Cathode for CNC electrolytic turning and boring of pressure storage cavity

A technology of electrolytic car and pressure storage chamber, which is applied in the direction of processing electrodes, electric processing equipment, electrode manufacturing, etc., which can solve the problems of affecting processing accuracy, cavity wall fatigue failure, tool tip vibration, etc., and achieve good surface quality and no processing Residual stress, effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

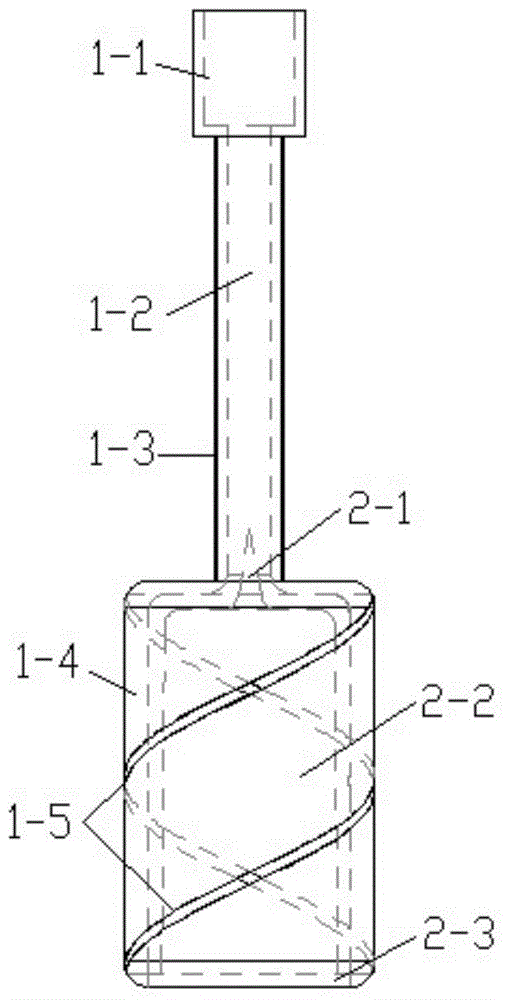

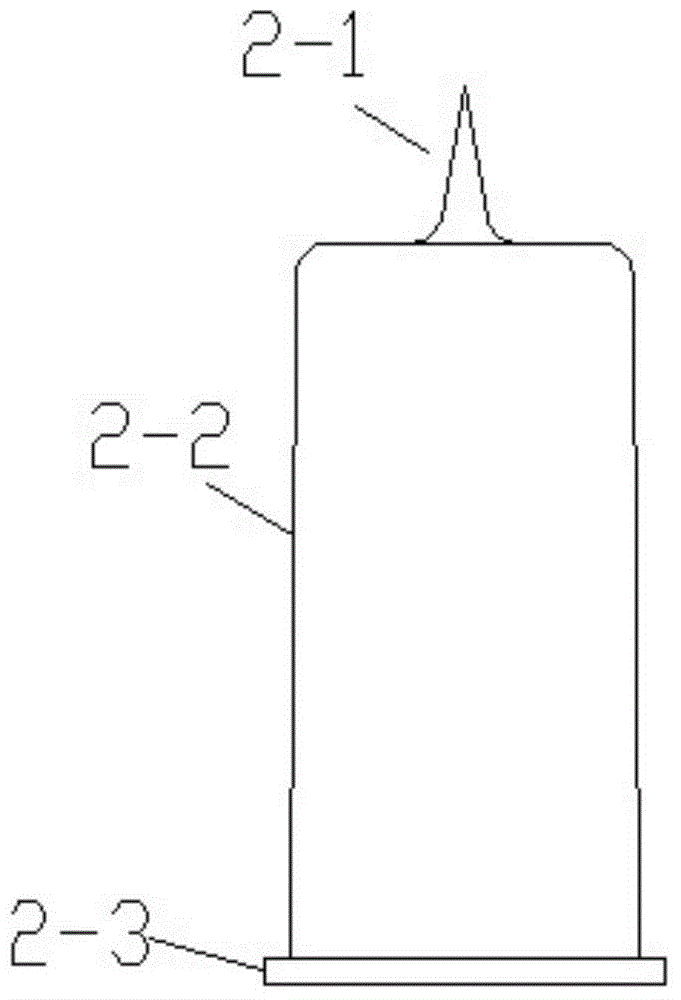

[0037] A cathode for CNC electrolytic turning and boring processing of a pressure storage chamber in this embodiment provides a processing such as Figure 4The special electrolytic cathode of the pressure storage container 3 shown, this type of pressure storage container 3 includes an inlet cavity 3-2 and a pressure storage cavity 3-1 whose radial dimension is larger than the radial dimension of the inlet cavity 3-2, and is bored by CNC electrolytic turning Hole processing replaces the traditional mechanical boring process, the boring cathode has no contact with the inner wall of the pressure storage chamber 3-1, and there is no machining residual stress on the wall of the pressure storage chamber 3-1, the machining accuracy is high, and the machined surface quality is good without microcracks , the processed pressure storage chamber 3-1 has a large pressure bearing and a long service life. It includes a cathode body 1 and a shunt block 2. The cathode body 1 is a rotating body ...

Embodiment 2

[0041] The basic structure of the cathode for CNC electrolytic turning and boring of a pressure storage cavity in this embodiment is the same as in Embodiment 1, except that the side taper angle of the conical rotating body 2-2 in this embodiment is 90° , the side taper angle refers to the angle between the axis section generatrix of the conical revolving body 2-2 and the bottom plane of the conical revolving body 2-2, that is, the conical revolving body 2-2 is substantially a cylinder and is easy to process Manufacture; the material of the shunt block 2 is plastic, and the plastic has relatively high strength. In addition, the connection mode between the positioning cylinder 2-3 and the lower end of the working part 1-4 in this embodiment is different from that of embodiment 1. The outside of the positioning cylinder 2-3 in this embodiment is provided with external threads, and the working part The bottom of the inner hole of 1-4 is provided with an internal thread matching t...

Embodiment 3

[0043] The basic structure of the cathode for CNC electrolytic turning and boring of a pressure storage cavity in this embodiment is the same as that in Embodiment 1, except that the side taper angle of the conical rotating body 2-2 in this embodiment is 75° , the side taper angle refers to the angle between the busbar of the axial section of the conical rotating body 2-2 and the bottom plane of the conical rotating body 2-2; the material of the diverter block 2 is machinable ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com