Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

331results about How to "Uniform clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ring binder mechanism

Owner:WORLD WIDE STATIONARY MFG CO LTD

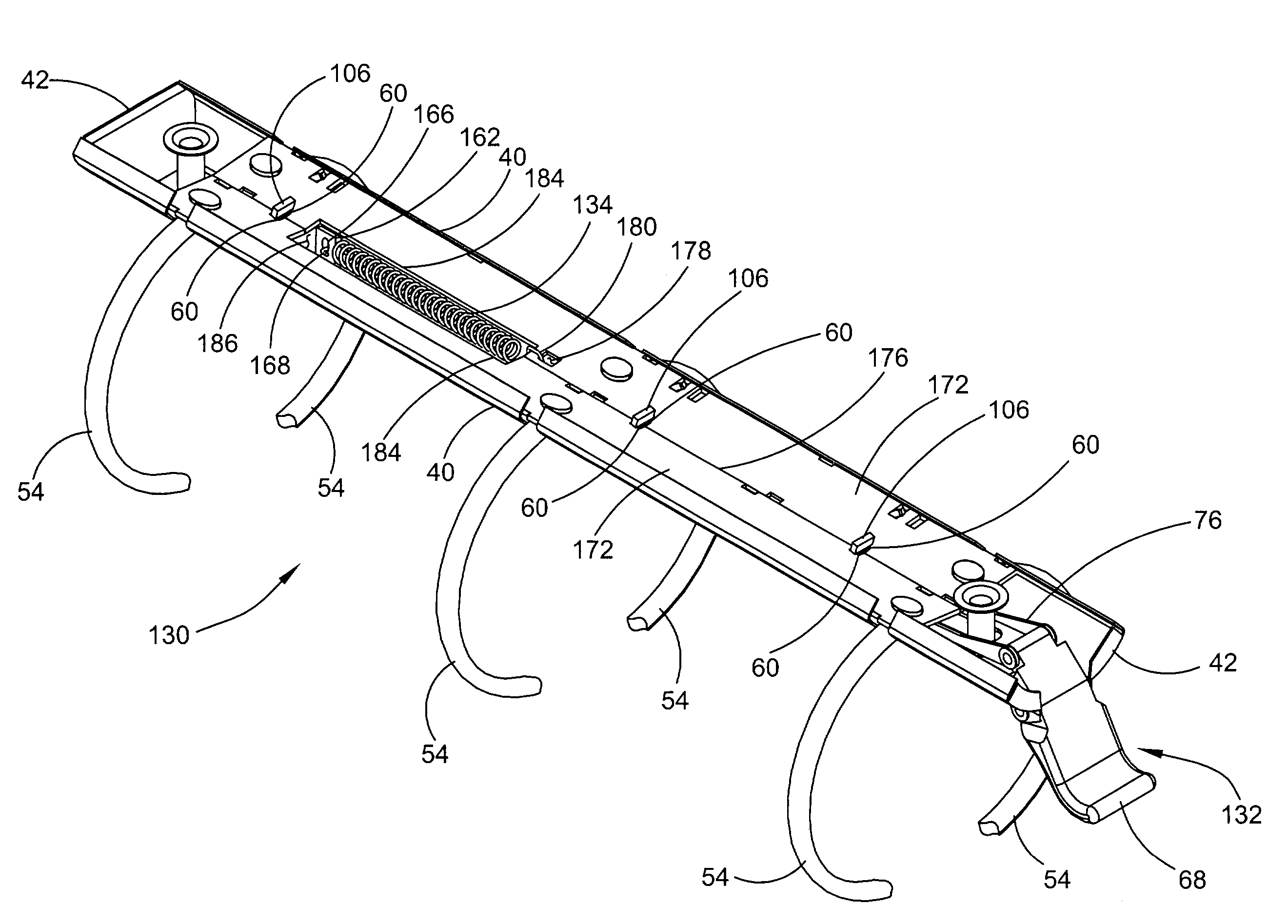

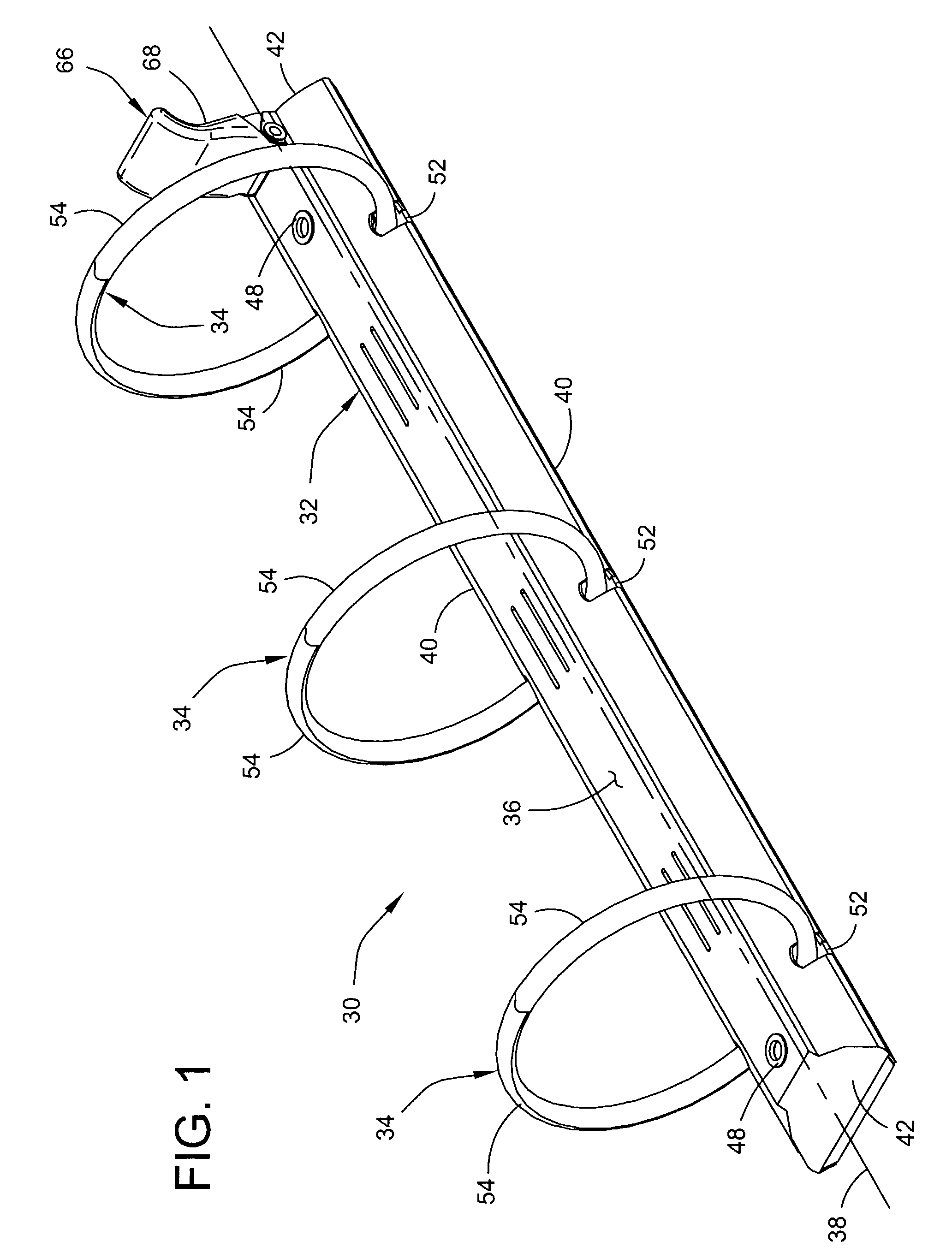

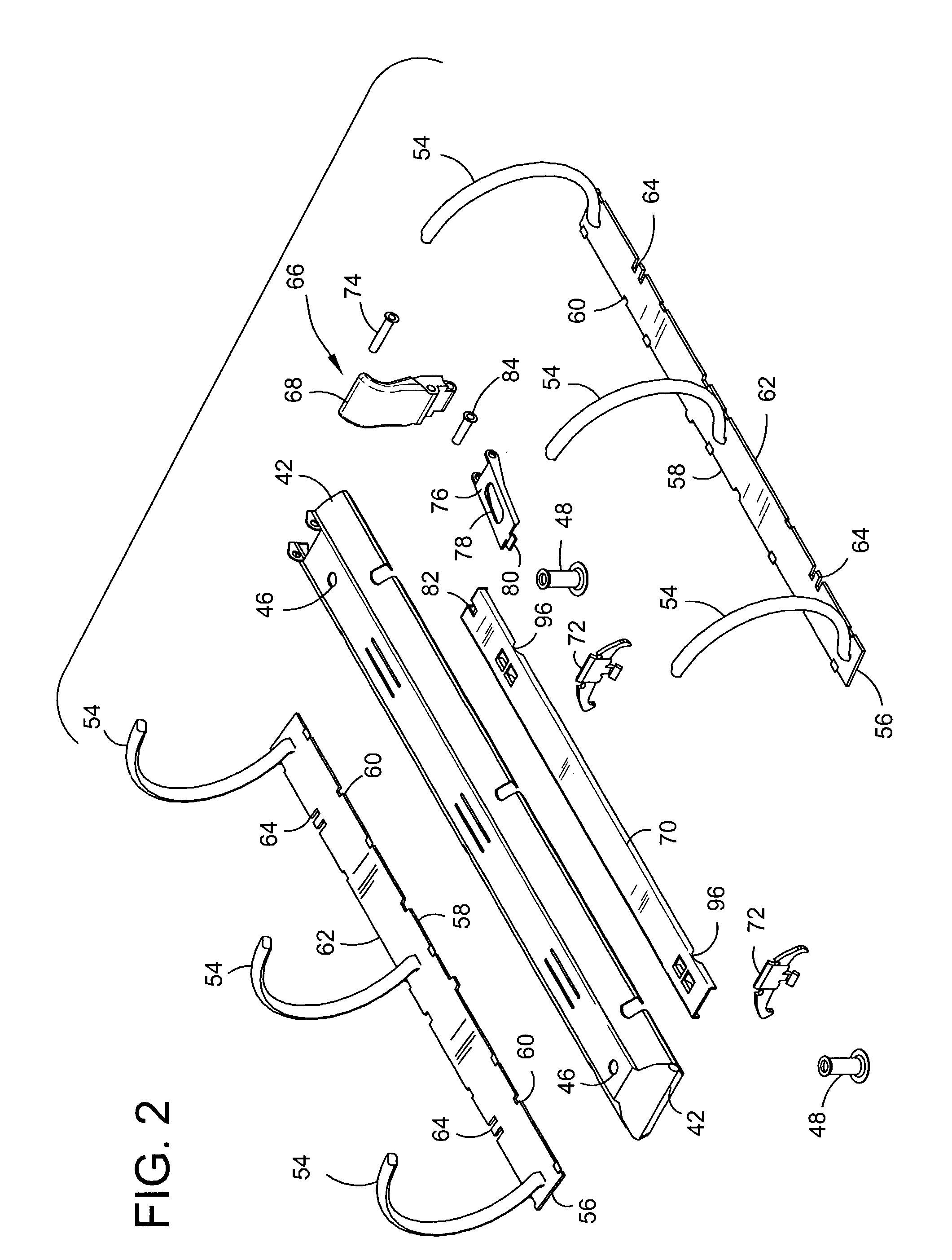

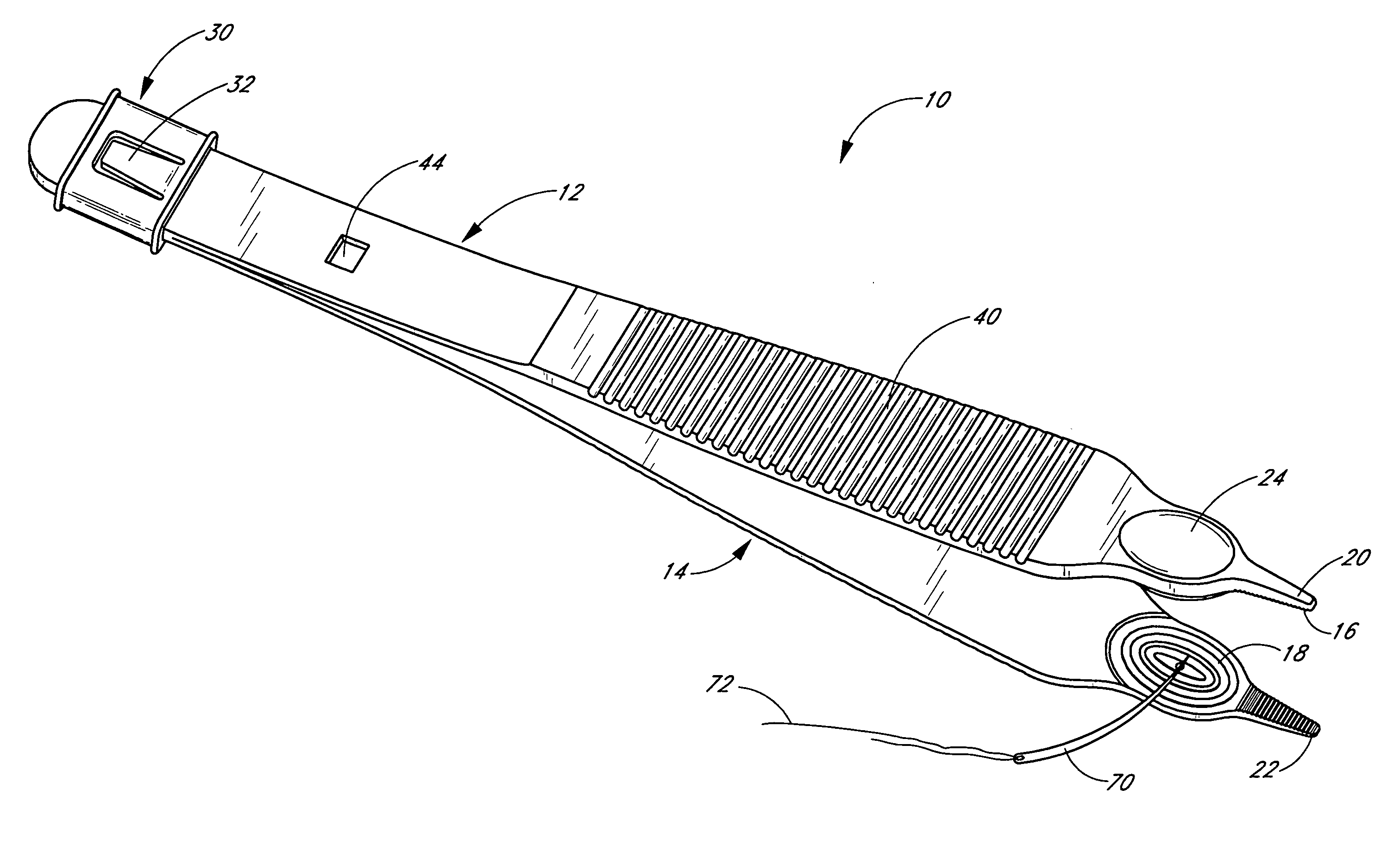

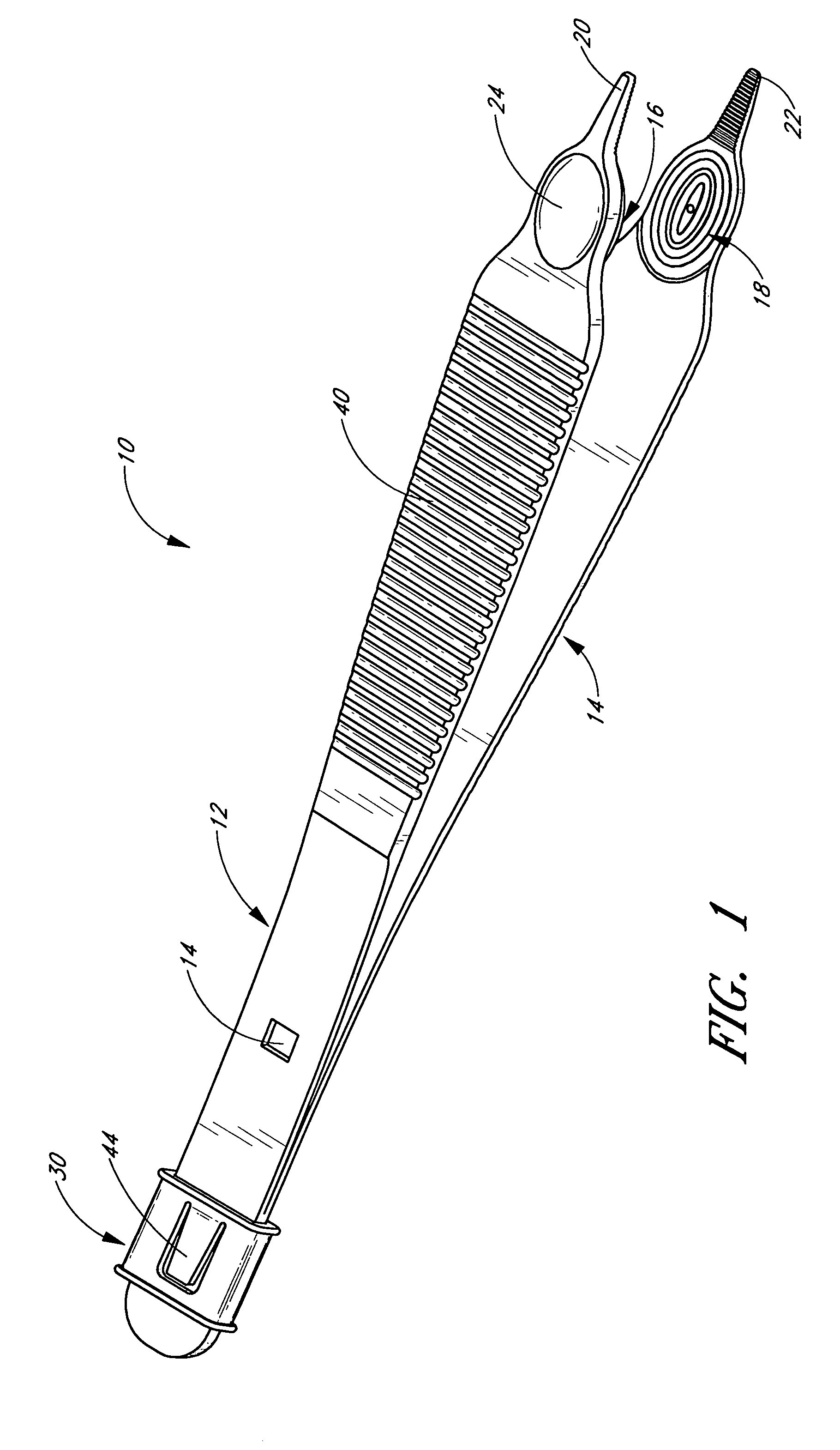

Safety surgical forceps

InactiveUS20050125013A1Reduce the possibilityEasy to useSuture equipmentsSurgical furnitureSuture needlesForceps

Surgical forceps, which have first and second elongate arms, are provided with gripping pads near the distal ends of the arms. The gripping pads are resilient so as to conform to the shape of an object being gripped between the arms. The surgical forceps is preferably provided with a locking mechanism for maintaining the forceps in the closed position in the absence of a gripping force. The surgical forceps are particularly well suited for gripping a suturing needle in a secure and predictable manner. The gripping pads are preferably sized for enclosing the distal pointed tip of the suturing needle. As a result, the forceps may be locked in the closed position with the needle tip fully enclosed for safe disposal.

Owner:KESSLER ALAN

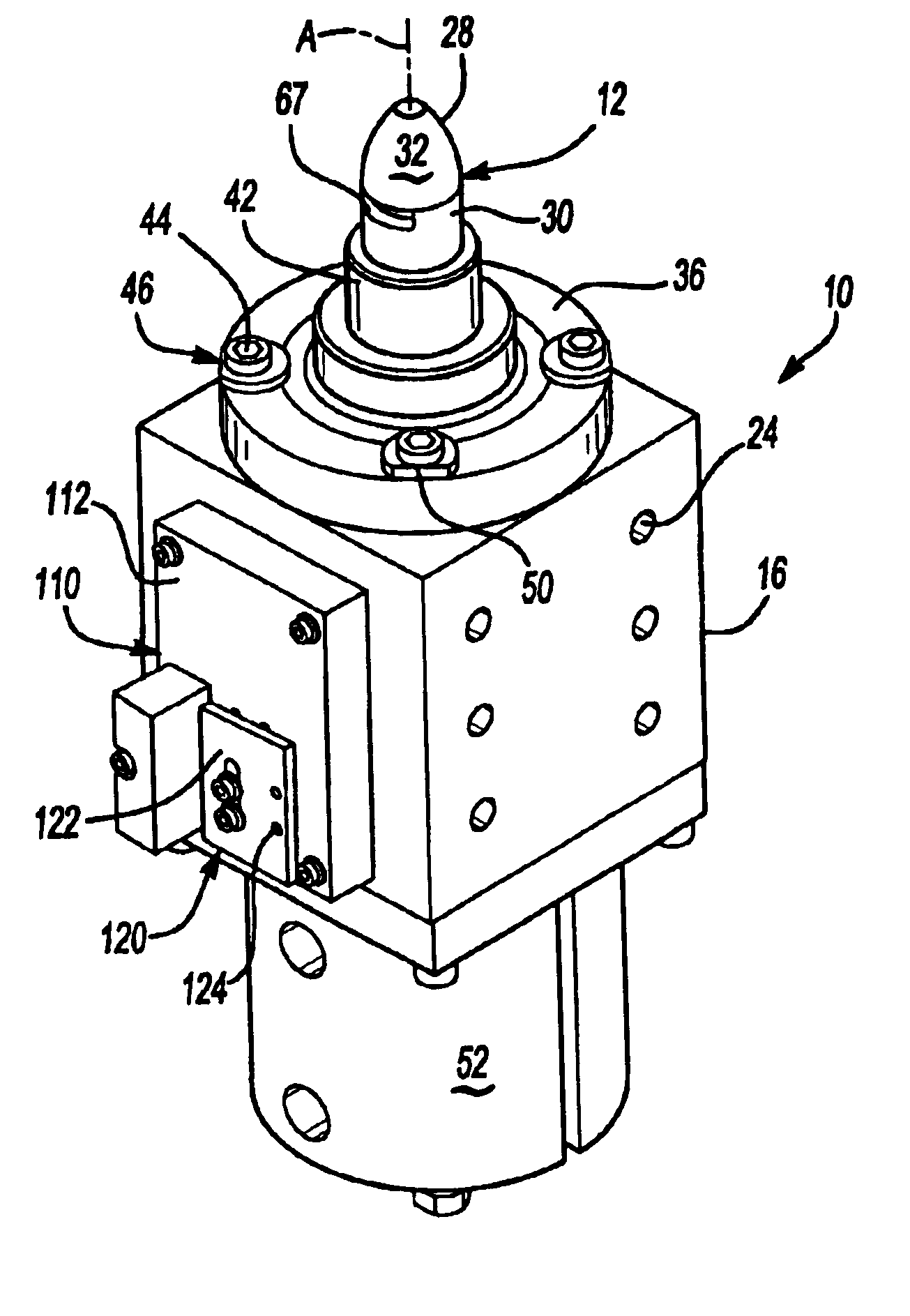

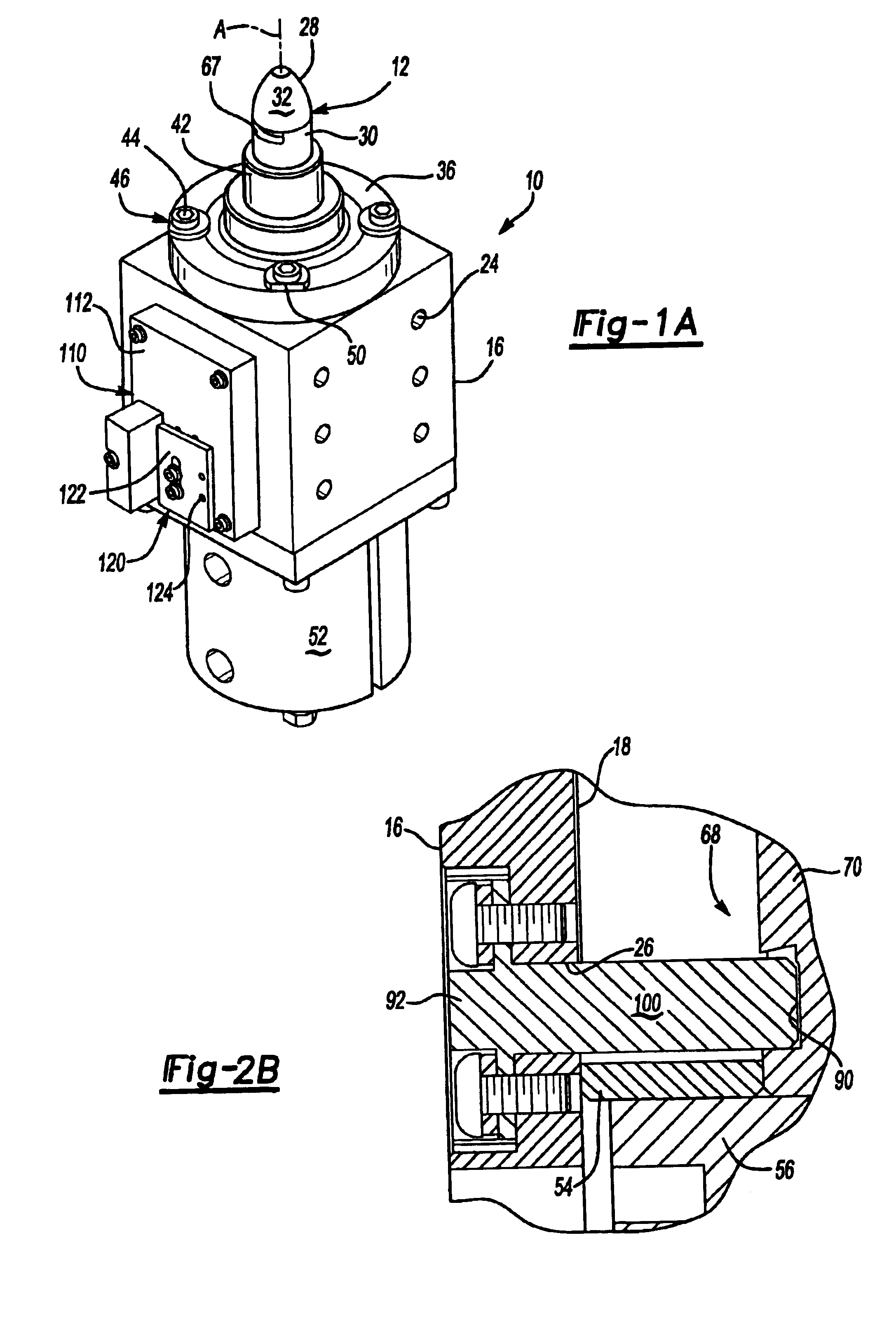

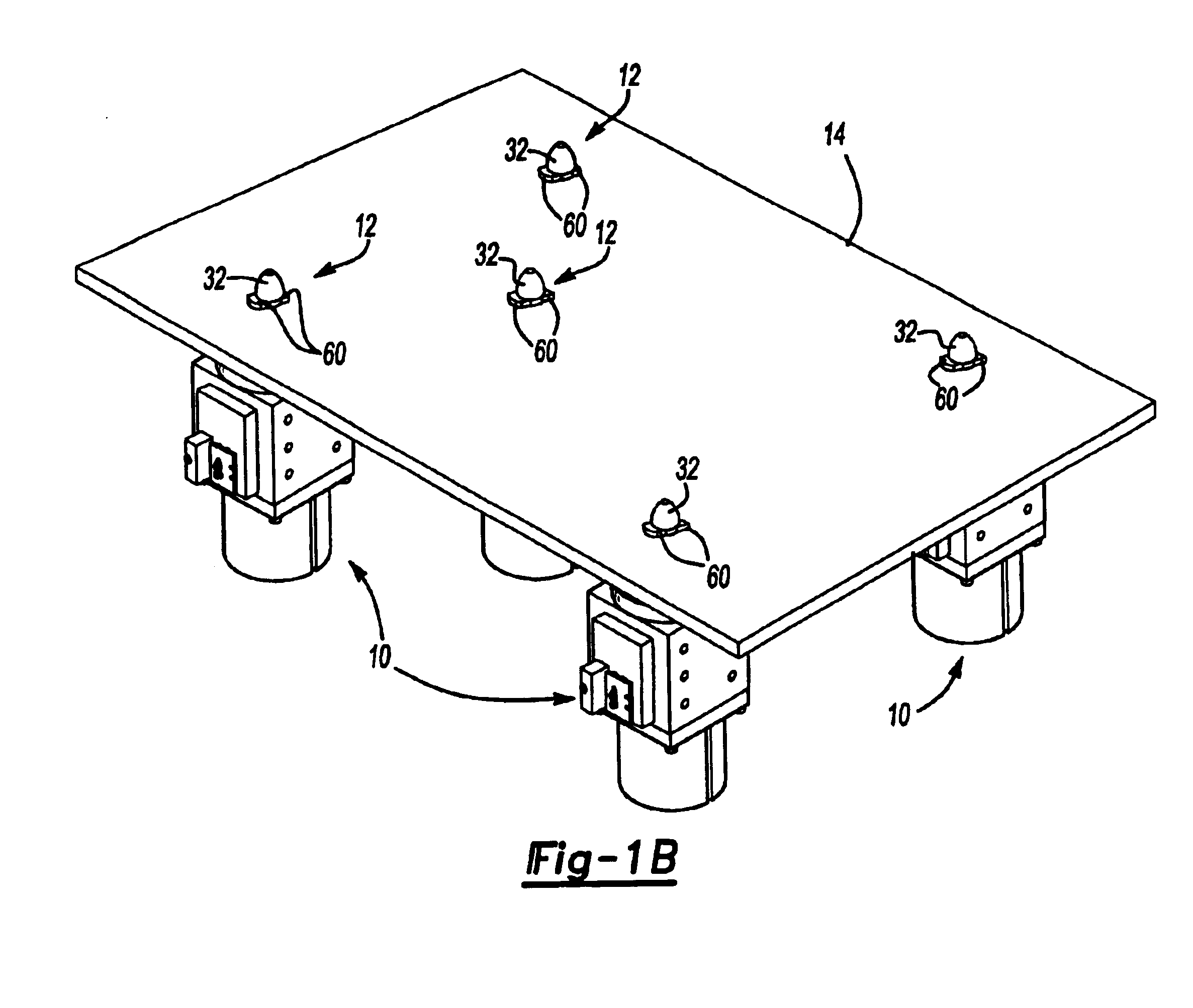

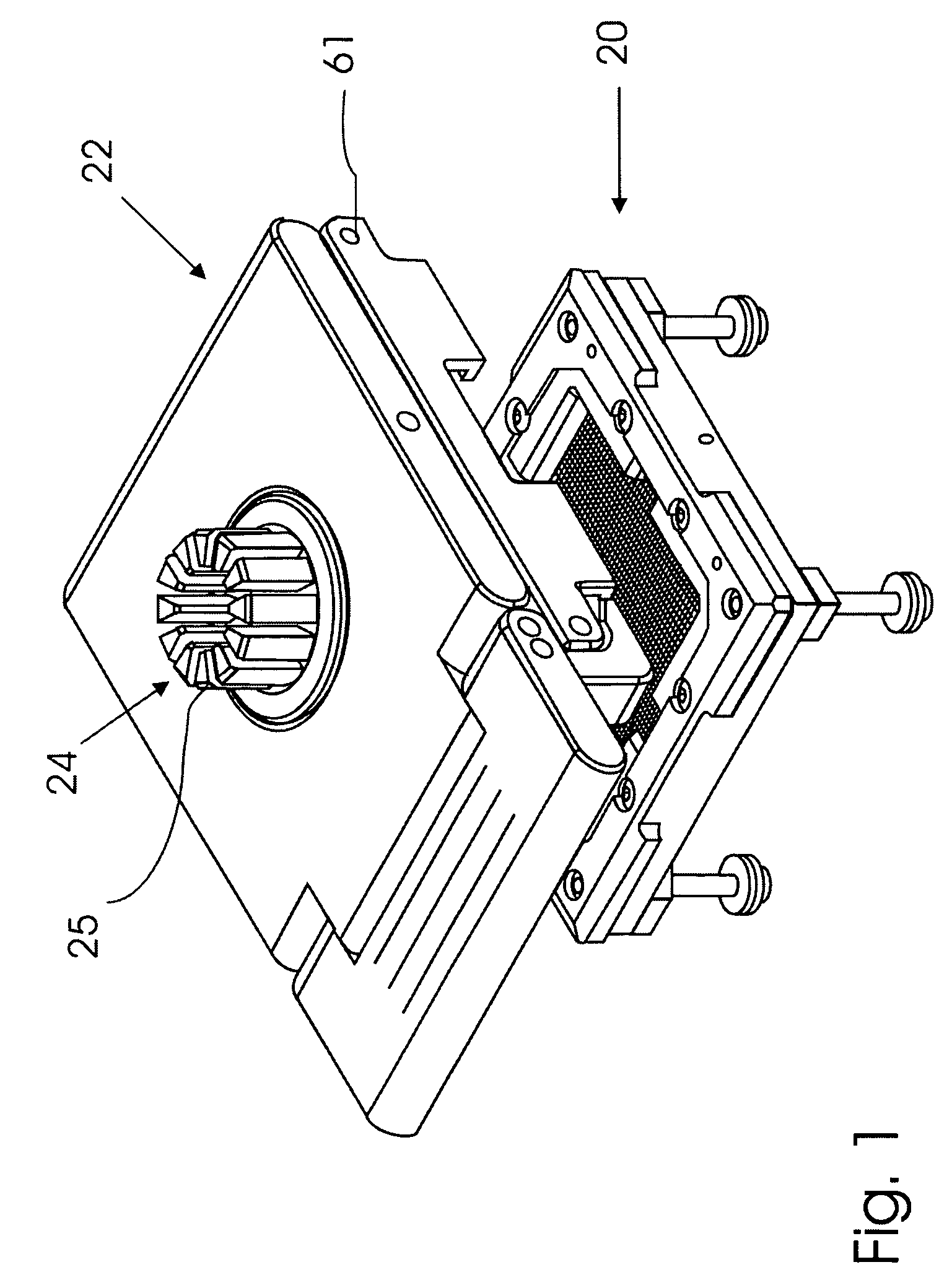

Locating assembly having an extendable clamping finger

InactiveUS6913254B2Work faster and moreEasy to operatePrecision positioning equipmentDovetailed workEngineeringActuator

The subject invention provides a locating assembly for centering and securing a work piece. The locating assembly includes a body. The body defines an internal cavity and an opening from the cavity to the exterior of the body. A locating pin is disposed in the cavity and extends along an axis out of the opening. An actuator moves the locating pin rectilinearly along the axis. A pair of fingers are supported by the locating pin and move radially into and out of the locating pin, transversely to the axis. A central post rotates in response to the rectilinear movement of the locating pin. A dowel extends from an end of the central post into a slot in the finger. The central post moves the dowel in an arcuate path through the slot to radially move the finger simultaneous with the rectilinear movement of the locating pin.

Owner:WELKER BEARING

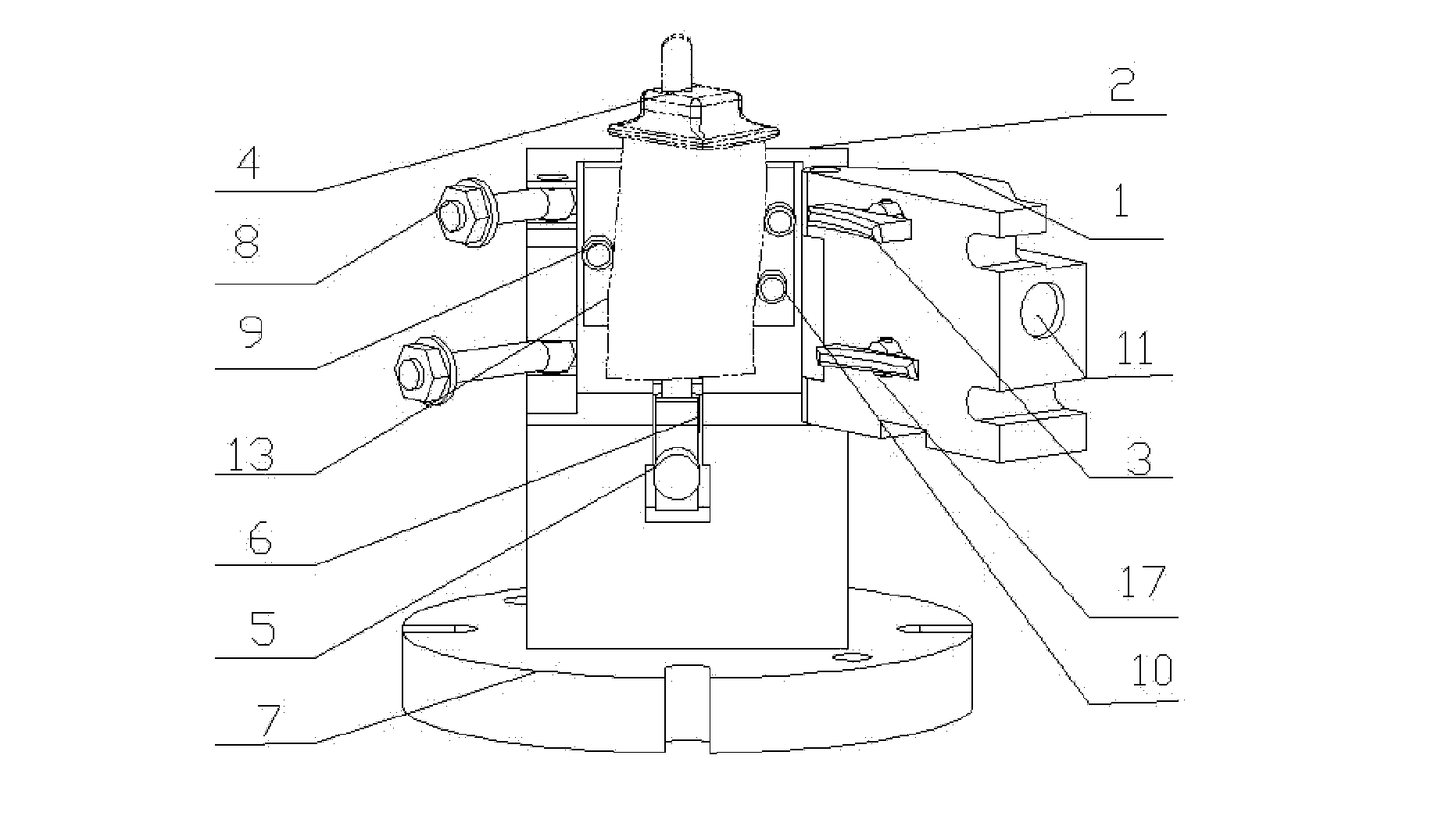

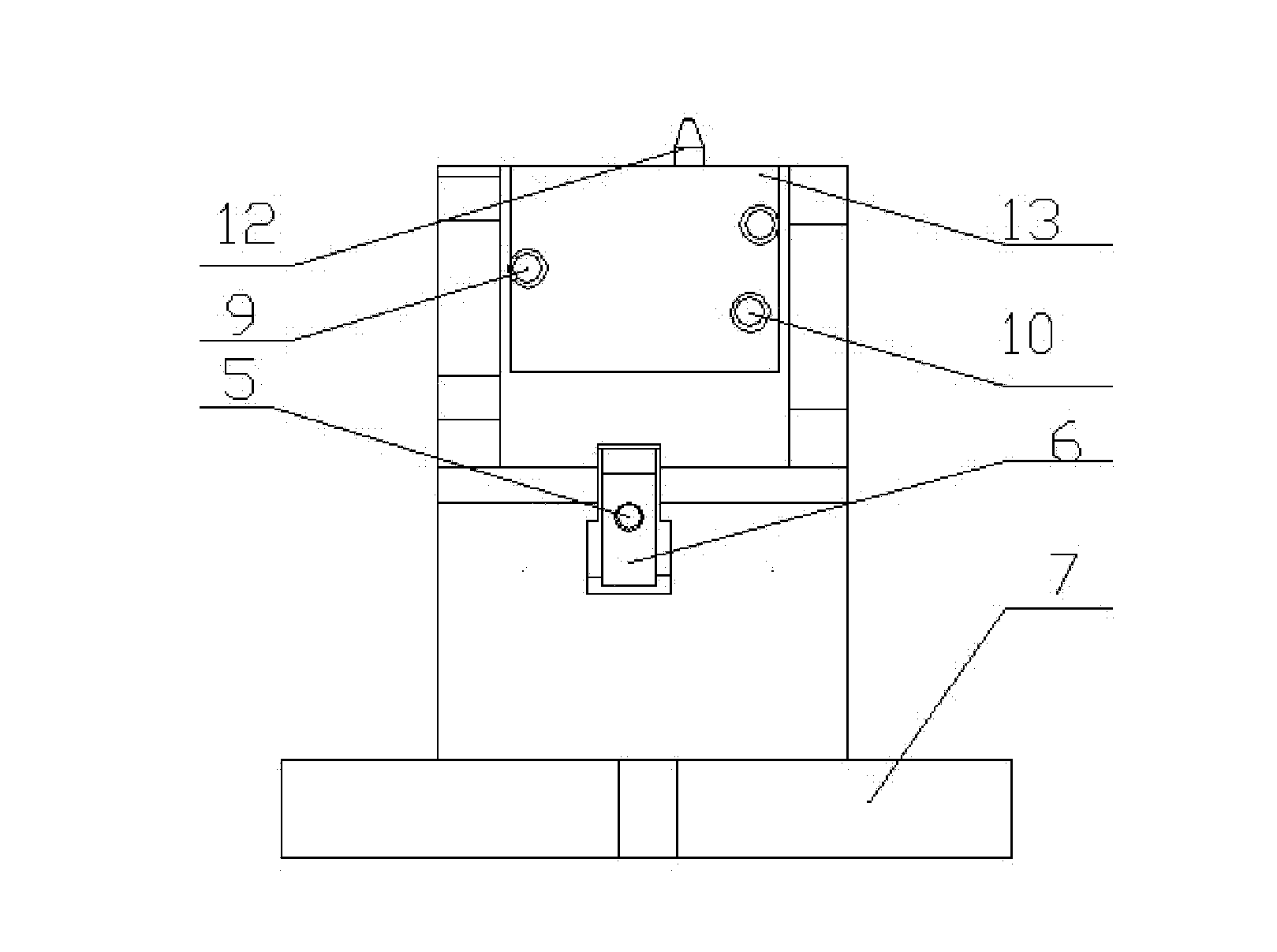

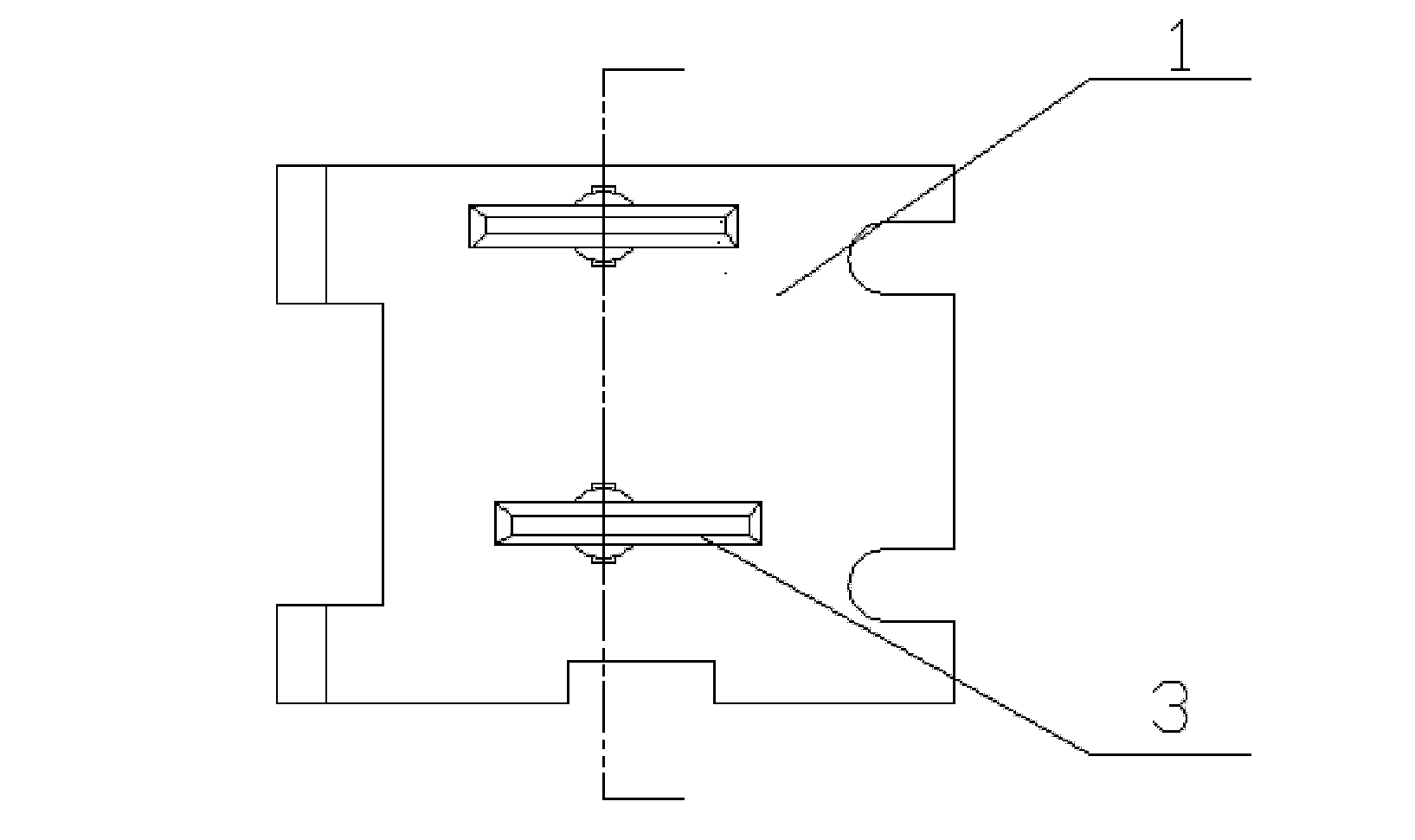

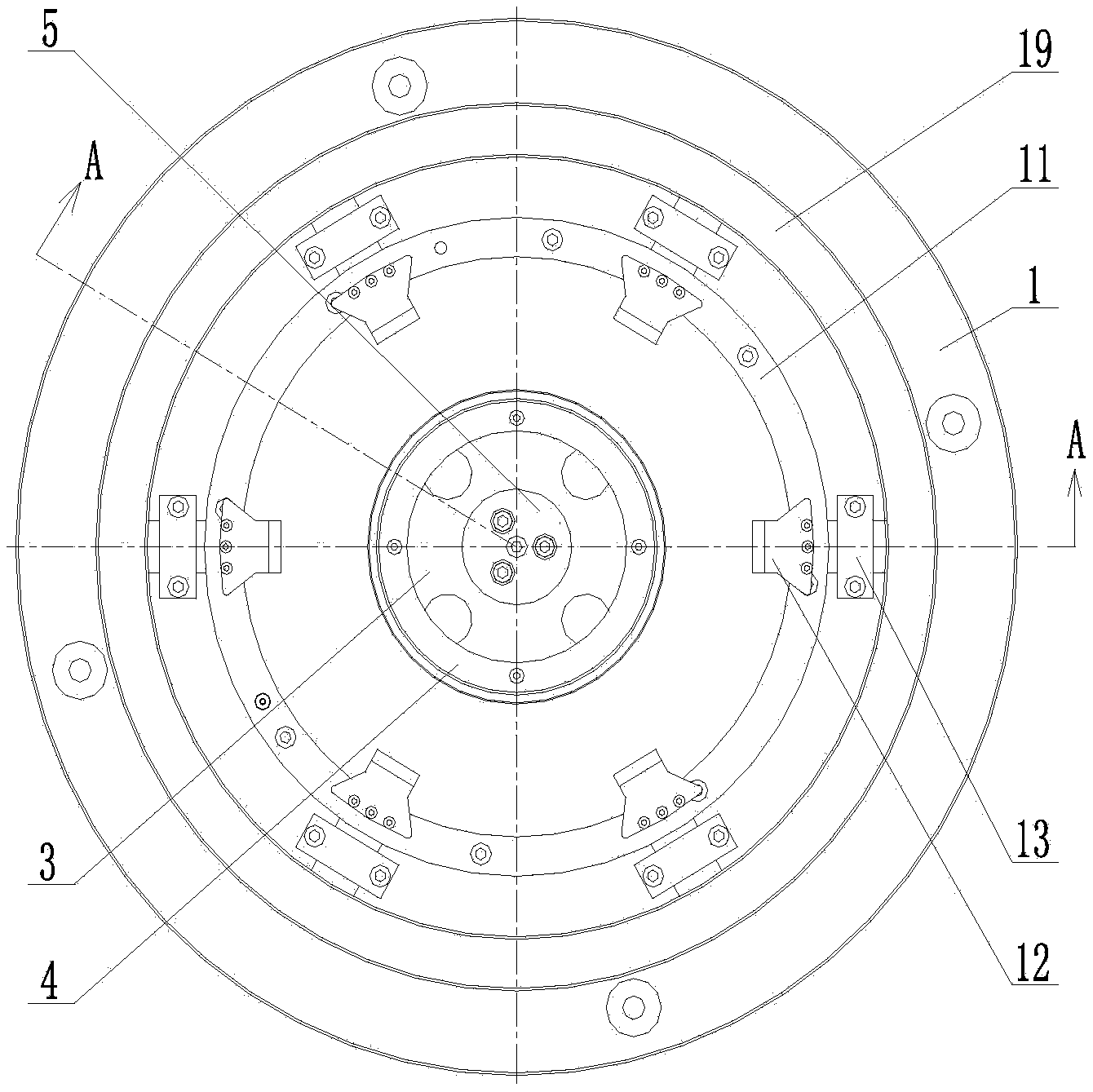

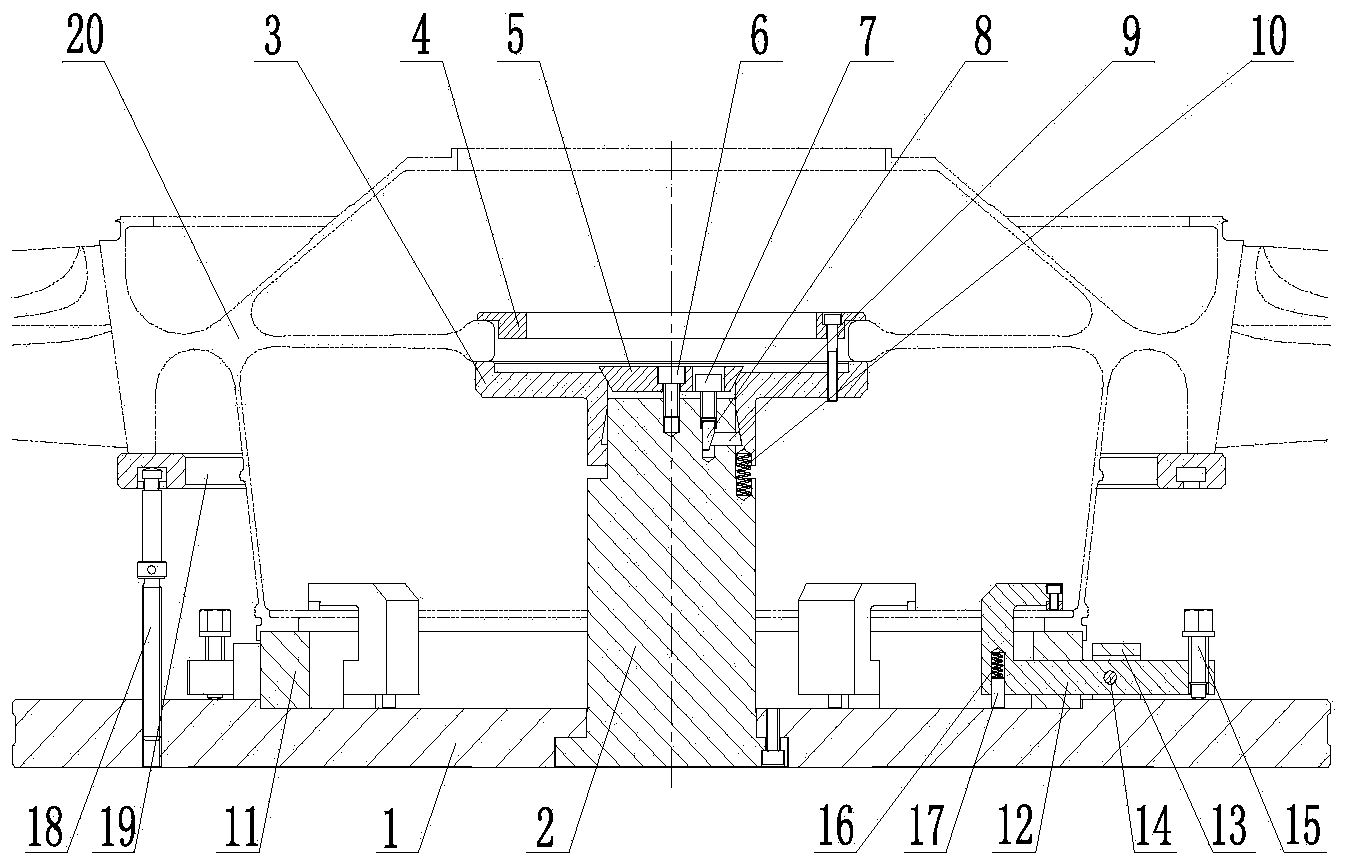

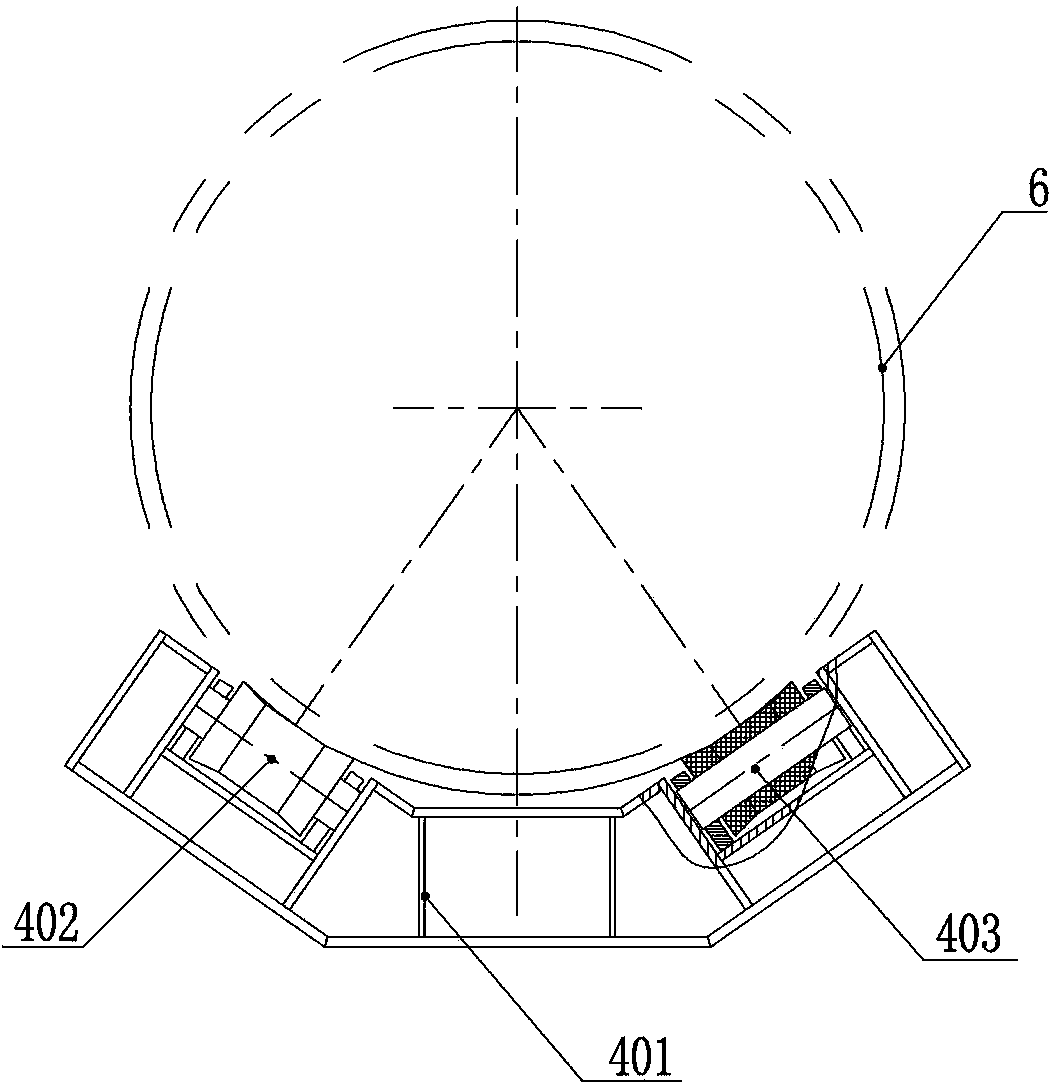

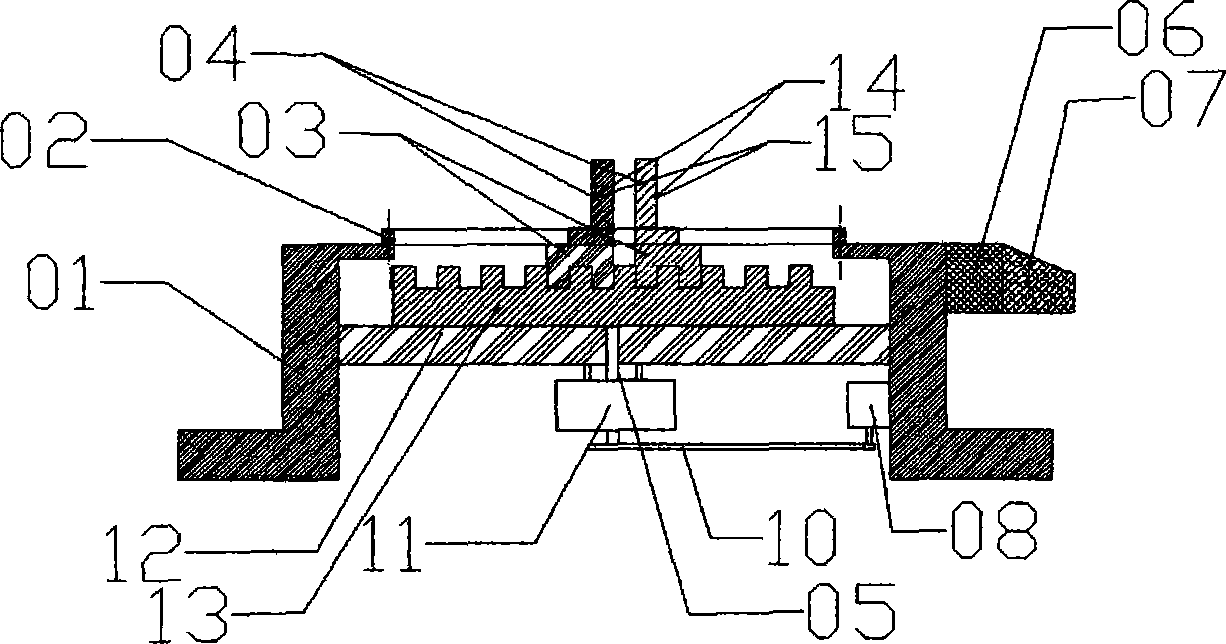

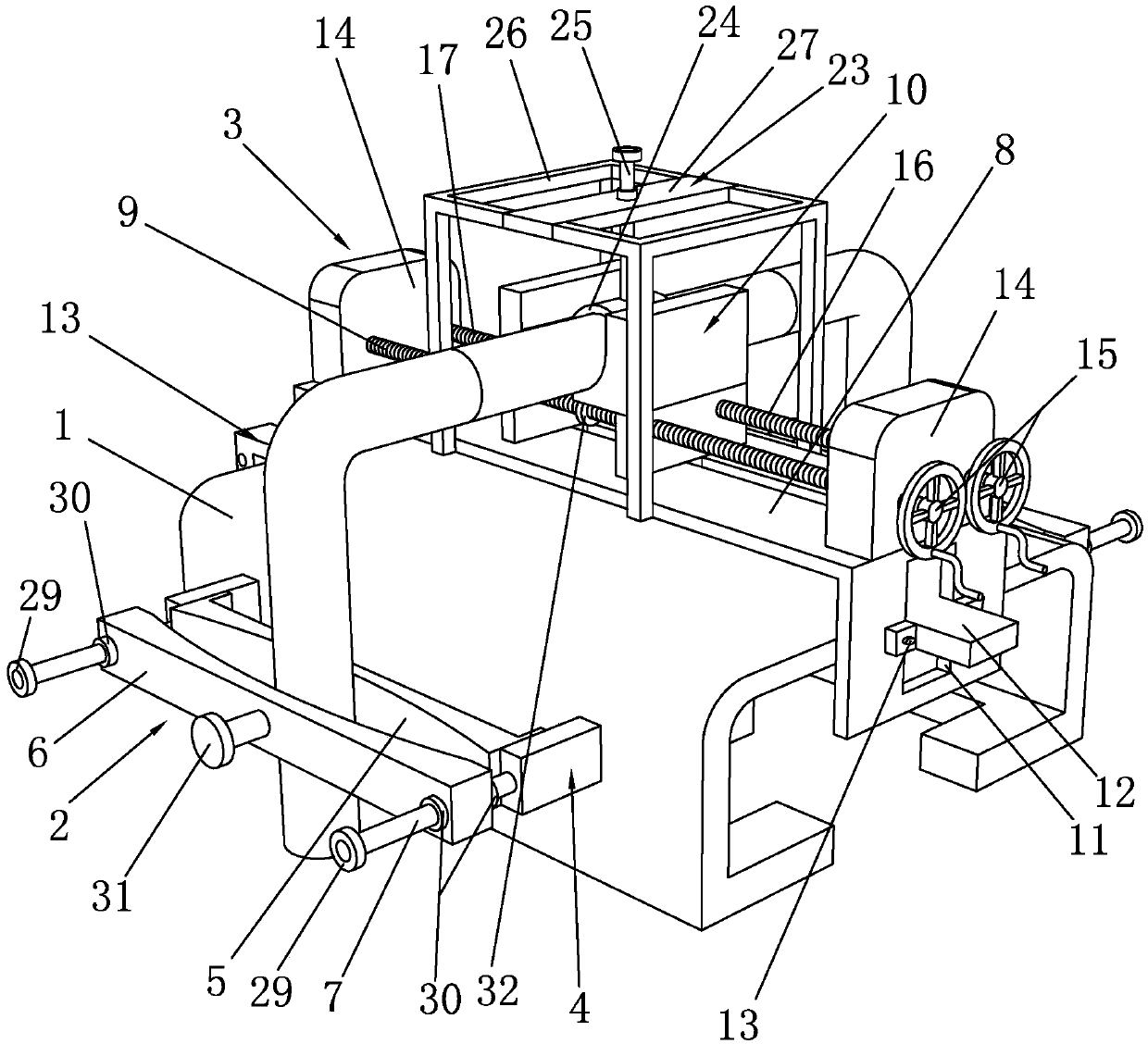

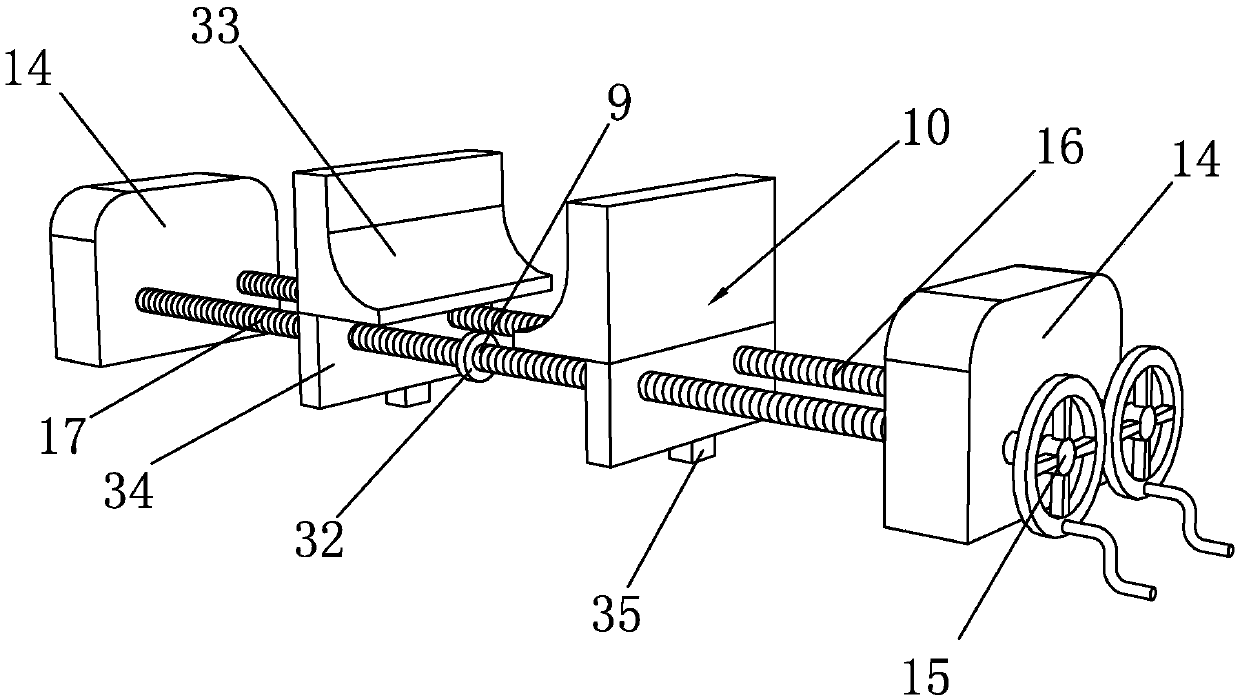

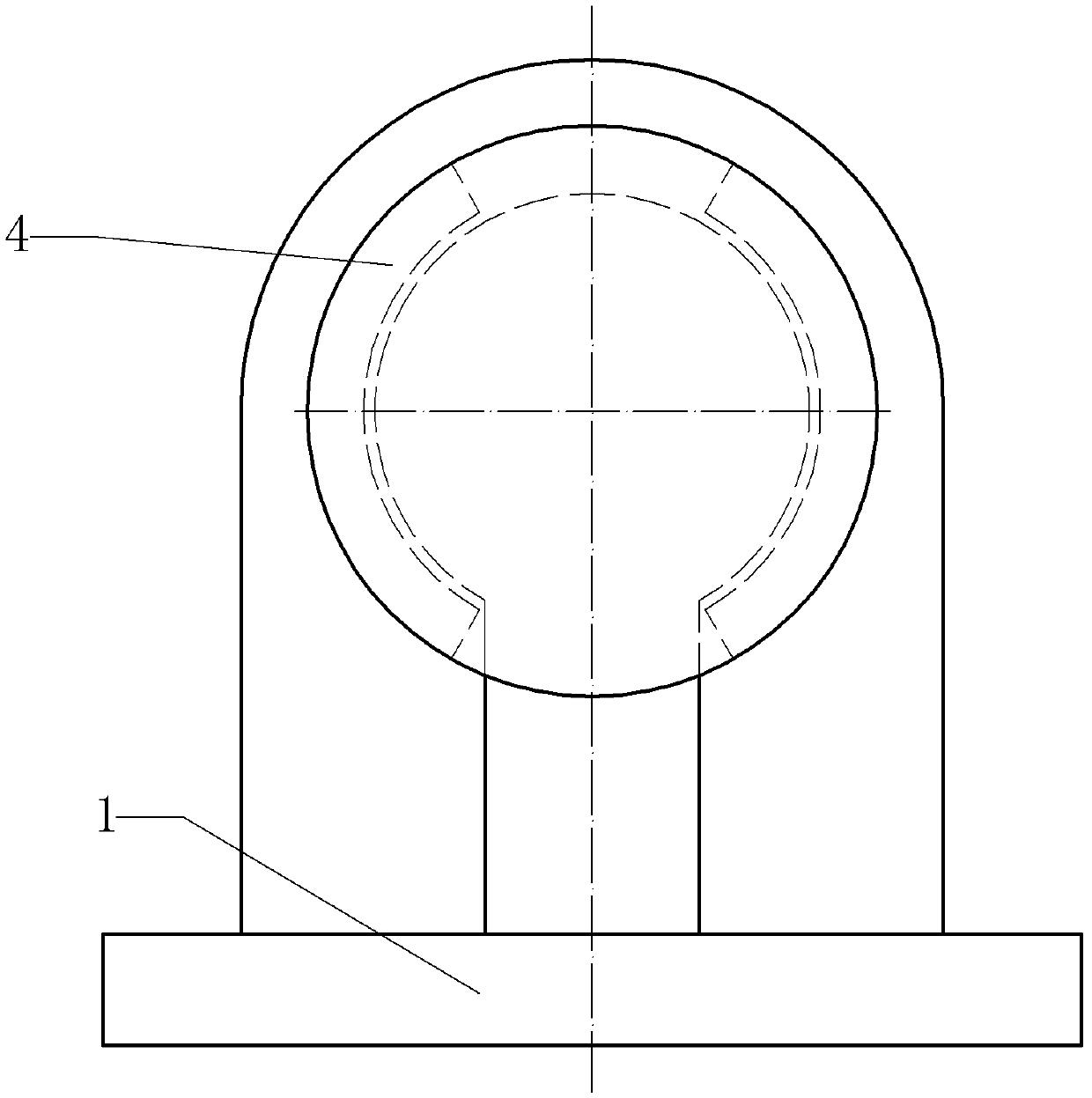

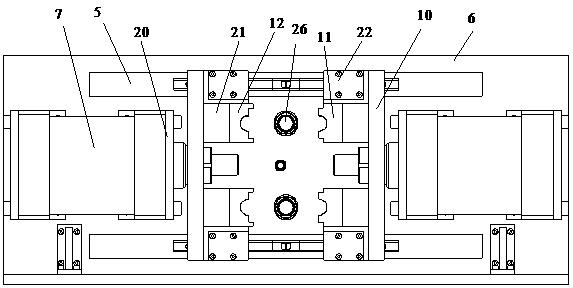

Central symmetry type circular pipe positioning device

InactiveCN105729346APrecise positioningUniform clamping forceWork clamping meansWork holdersEngineeringCentral symmetry

The invention discloses a central symmetry type circular pipe positioning device. The central symmetry type circular pipe positioning device comprises a bottom positioning die, an upper pressing die, a left V-shaped block, a right V-shaped block, a levorotation nut slide block, a dextrorotation nut slide block and a two-way lead screw. The upper pressing die is arranged over the bottom positioning die. The left V-shaped block and the right V-shaped block are arranged on the left side and the right side of the bottom positioning die in a symmetrical manner. The levorotation nut slide block is arranged below the left V-shaped block. The dextrorotation nut slide block is arranged below the right V-shaped block. The two-way lead screw penetrates in one end of the levorotation nut slide block and then penetrates out of the other end of the dextrorotation nut slide block. By means of the manner, a circular pipe is positioned and clamped in four directions through the central symmetry type circular pipe positioning device, and the central symmetry type circular pipe positioning device has the beneficial effects of being accurate and reliable in positioning, uniform in clamping force, simple in structure and convenient to manufacture and is suitable for positioning and clamping circular pipes of various diameters.

Owner:SUZHOU DODRON MACHINERY MFG

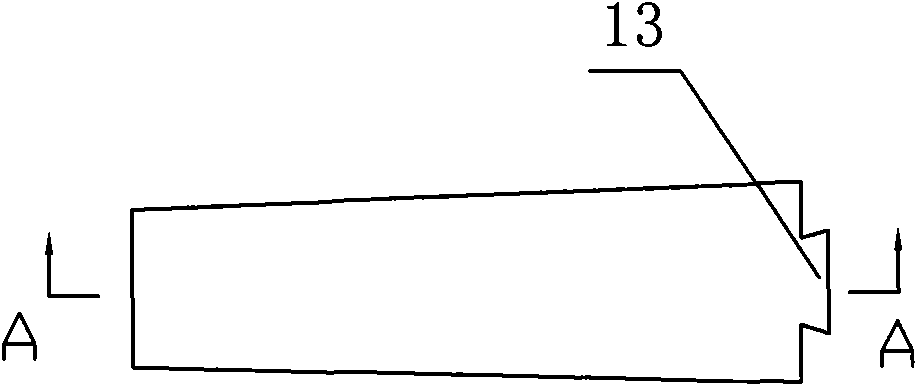

Hydraulic fixture used for machining precision forging blade tenon root

InactiveCN102615534AUniform clamping forceStable clamping forcePositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a hydraulic fixture used for machining a precision forging blade tenon root. The fixture consists of a fixture box cover part in contact with a blade back and a fixture box body part in contact with a blade basin; by transferring pressure of liquid in a hydraulic cavity of the fixture to other parts, a blade is clamped, so that the clamping force applied on the blade is more uniform and stable; when the hydraulic fixture is used for clamping, the blade can be clamped and loosened only by screwing a pressing regulation rod in and out, the operation control is convenient, and the damage to the blade is reduced. According to the hydraulic fixture used for machining the precision forging blade tenon root, the machining efficiency of the blade of an aviation engine can be improved, the machining precision of the blade of the aviation engine is also improved, and the clamping problem brought about when the precision forging blade tenon root is machined is solved; the fixture is simple in structure, convenient to install and high in positioning precision; the positioning precision is not affected even when the hydraulic fixture is dismounted for a plurality of times; and the hydraulic fixture is also applicable to the machining and application of the other types of blades.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

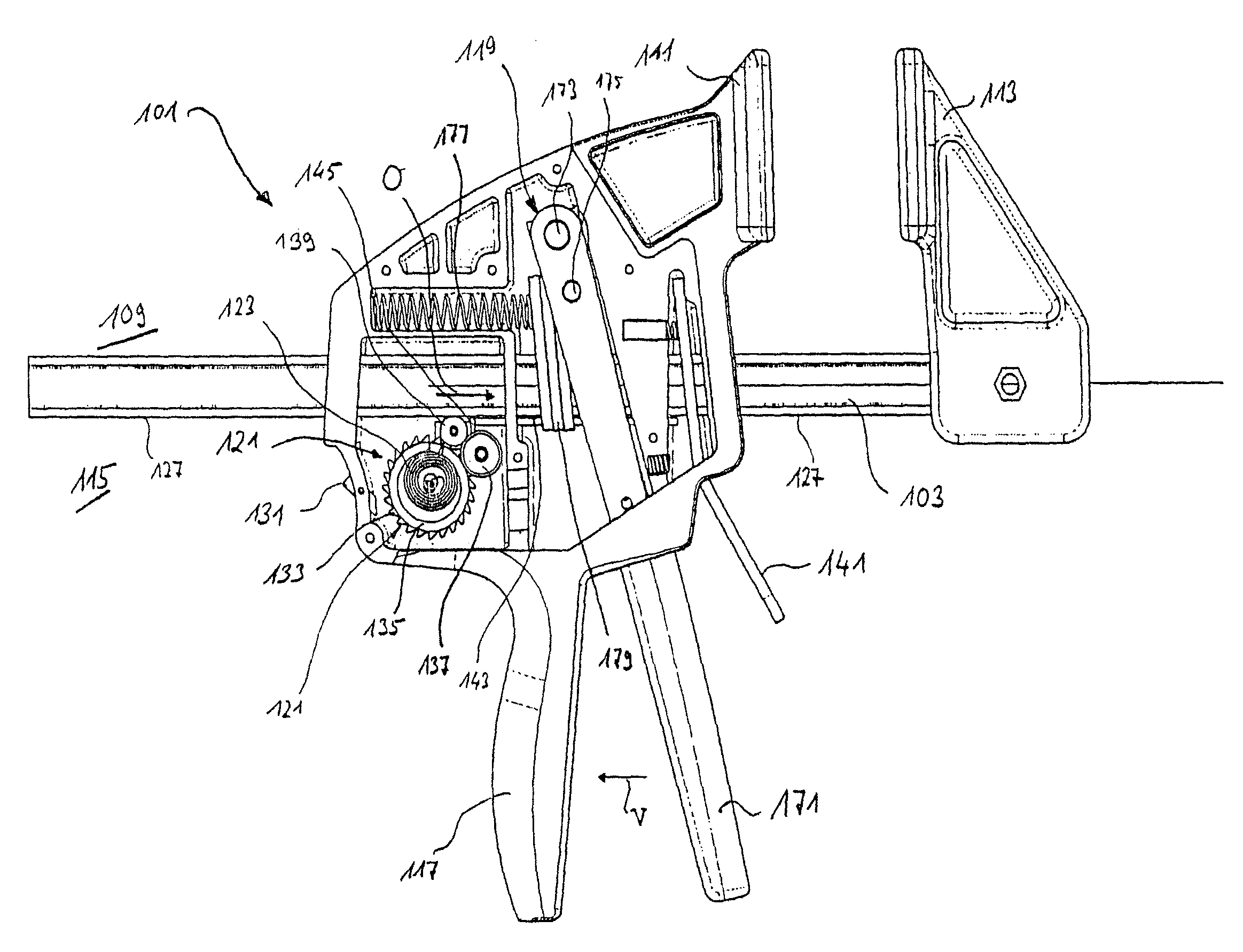

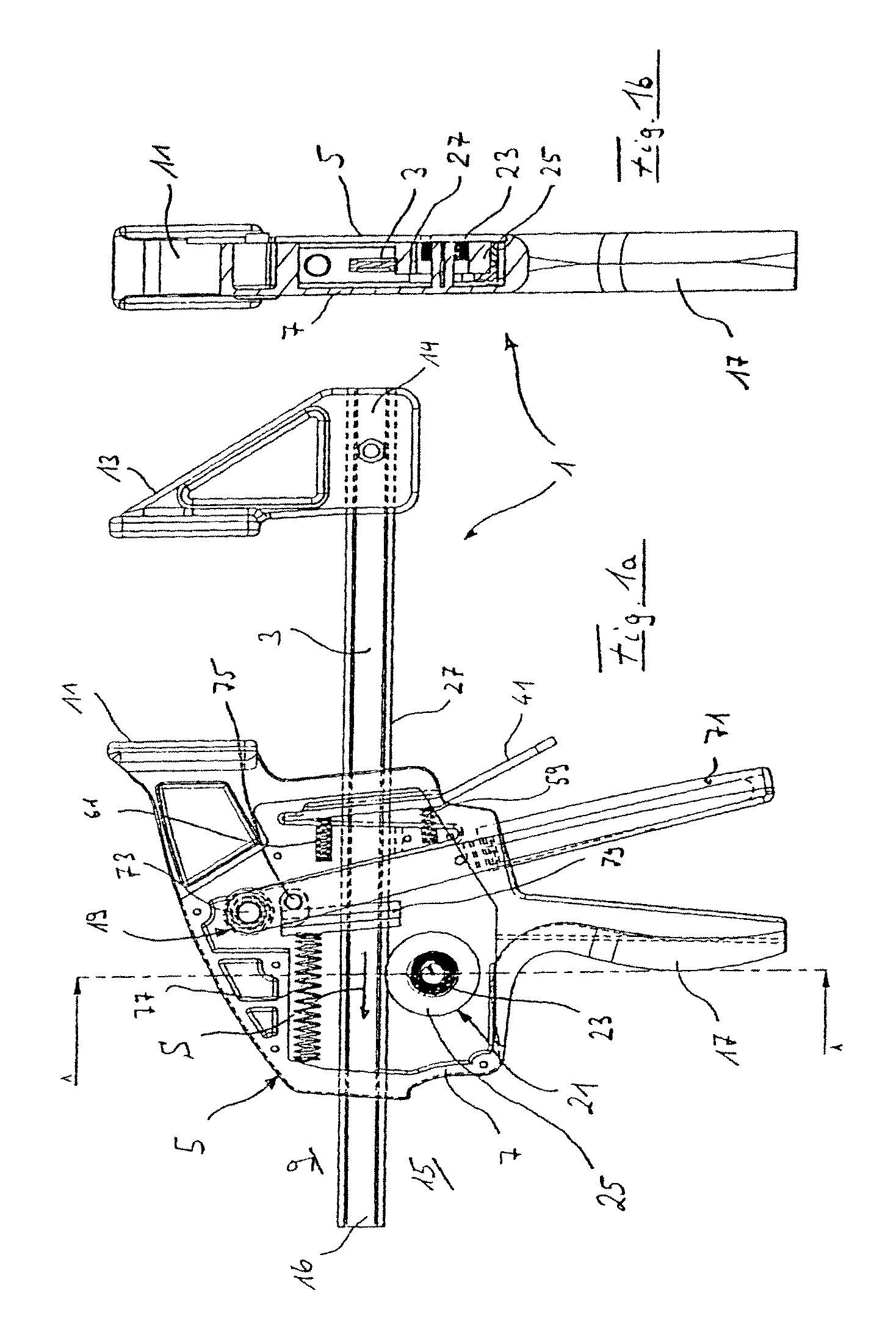

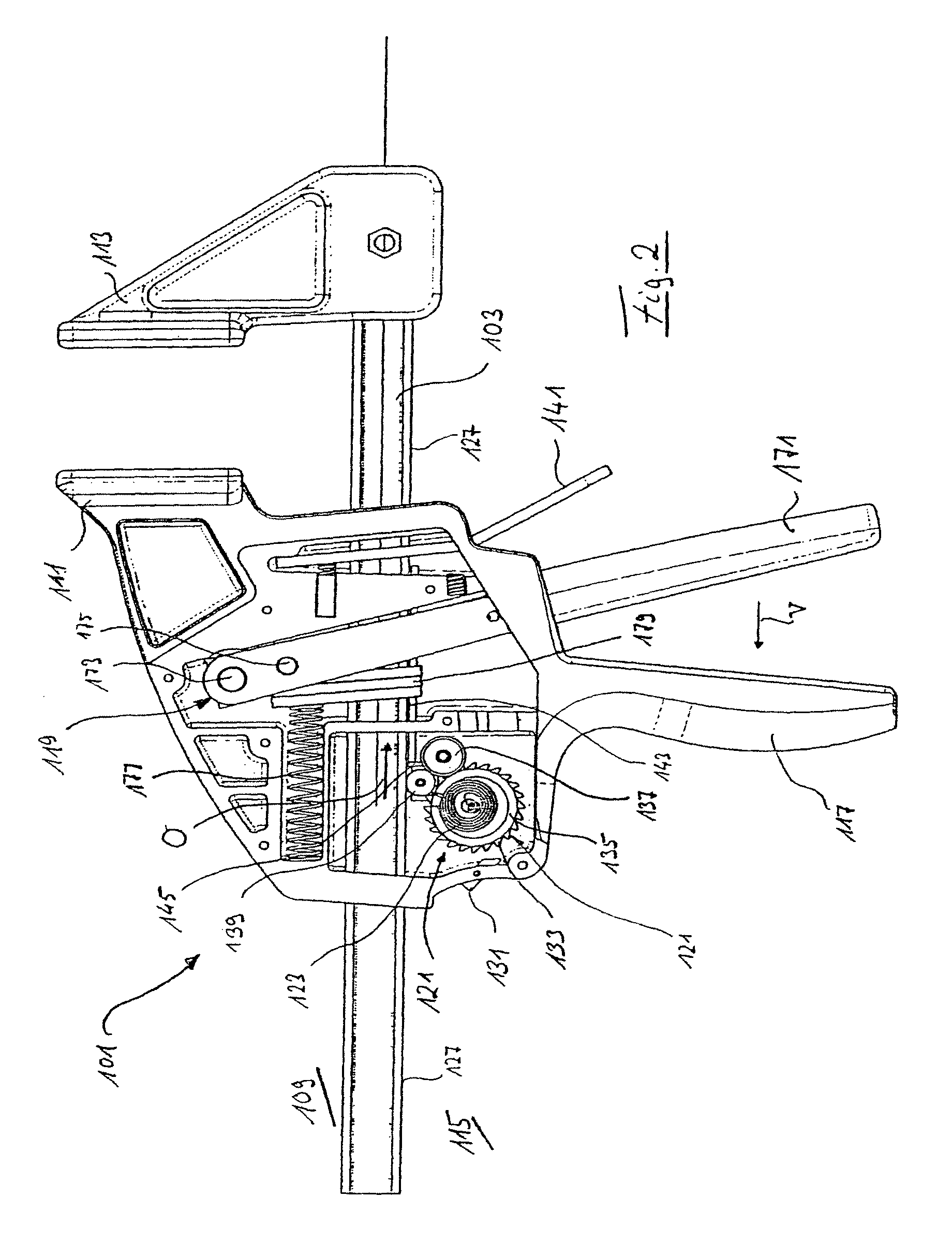

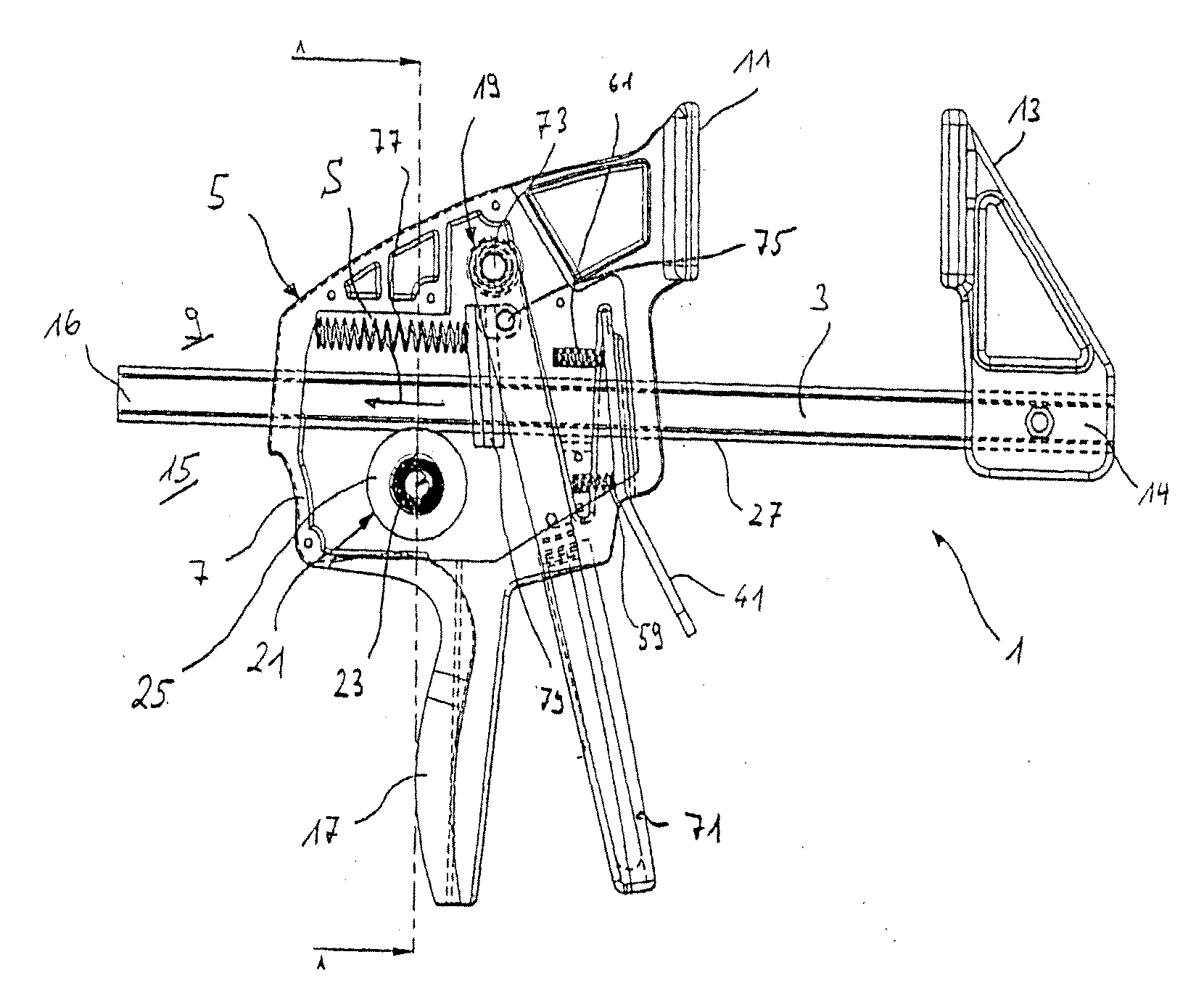

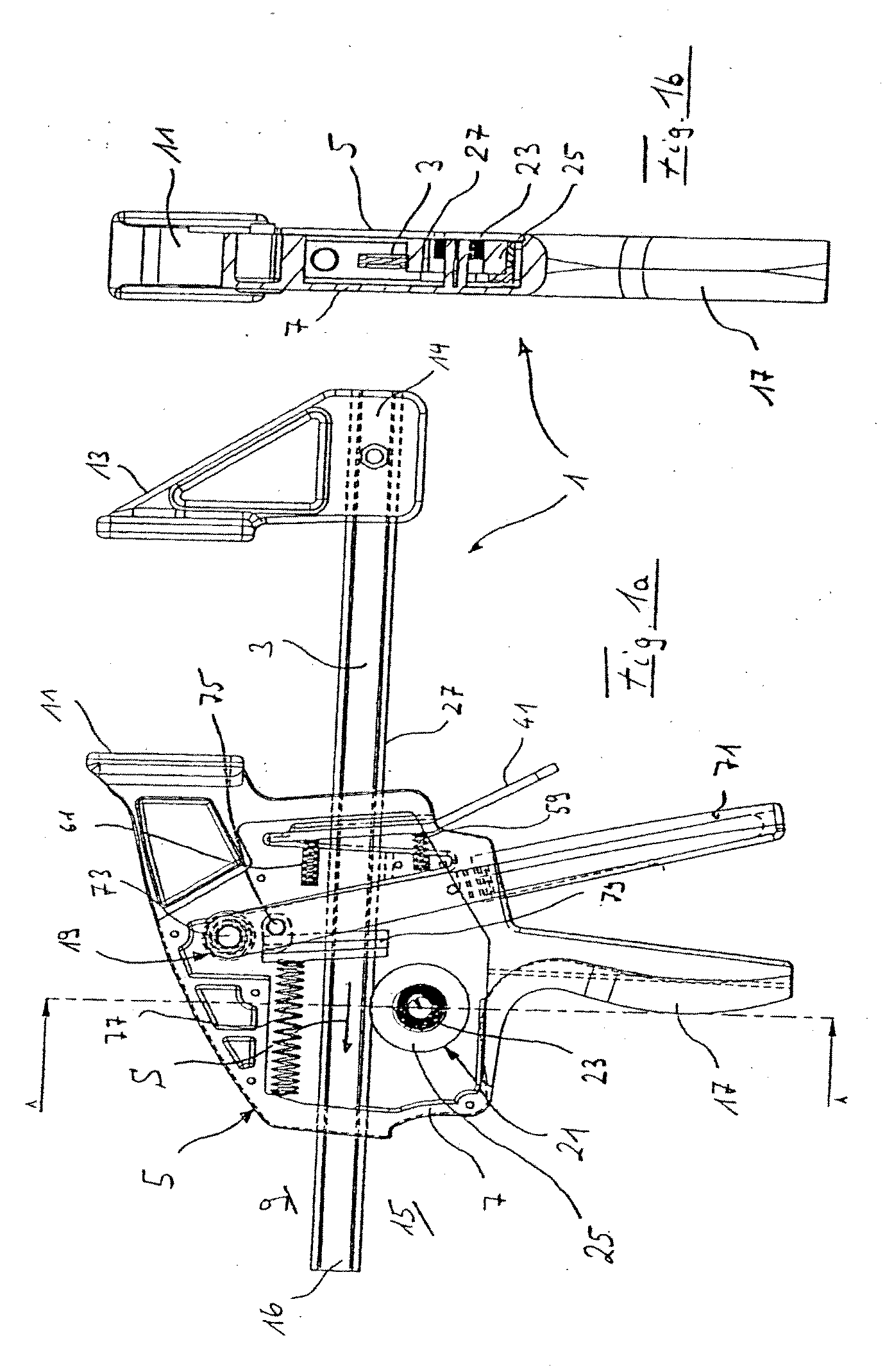

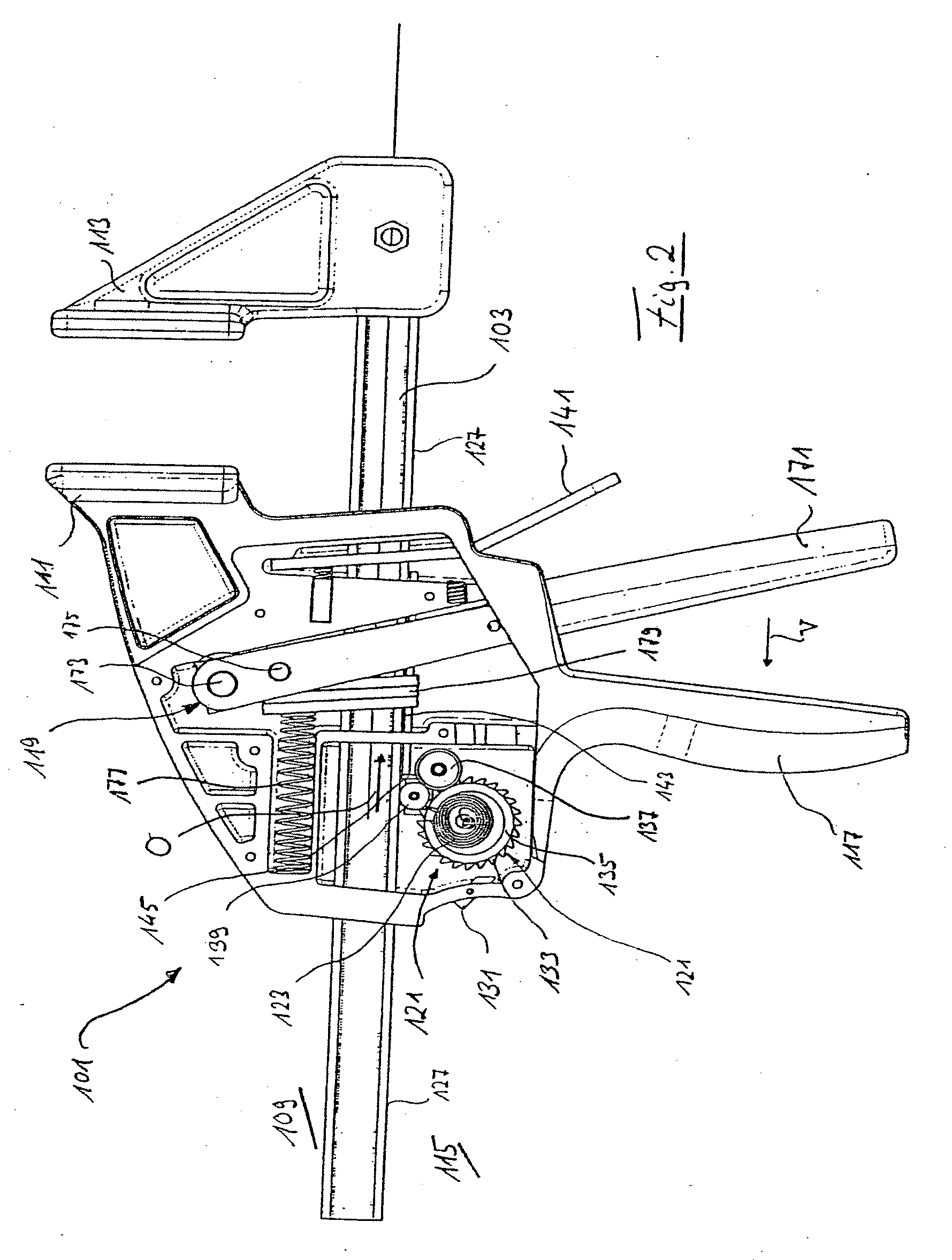

Clamping or spreading tool

ActiveUS8240647B2Dimension in spaceReduce weightSpring motorMachines/enginesPush and pullTorsion spring

A clamping and / or spreading tool comprises a drive for displacement of a push or pull rod to which a movable jaw is fixed with respect to a support carrying a stationary jaw in longitudinal direction of the push and pull rod, the drive comprising a torsion spring and being adapted to enter torque transmitting engagement with the push or pull rod for displacement of the same.

Owner:IRWIN IND TOOL CO

Adaptive deformation-resistant supporting fixture

InactiveCN103612129AUniform clamping forceImprove structural rigidityPositioning apparatusMetal-working holdersSelf adaptiveEngineering

The invention provides an adaptive deformation-resistant supporting fixture, and belongs to the technical field of manufacture of parts of aero-engines. A center support of the adaptive deformation-resistant supporting fixture is fixedly arranged in the center of a base; a center supporting plate is sleeved at the upper end of the center support; a thrust spring is arranged between the center supporting plate and the center support; a second center pressing plate is in contact fit with the center supporting plate, and a contact surface is an inclined surface; the second center pressing plate is connected with the center support through a first locking bolt; a second locking bolt is arranged on the center support and faces the second center pressing plate; a vertical lifting pin and a transverse lifting pin are arranged in the center support and at the second locking bolt; the transverse lifting pin corresponds to the inner wall of a sleeving section of the center supporting plate; a first center pressing plate is arranged above the second center pressing plate; a positioning ring is positioned on the base and on the outer side of the center support; one end of a peripheral pressing plate is positioned above the positioning ring; the other end of the peripheral pressing plate is matched with the base through a compression bolt; the peripheral pressing plate is provided with a rotating shaft; the rotating shaft is arranged on the base through a fixing block; and a supporting ring is arranged on the outer side of the positioning ring.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

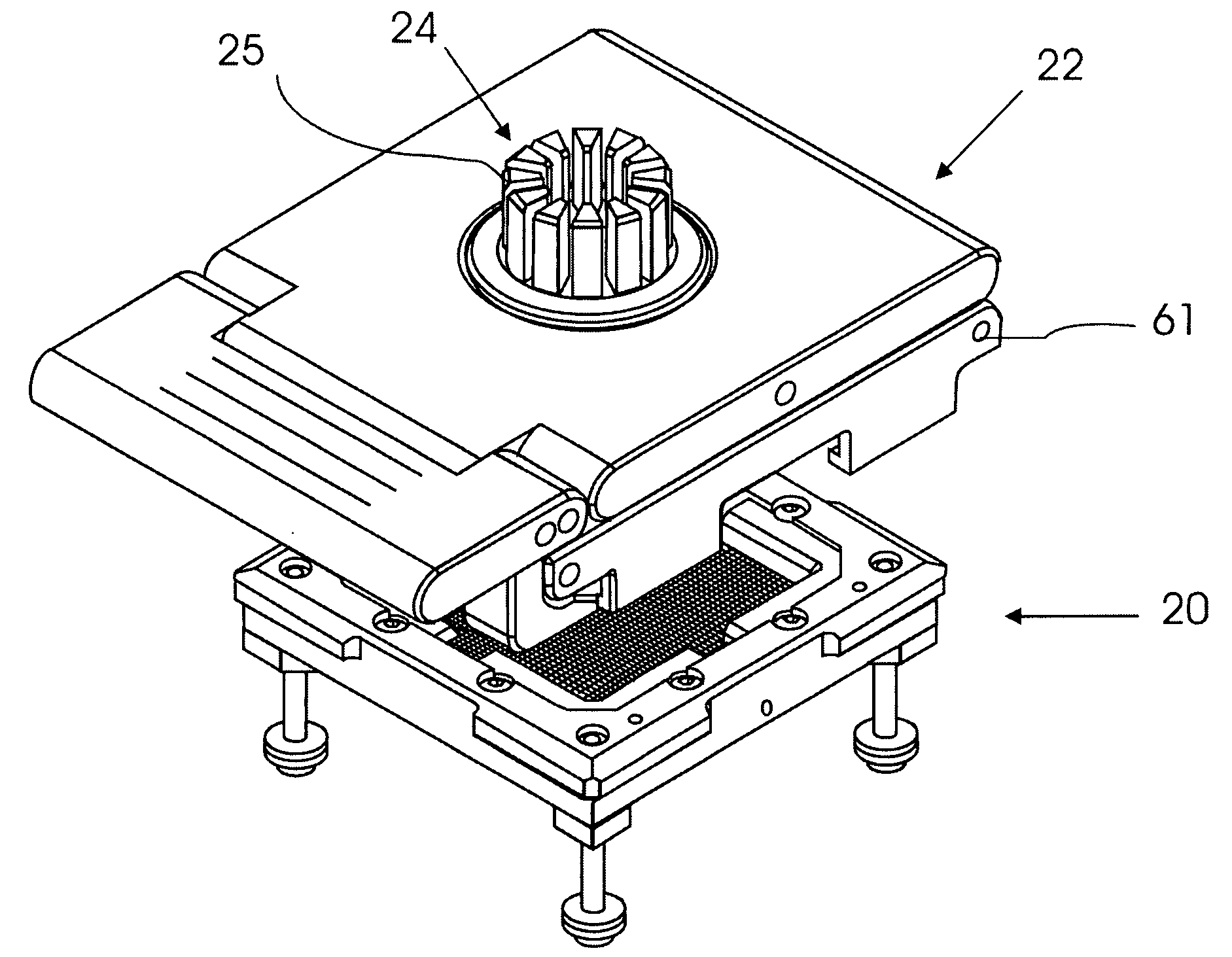

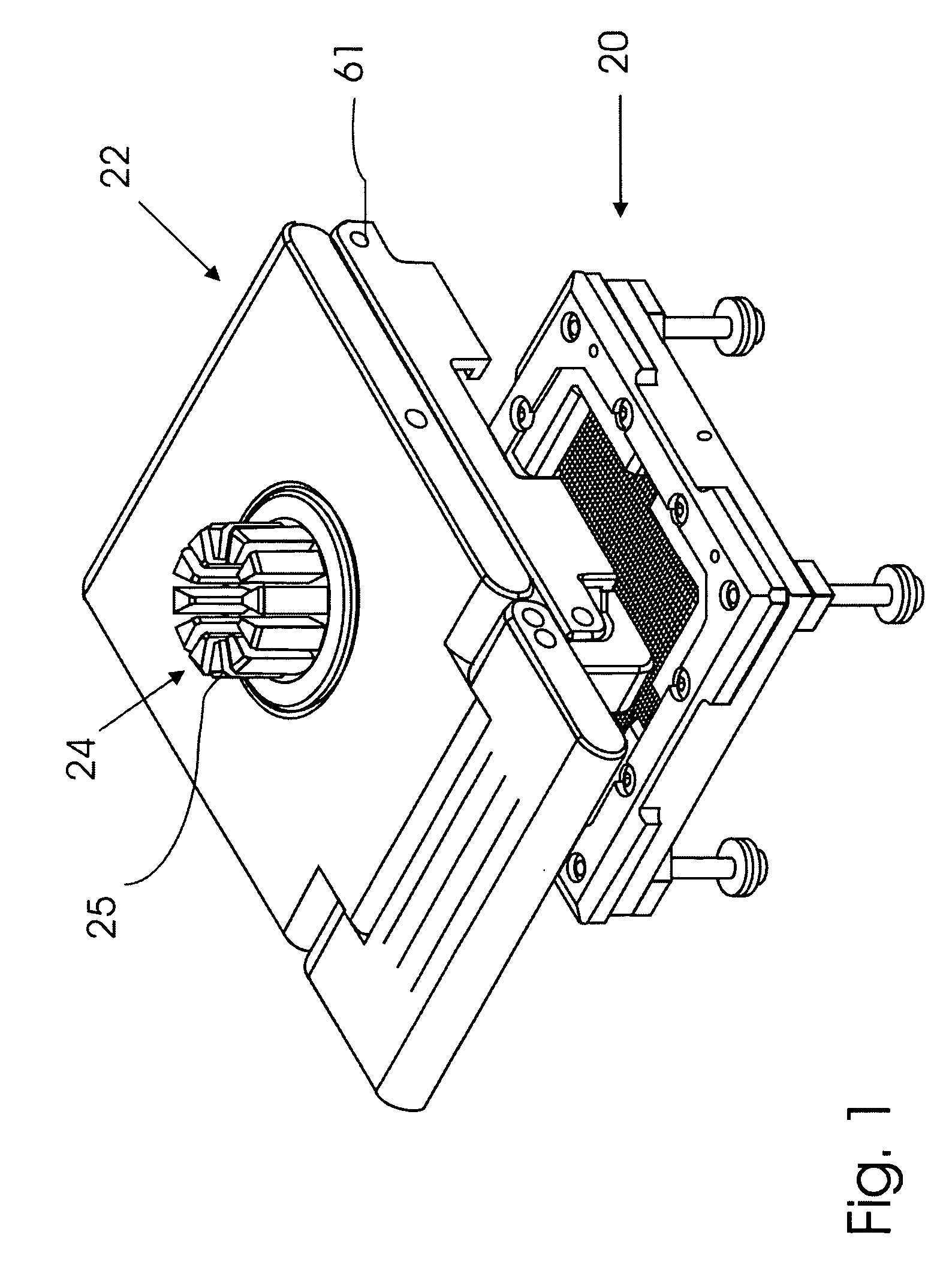

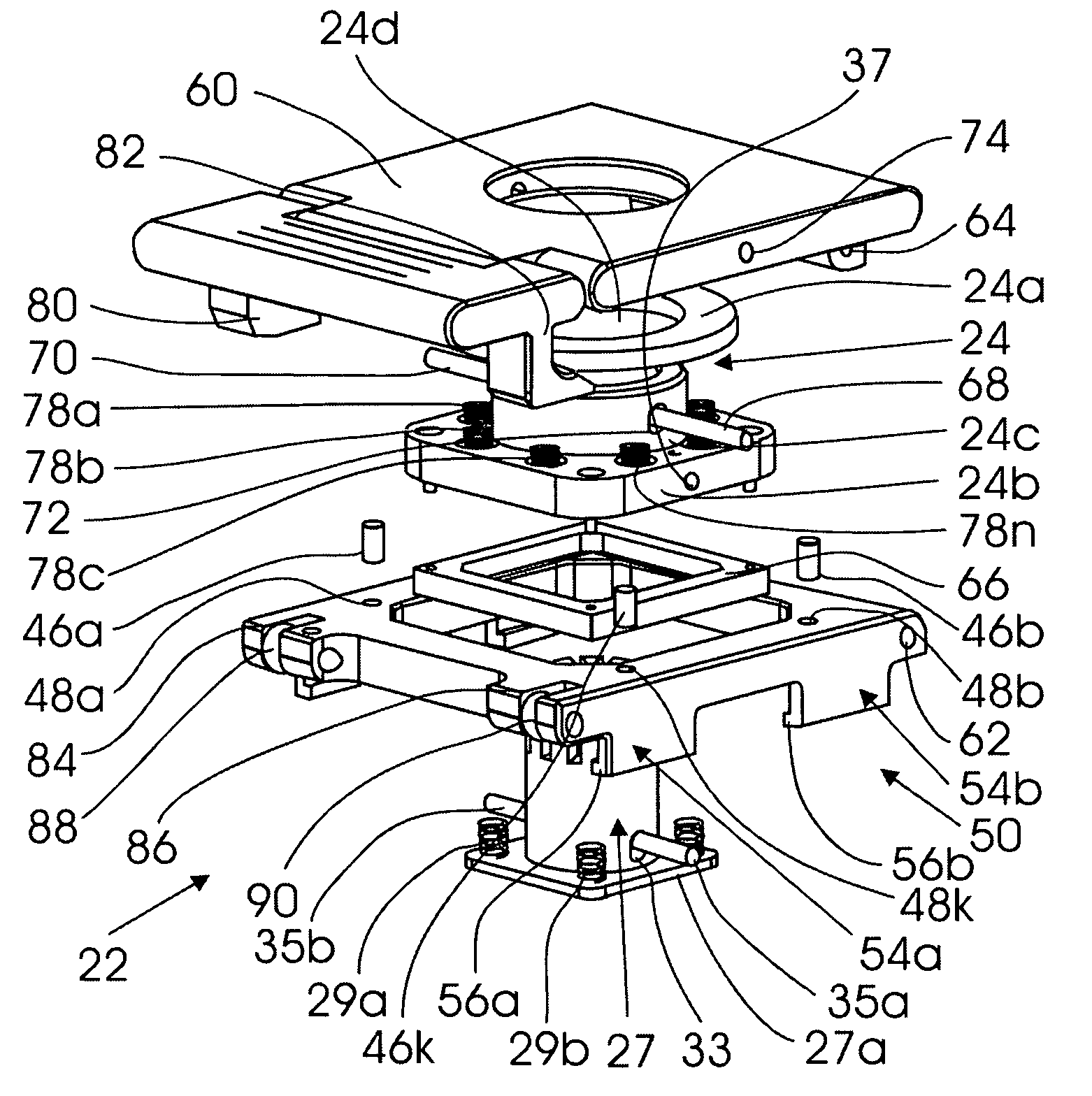

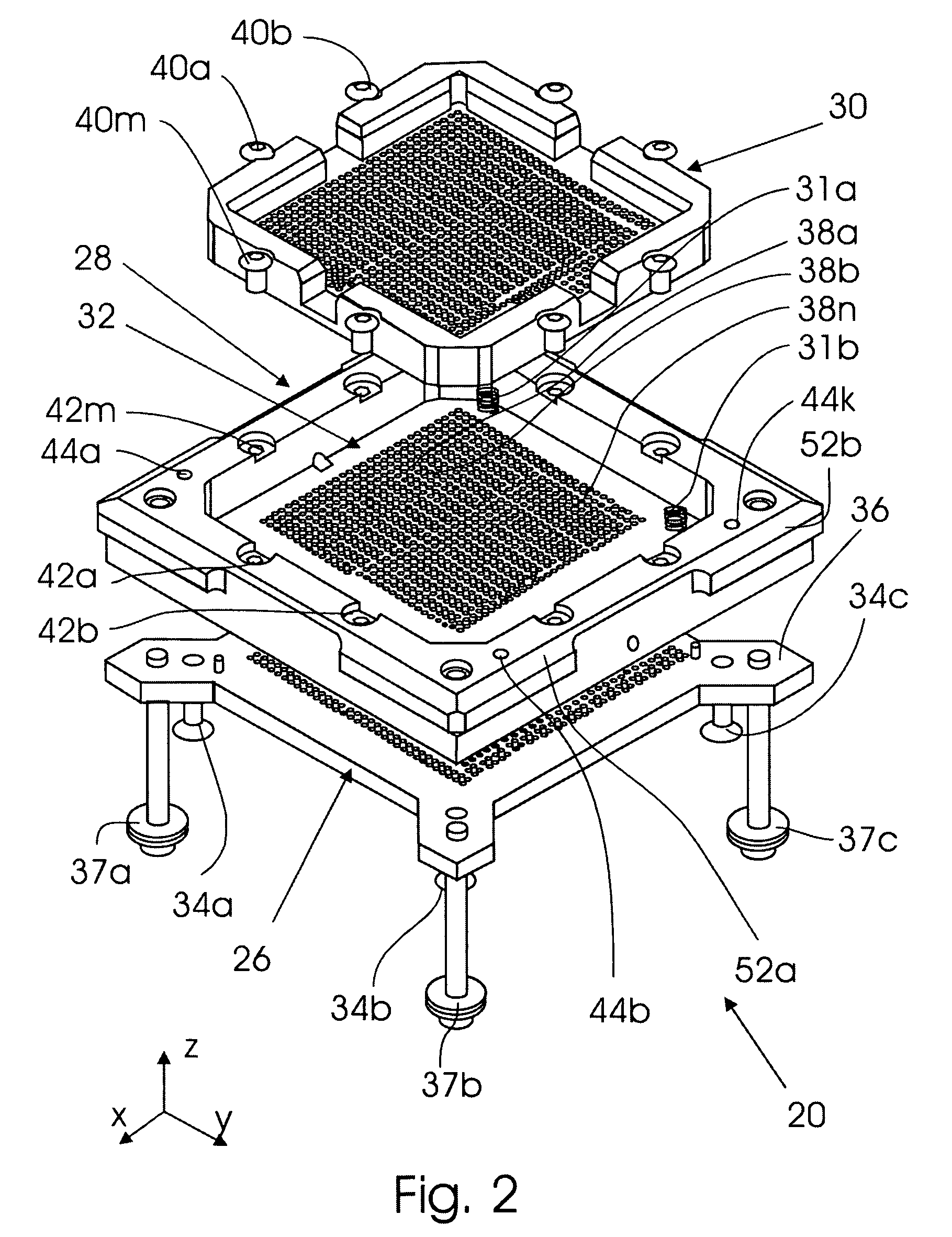

Test socket-lid assembly

InactiveUS20080020623A1Uniform clamping forceUniform heat transferEngagement/disengagement of coupling partsCoupling contact membersComposite structureBiomedical engineering

A test socket-lid assembly for testing electronic devices such as IC chips consists of a socket sub-assembly and a lid-sub-assembly, which is separated from the socket sub-assembly. In the lid sub-assembly, the lid is pivotally connected to the frame and supports a spring-loaded pusher that can slide in a vertical direction relative to the lid and can perform rocking movements relative to the lid. The assembly is distinguished from existing devices of this type in that the IC chip is supported and clamped in the lid sub-assembly and in that the entire lid sub-assembly together with the clamped and spring-loaded pusher is attached to the socket by guiding the lid sub-assembly in a transverse direction along the socket guide to the position wherein the spring plungers are locked into their respective openings on the surface of the socket. In one embodiment the pusher is a single part that has three degrees of freedom relative to the IC chip; in another embodiment, the pusher is of a composite structure and has five degrees of freedom.

Owner:PROTOS ELECTRONICS

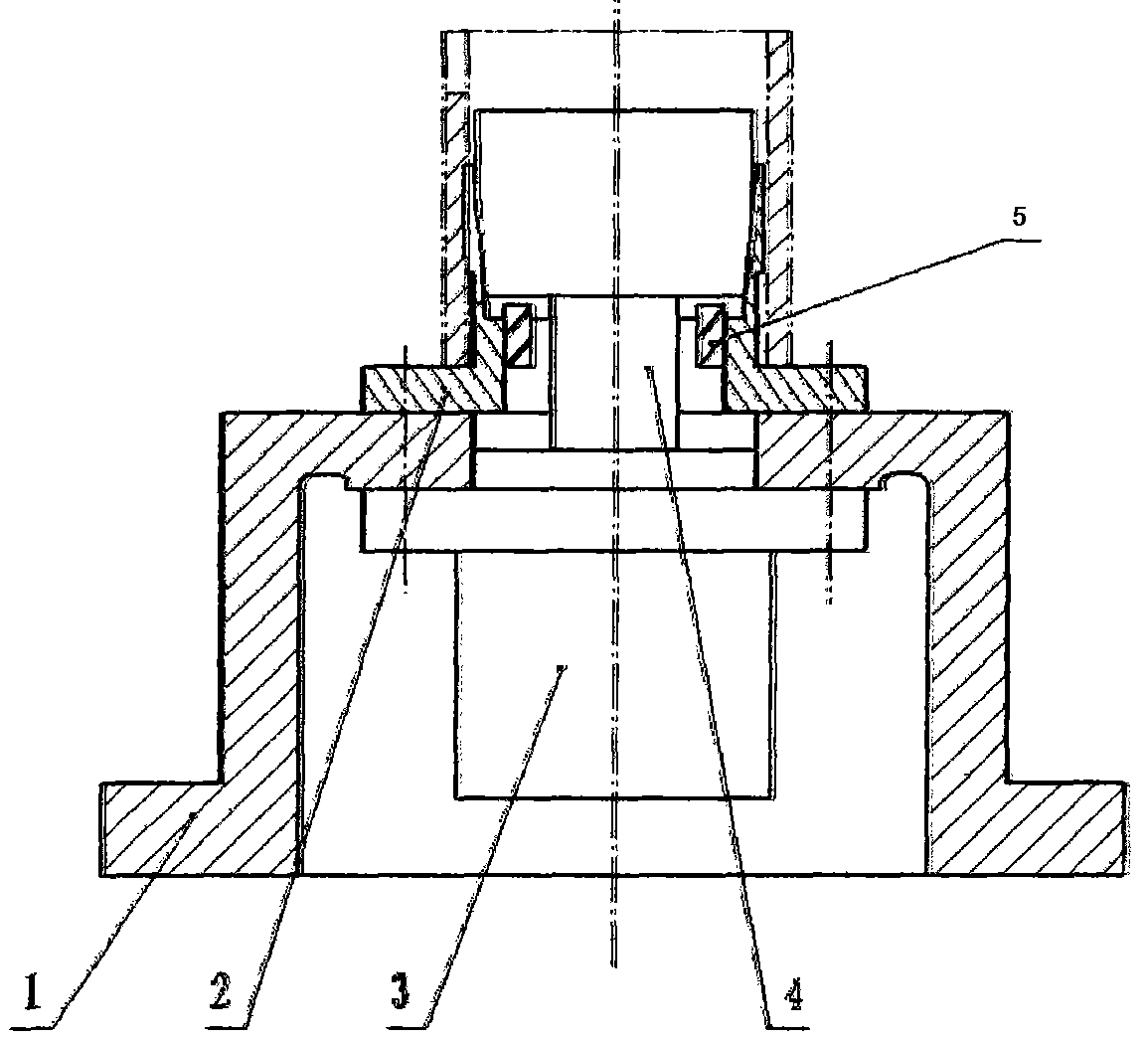

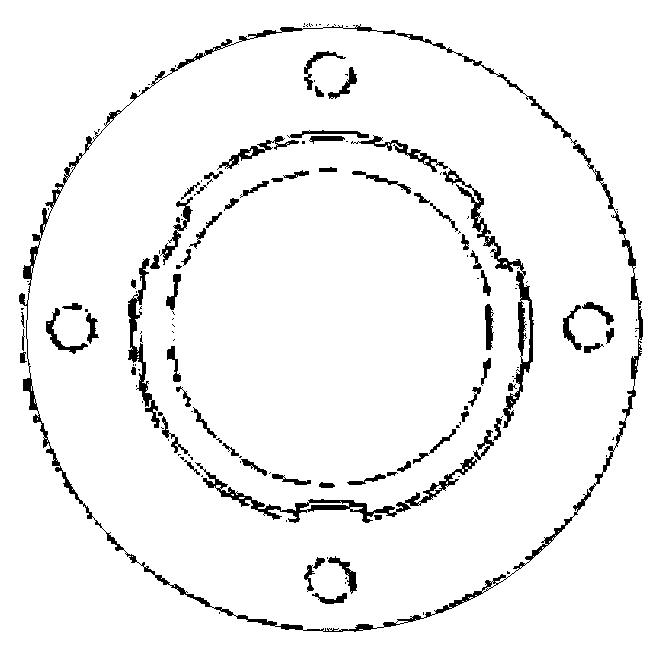

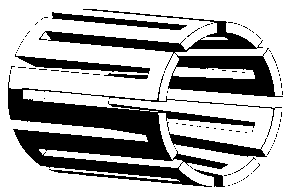

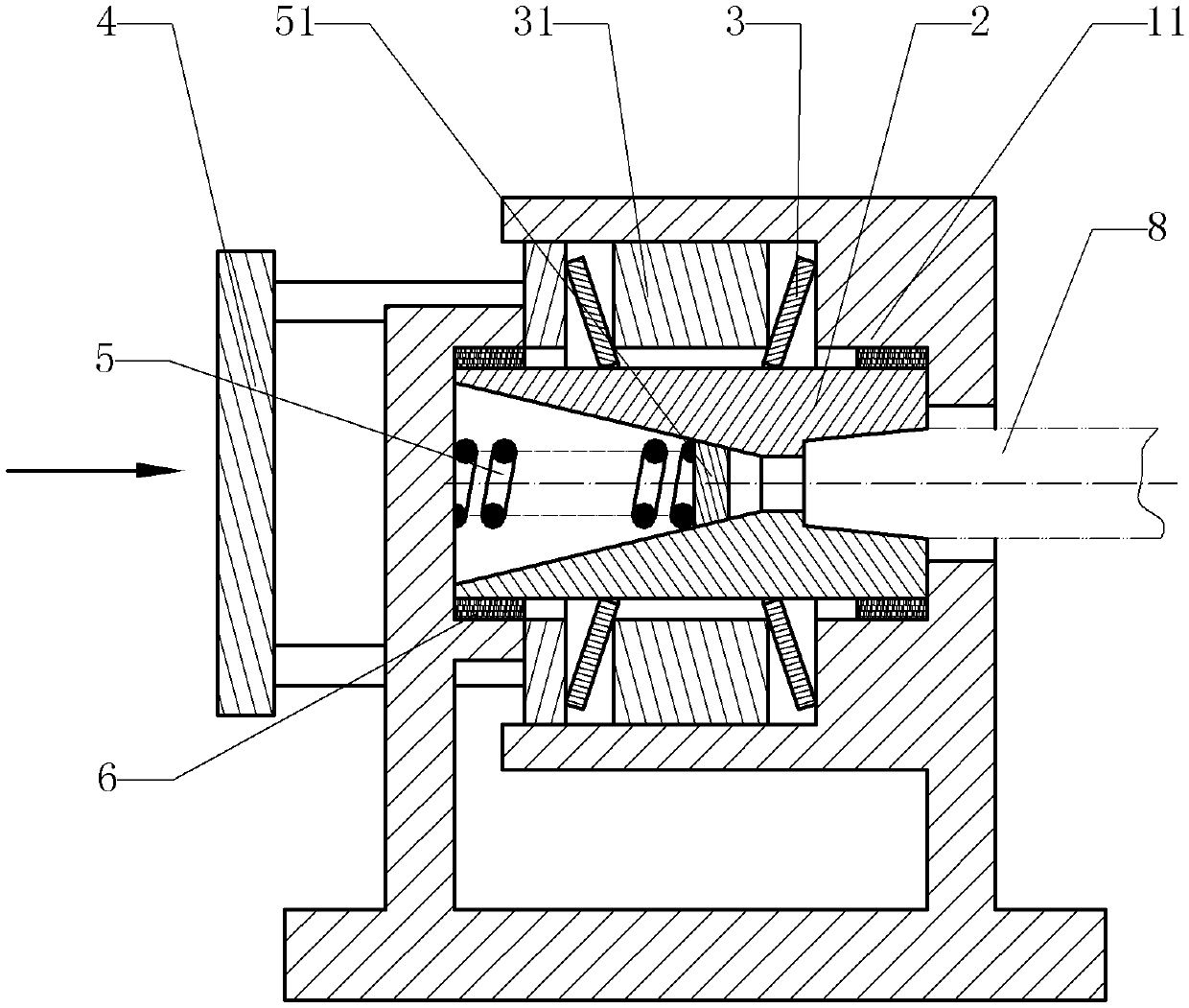

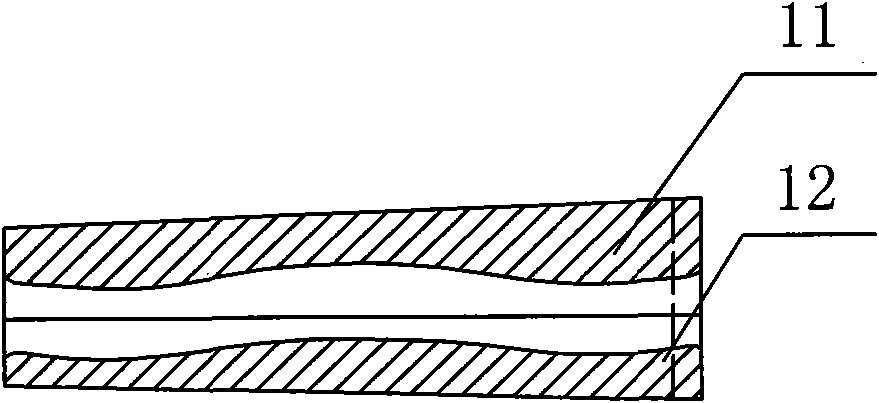

Special tooling for turning high-precision thin-wall cylinder liner bores

InactiveCN104493600AReliable positioning and clampingUniform clamping forcePositioning apparatusMetal-working holdersCircular coneEngineering

The invention discloses a special tooling for turning high-precision thin-wall cylinder liner bores, which comprises an internal taper sleeve, an elastic clamp and an axial positioning disk, the left end of the internal taper sleeve is connected with a spindle flange, the right end of the internal taper sleeve is connected with the axial positioning disk, the right side of the internal taper sleeve is provided with a taper hole, the taper hole is connected with a cylindrical hole of the left side, the sidewall of one side of the cylindrical hole is provided with a guide hole, a vent hole is formed in the left side of the guide hole, the elastic clamp comprises an internal cylindrical hole and an external conical surface, the external conical surface is connected with an external cylindrical surface, a pull rod holder is arranged on the external cylindrical surface, the pull rod holder is provided with a pull rod-fixing hole, a washer is arranged at the right side of the pull rod-fixing hole, the outer diameter of the washer is greater than the inner diameter of the pull rod-fixing hole, the excircle of the end of an oil cylinder pull rod is matched with the pull rod-fixing hole, the end of the oil cylinder pull rod is provided with a threaded hole, and the oil cylinder pull rod is connected with the washer. The structural precision of the special tooling is high, a thin-wall cylinder liner can be positioned and clamped reliably, clamping stress is uniform, the deformation of the thin-wall cylinder liner caused by clamping force is reduced, and the precision requirement of workpieces is met.

Owner:JINAN FIRST MACHINE TOOL GROUP

Test socket-lid assembly

InactiveUS7338295B2Uniform clamping forceEasy to useEngagement/disengagement of coupling partsCoupling contact membersThree degrees of freedomDegrees of freedom

A test socket-lid assembly for testing electronic devices such as IC chips consists of a socket sub-assembly and a lid-sub-assembly, which is separated from the socket sub-assembly. In the lid sub-assembly, the lid is pivotally connected to the frame and supports a spring-loaded pusher that can slide in a vertical direction relative to the lid and can perform rocking movements relative to the lid. The assembly is distinguished from existing devices of this type in that the IC chip is supported and clamped in the lid sub-assembly and in that the entire lid sub-assembly together with the clamped and spring-loaded pusher is attached to the socket by guiding the lid sub-assembly in a transverse direction along the socket guide to the position wherein the spring plungers are locked into their respective openings on the surface of the socket. In one embodiment the pusher is a single part that has three degrees of freedom relative to the IC chip; in another embodiment, the pusher is of a composite structure and has five degrees of freedom.

Owner:PROTOS ELECTRONICS

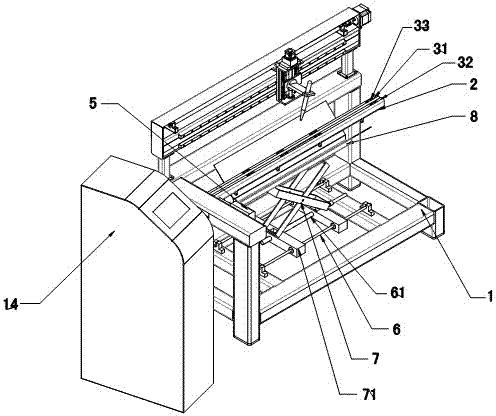

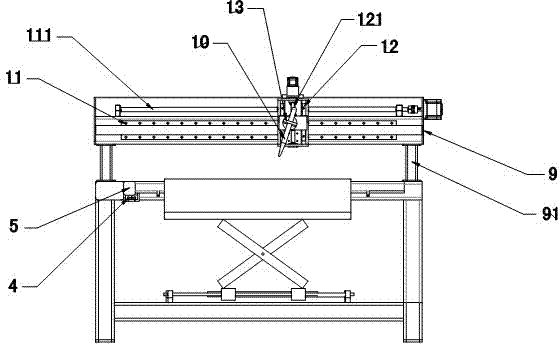

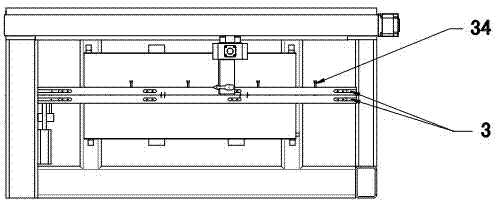

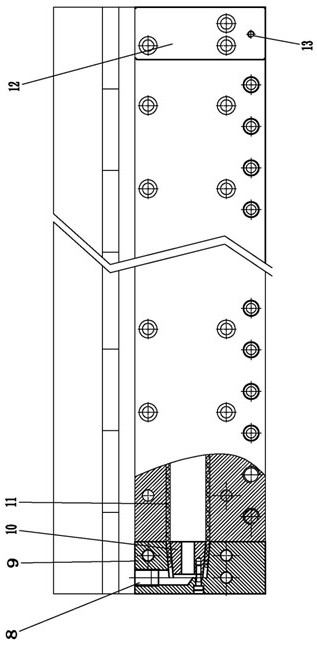

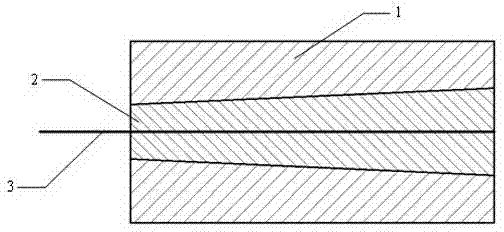

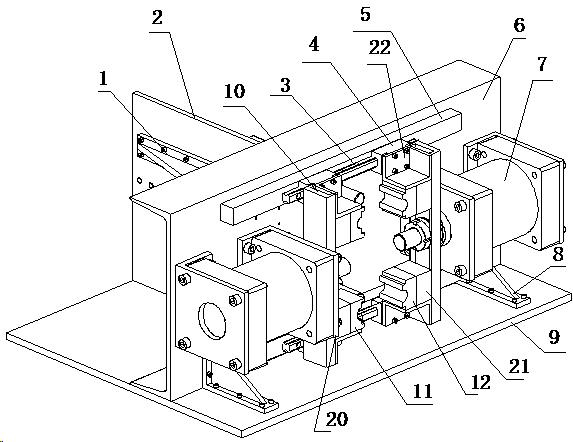

Longitudinal joint automatic welding machine

ActiveCN103495822ASolve problems such as levelingSolve problems such as poor consistency of weld qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringCantilever

The invention provides a longitudinal joint automatic welding machine which comprises a machine frame (1). A supporting mechanism and an adsorption device for clamping a workpiece are arranged in the machine frame, the adsorption device comprises an adsorption base (2) fixedly arranged at the upper end of the machine frame (1), a vacuum adsorption tube (3) for adsorbing the workpiece is arranged at the top end of the adsorption base (2) in the length direction, the supporting mechanism comprises a lifting device and a supporting portion which is used for supporting the workpeice and arranged at the upper end of the lifting device, the supporting portion is a V-shaped supporting groove (8) with an upward opening, and the V-shaped supporting groove is located below the adsorption base (2) and is arranged in parallel with the adsorption base (2) on a vertical face. A vacuum adsorption method is adopted for clamping the workpiece, so that working efficiency of welding joint clamping and calibration is improved. The V-shaped supporting groove is adopted to serve as a workpiece supporting frame, so that the problem of poor consistency of the welding quality caused by the adoption of cantilever for supporting the workpiece in ordinary welding is solved.

Owner:安徽中科维德数字科技有限公司

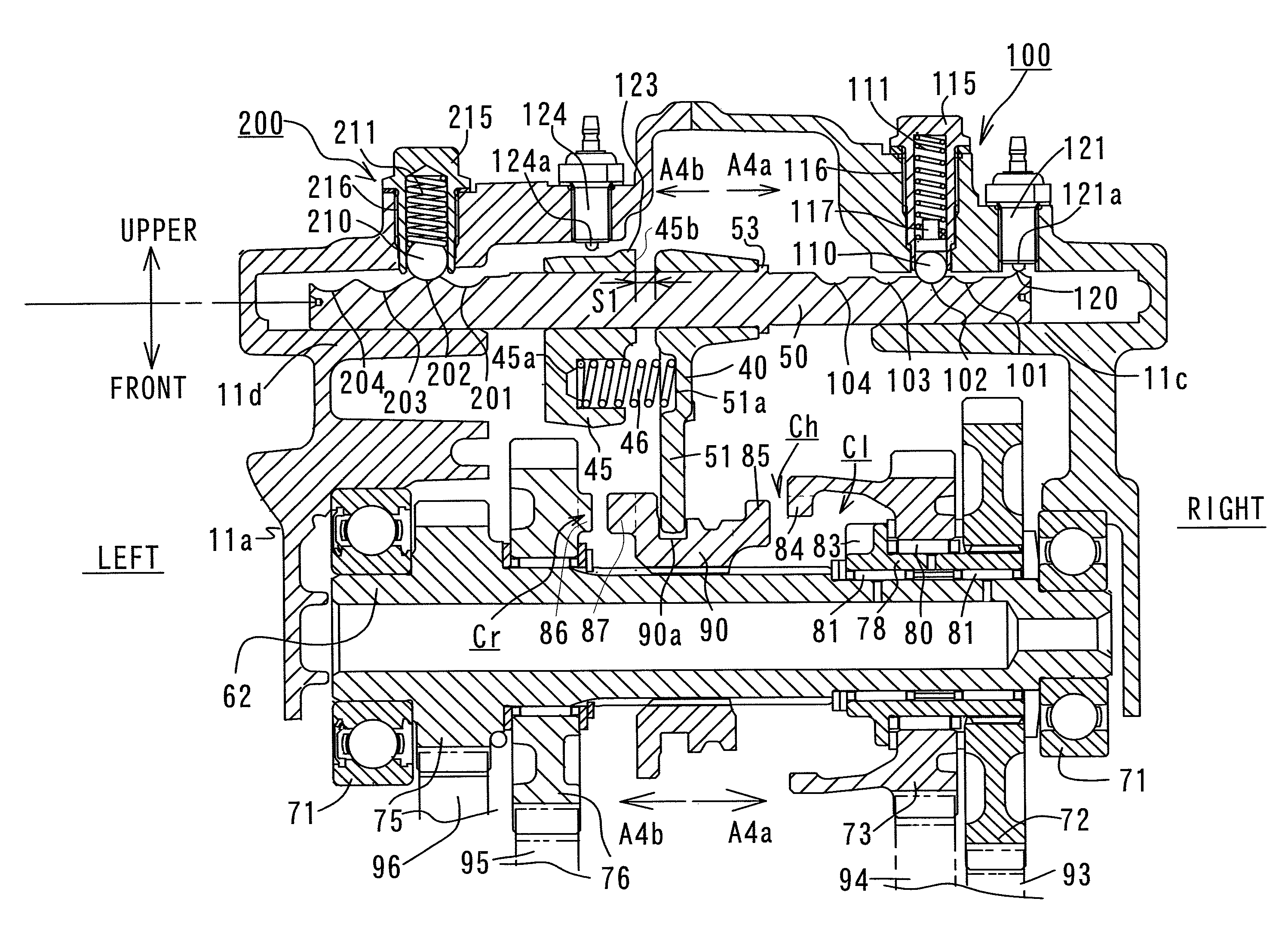

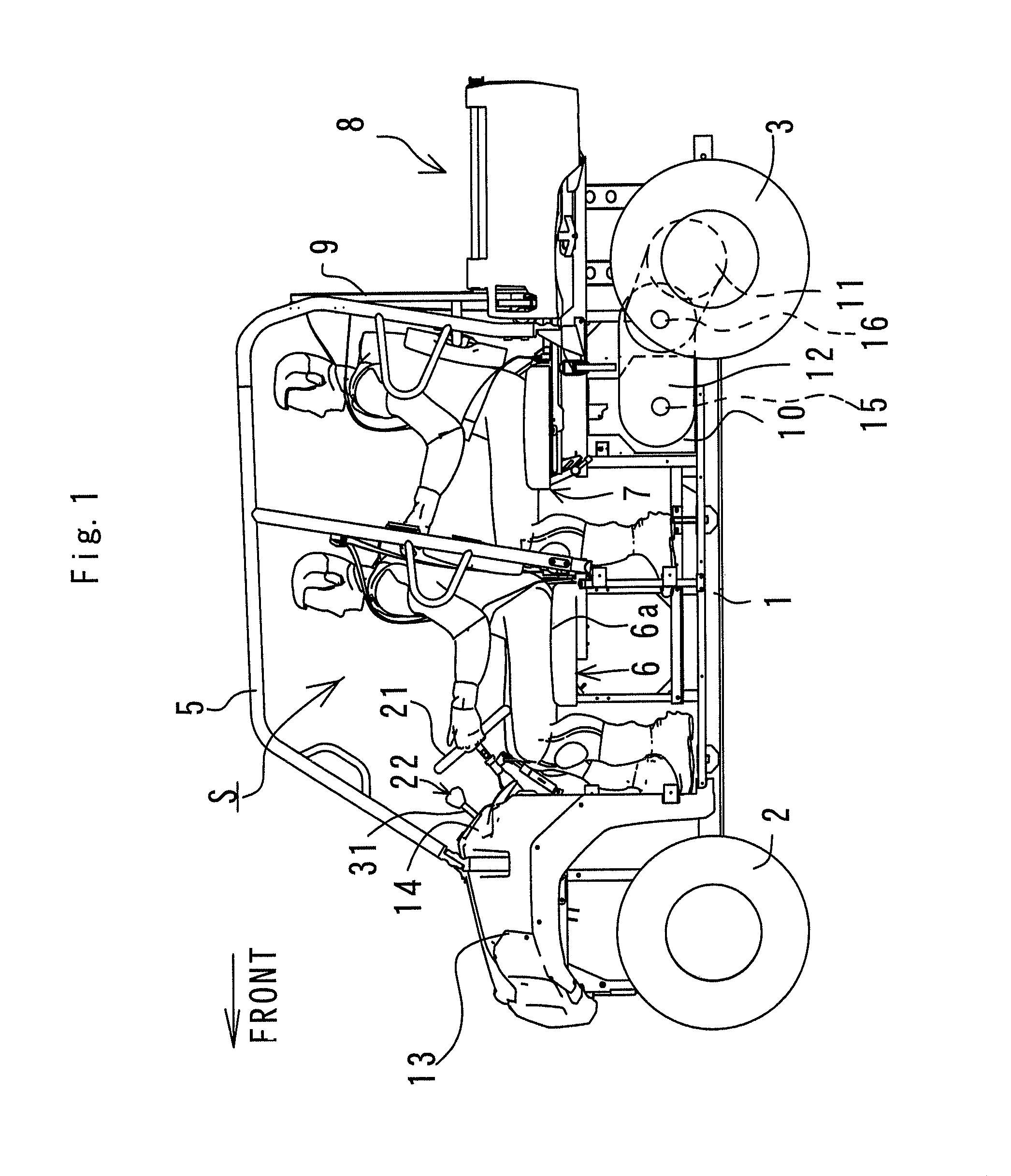

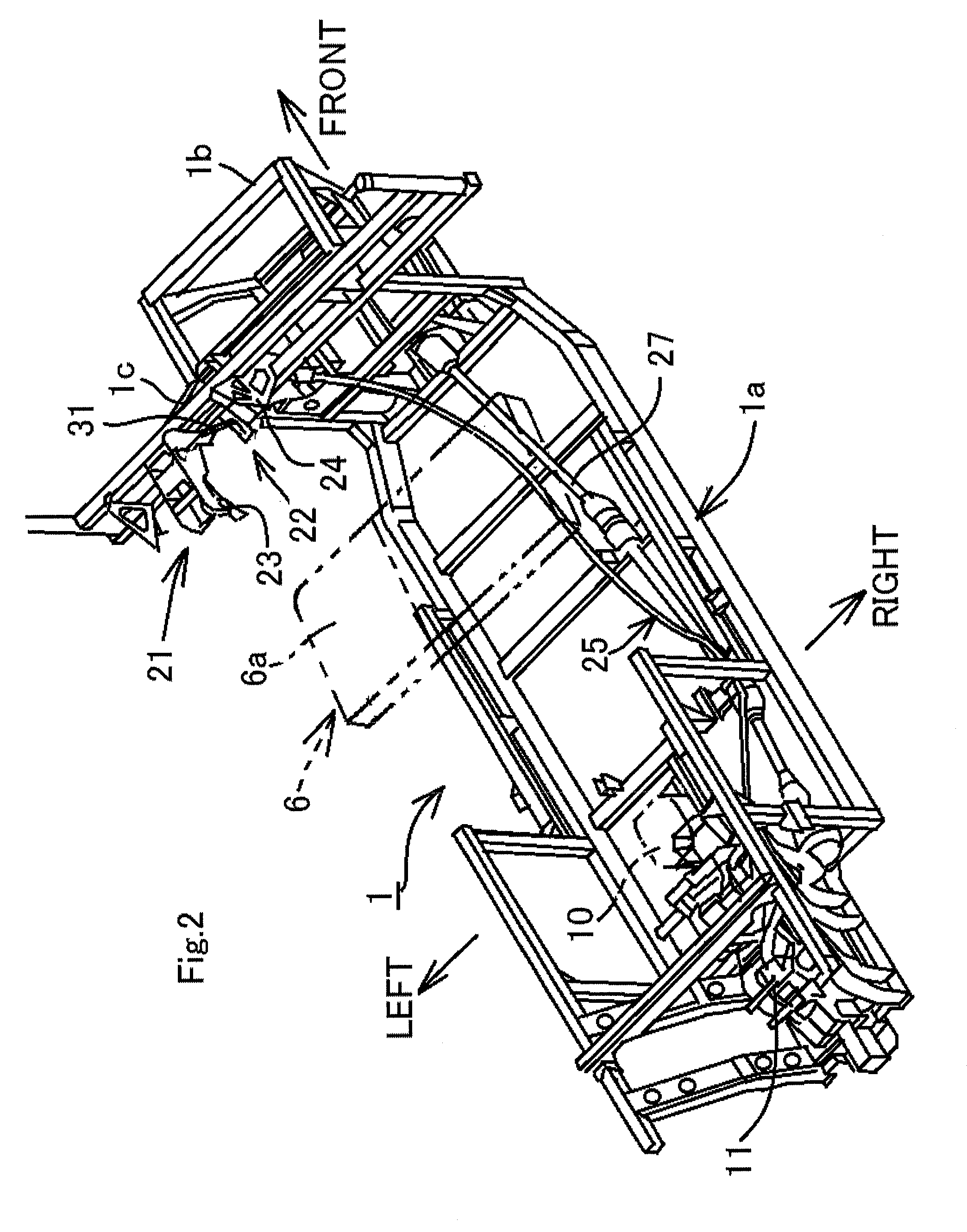

Shift device for transmission

ActiveUS9057436B1Compact construction is achievableIncrease elastic flexibilityToothed gearingsGearing controlEngineeringDog clutch

The present invention is a shift device for switching a dog clutch mechanism in a transmission, comprising: a shift shaft capable of moving in an axial direction; a shift member capable of moving in the axial direction within a predetermined waiting stroke range; an elastic member holder for a waiting mechanism; and an elastic member provided in outside of the shift shaft in a radial direction so as to be compressed and expanded between the elastic member holder and the shift member, wherein the elastic member biases the shift member toward one side in the axial direction.

Owner:KAWASAKI MOTORS LTD

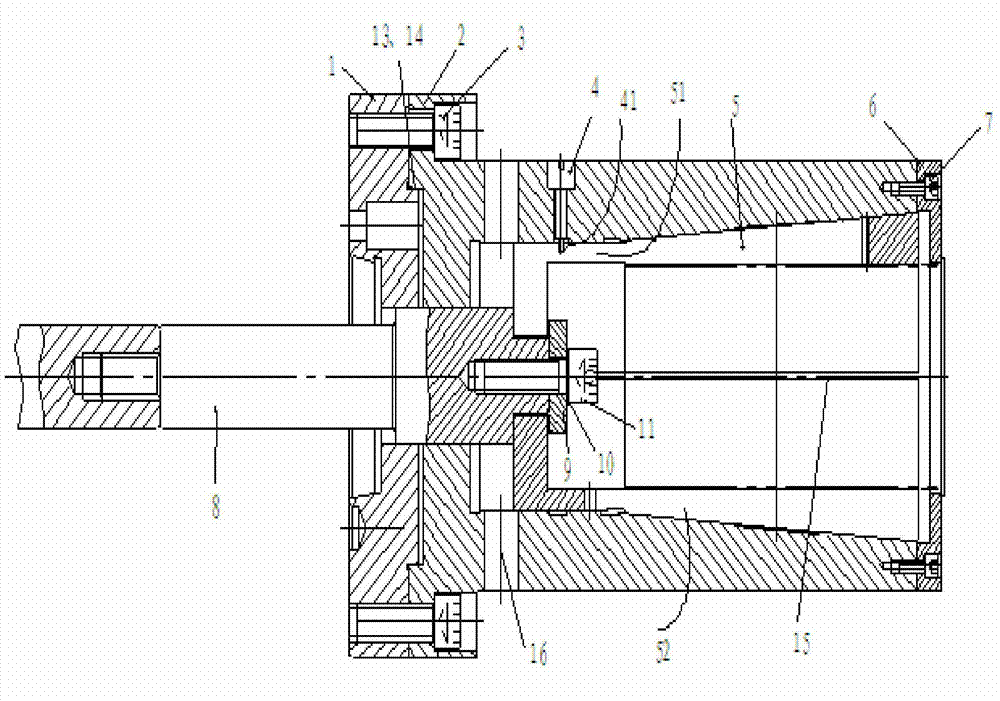

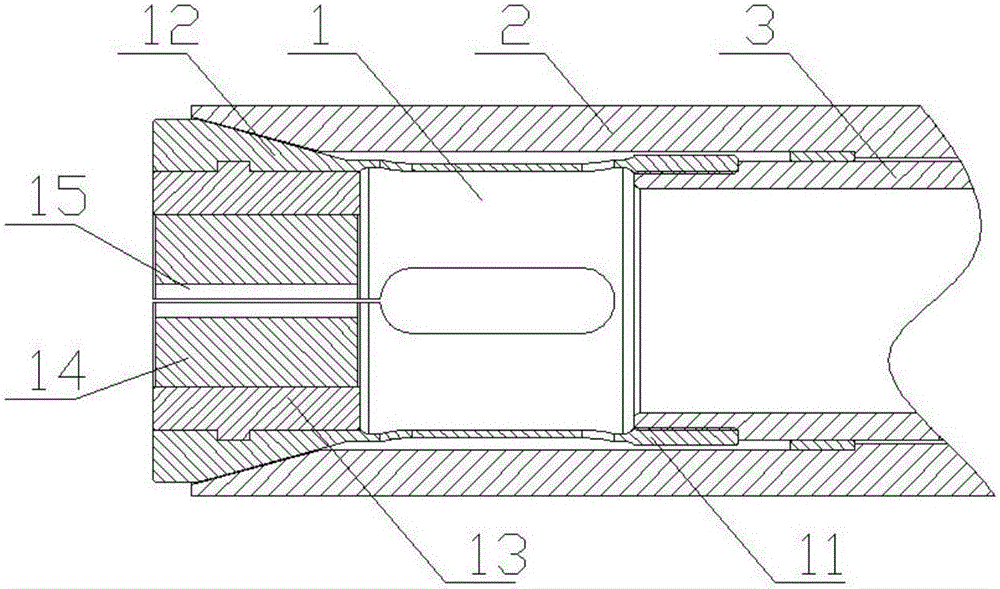

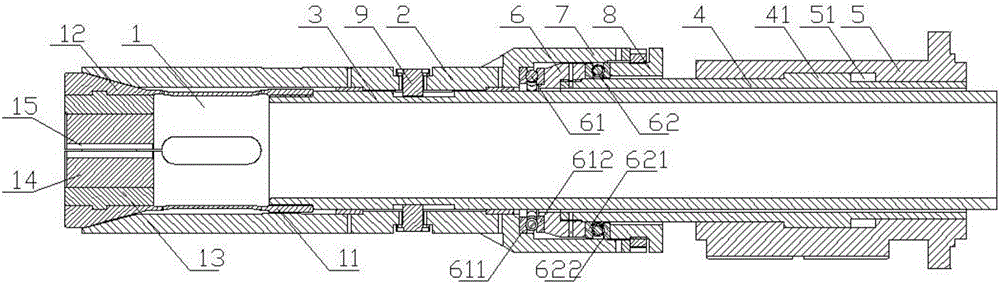

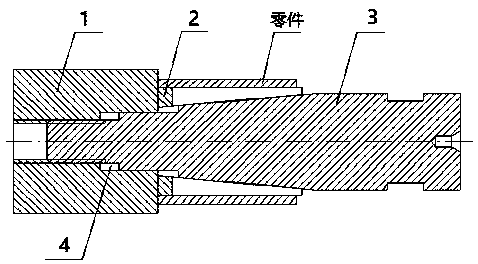

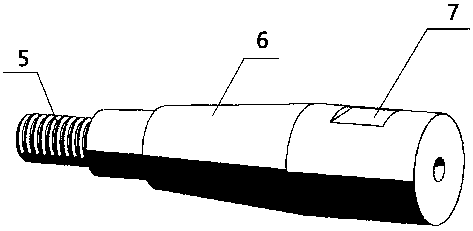

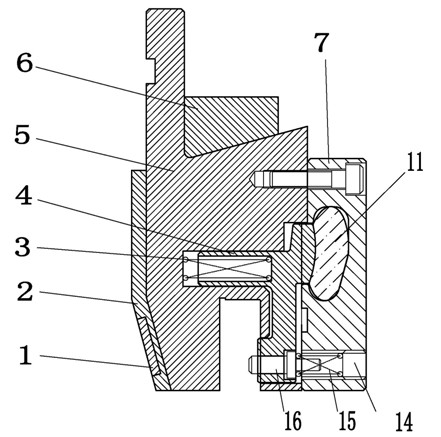

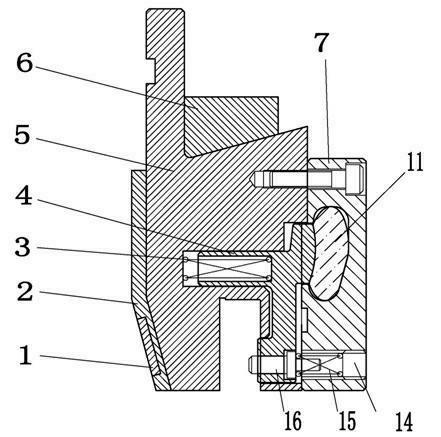

Improved inner-pushing type clamping device for numerical control tube bending machine

ActiveCN105750384AQuick putAccurate placementMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention discloses an improved inner-pushing type clamping device for a numerical control tube bending machine and belongs to the field of numerical control tube bending machines. The improved inner-pushing type clamping device solves the problems that an oil cylinder of an existing clamping device for a numerical control tube bending machine is poor in rotation sealing in the autorotation process and is likely to leak oil, and the service life is short. The improved inner-pushing type clamping device comprises a flexible chuck, an oil cylinder and a component, wherein the flexible chuck and the oil cylinder are connected through the component. The component for connecting the flexible chuck and the oil cylinder comprises a chuck pushing bush and a rotating rod. The oil cylinder comprises a cylinder body and a piston rod arranged in the cylinder body, and the chuck pushing bush is arranged at the stretching-out end of the piston rod, is fixed relative to the piston rod in the axial direction and can relatively rotate around the axis. The rotating rod is arranged in the piston rod, and is connected with the chuck pushing bush in the connecting mode that the rotating rod and the chuck pushing bush can rotate synchronous and move relatively in the axial direction. The flexible chuck is arranged at one end of the rotating rod. By means of the improved inner-pushing type clamping device, the problem of oil leakage caused by poor rotation sealing of the oil cylinder can be solved, so that the working stability of the clamping device is improved, and the service life is prolonged.

Owner:ANHUI DEXI DHI TECH

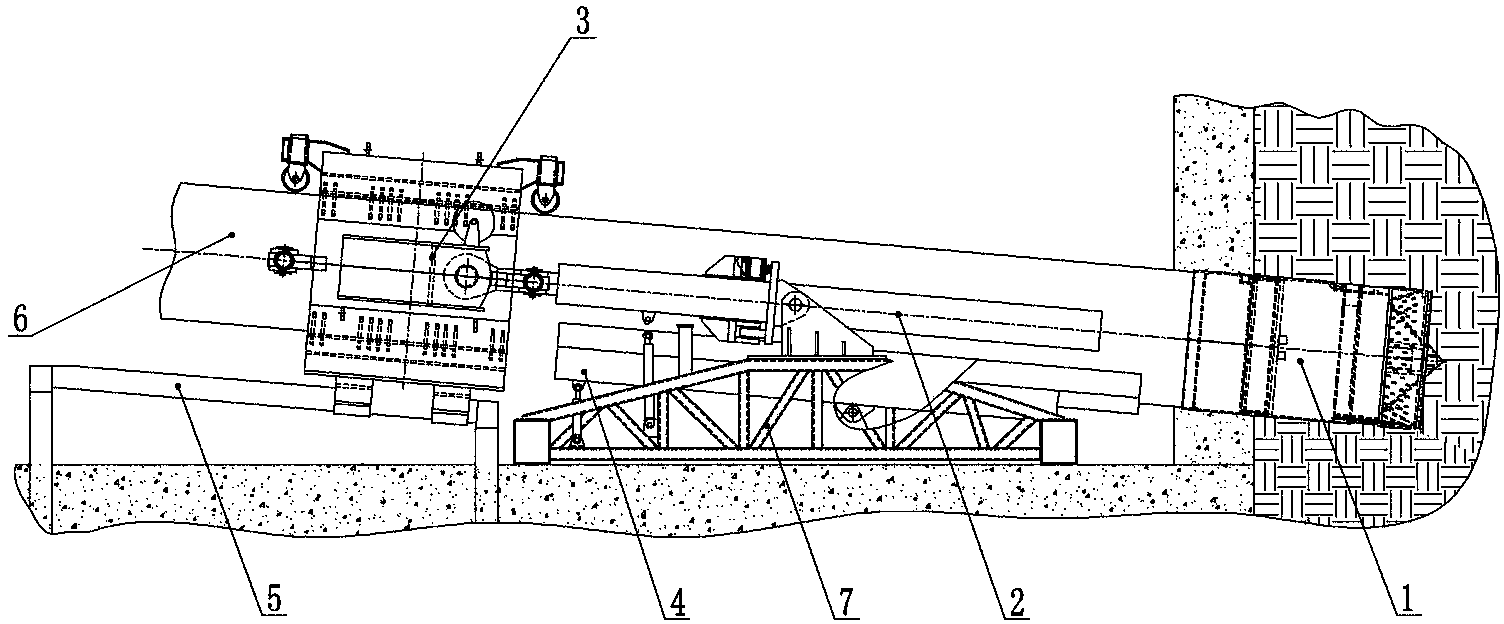

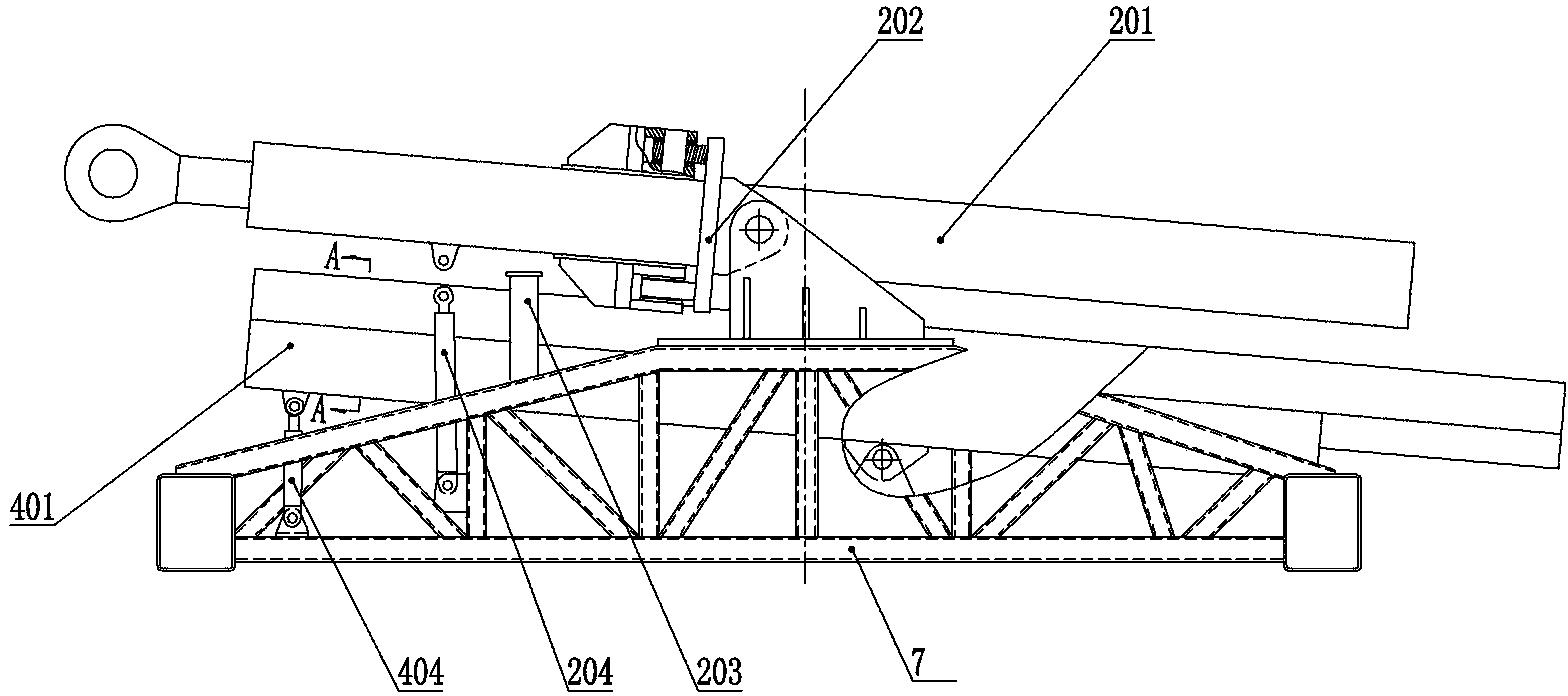

Direct pipe laying machine

The invention belongs to the technical field of trenchless construction machinery, and discloses a direct pipe laying machine comprising a heading machine, a holding device, a pipeline connected to the rear end of the heading machine, a clamping device which is arranged on the rear portion of the heading machine and which supports the pipeline, and a propulsion device arranged between the clamping device and the holding device. The holding device comprises a holding beam, one end of the holding beam is hinged to a supporting post, and the other end of the holding beam is hinged to a holding beam positioning cylinder. The clamping device comprises an annular upper main frame and clamping cylinders which are connected through pins, the ends of the clamping cylinders are fixed with arc friction plates matching with the heading machine or pipeline, and a sliding lug is arranged on the lower portion of a lower main frame and slides on a guide rail arranged on the lower portion in a matching manner. The propulsion device comprises a base frame and two propulsion cylinders, and the other ends of the propulsion cylinders are hinged to connecting lugs arranged on the main frames of the clamping device.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Thin-wall motor case milling fixture

ActiveCN103465072AWon't breakEnsure consistencyPositioning apparatusMetal-working holdersMachined surfaceReciprocating motion

The invention relates to the field of motor machining, in particular to a thin-wall motor case milling fixture, aiming at realizing the goals that the requirements on positioning and clamping reliability and production efficiency are met, the accuracy is guaranteed, the clamping force is uniform, machined surfaces are not damaged, the production cost is decreased and the situation of case deformation caused by excessive pressing during clamping is avoided. In order to realize the goals, the technical scheme adopted by the invention is that the thin-wall motor case milling fixture comprises a fixture body, an elastic thin wall sleeve and a clamping block, the elastic thin wall sleeve is installed on the fixture body, the outer surface of the clamping block is conical and the thin-wall motor case milling fixture additionally comprises a device which is installed below the fixture body and can control the fixture body to move back and forth.

Owner:芜湖杰诺瑞汽车电器系统有限公司

Thin-wall rotary type component cylindrical lathe cutting clamping method and device

The invention discloses a thin-wall rotary type component cylindrical lathe cutting clamping method and device. According to the method, an inner hole of a thin-wall rotary type component is tightened, and the purpose of clamping the thin-wall rotary type component is achieved; the clamping device used in the method comprises a base, an elastic hollow shaft and a top rod with a threaded conical surface, wherein a guide hole is formed in the center of the base; the guide hole is in threaded connection with the top rod of the threaded conical surface; the elastic hollow shaft is arranged at theperiphery of the top rod with the threaded conical surface. The device is relatively simple in structure, convenient in clamping operation and reliable in clamping mode, the situation that the thin-wall rotary type component is deformed or scraped in cylindrical latch cutting operation is avoided. Not only is the processing precision improved, but also the processing rejection rate is reduced, andthe processing cost is reduced.

Owner:GUIZHOU HONGLIN MACHINERY

Adjustable positioning milling fixture

ActiveCN104227440APrecise positioningClamp firmlyMeasurement/indication equipmentsLarge fixed membersReducerEngineering

An adjustable positioning milling fixture comprises a fixture body, a guide rail, sliders, clamping blocks, a single-chip processor, a control panel, a motor, a conveying belt, a reducer, a positioning seat, a positioning block, a pressure sensor and a sensor mounting groove. The fixture is mainly used for clamping parts with thin walls and housings. The clamping blocks are capable of moving along the straight guide rail through the spiral rail, straight guide rail and rails at the bottoms of the sliders in a matched manner. The fixture is used for clamping the thin-wall motor housing when the thin-wall motor housing is milled, and the thin-wall motor housing is guaranteed being fixed during machining.

Owner:芜湖杰诺瑞汽车电器系统有限公司

Polishing device and technology for false tooth machining

ActiveCN111251143APrevent overthrowUndershootGrinding drivesLapping machinesPolishingFixed prosthodontic

The invention relates to a polishing device for false tooth machining. The polishing device comprises a base, an installation seat which is placed on the base and is used for fixing a false tooth in the polishing process, a support fixed to the base and a grinding tool which is installed at the end, away from the base, of the support and is used for grinding the false tooth. The polishing device is characterized in that a magnetic worktable is arranged on the upper end face of the base; multiple concentric ring-shaped grooves are formed in the lower end face of the installation seat; magnets are arranged in the ring-shaped grooves; and a clamping mechanism used for clamping and fixing the false tooth is arranged on the installation seat. The polishing device has the effects that the relative position between the installation seat and the base is conveniently adjusted, and therefore the grinding process is more convenient.

Owner:泉州市超维医疗科技有限公司

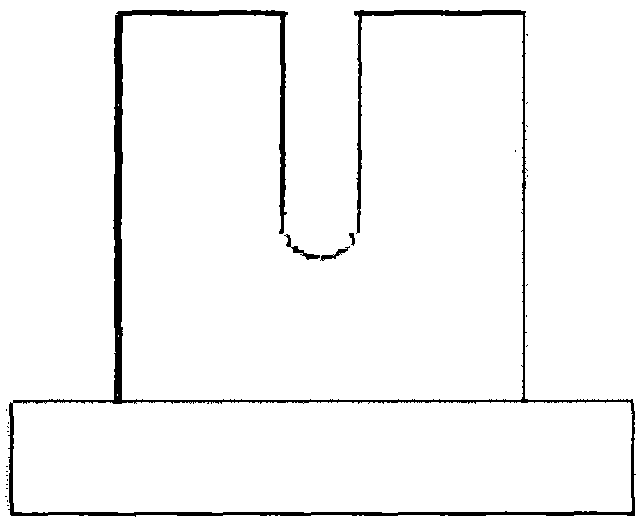

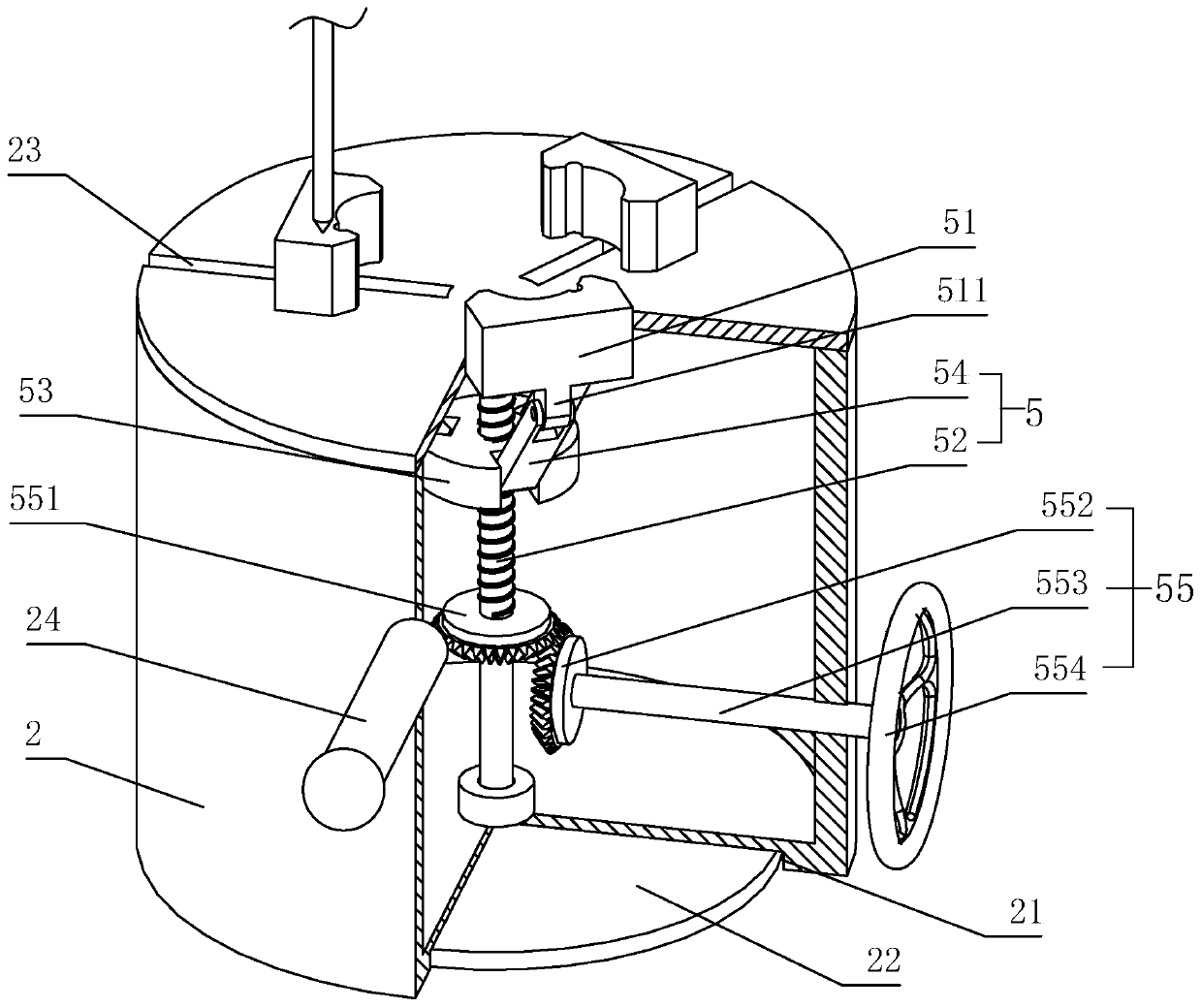

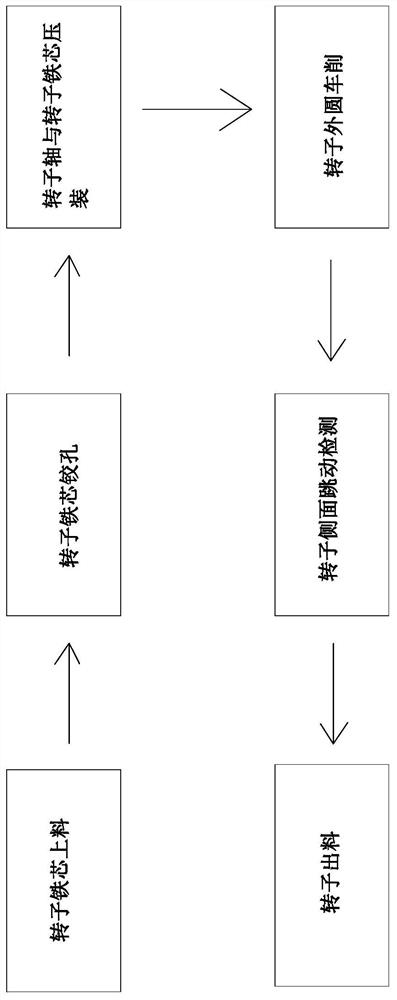

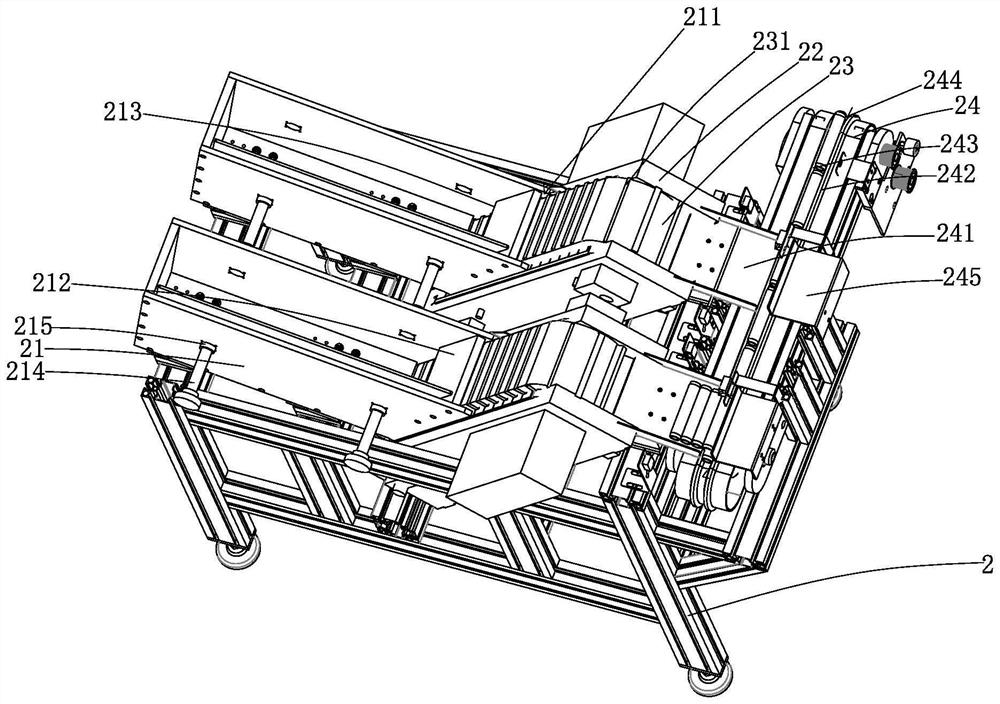

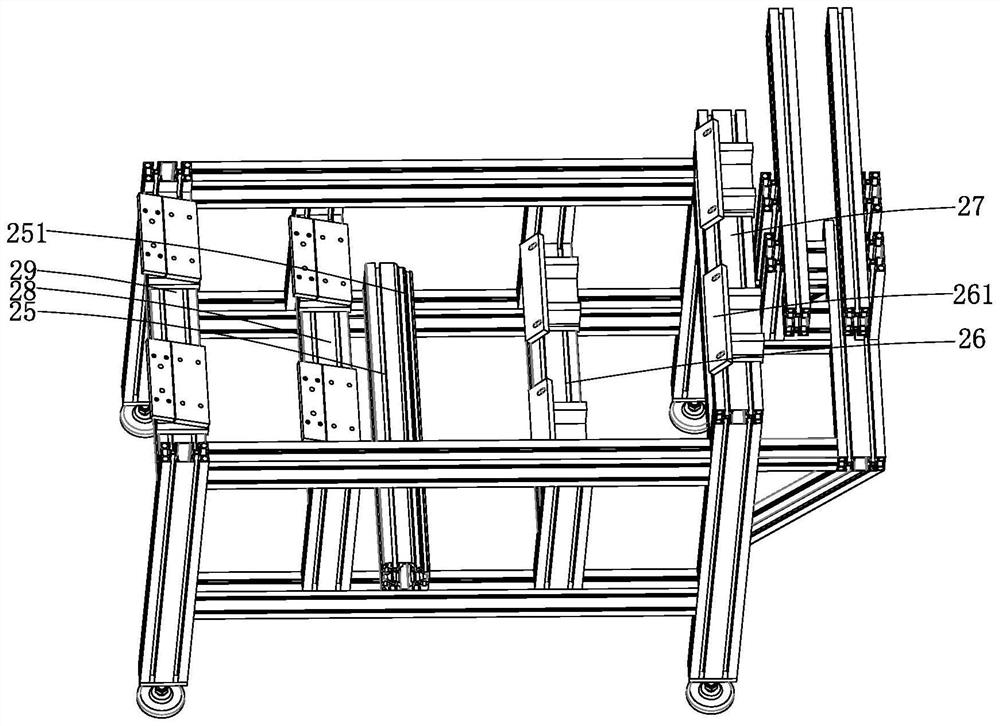

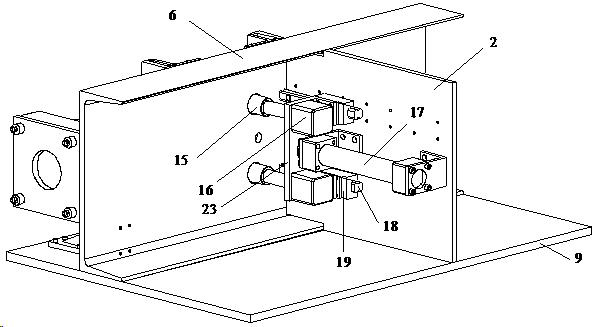

Rotor core and rotor shaft press-fitting assembly line

ActiveCN112217351AUniform clamping forceEasy to adjustManufacturing stator/rotor bodiesAssembly linePhysics

The invention relates to a rotor iron core and rotor shaft press-fitting assembly line which comprises rotor iron core automatic feeding equipment, rotor iron core automatic reaming equipment, rotor shaft and rotor iron core press-fitting equipment, rotor outer circle turning equipment, rotor side face bounce detection equipment and rotor automatic discharging equipment which are sequentially arranged. The rotor iron core automatic reaming equipment comprises a first bottom plate, a first fixing plate is arranged above the first bottom plate, a first V-shaped clamping block and a second V-shaped clamping block are arranged on the first fixing plate, a first connecting arm and a second connecting arm are arranged below the first fixing plate, one end of the first connecting arm is rotationally connected with the first V-shaped clamping block. The second connecting arm is rotationally connected with the second V-shaped clamping block, and the other end of the first connecting arm and theother end of the second connecting arm are rotationally connected with the same connecting shaft. The clamping device has the advantages of being suitable for workpieces of various specifications, uniform in clamping force, easy and convenient to adjust and the like.

Owner:ZHEJIANG LINIX MOTOR

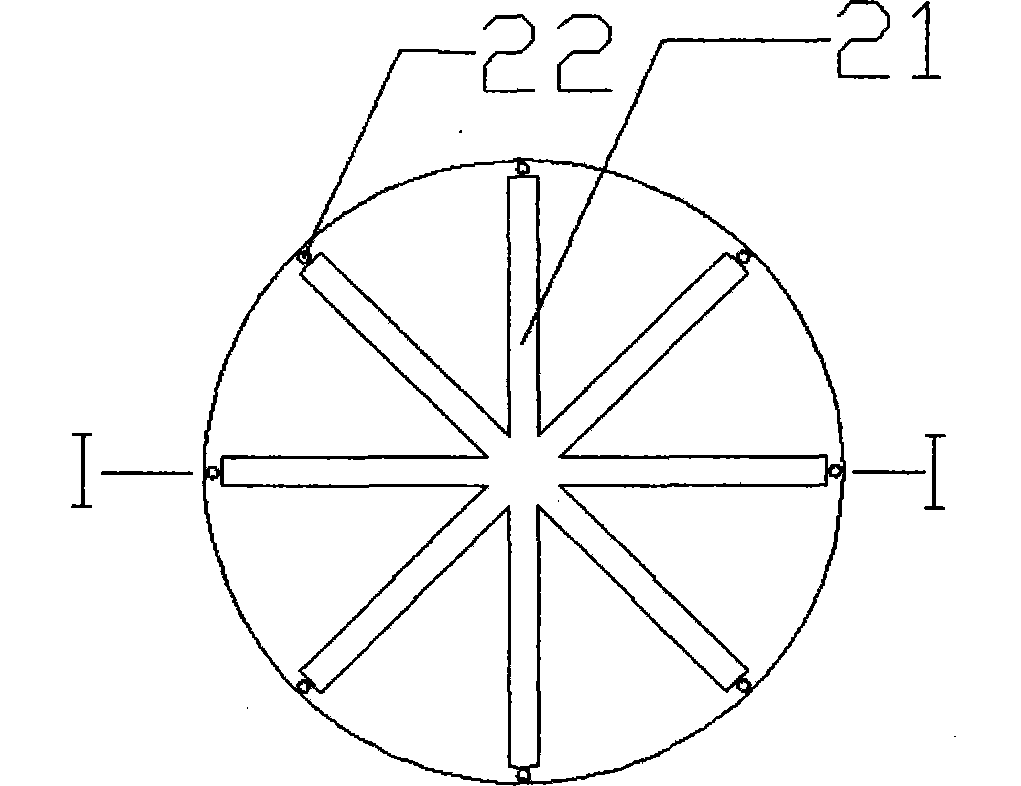

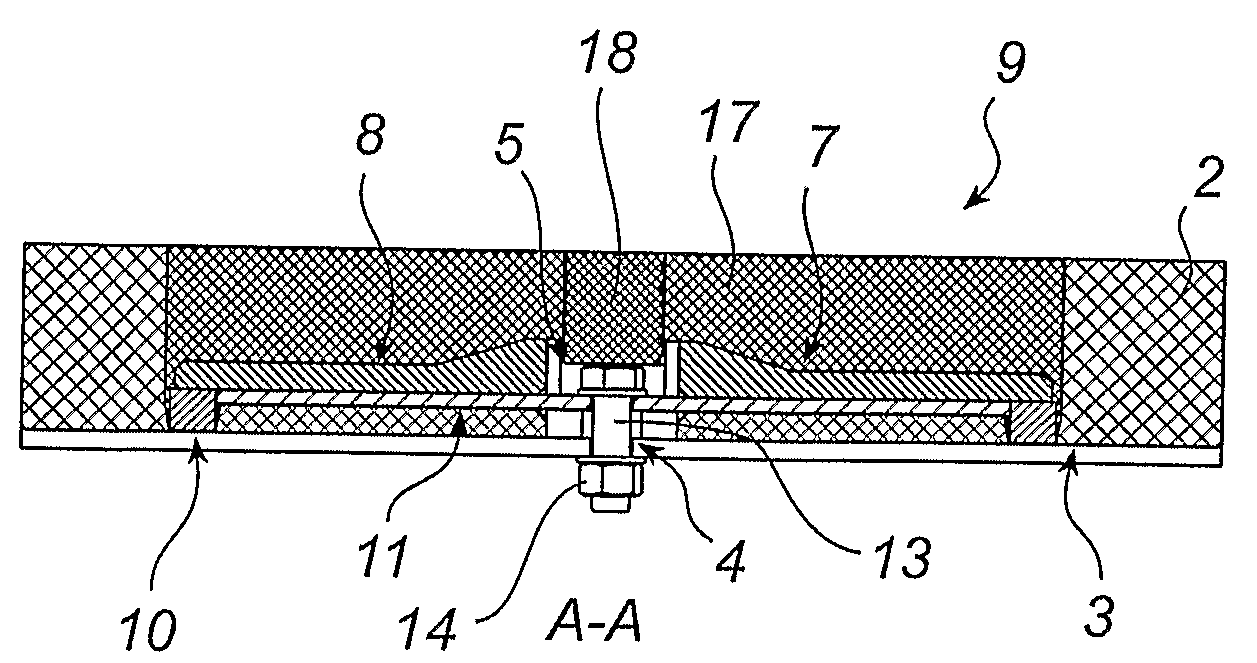

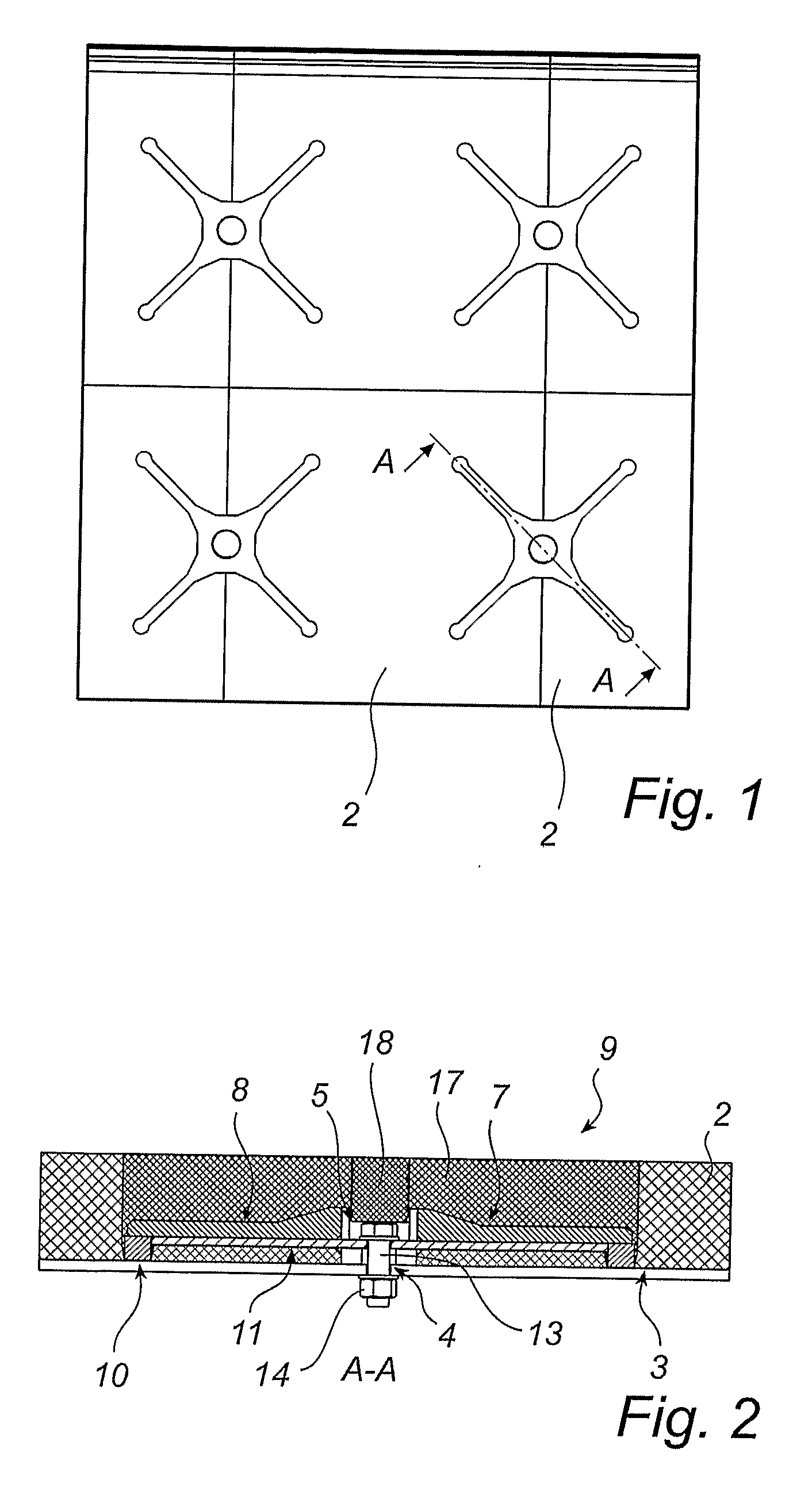

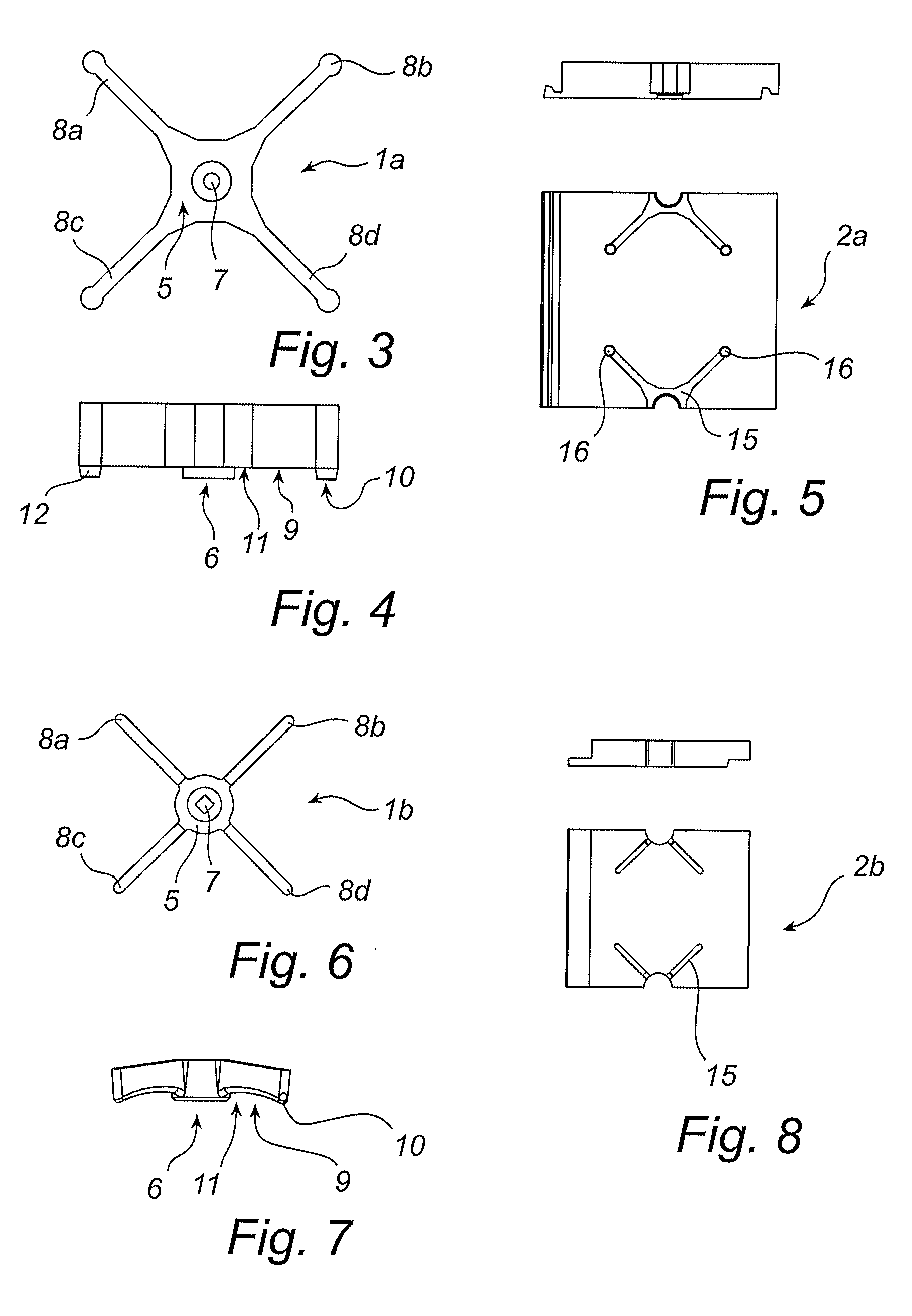

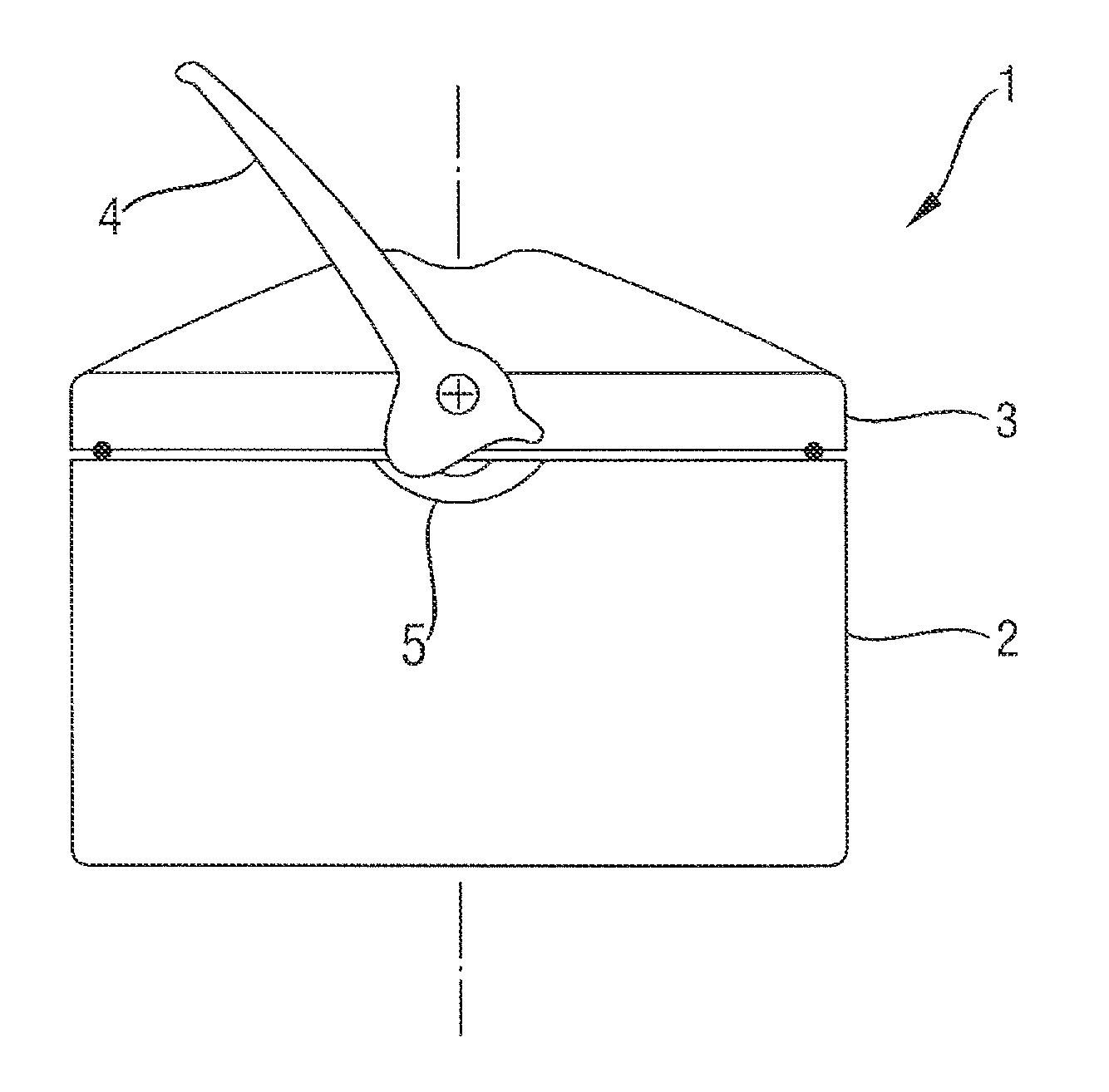

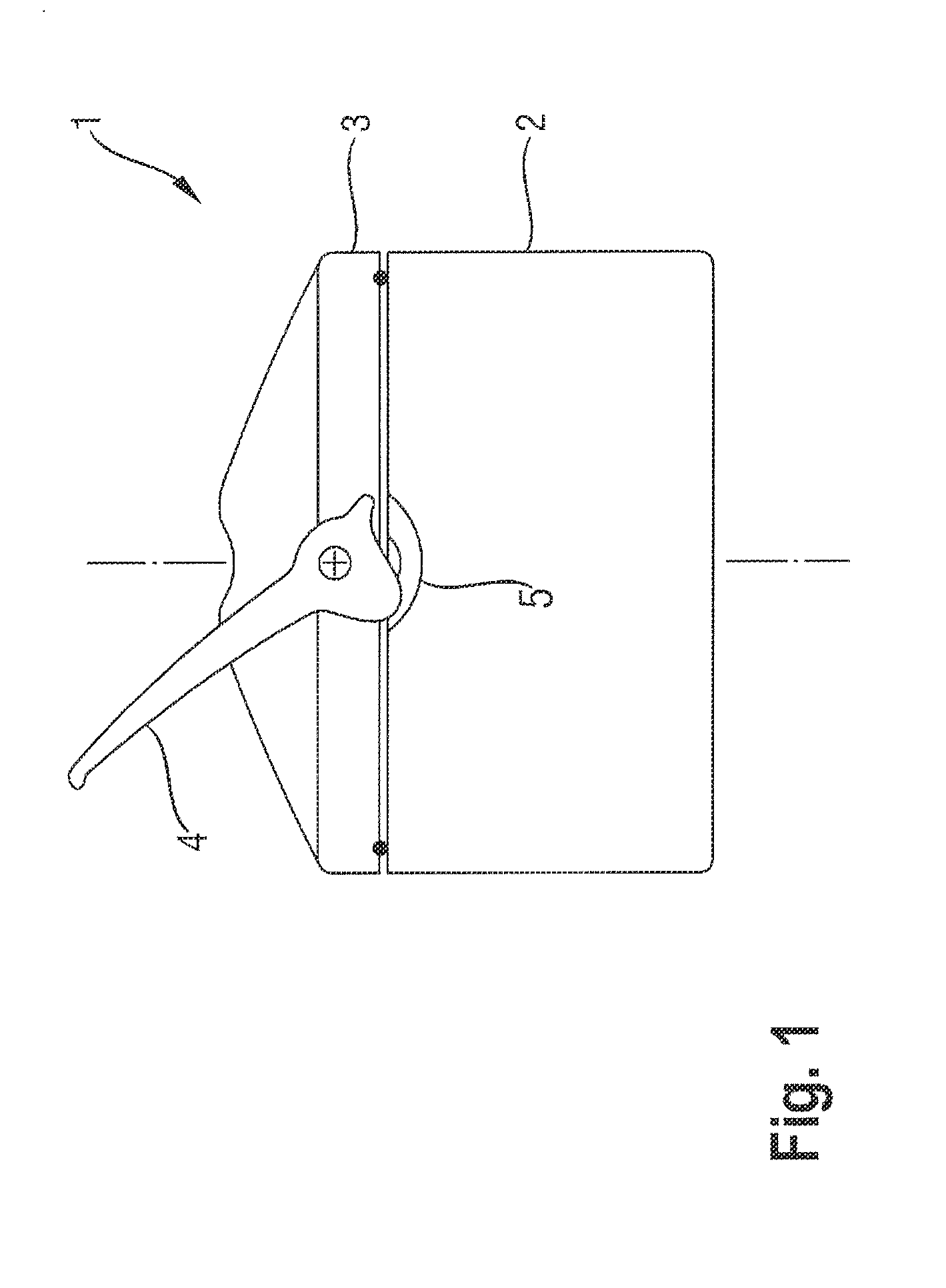

Fastening Spider and Method of Fastening

ActiveUS20090173857A1Easy constructionEasy and inexpensive to manufactureSnap fastenersCandle holdersWear resistantMechanical engineering

A fastening spider (1) and a method of fastening a wear-resistant lining element (2) to a support surface (3), over which wear-resistant lining element (2) material in the form of pieces or particles is intended to move. The fastening spider (1) comprises a mounting portion (5) for mounting positioning and clamping to the support surface (3) and at least one leg (8a-8b) projecting from the mounting portion (5) and having an underside for holding the wear-resistant lining element (2) to the support surface (3). The underside of the leg has an outer portion (10) and an inner portion (11), the inner portion (11) being positioned closer to the mounting portion (5) than the outer portion (10). The outer portion (10) is, at least in the mounting positioning of the mounting portion, positioned closer to the support surface (3) than the inner portion (11).

Owner:METSO OUTOTEC (FINLAND) OY

Clamping or spreading tool

ActiveUS20100276860A1Dimension in spaceReduce weightSpring motorSemiconductor/solid-state device manufacturingPush and pullTorsion spring

A clamping and / or spreading tool comprises a drive for displacement of a push or pull rod to which a movable jaw is fixed with respect to a support carrying a stationary jaw in longitudinal direction of the push and pull rod, the drive comprising a torsion spring and being adapted to enter torque transmitting engagement with the push or pull rod for displacement of the same.

Owner:IRWIN IND TOOL CO

External pipeline paving device of large-scale air purifying equipment

The invention discloses an external pipeline paving device of large-scale air purifying equipment. The device comprises a fixing cover, horizontal positioning frames and a vertical positioning frame;the vertical positioning frame comprises a U-shaped bottom plate, transverse sliding rods and supporting brackets, the front end and the rear end of the transverse sliding rods are provided with firstthreaded sections and second threaded sections, and the thread directions of the first thread sections and the second thread sections are opposite, and the first threaded sections and the second threaded sections are provided with supporting brackets. According to the device, the external pipeline is integrally supported and fixed through the paving device, so that the overall stability of the pipeline is ensured, then the paving device and the equipment are connected and fixed, the operation difficulty of directly paving the pipeline on the surface of the equipment is reduced, and the pipeline and the inner pipeline in the equipment can be conveniently connected and fixed, and the tight performance after the pipeline is in butt joint is improved, and the multiple parts of the pipeline can be simultaneously supported and positioned through the paving device, the structure stability of the external pipeline is effectively ensured, and the effects of damping and noise reducing are achieved.

Owner:嘉兴市良友制衣有限公司

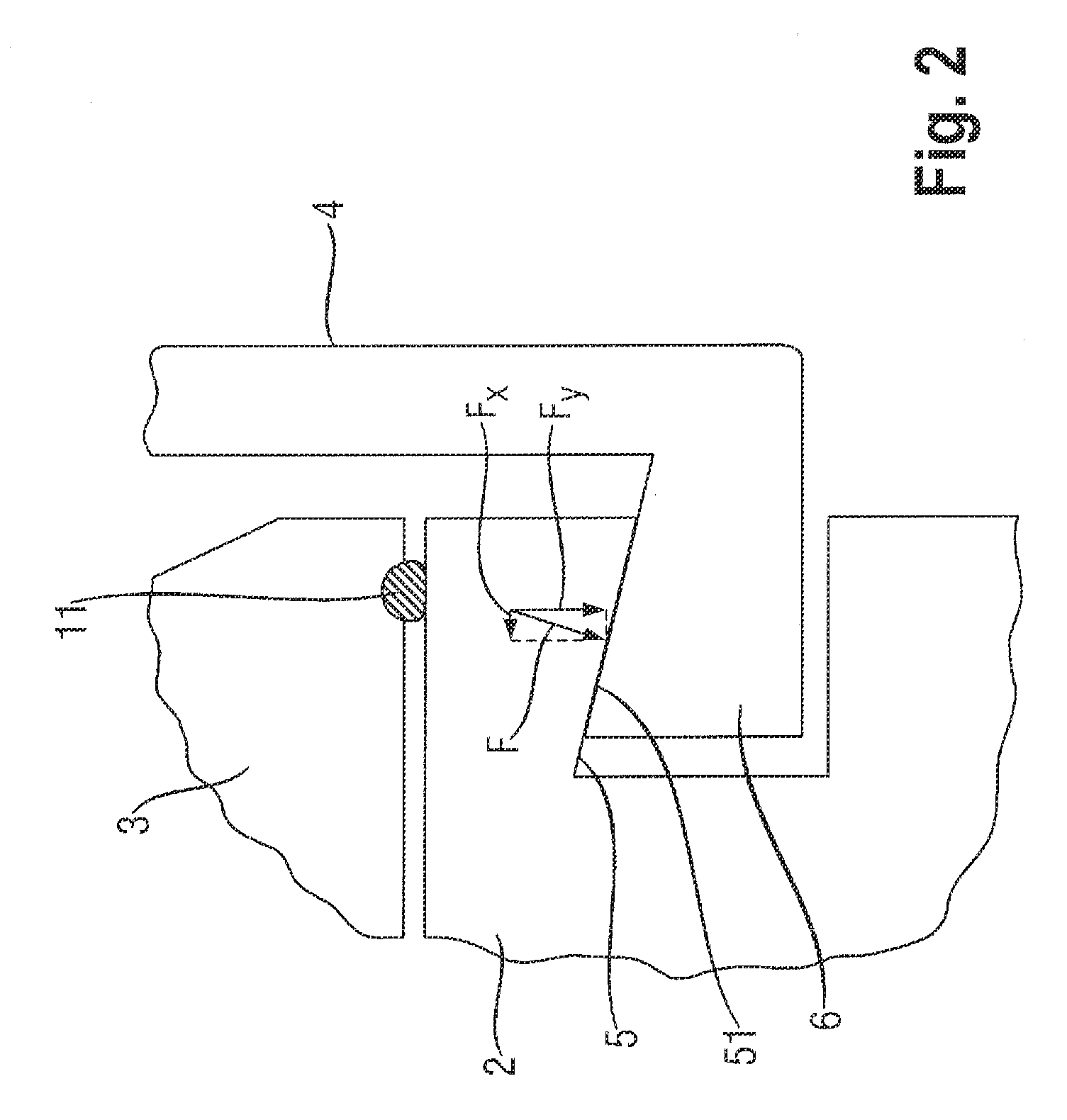

Centrifuge cup

ActiveUS20100004109A1Simple handlingReduce manufacturing tolerancesRotary centrifugesClamping mechanismEngineeringContact line

The invention relates to a centrifuge cup, which has a container and a cover. The cover has a lever including a guide element in each case on opposing edge areas thereof. The guide elements are able to be introduced into an associated guide path of the container by pivoting the lever. The guide elements are implemented in such a way that in a closed state of the cover with the container, a clamping force (F) having vertical force component (Fy) and horizontal force component (Fx) is provided at a contact point or a contact line of the guide elements with the particular associated guide path.

Owner:THERMO ELECTRONICS LED GMBH

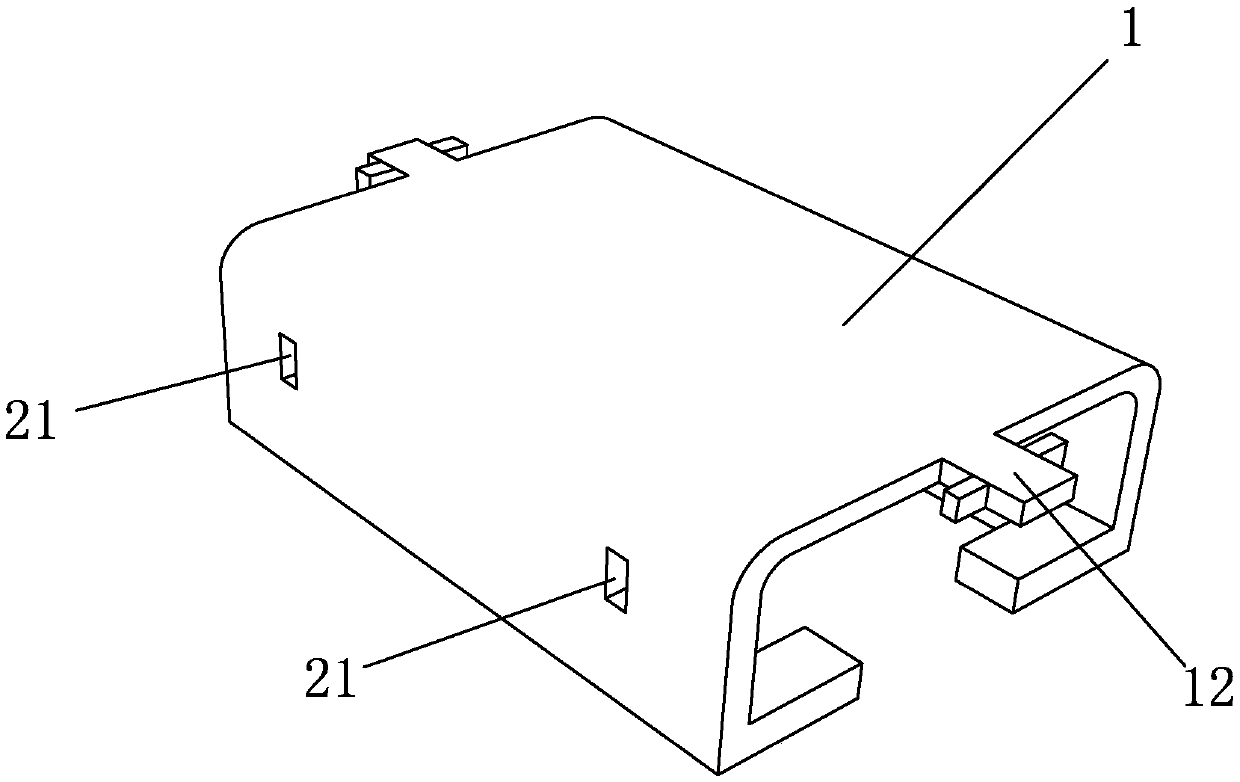

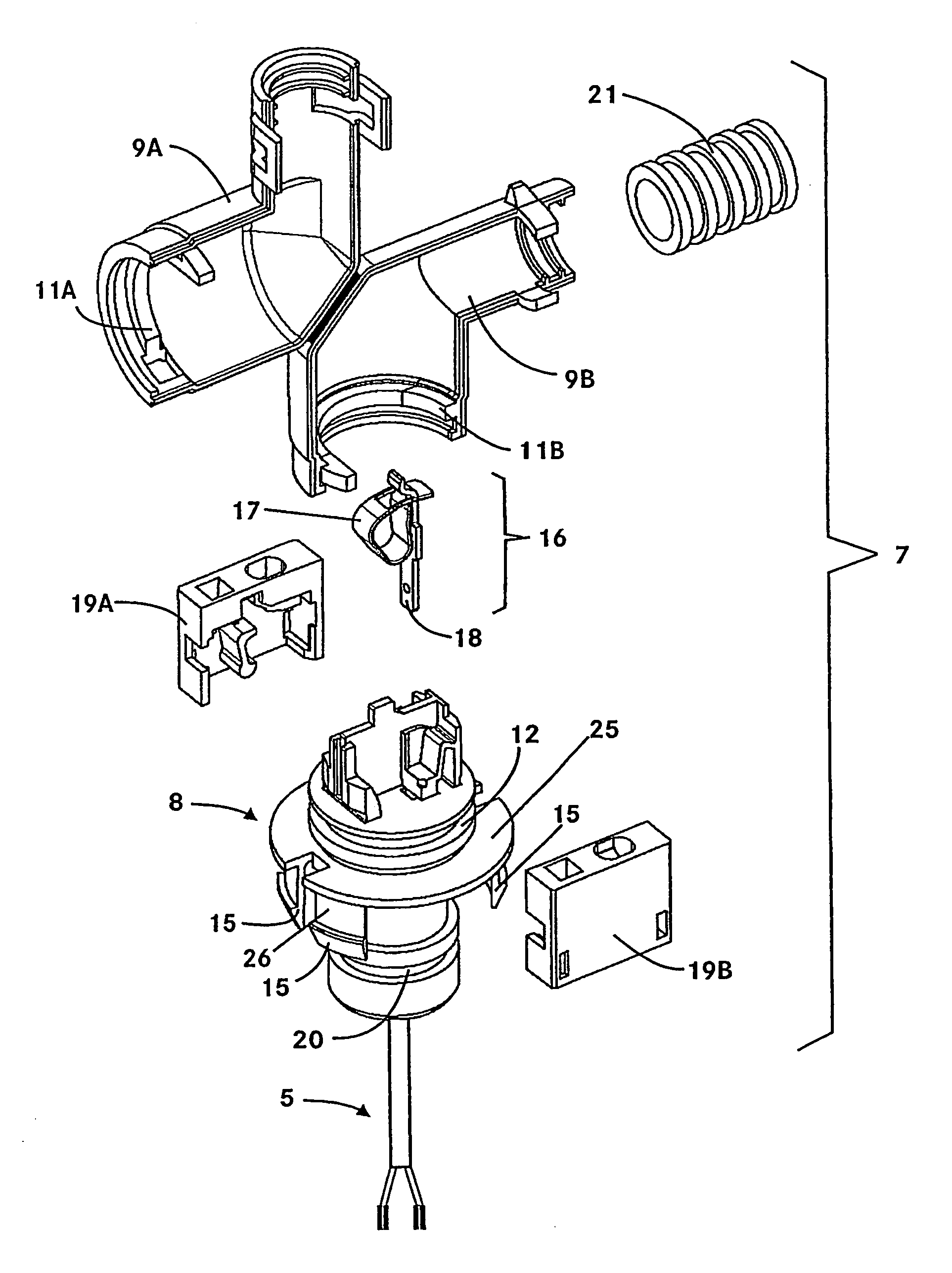

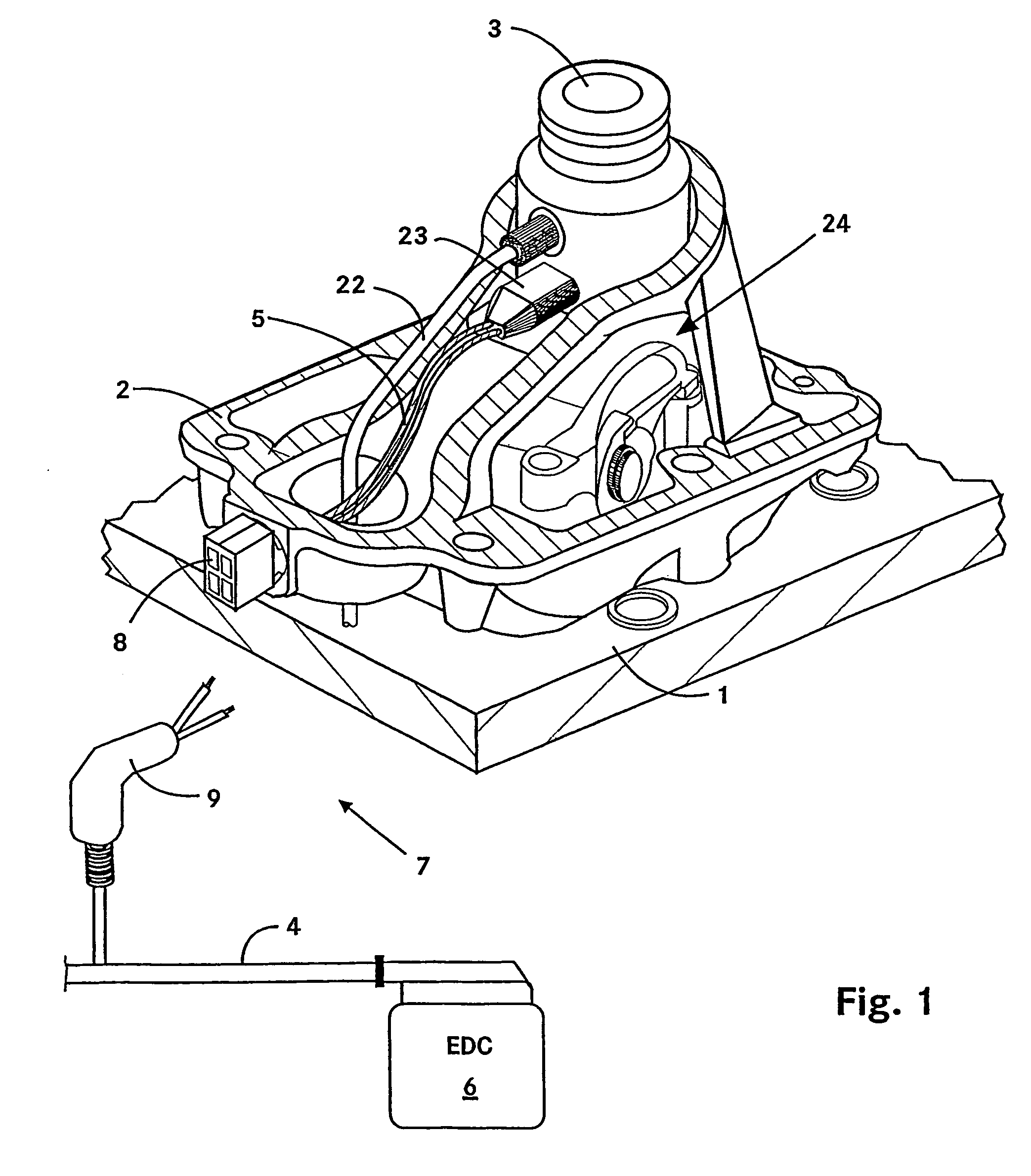

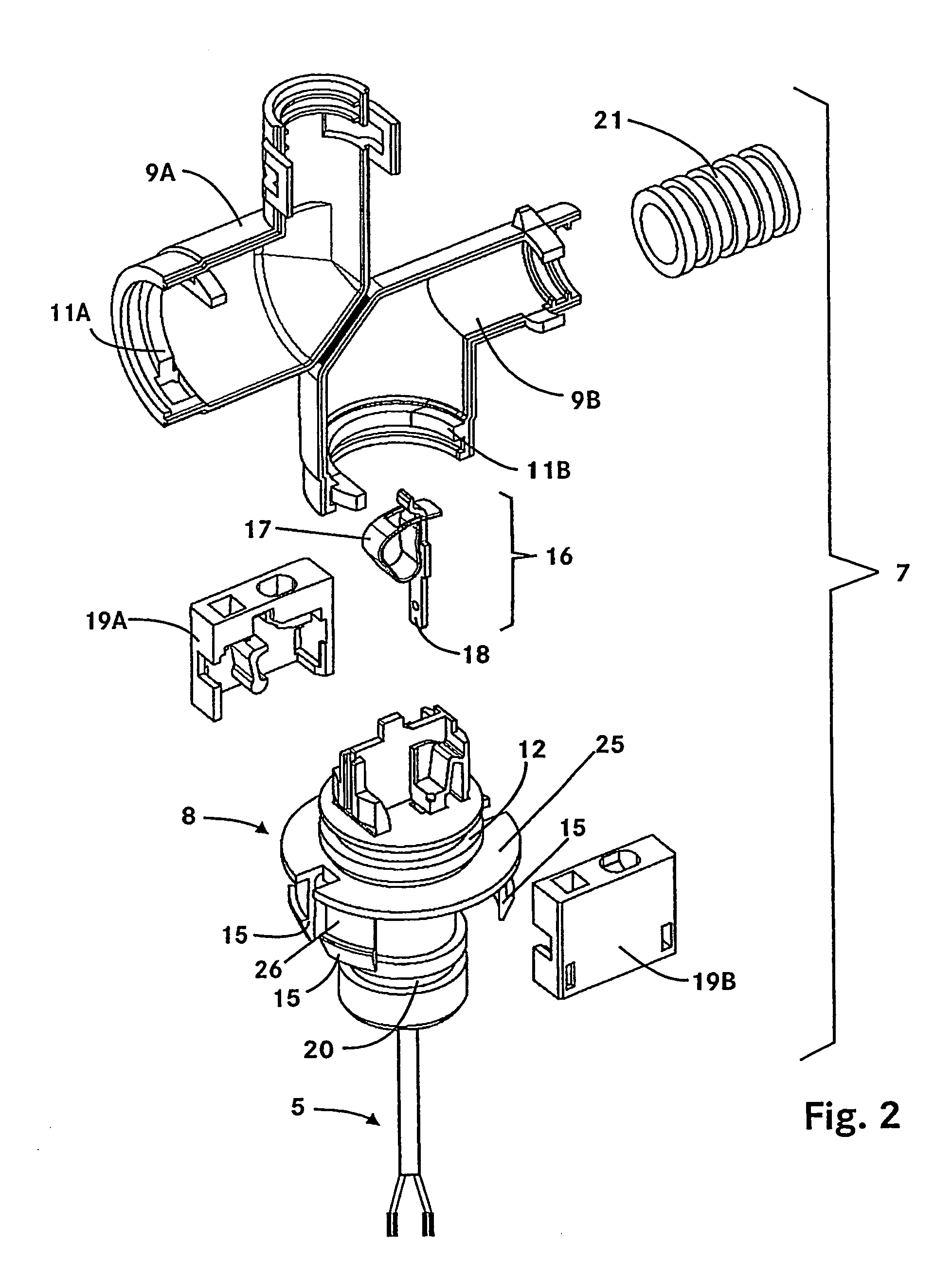

Internal combustion engine comprising a connecting means for connecting a first section of a wire harness on a cylinder head housing to a second section of the same

The invention relates to an internal combustion engine comprising an injector (3) which is arranged in the cylinder head. According to the invention, said internal combustion engine is provided with a connecting means (7) for connecting a first section (4) of the wire harness to a second section (5) of the same. Said connecting means (7) comprises a terminal carrier (8) and a cover (9, 10). Both the terminal carrier (8) and the cover (9, 10) are provided with self-locking means. In this way, a cost-effective connecting means (7) is provided, which can be easily and quickly mounted.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

Upper die clamping device of bending machine

The invention discloses an upper die clamping device of bending machine, wherin the device comprises a clamp body. The upper of the clamp body is connected with the bending machine and the lower of the clamp body is connected with the upper die of the bending die. The inner of the clamp body is provided with a clamping block for clamping the upper die of the bending die. The lower end of the clamping block forms an connection with the clamp body through an elastic ejector pin, and the upper end of the clamping block is connected with a hydraulic pipeline system for providing clamping force. The upper die clamping device of bending machine provided by the invention has the advantages of stable structure, fast and convenient usage and uniform clamping force, meeting the needs of rapid dismantlement and replacement of the upper die of the bending machine and flexibility compensation of a slide block ofthe bending machine, and improving work efficiency ofthe bending machine and quality of bending products.

Owner:ANHUI LIANMENG MOLD IND

Necking device for metal pipe ends

ActiveCN105499417AWith tensionUniform clamping forceMetal-working feeding devicesPositioning devicesBiomedical engineeringMetal

The invention relates to a necking die and provides a necking device for metal pipe ends. The necking device comprises a machine frame, a clamping head, belleville springs and a pressing sleeve; the clamping head is divided into a plurality of independent blocks, the belleville springs are arranged on the periphery of the clamping head in a sleeving mode, and a tensioning springis arranged in the clamping head; when the belleville springs are compressed, the inner diameter is reduced, the clamping head is extruded and tightened, and the tensioning springs can realize the tensioning effect when the belleville springs are not deformed. According to the invention, the clamping head is tightened and exerts pressure on the pipe ends for pressing the pipe ends and realizing necking, pipes are fixed in the necking process according to the scheme, and no limit for the appearances of the pipes exists.

Owner:CHONGQING WANSI METAL SPECIAL TYPE FORMING

Measurement device for rock resistivity test and special-purpose electrode pad thereof

The invention discloses a measurement device for a rock resistivity test and a special-purpose electrode pad thereof. An electrode pad is arranged between a holder and a rock core end surface. The electrode pad comprises a rubber pad and a circular pressing ring. One surface of the rubber pad is a spherical plump surface and the other surface is a flat surface. The spherical plump surface contacts with the rock core end surface. The flat surface is provided with the circular pressing ring. The circular pressing ring is provided with an external electrode. The rubber pad has a cavity and the cavity is filled with a liquid. The holder comprises a horizontal pushing rod. The horizontal pushing rod extrudes the electrode pad through an insulating separation plate. The horizontal pushing rod is installed on a base of the holder. A liquid is used as an elastic medium of the pad so that clamping forces on two end surfaces of the rock core are uniform and stable and it is avoided that rock core end surface sags and crests or poor flat treatment effects causes deficient contact between the rock core and the holder electrode so that resistivity test results are inaccurate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Quick double-brake self-locking type strain clamp

ActiveCN101834417AUniform clamping forceLarge clamping forceAdjusting/maintaining mechanical tensionSelf lockingEngineering

The invention discloses a quick double-brake self-locking type strain clamp, which comprises a tapered tube body, a reaction spring, clamping pieces and a U-shaped bolt, wherein the clamping pieces comprise four parts in a left group and a right group; a first curve clamping piece and a second curve clamping piece are combined to form the tapered tube body and be matched with the inner wall of the tapered tube body, and a first dovetail boss is arranged at the combined tapered bottom; a third curve clamping piece and a fourth curve clamping piece are combined to form the tapered tube body and be matched with the inner wall of the tapered tube body, and a second dovetail boss is arranged at the combined tapered top; a connecting block of the clamping pieces is arranged in the middle of the two groups of clamping pieces; dovetail grooves mutually vertical are arranged at the two end surfaces of the connecting block and respectively matched with the first dovetail boss and the second dovetail boss; a tube plug is arranged at the tapered bottom of the tapered tube body; the reaction spring is arranged between the tube plug and the clamping pieces; a matched straining sleeve is arranged at the outer wall of the tapered tube body; and the U-shaped bolt passes through the matched straining cover and is fixed by a nut. The strain clamp has simple structure, small volume and light weight, and adopts a bidirectional locking structure, thus a lead wire is locked more firmly.

Owner:王吉敏 +1

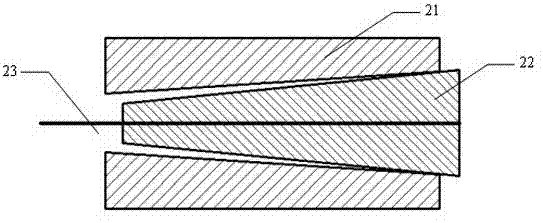

Strand tapered anchorage for tension of carbon fiber plate

InactiveCN103758289AAvoid destructionImprove the anchoring effectBuilding reinforcementsFiberStress concentration

The invention relates to a strand tapered anchorage for tension of a carbon fiber plate. The strand tapered anchorage comprises an anchor plate and a clamping piece, wherein the anchor plate is provided with a square hole for installing of the clamping piece, two extruded surfaces have a 1-5 degree dip angle, and the dip angle outside the clamping piece is greater than the corresponding dip angle on the anchor plate by 0.1-1 degree. Due to the inclination difference between the clamping piece and the anchor plate, after being installed in the anchor plate, the clamping piece bears uniform clamping force on the side surface, so that the problem that the carbon fiber plate breaks at the tip of the clamping piece due to stress concentration is solved, the carbon fiber plate is prevented from being damaged, and the anchoring effect of the anchorage is improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

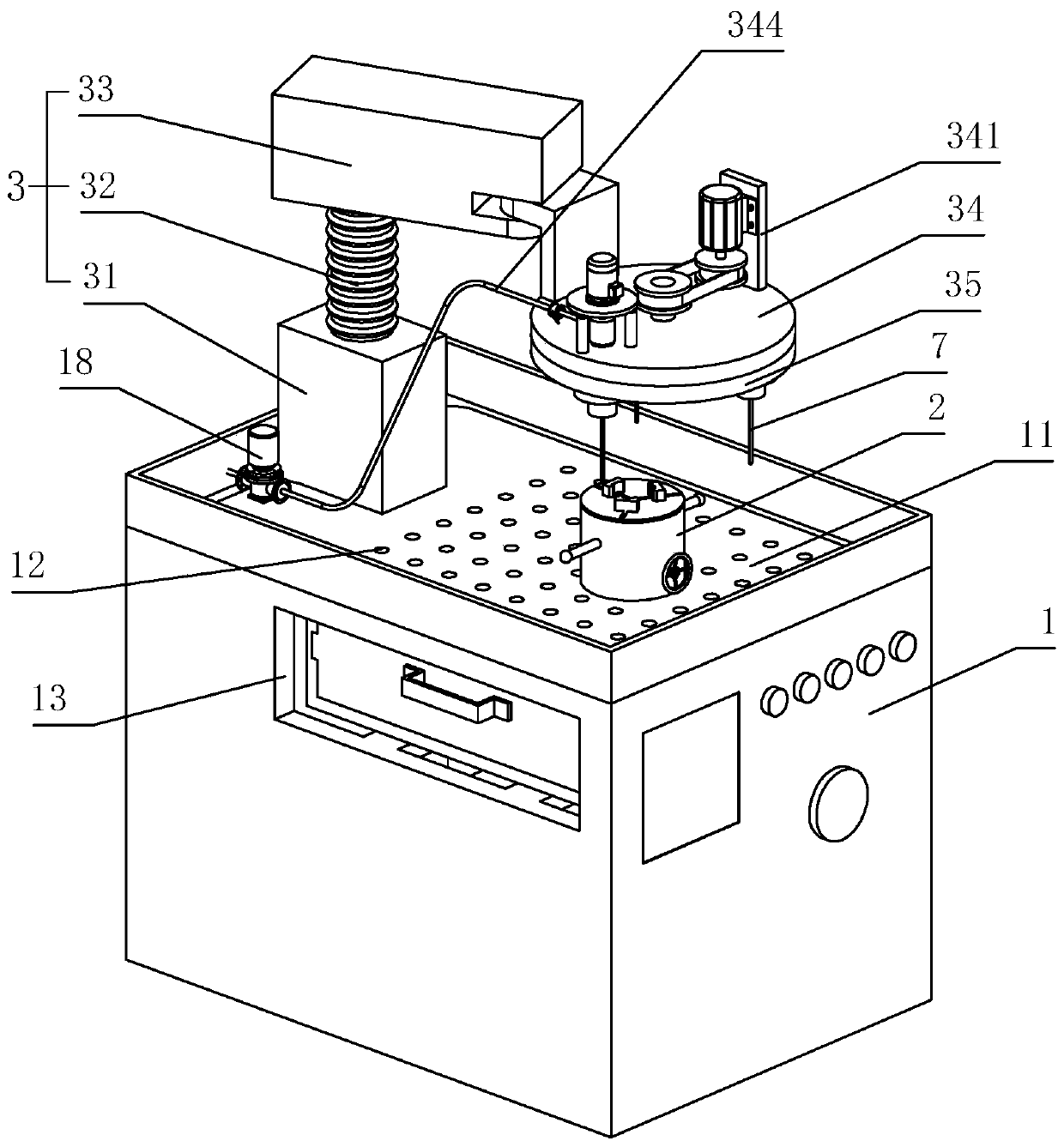

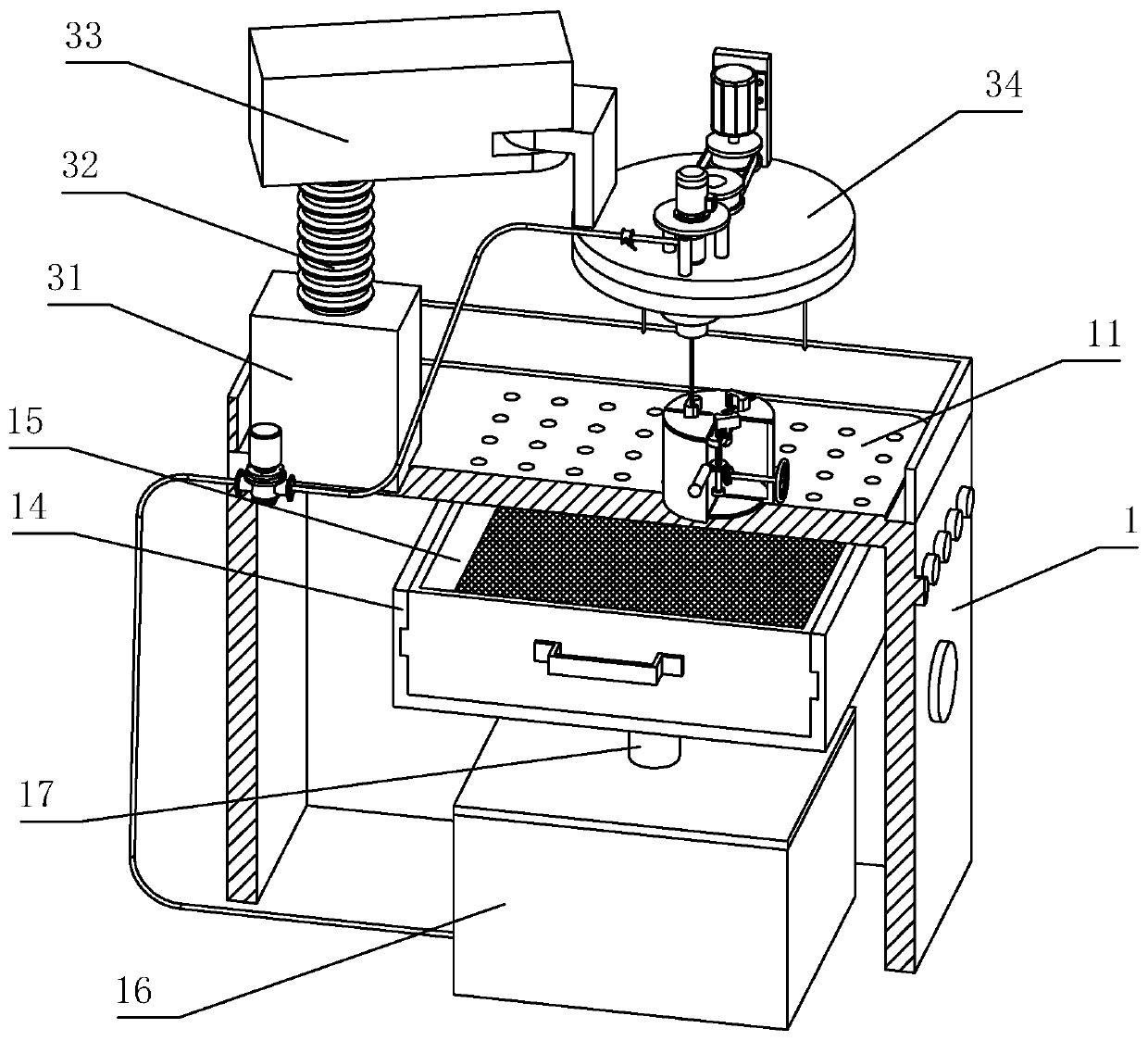

Coreless motor coil accurate reshaping machine

InactiveCN102684402AGood plastic effectMeet the finishing process requirementsManufacturing dynamo-electric machinesElectric machineMotive power

The invention relates to a coreless motor coil accurate reshaping machine, which comprises a bottom plate, a clamping mechanism and a telescopic mechanism, wherein the clamping mechanism and the telescopic mechanism are perpendicularly arranged on the bottom plate; the clamping mechanism comprises a clamping supporting plate which is fixed on the bottom plate, a propulsion supporting plate which is arranged on the clamping supporting plate, a clamping mold which is arranged on the propulsion supporting plate, and a power cylinder which drives the propulsion supporting plate to operate; the telescopic mechanism comprises a telescopic mechanism supporting plate, a telescopic propulsion plate and a propulsion cylinder which drives the telescopic propulsion plate to operate; and at least one core shaft rotary mechanism is arranged on the telescopic propulsion plate. The coreless motor coil accurate reshaping machine has the advantages that different surfaces of a coreless motor coil can be uniformly clamped and stressed, a reshaping effect of the coil is improved, a plurality of coreless motor coils can be accurately reshaped, the coreless motor coil accurate reshaping machine is high in working efficiency, high in degree of automation and high in positioning accuracy, requirements for accurate reshaping procedures in the manufacturing process of the coreless motor coils with different diameters and of different shapes can be met, and the compatibility of the coil accurate reshaping machine is improved.

Owner:KUSN KUKE AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com