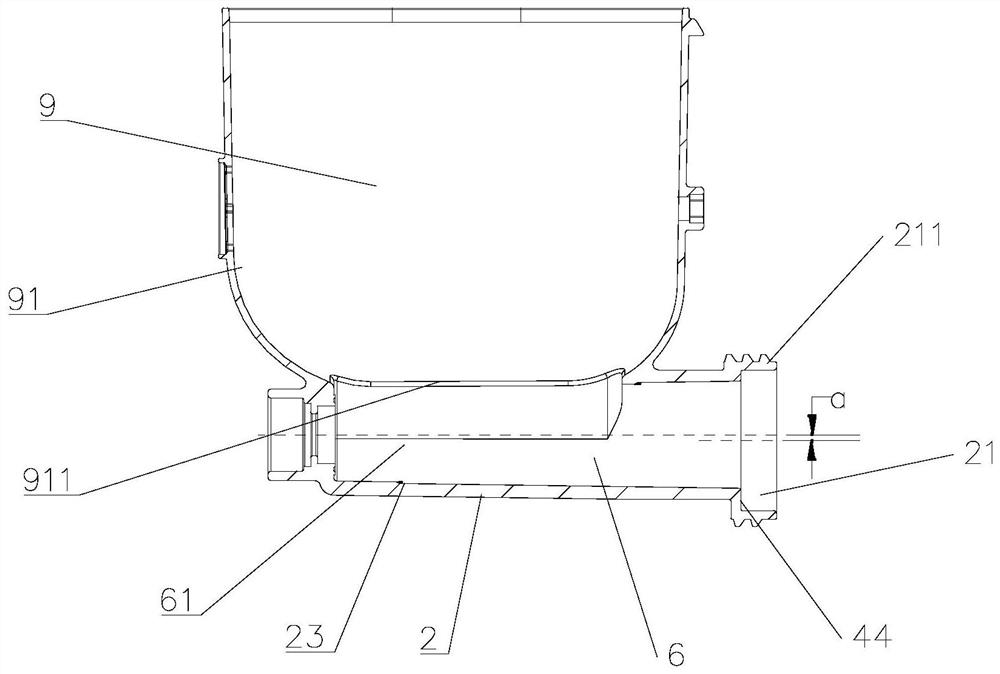

A smooth running pasta machine

ActiveCN112137449BFirmly connectedUniform and stable forceKitchen equipmentElectric machineryEngineering

The invention provides a pasta machine with smooth operation, which includes a machine base, an extruding assembly arranged on the machine base, a motor is arranged in the machine base, the extruding assembly includes an extruding cylinder, and screw, a die head assembly arranged at the front end of the extrusion barrel, the die head assembly includes a die head bracket and a die head, wherein the extrusion assembly includes an eccentric structure, and the eccentric structure is offset relative to the central axis of the screw rod , the extrusion cylinder and the die assembly are connected through an eccentric structure, so that the extrusion cylinder and the die assembly are surrounded to form a concentric material transportation channel, so that the internal force of the extrusion assembly is balanced and stable, and at the same time, the extrusion assembly is partially reinforced. With the connection structure, the surface water mixture runs stably in the material transportation channel, and the surface is comfortable.

Owner:JOYOUNG CO LTD

A special planer for slide valve processing and its processing method

ActiveCN113510285BSimple structureAchieve interval exercisePlaning/slotting toolsPlaning/slotting machinesSpool valveLinear motion

Owner:TAIZHOU XINYU VACUUM EQUIP MFG CO LTD

Multi-hole drilling transmission mechanism

ActiveCN103182551BHigh transmission precisionEasy to installBoring/drilling componentsEngineeringScrew thread

The invention relates to a multi-hole drilling transmission mechanism which can be used for processing a plurality of holes at the same time, belonging to the technical field of machining; the multi-hole drilling transmission mechanism comprises an upper plate, a middle plate and a lower plate, wherein a plurality of drilling rod shafts are respectively and rotatablely supported on the middle plate and the upper plate; the drilling rod shafts are respectively and fixedly provided with a drill bit; the lower plate is provided with drilling rod holes, and the drill bits can respectively and conveniently pass through the drilling rod holes in a corresponding way; the middle plate and the upper plate are also respectively provided with a plurality of support sleeve mechanisms which are used for relatively fixing the upper plate and the middle plate; the lower plate is provided with a plurality of guide pillars which are respectively and correspondingly matched with inner holes of the support sleeve mechanism up and down in a sliding way; two hollow shaft sleeves are respectively and rotatablely supported at the centers of the middle plate and the upper plate; two thread guide sleeves which are respectively sheathed in the hollow shaft sleeves in a matching way and can synchronously rotate together with the hollow shaft sleeves are rotatablely supported on the lower plate; a lifting screw rod shaft matched with the thread in each thread guide sleeve passes through each hollow shaft sleeve; the upper ends of the lifting screw rod shafts are connected with the upper plate in a rotary support way; the hollow shaft sleeves are connected with the drilling rod shafts by a main transmission mechanism in a transmission way; and hollow shaft sleeves are connected with the lifting screw rod shafts by a feeding mechanism in a transmission way.

Owner:YANGLI GRP CORP LTD

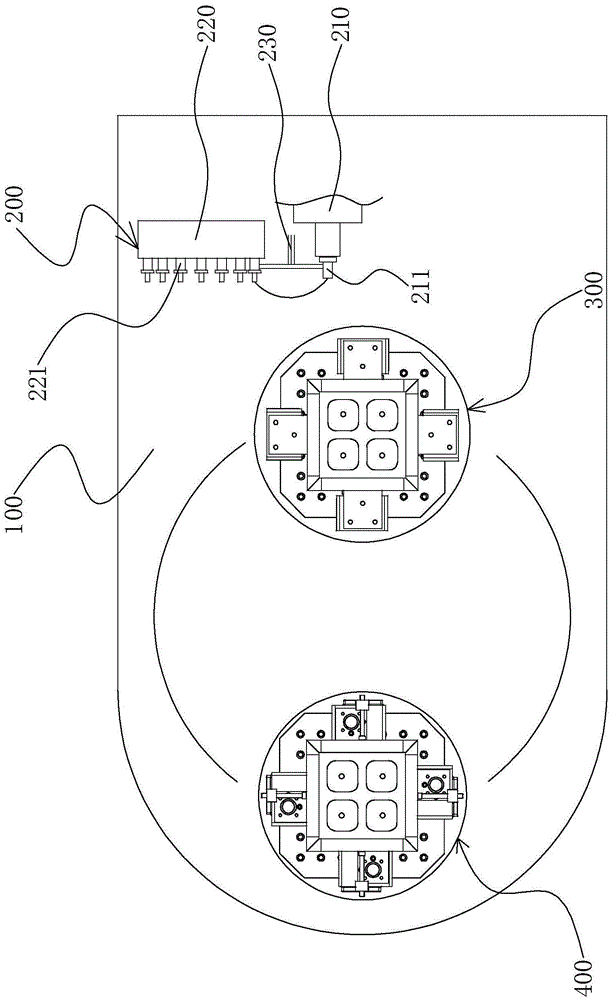

Pressure valve

InactiveCN109955085AHigh positioning accuracyGood consistency of precisionMetal working apparatusPositioning apparatusMachine controlEngineering

The invention provides a pressure valve and belongs to the technical field of lathe machining. The technical problems that an existing control valve machining process is complex, the production efficiency is low, and the locating precision is poor are solved. The pressure valve comprises a fixed platform, an annular guide rail and a machining unit are arranged on the fixed platform, and a first mounting unit and a second mounting unit are arranged on the annular guide rail. The first mounting unit and the second mounting unit are provided with a plurality of control valves correspondingly, andeach control valve is provided with six faces, wherein three adjacent faces form a first set of machining faces, and the other three faces form a second set of machining faces. The first mounting unit and the second mounting unit revolute on the annular guide rail, and the first sets of machining faces of the control valves in the first mounting unit and the second sets of machining faces of thecontrol valves in the second mounting unit are machined by the machining unit. The pressure valve is high in production efficiency, simple in process, accurate in positioning and good overall precision consistency of the machined control valves.

Owner:郑霄

A processing device for processing anti-pinch grooves of ultra-thin diamond cutting discs

Owner:HENAN POLYTECHNIC UNIV

Machining method of the half case of the compressor of the aero-engine

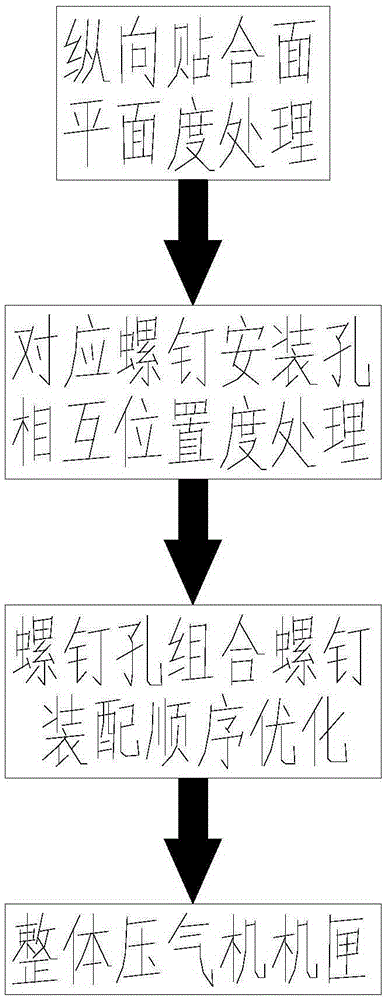

The invention discloses a method for machining half-and-half casings of a gas compressor of an aero-engine. The method comprises the following steps that a, flatness processing is carried out on the longitudinal faying surfaces of the two half-and-half casings, wherein plane processing is carried out on the two half-and-half casings after rough machining in a mode that the base levels abut against each other so as to ensure the flatness of the longitudinal faying surfaces of the two half-and-half casings; b, the mutual location degree processing is carried out on corresponding screw installation holes in the longitudinal faying surfaces of the two half-and-half casings, wherein finish machining is carried out on at least part of screw installation holes which are correspondingly formed, and screws provided with locating cylindrical surfaces are arranged in the screw installation holes after the finish machining in a matched mode; c, the screws are assembled in the screw installation holes of the longitudinal faying surfaces of the two half-and-half casings according to the preset optimized assembly sequence; d, the two half-and-half casings form an integrated casing of the gas compressor. The method for machining the half-and-half casings of the gas compressor of the aero-engine adopts the half-and-half casing combined deformation control technology, combined deformation of the half-and-half casings is eliminated, the accuracy of consistency of repeated combination is good, and the application prospects are wide.

Owner:CHINA HANGFA SOUTH IND CO LTD

Two-wheel fillet rolling strengthening machine used for bolt rolling strengthening

PendingCN113231789AGood consistency of precisionLow manufacturing costStructural engineeringManufacturing engineering

The invention discloses a two-wheel fillet rolling strengthening machine used for bolt rolling strengthening. The fillet rolling strengthening machine comprises a rack, and a feeding device, a rolling device, a rotary driving head device and a control system are arranged on the rack. The rolling device comprises two rolling wheels which are symmetrically arranged, and the distance of the two rolling wheels is adjustable. The feeding device further comprises a feeding positioning device, the feeding positioning device is used for positioning a bolt transferred by a feeding transferring device between the two rolling wheels, the rotary driving head device drives the positioned bolt to rotate, and the two rolling wheels carry out fillet rolling strengthening on the bolt along with the rotating bolt. According to the two-wheel fillet rolling strengthening machine, arc rolling strengthening of the bolt can be realized, precision consistency is good, the manufacturing cost is greatly reduced, a pin shaft and rolling wheel inner holes are not prone to being worn, and meanwhile the radial run-out and the end face run-out of the rolling wheels are reduced to 0.01 mm.

Owner:艾洛钛紧固件(上海)有限公司

Machining Technology of Rotor Shaft and Its Rotor Shaft

The invention discloses a rotor shaft processing technology, which is characterized in that the following steps are performed in sequence: punching and forming a blank; wearing and grinding: rough turning A shaft section and B shaft section; quenching and tempering; fine grinding; finishing turning A shaft segment and B shaft segment; taper grinding; high-frequency heat treatment and tempering for the tapered part and the small shaft part; gear hobbing; high-frequency heat treatment and tempering for the formed teeth to form a semi-finished product; grinding the semi-finished product to the third gear; Ribbon punching; anti-rust treatment and inspection. The invention also discloses a rotor shaft. The equipment of the invention is mostly automatic operation, the production efficiency is improved, the production safety is good, the quality of the produced rotor shaft is improved, the product accuracy is consistent, the waste products are reduced by more than 60% compared with the original process, and it has the advantages of saving raw materials, reducing production costs, and saving energy. Advantages of energy consumption.

Owner:上海秋乐实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com