Sloping cover sleeve product machining clamp

A technology of products and bevels, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high equipment investment cost, inability to directly process bevel set products, and affecting production efficiency, so as to achieve convenient maintenance and assembly, Simple structure and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] like figure 1 shown, combined with Image 6 , The present invention provides a product processing fixture for slope sleeves, which includes a positioning block 1 , positioning claws 2 , guide rods 3 , and a base 4 .

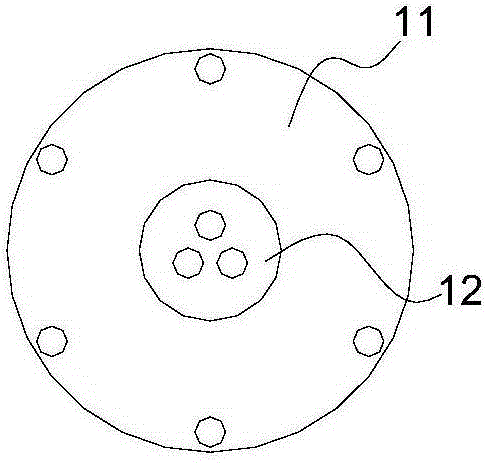

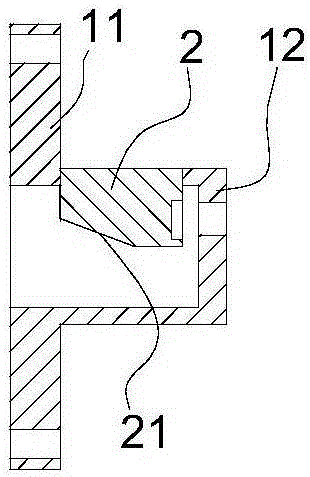

[0016] like figure 2 shown, combined with image 3 , the positioning block 1 includes a boss 12 protruding in the middle and a supporting platform 11 at the edge. In this way, the support platform 11 can support and position the inner circle of the inclined-surface sleeve product. Preferably, several positioning bosses 13 are symmetrically arranged on the support platform 11 . In this way, the contact area between the positioning block 1 and the slope cover product can be reduced, preventing damage to the appearance of the slope cover product.

[0017] The positioning block 1 and the base 4 are fixedly arranged and their central axes intersect, and the base 4 is fixedly connected with the machine tool. Accompanying drawing omits machine tool. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com