Adjustable positioning milling fixture

An adjustable and clamping technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of clamping deformation and low production efficiency, and achieve the effect of reliable clamping, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

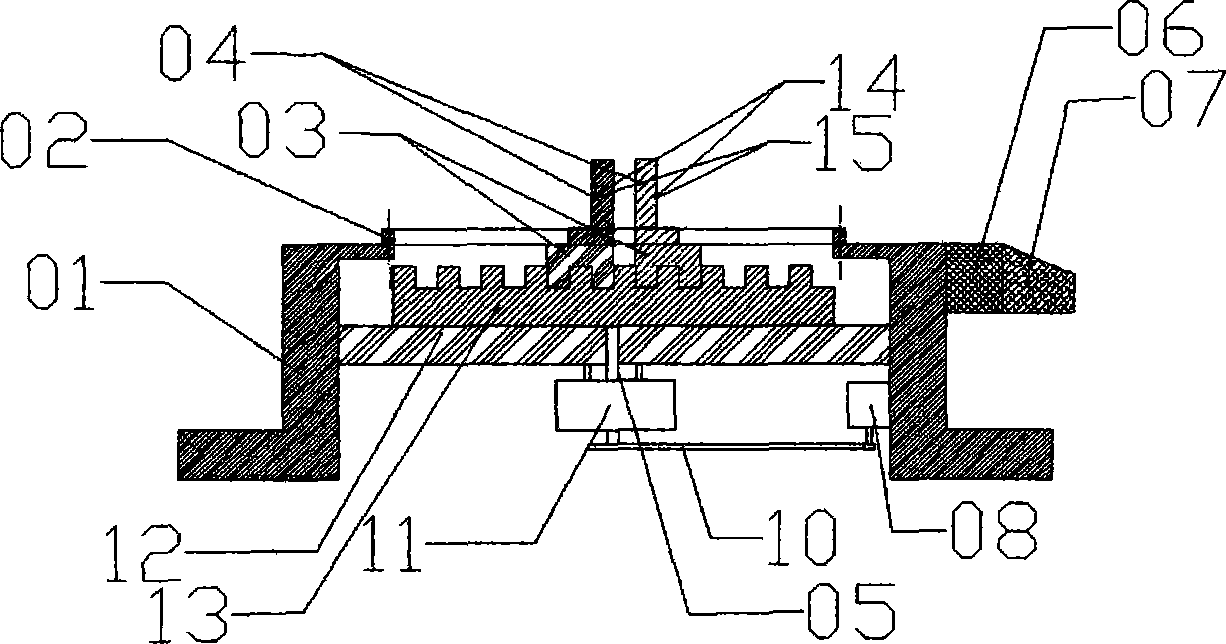

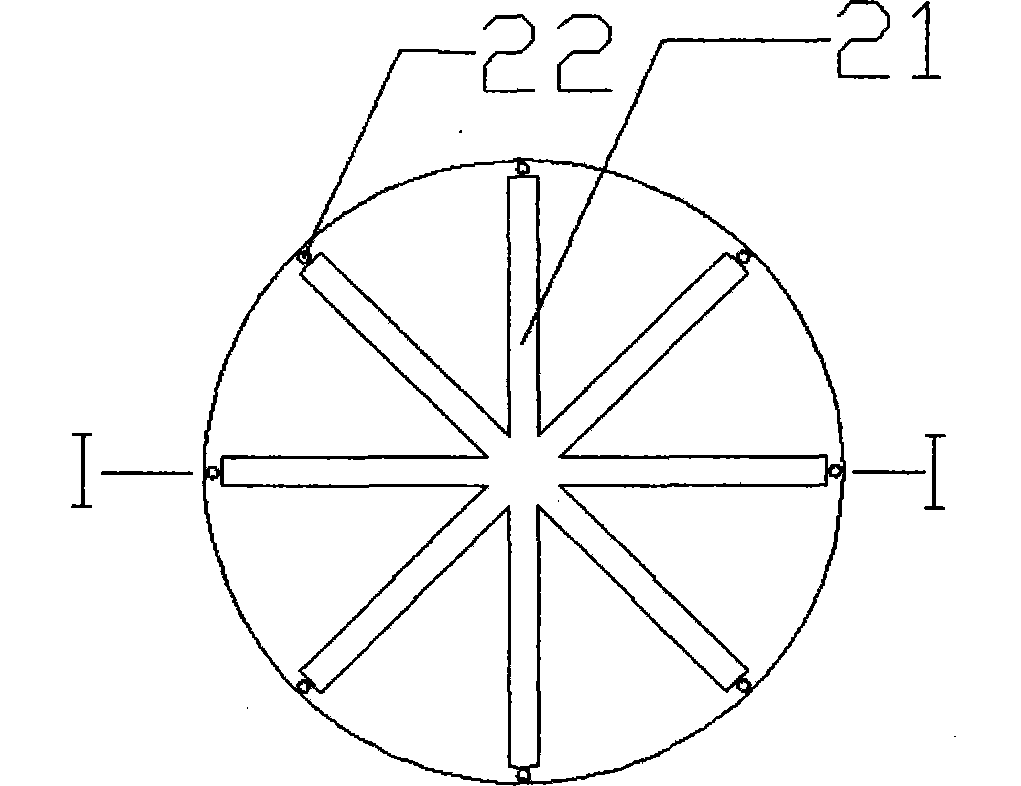

[0025] As shown in the figure, the adjustable positioning milling fixture provided by the present invention includes a fixture body 01, a guide rail 02, a slider 03, a clamping block 04, a shaft 05, a single-chip microcomputer 06, a control panel 07, a motor 08, and a conveyor belt 10. Reducer 11, positioning seat 12, positioning block 13, pressure sensor 14, sensor installation groove 15; there is a sensor installation groove 15 on the side of the clamping block 04 in direct contact with the motor casing, and the pressure sensor 14 is installed on the sensor installation In the groove 15, the clamping block 04 passes through the guide rail 02 and is connected with the slider 03. When clamping thin-walled motor casings with different diameters, in order to make the clamping block 04 and the motor casing tightly fit, you can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com