Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce manufacturing tolerances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

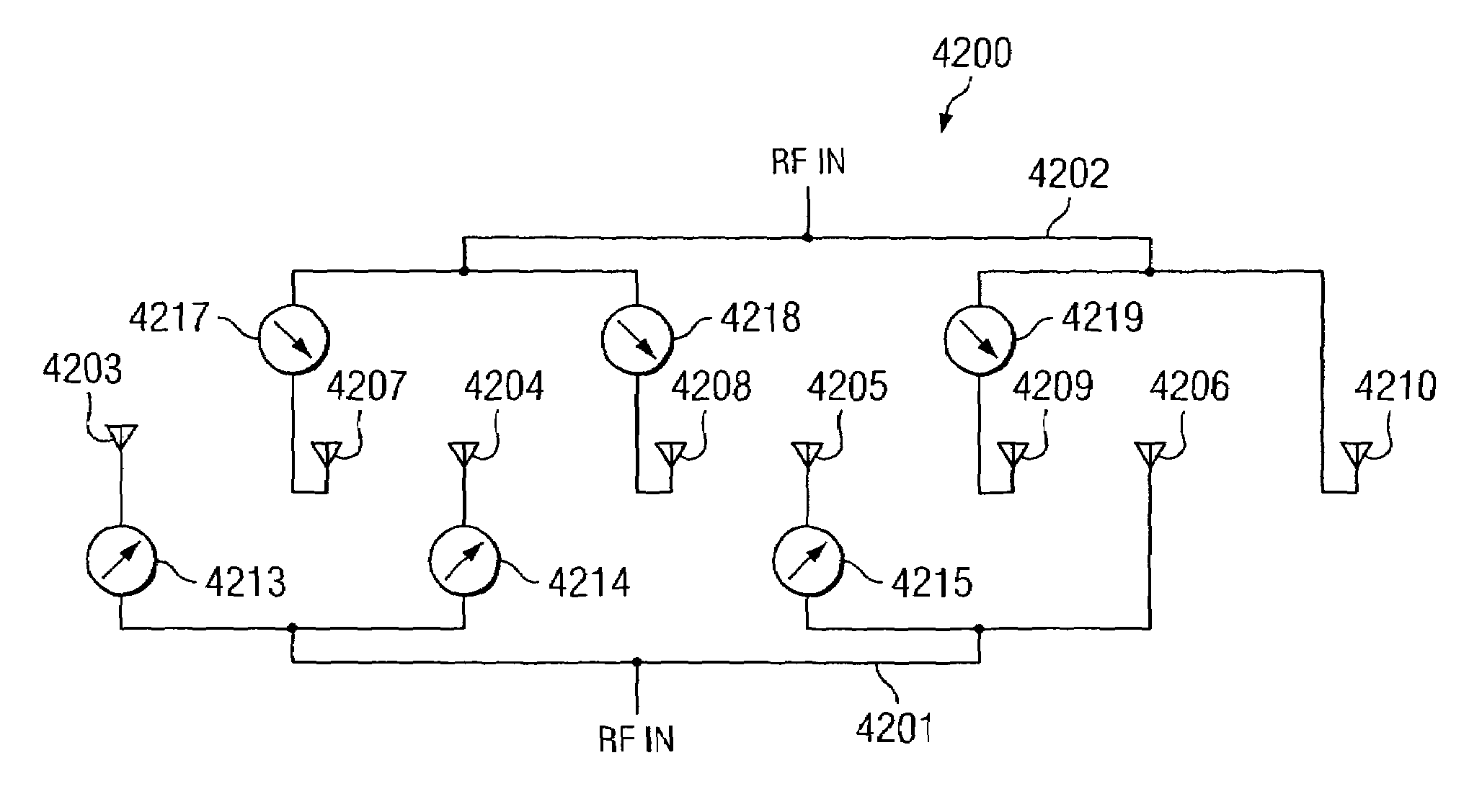

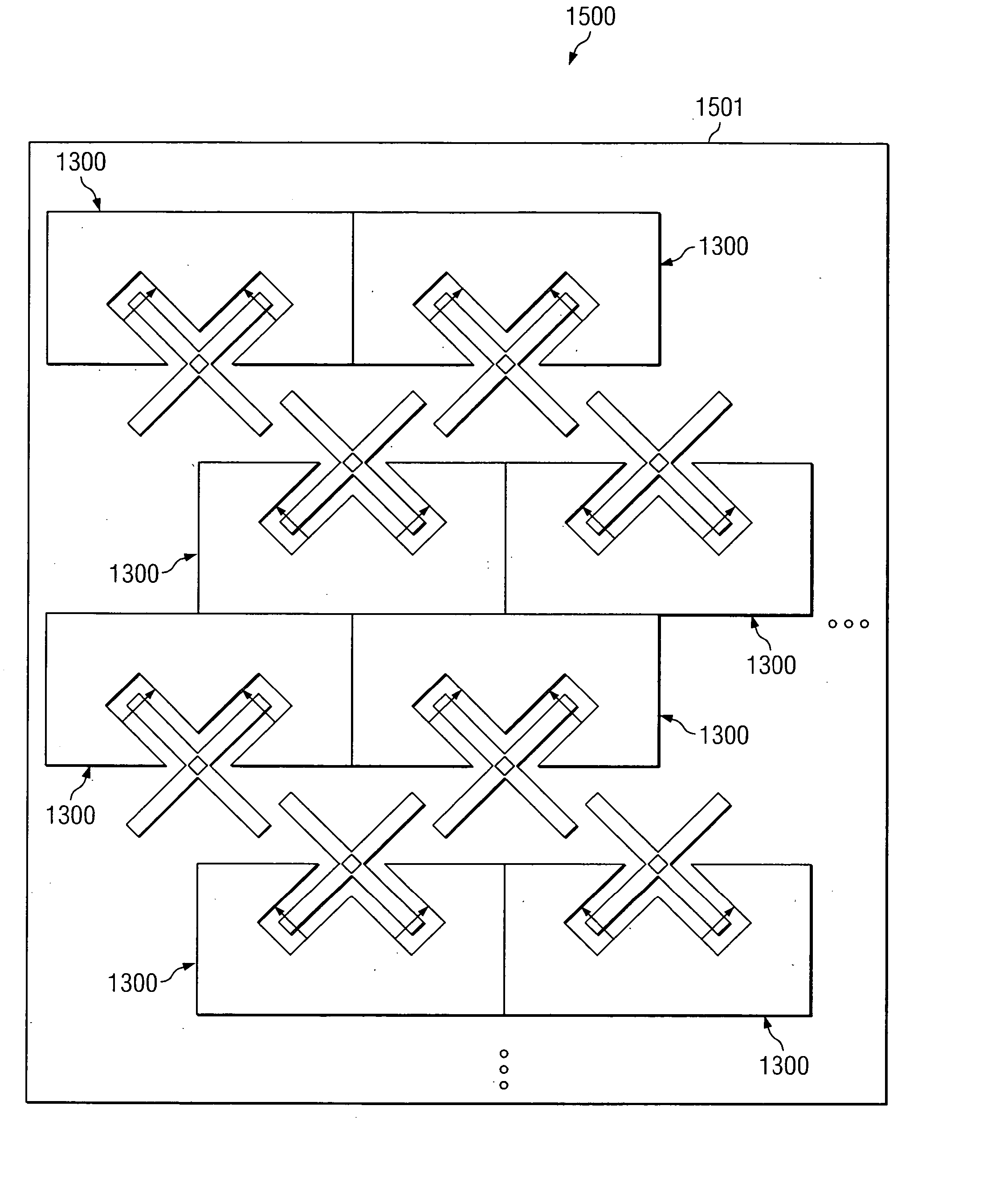

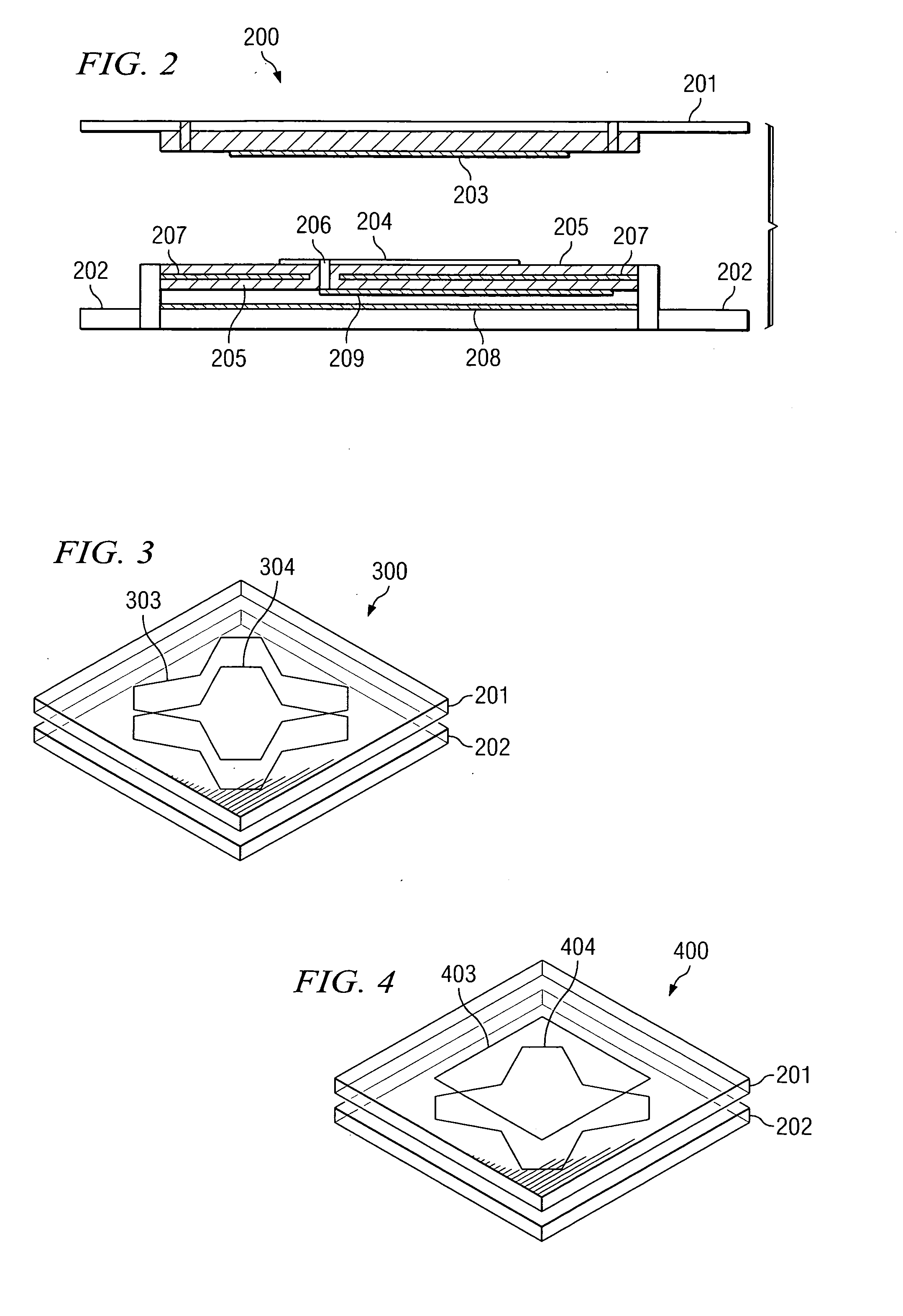

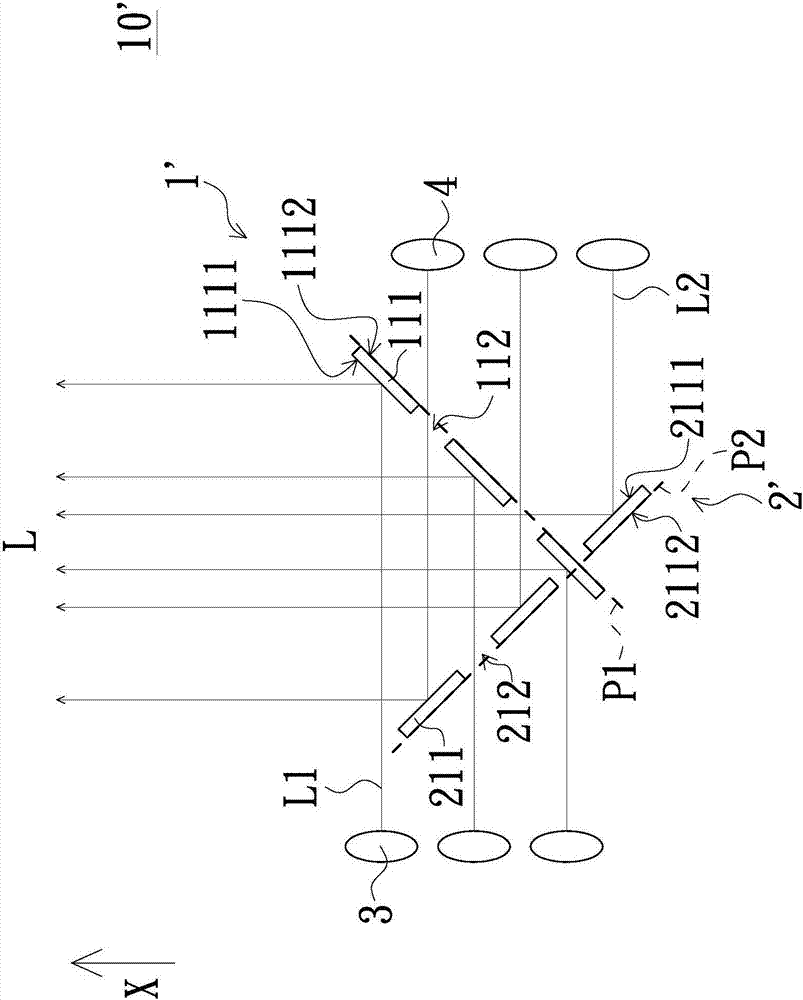

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

ActiveUS7075485B2Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

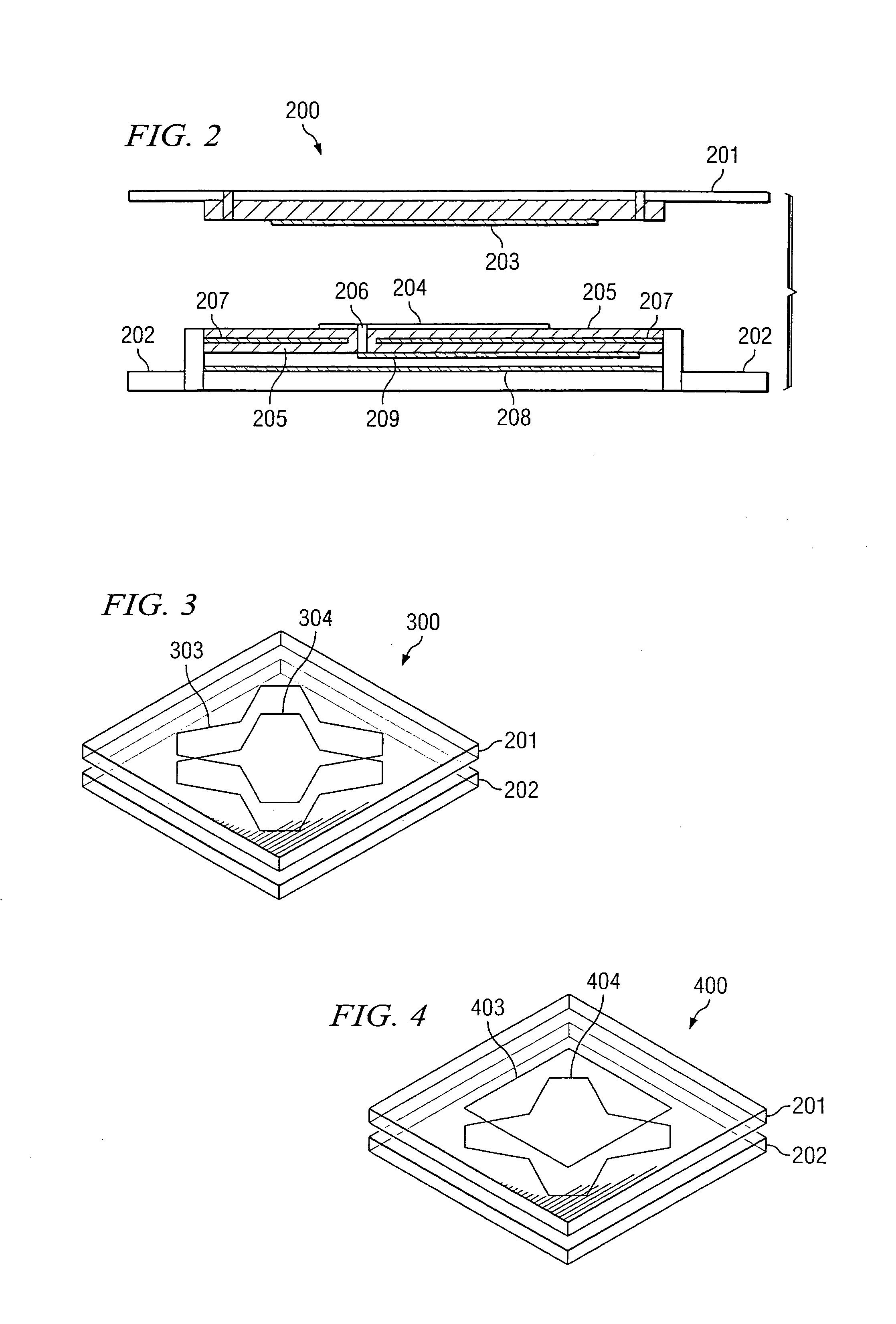

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

InactiveUS7525504B1Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

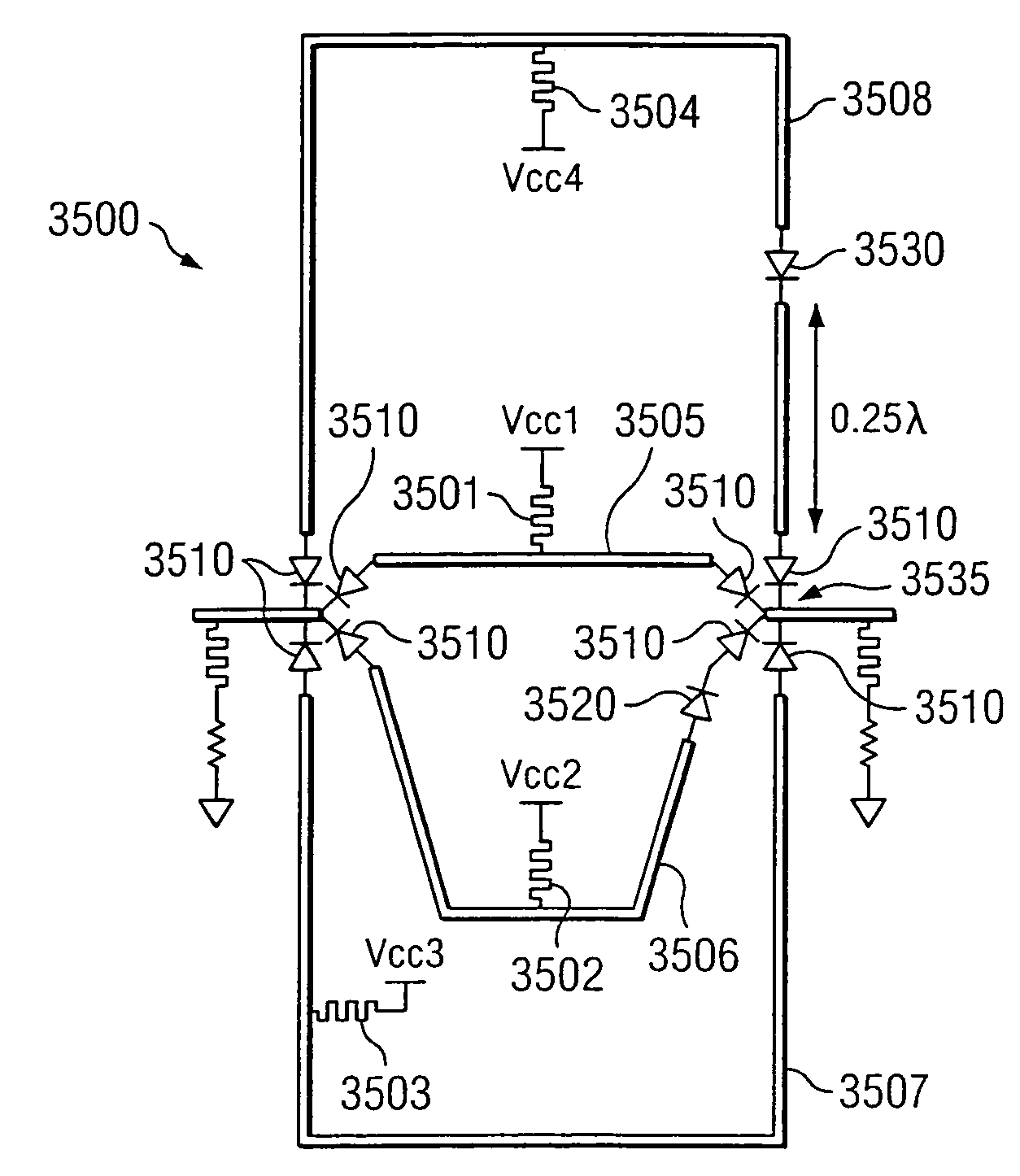

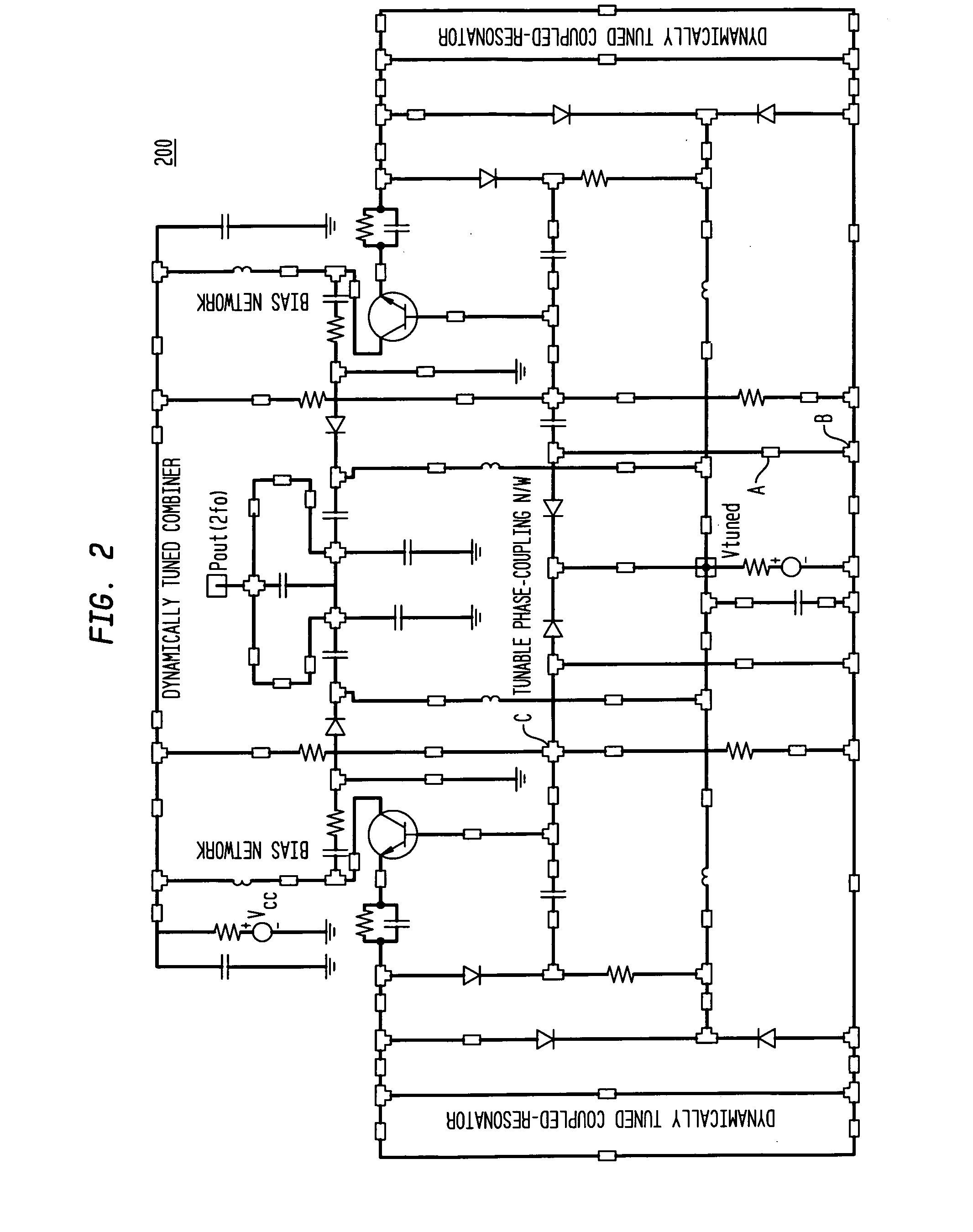

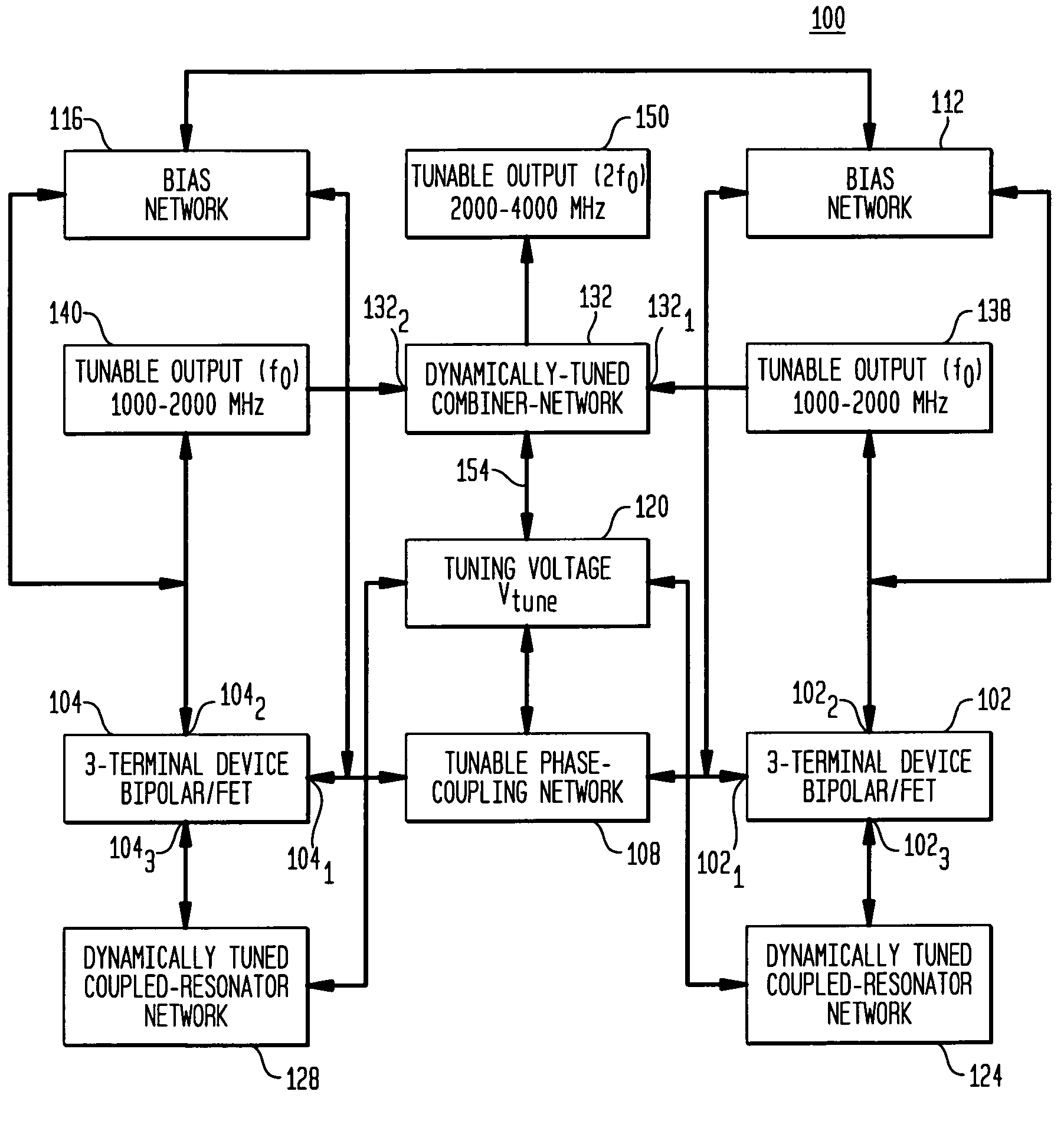

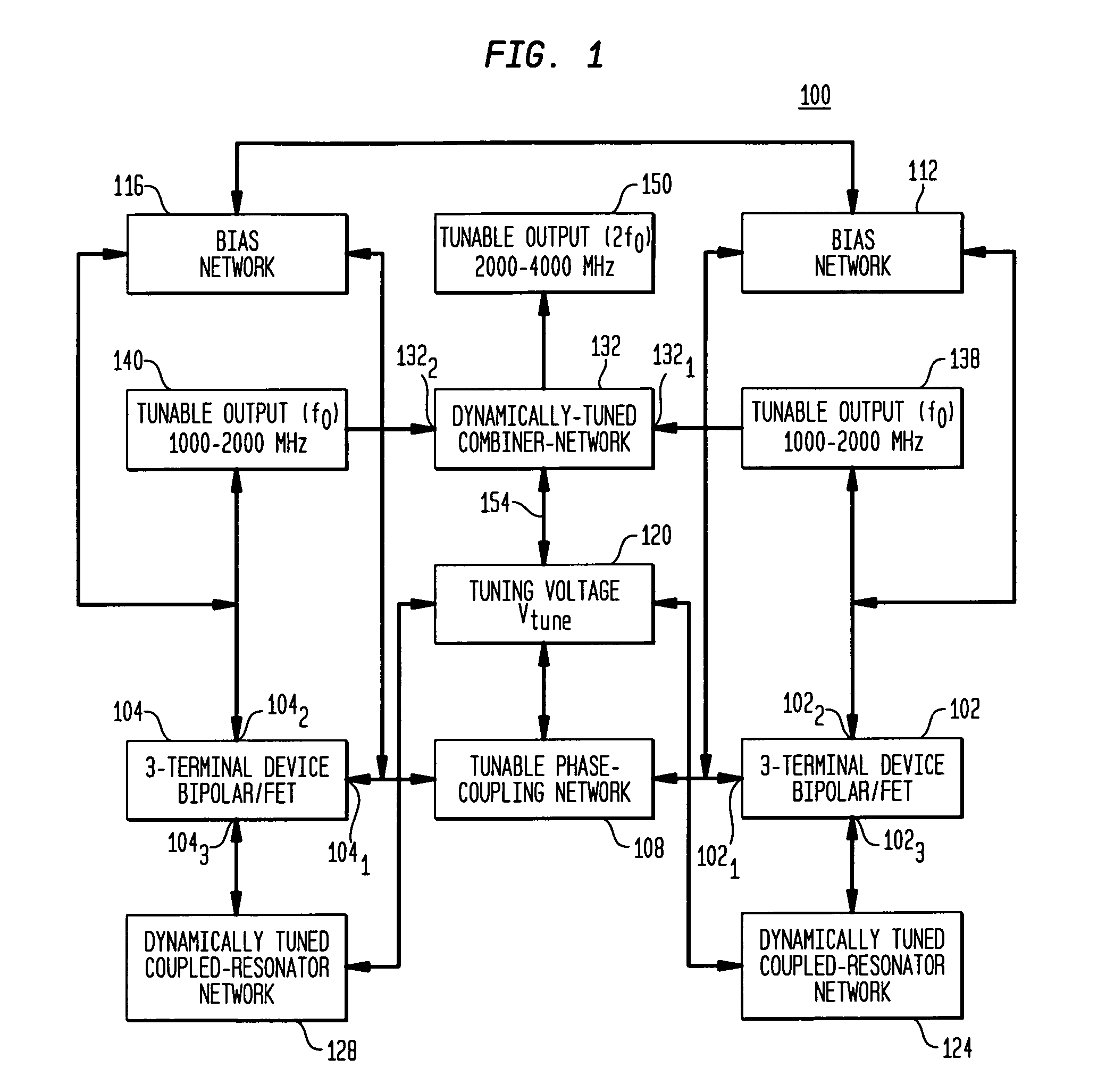

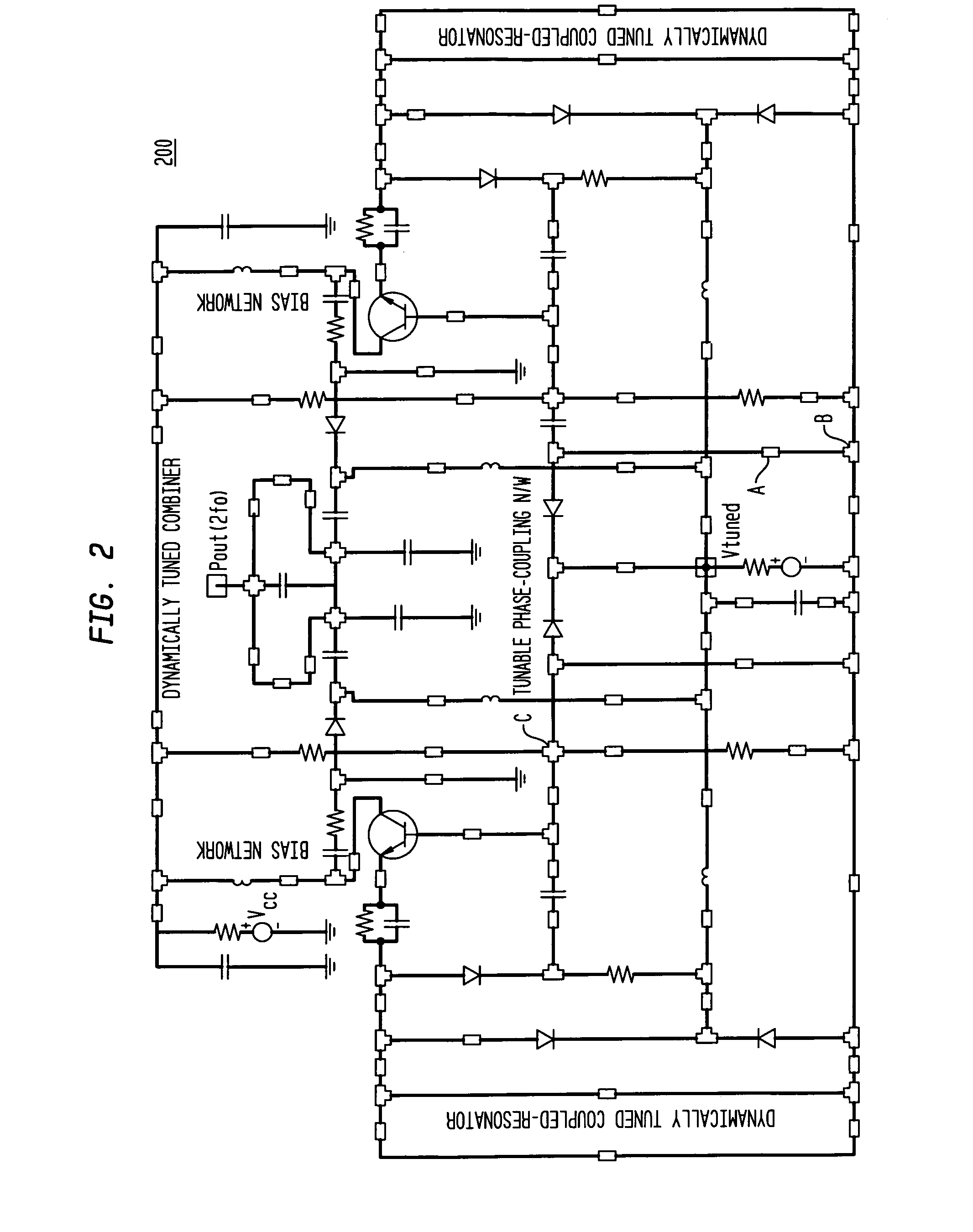

Integrated low noise microwave wideband push-push VCO

ActiveUS20050156675A1Enhance time average loaded Q factorIncrease the frequency bandConveying record carriersPulse automatic controlLow noiseTerminal equipment

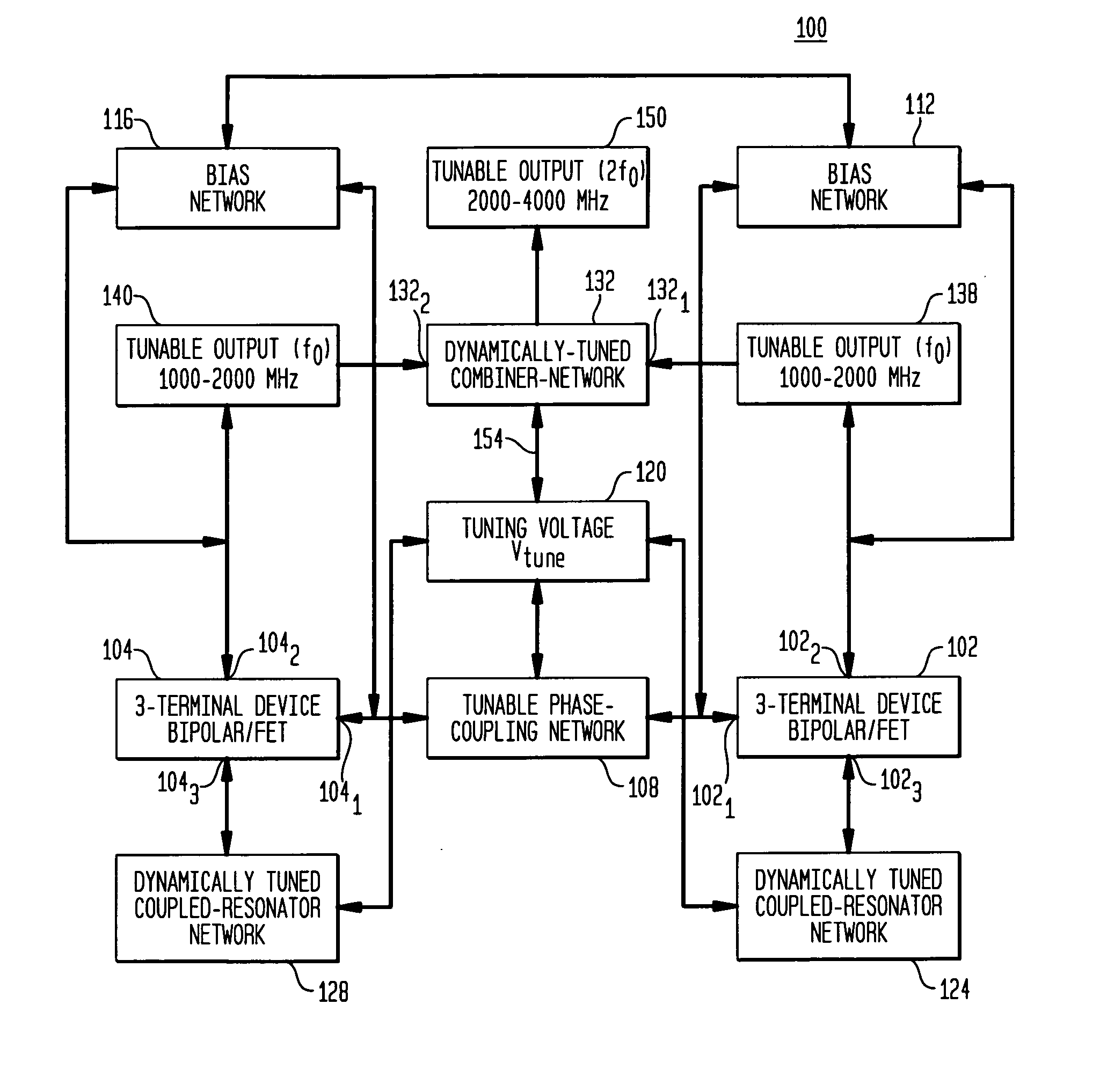

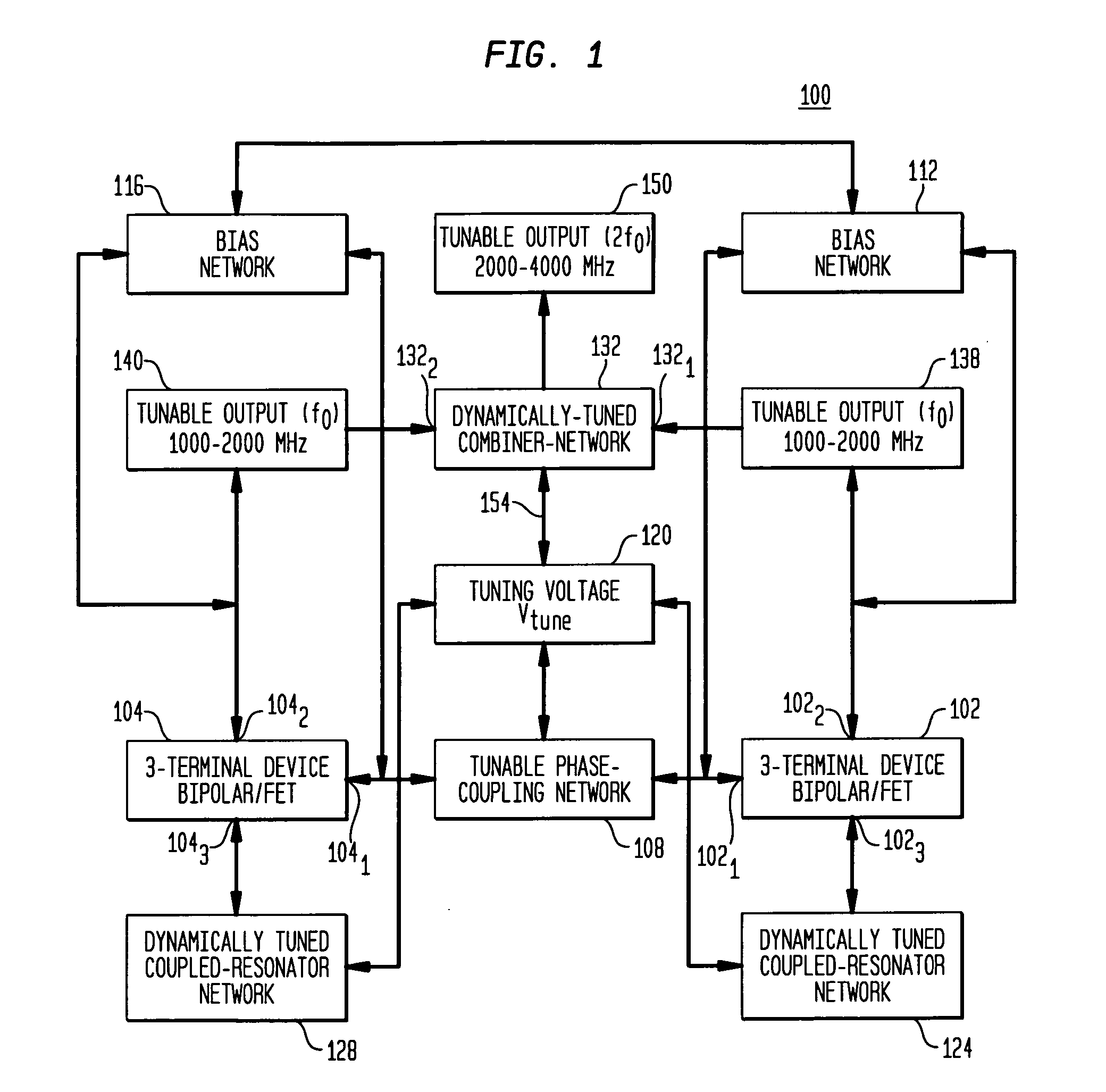

In one aspect, a voltage controlled oscillator is provided that includes circuitry comprising tunable coupled resonator networks, which are coupled to a terminal of a pair of three-terminal devices through a tuning voltage network which supports wide-band tunability. In another aspect, a wide-band tunable resonator is provided that is amenable to integration in the integrated circuit form.

Owner:SYNERGY MICROWAVE CORP

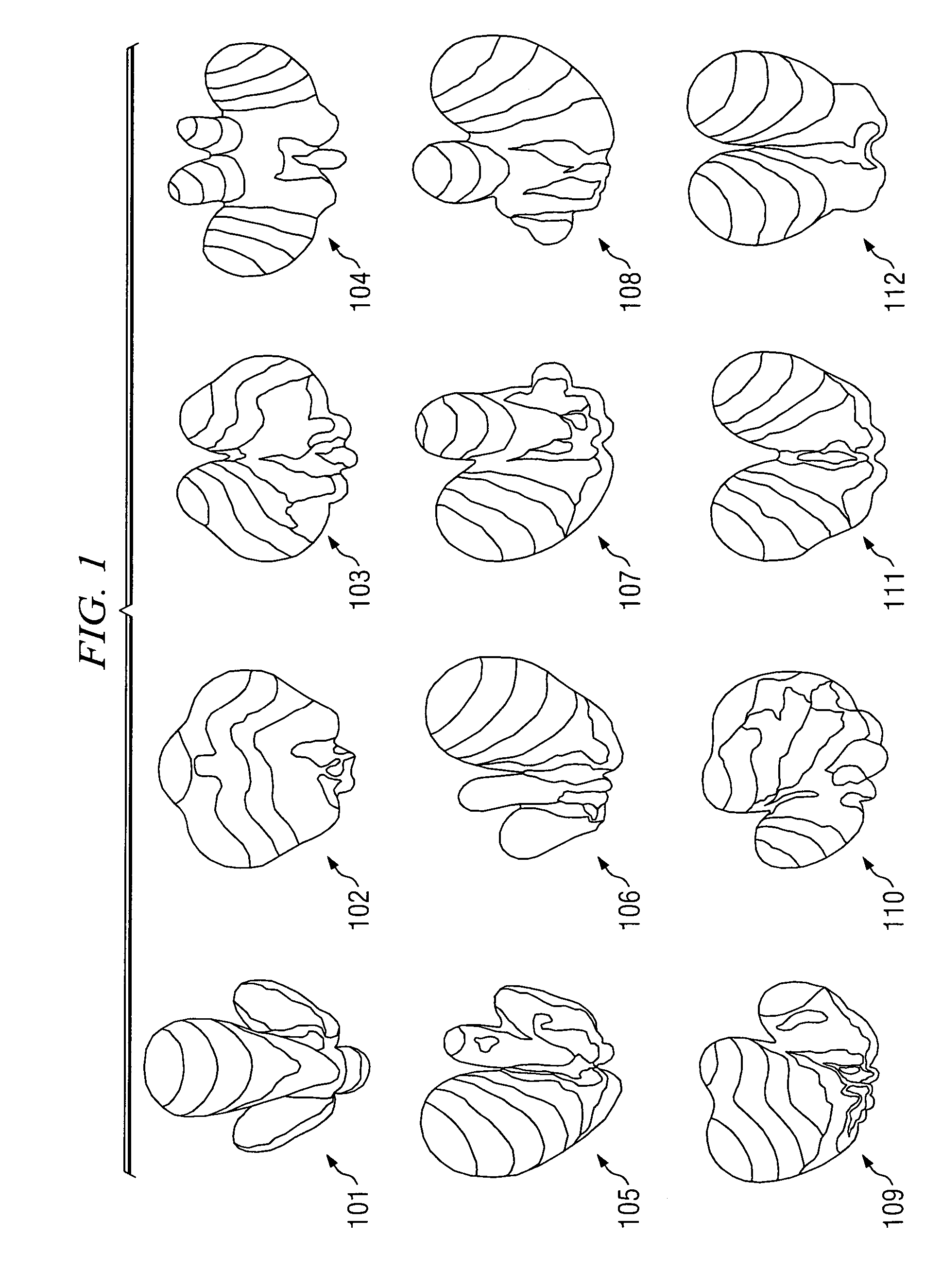

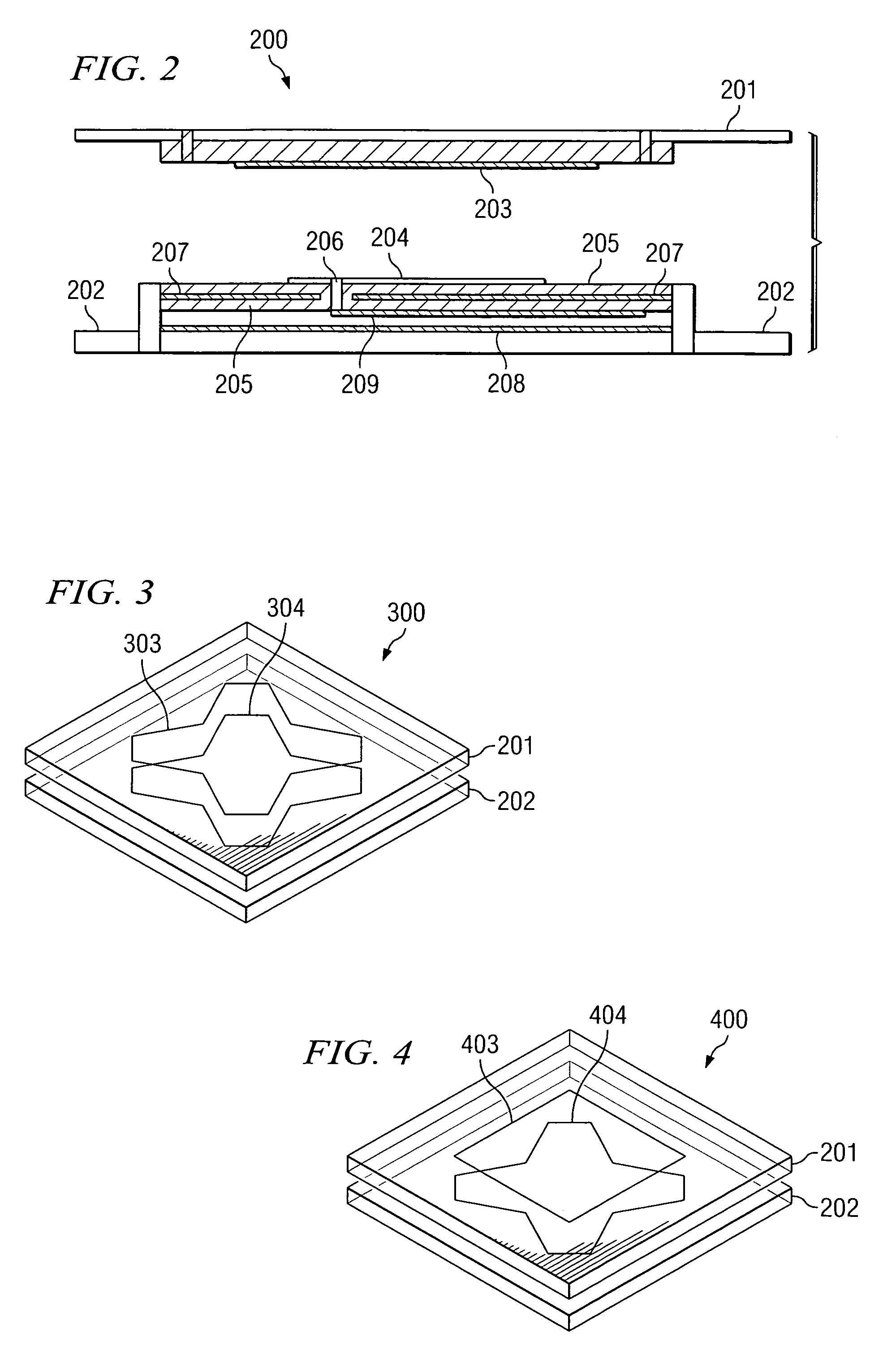

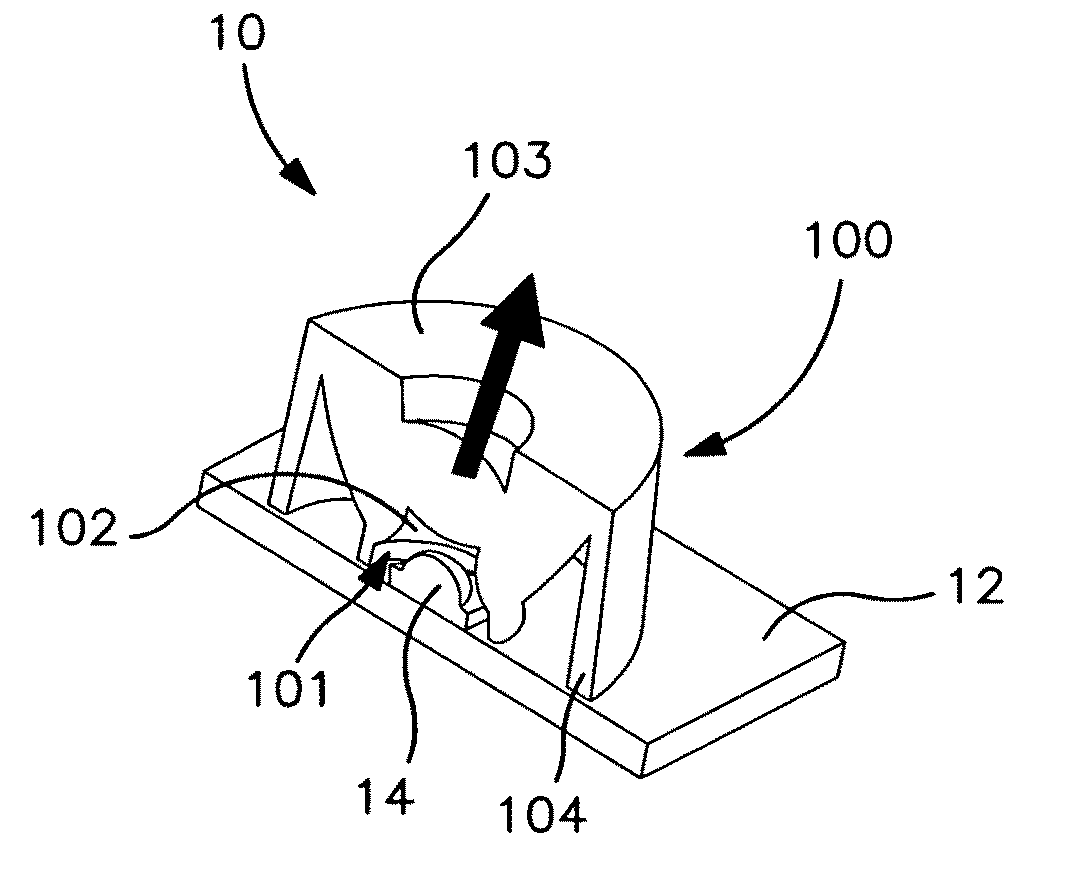

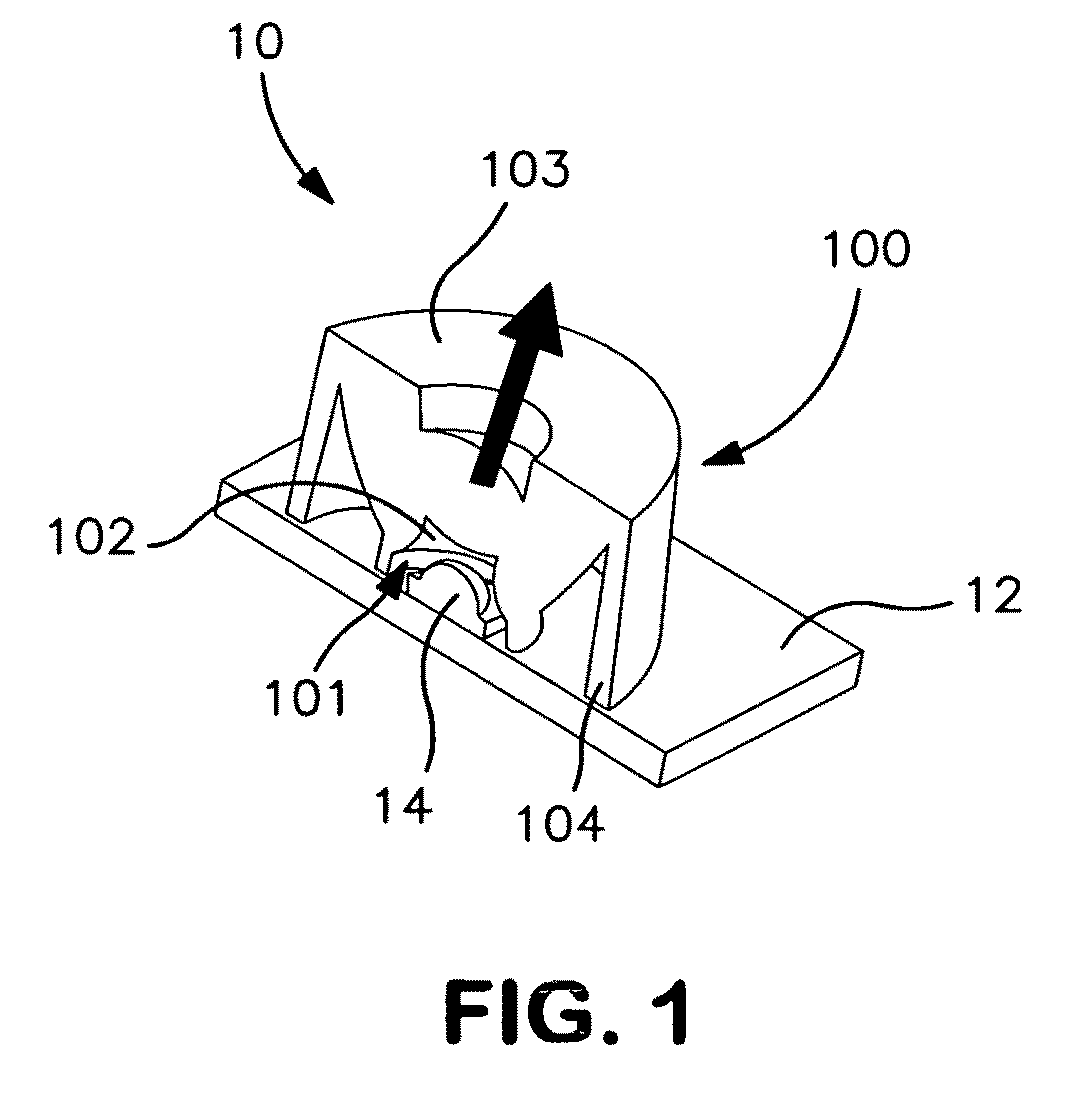

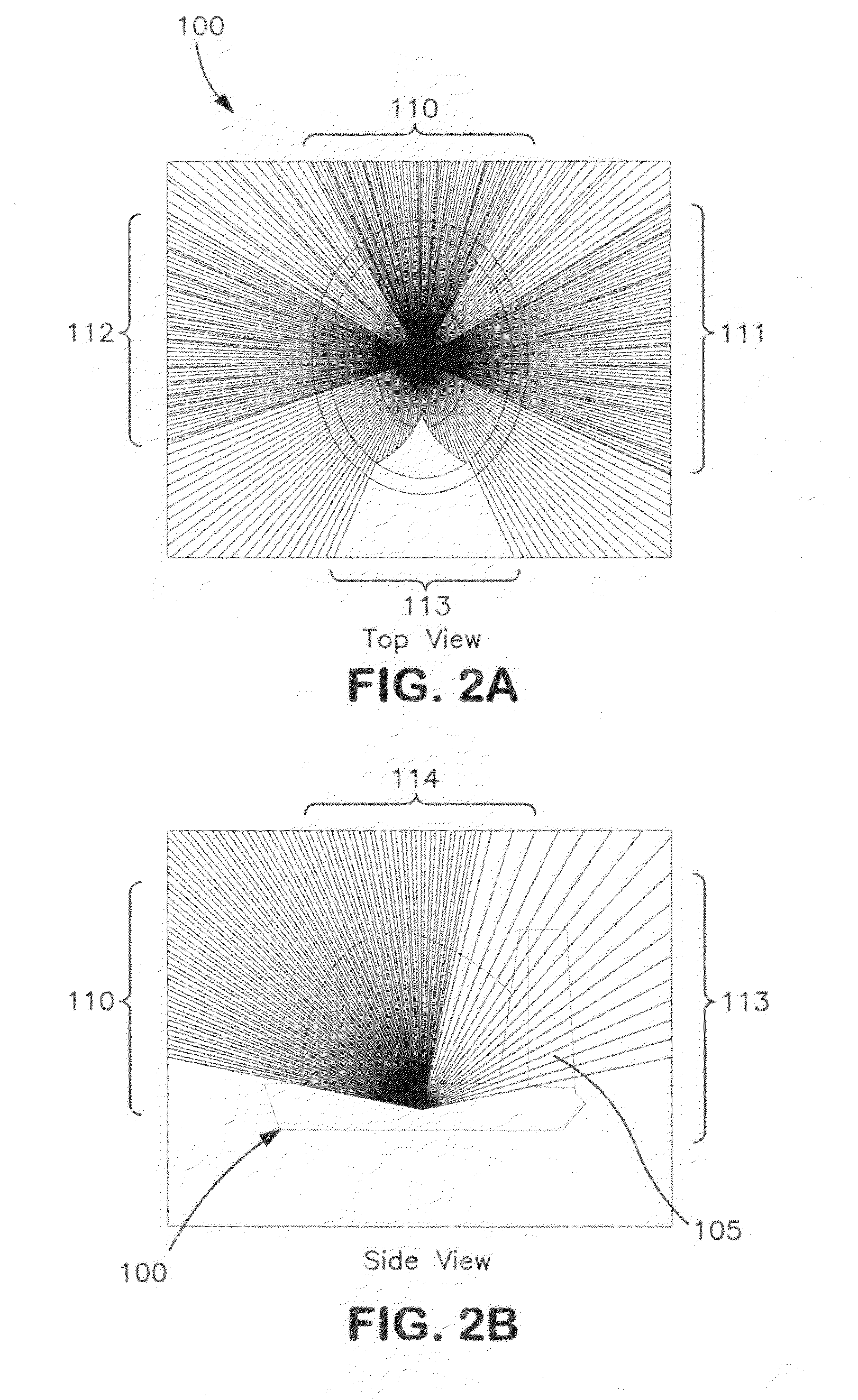

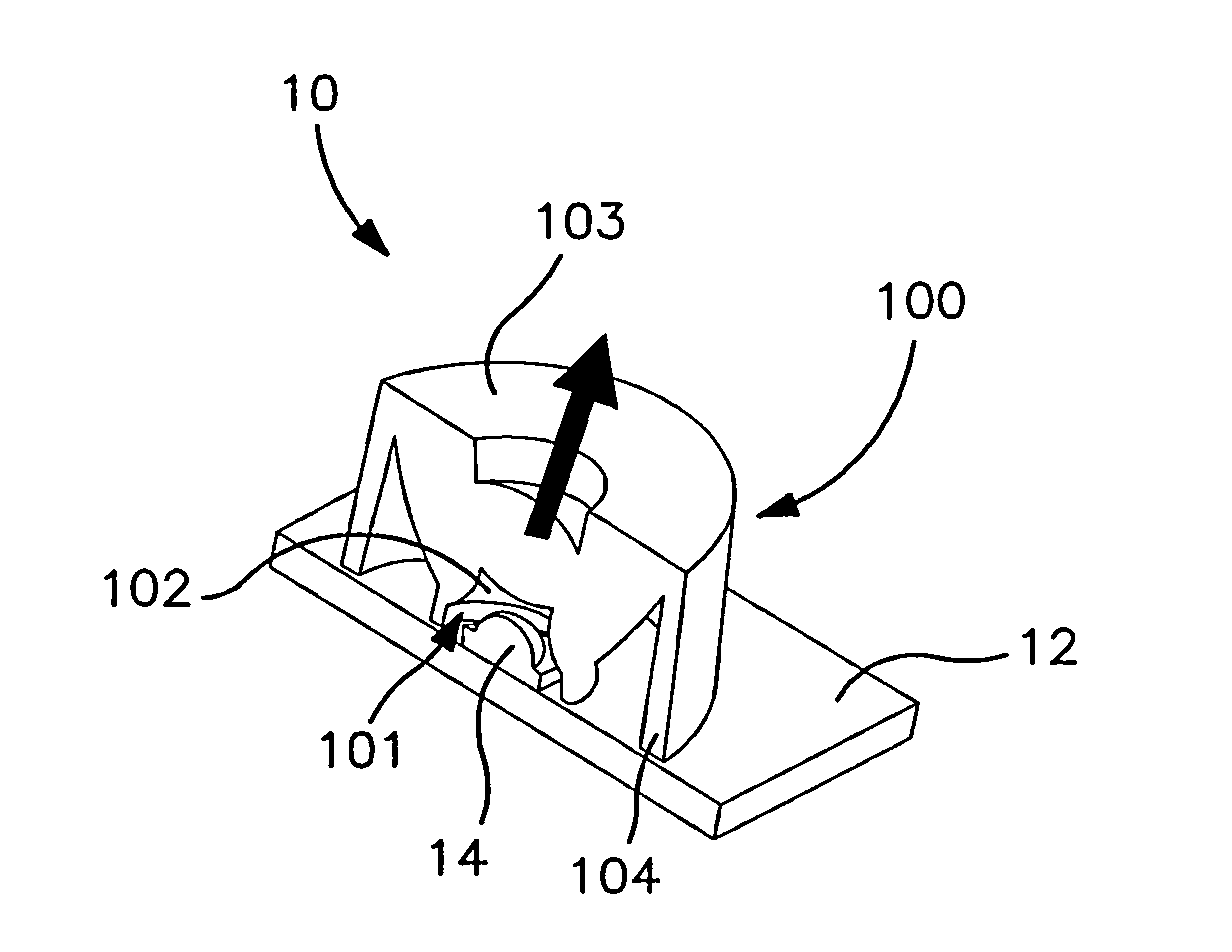

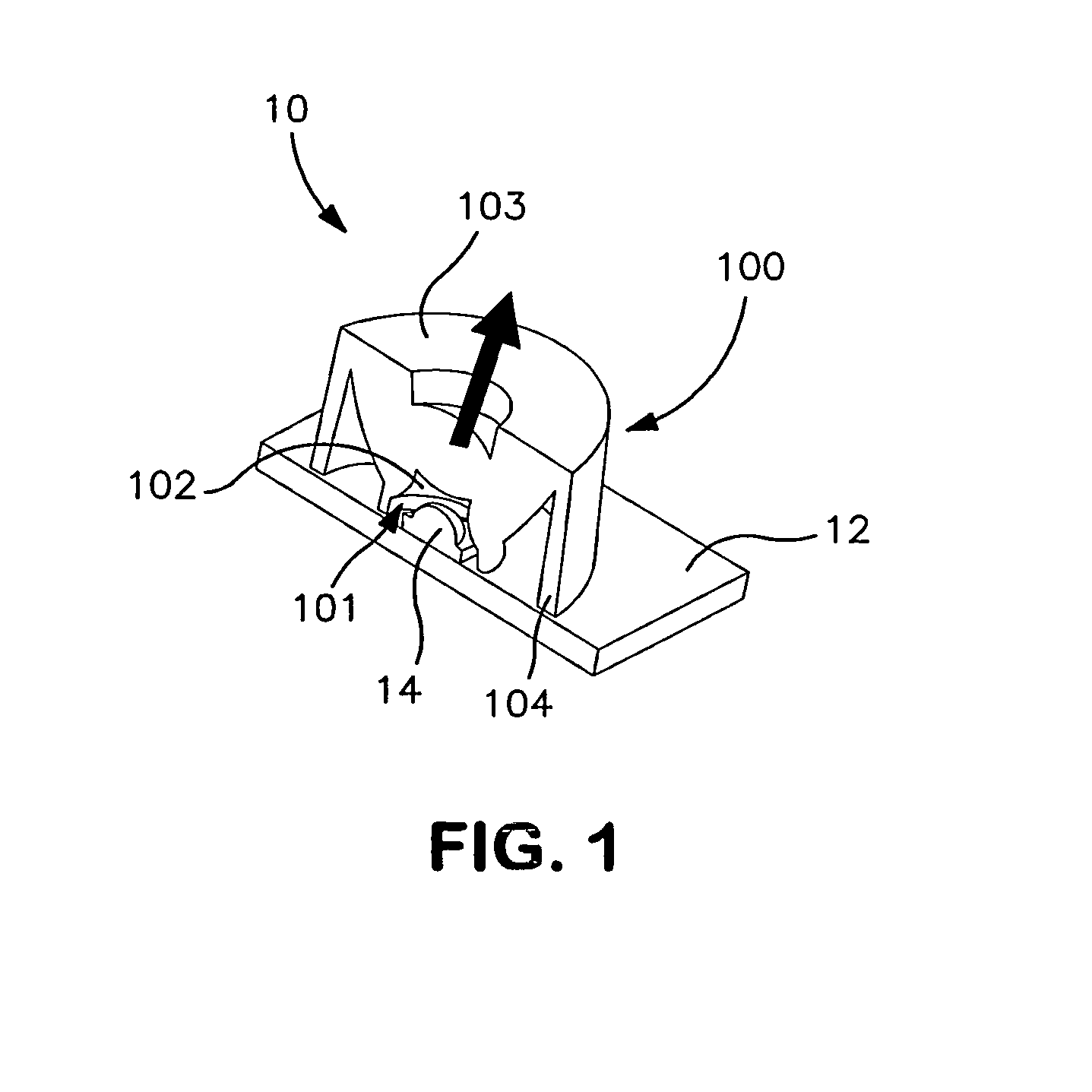

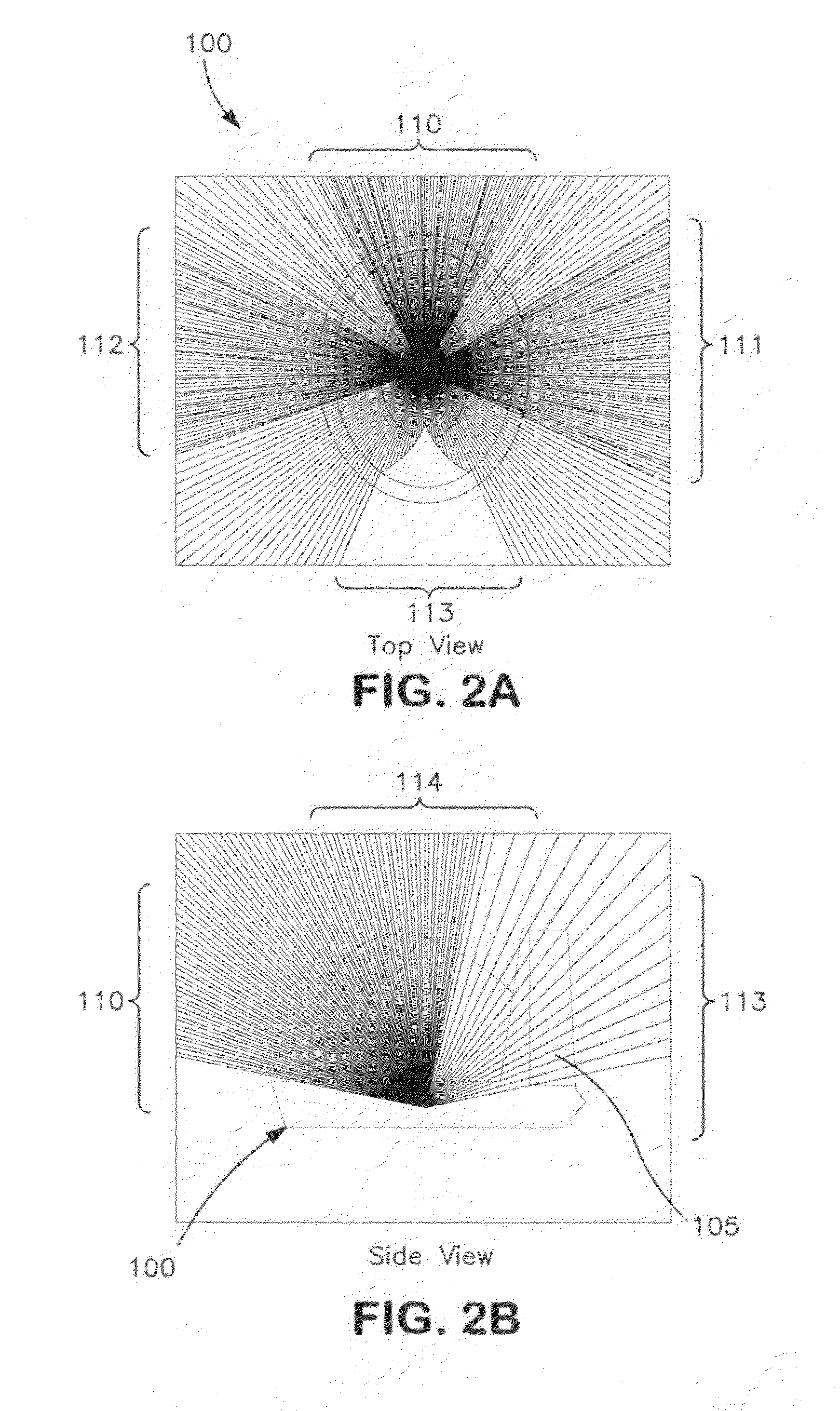

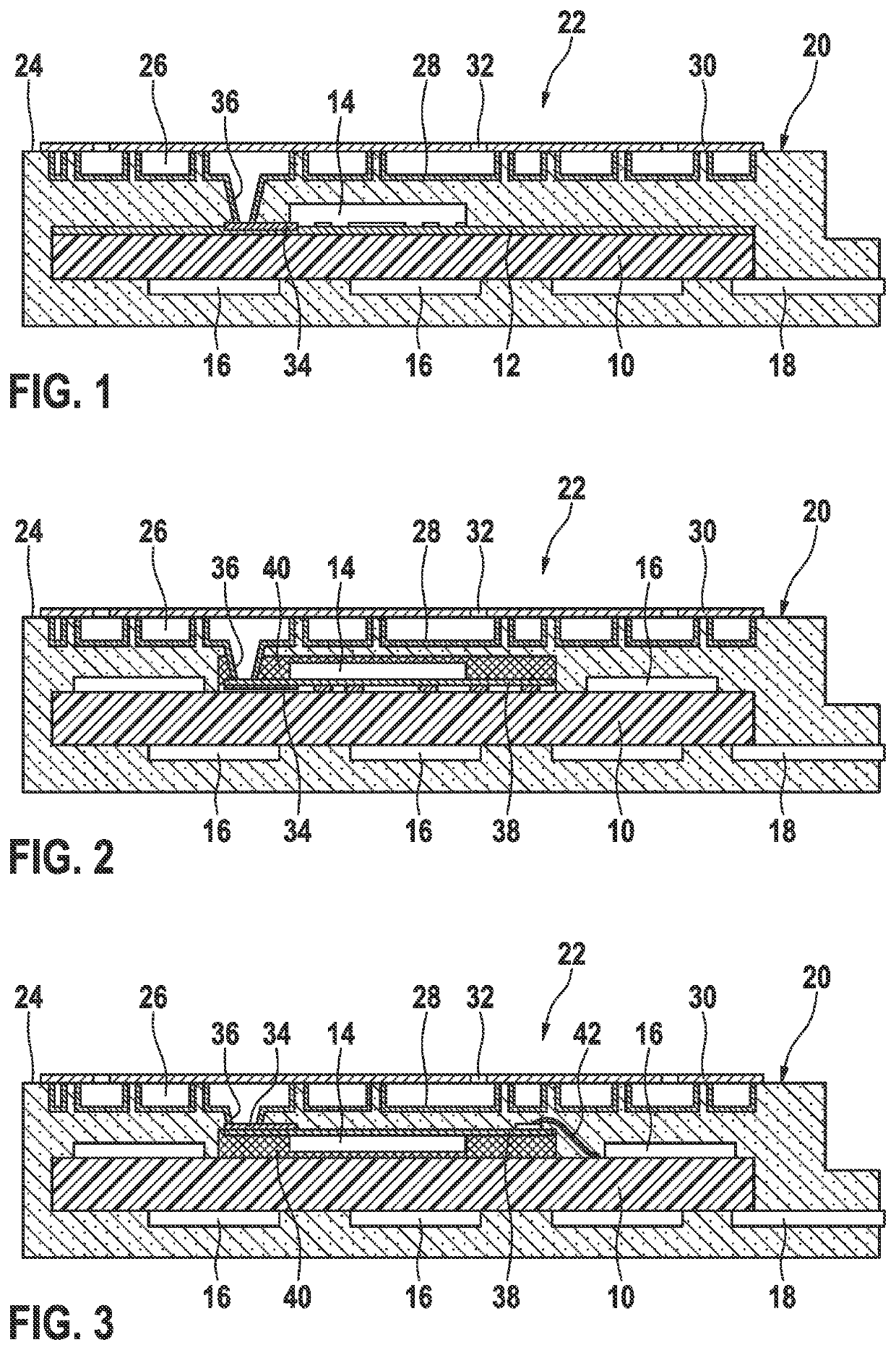

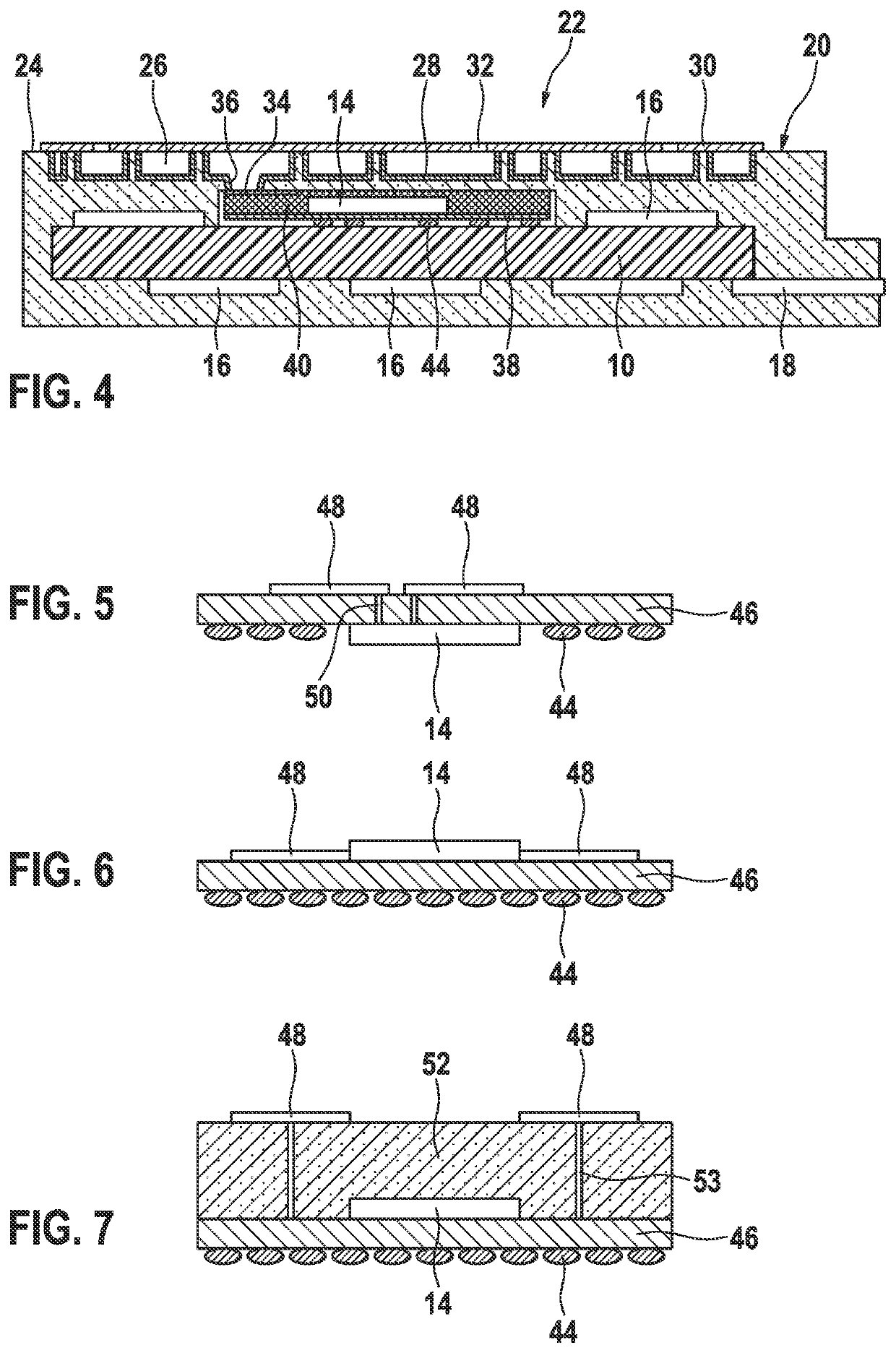

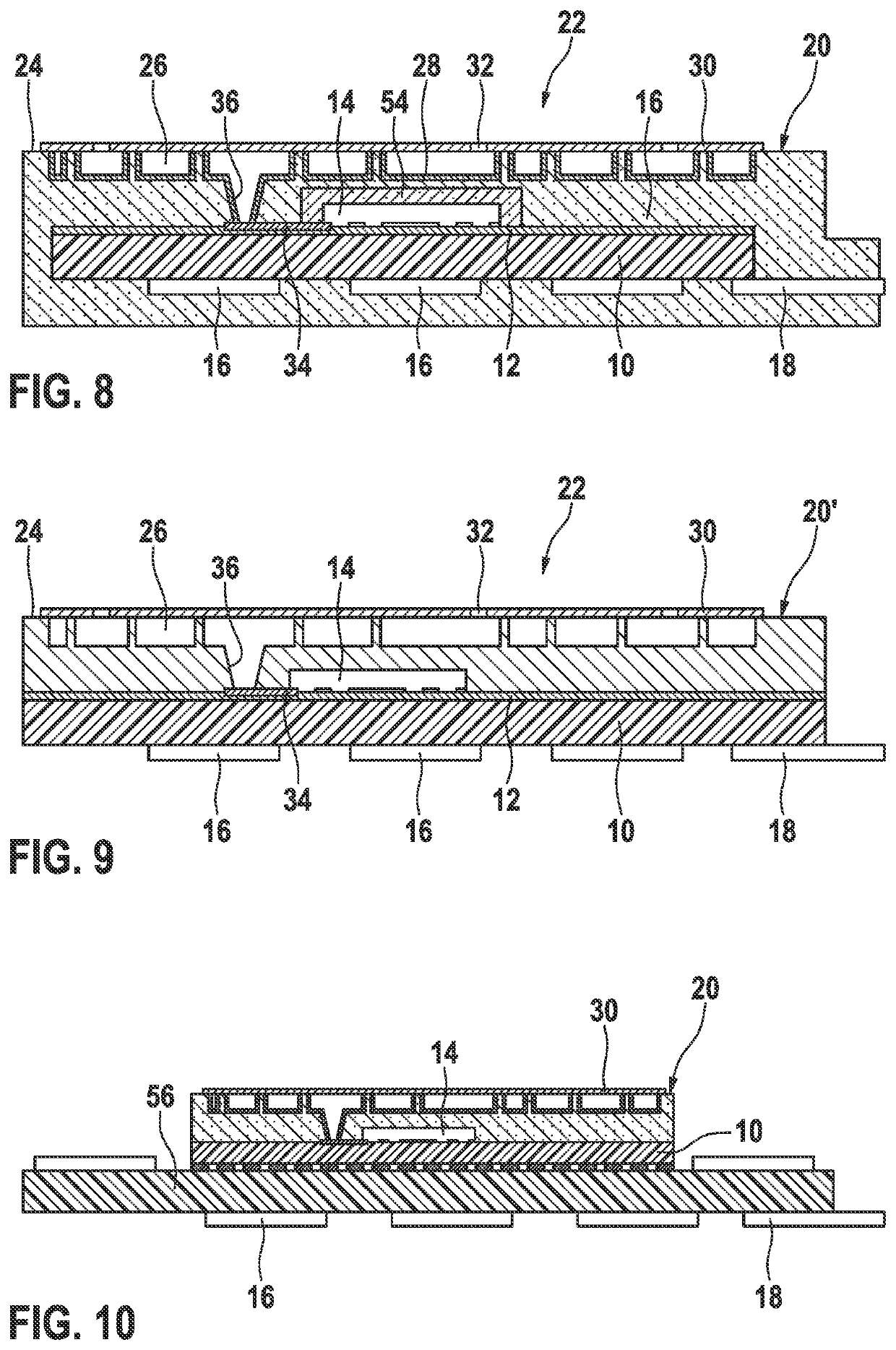

Illuminating optical lens for light emitting diode (LED)

ActiveUS20110075418A1Equally distributedImprove optical efficiencyPoint-like light sourcePortable electric lightingRoboticsAdhesive

An illuminating optical lens article of manufacture for use with a light emitting diode (LED) mounted on a circuit board is provided. The lens has (a) a base portion defining a rim on a plane having a bottom surface around a longitudinal axis for mounting over the LED; (b) an integral refractory outer surface of the lens extending towards the longitudinal axis from the base; (c) an integral refractory inner surface of the lens extending from the base forming a cavity shaped and sized to receive an LED; and optionally (d) a plurality of grooved sections for receiving an adhesive formed on the bottom surface of the base portion. The base is adapted to be mounted on the circuit board onto which the LED is mounted. The integral refractory outer and inner surfaces each define a predetermined geometry adapted to direct and focus light emitting from the LED to a predetermined path. The lens is fabricated with a tolerance range of within 0.15 mm or better. The lens can be incorporated into a luminaire system and mounted on to a circuit board using adhesive polymers. The assembly of the lens into the luminaire system can be automated using robotics.

Owner:CORELED SYST

Low cost multi-beam, multi-band and multi-diversity antenna systems and methods for wireless communications

ActiveUS20050110683A1Low costImprove performanceSimultaneous aerial operationsAntenna supports/mountingsMulti bandCommunications system

Systems and methods for employing switched phase shifters and a feed network to provide a low cost multiple beam antenna system for wireless communications. The present systems and methods may also facilitate multi-band communications and employ multi-diversity. The present systems and methods allow communication systems to achieve enhanced performance for communication or other services such as location tracking. The present systems and methods may employ switched phase shifters, multiple diversity antennas and / or a feed network having a multi-layer construction to provide an antenna system with low losses, low external component count and / or which is thin and compact.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Illuminating optical lens for light emitting diode (LED)

ActiveUS8573815B2Improve optical efficiencyReduce manufacturing tolerancesPoint-like light sourcePortable electric lightingEngineeringLight-emitting diode

An illuminating optical lens article of manufacture for use with a light emitting diode (LED) mounted on a circuit board has (a) a base portion defining a rim on a plane having a bottom surface around a longitudinal axis for mounting over the LED; (b) an integral refractive outer surface of the lens extending towards the longitudinal axis from the base; (c) an integral refractive inner surface of the lens extending from the base forming a cavity shaped and sized to receive an LED; and optionally (d) a plurality of grooved sections for receiving an adhesive formed on the bottom surface of the base portion. The base is adapted to be mounted on the circuit board onto which the LED is mounted. The integral refractive outer and inner surfaces each define a predetermined geometry adapted to direct and focus light emitting from the LED to a predetermined path.

Owner:CORELED SYST

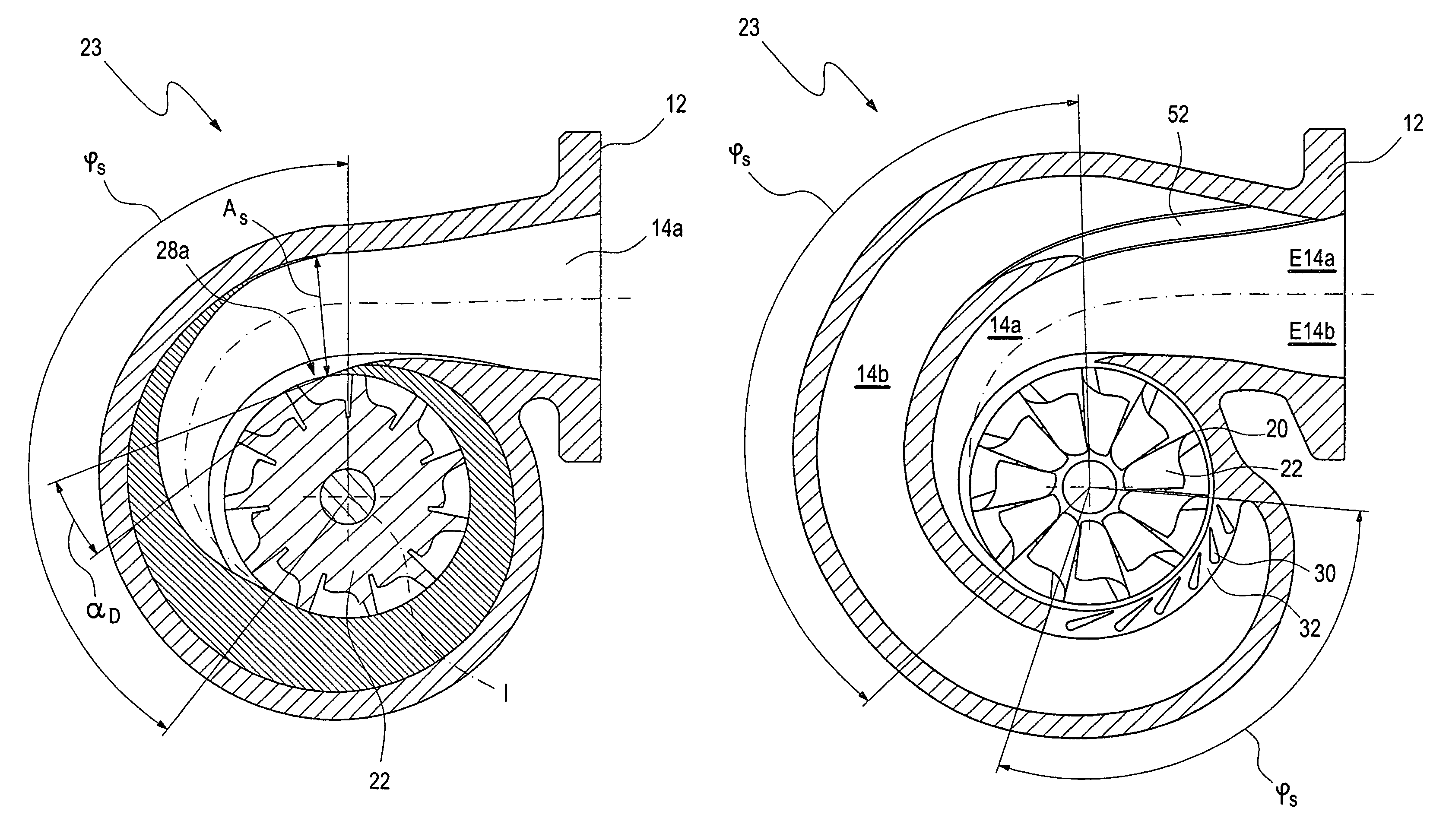

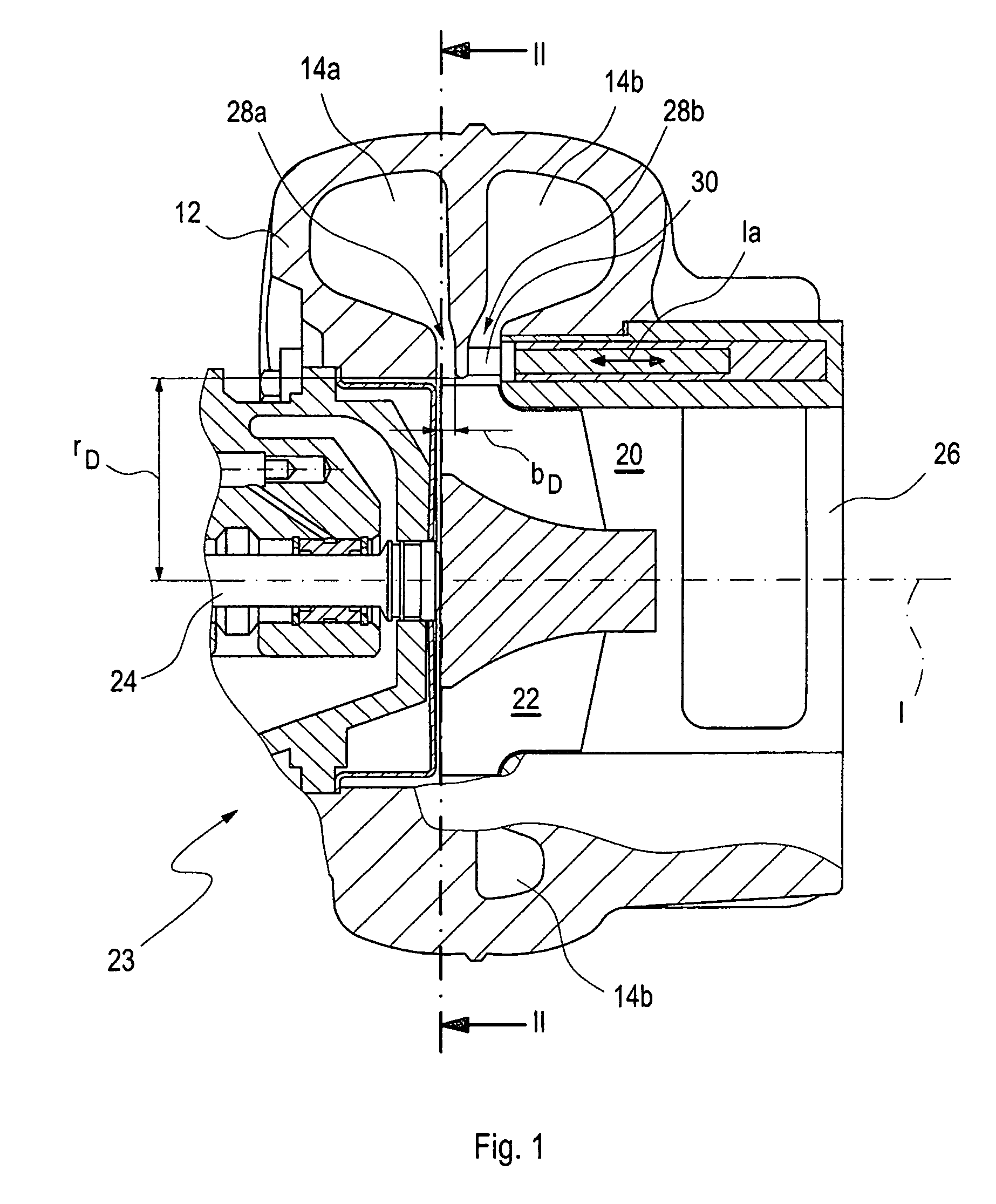

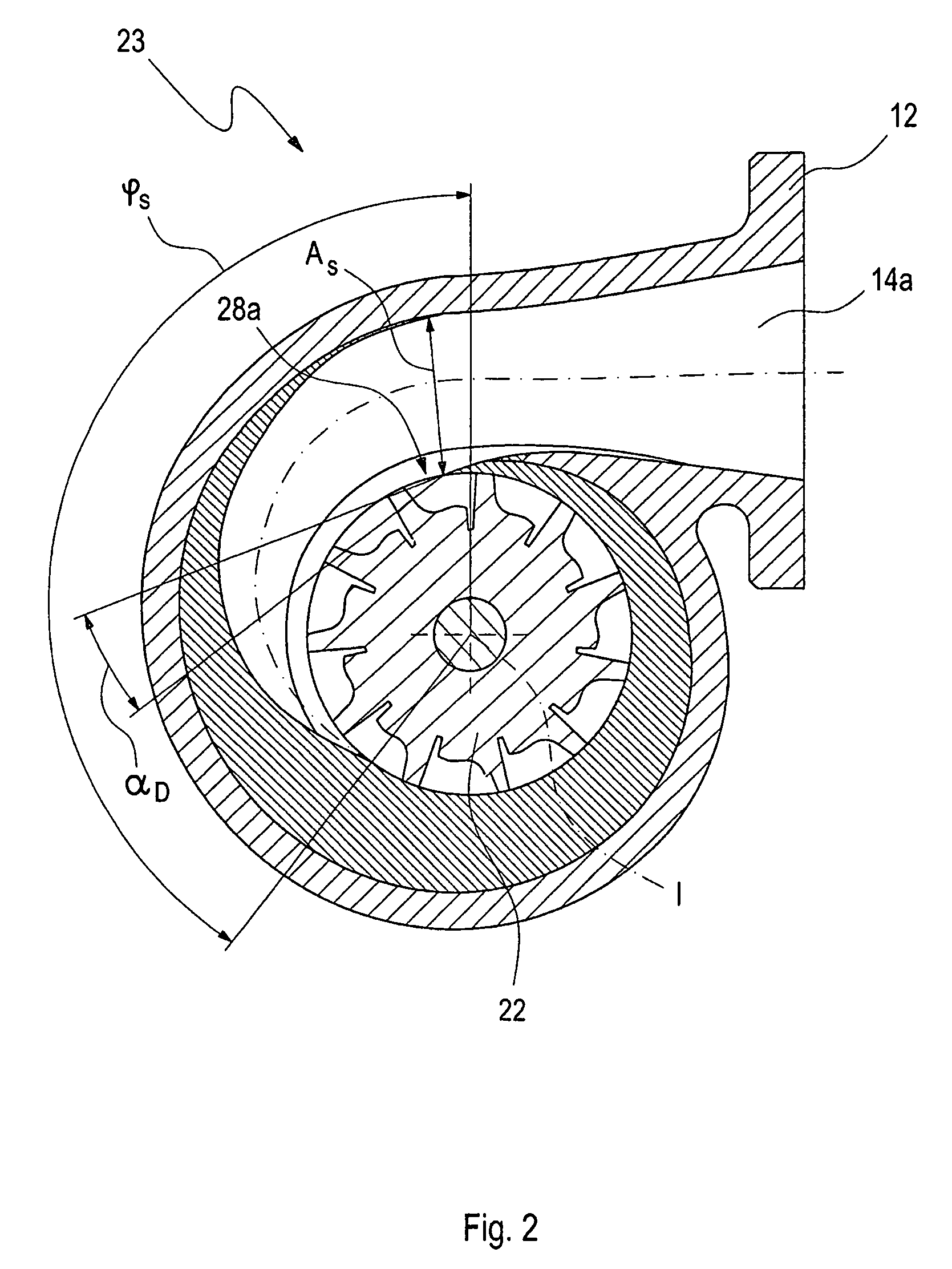

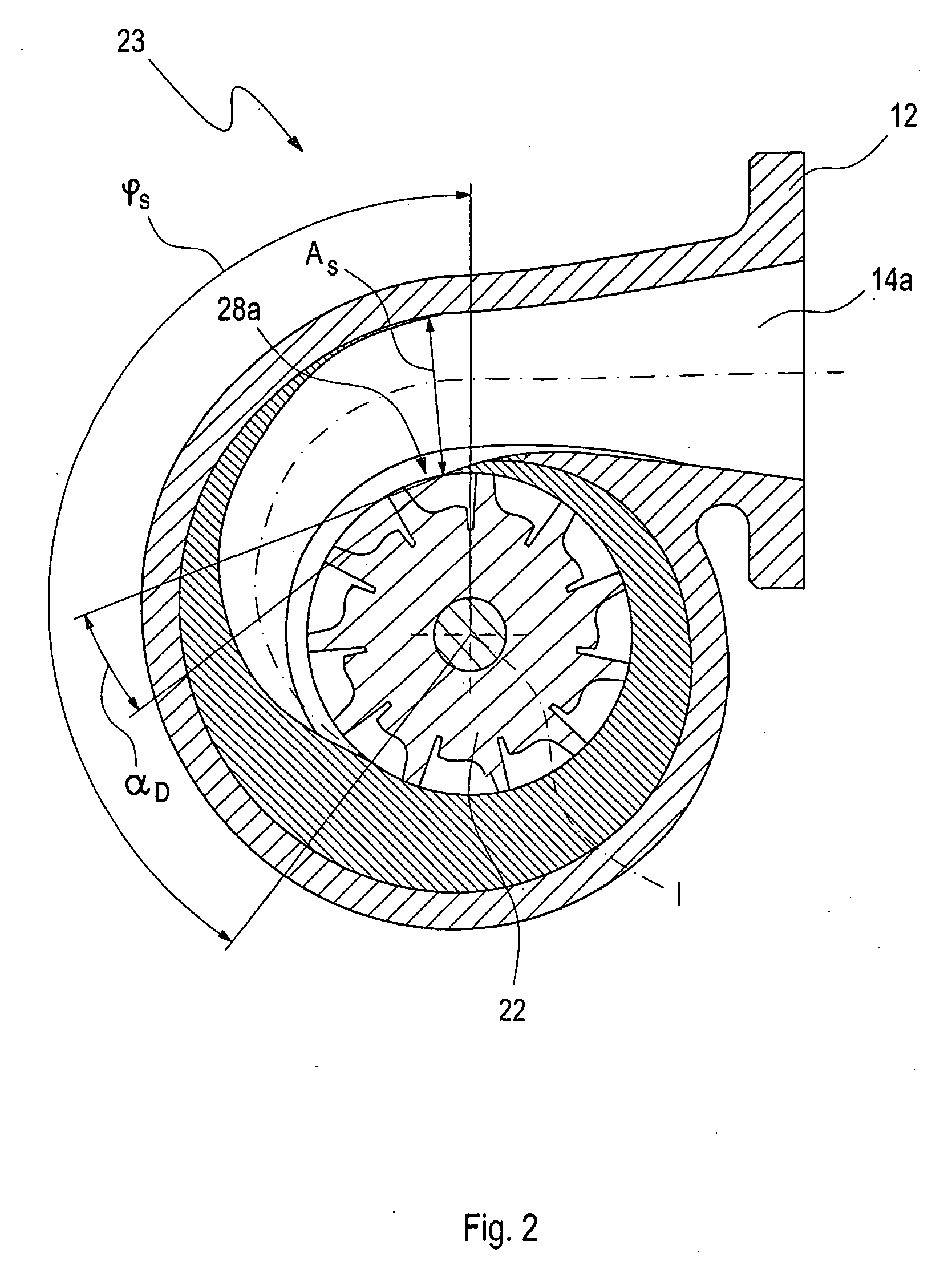

Turbocharger for an internal combustion engine of a motor vehicle

InactiveUS8621863B2Improve efficiencyLow manufacturing tolerance requirementsInternal combustion piston enginesWind motor controlMobile vehicleImpeller

In a turbocharger for an internal combustion engine of a motor vehicle, comprising a turbine housing having first and second spiral passages, each of which is connected to at least one exhaust gas line of an exhaust train of the internal combustion engine and a turbine wheel disposed within a rotor chamber of the turbine housing and connected to a compressor impeller via a drive shaft for rotation with the impeller, the exhaust gas of the internal combustion engine can be routed through the spiral passages for admission to the turbine wheel via the first and second spiral passages which have different wrap angles around the turbine wheel.

Owner:DAIMLER AG

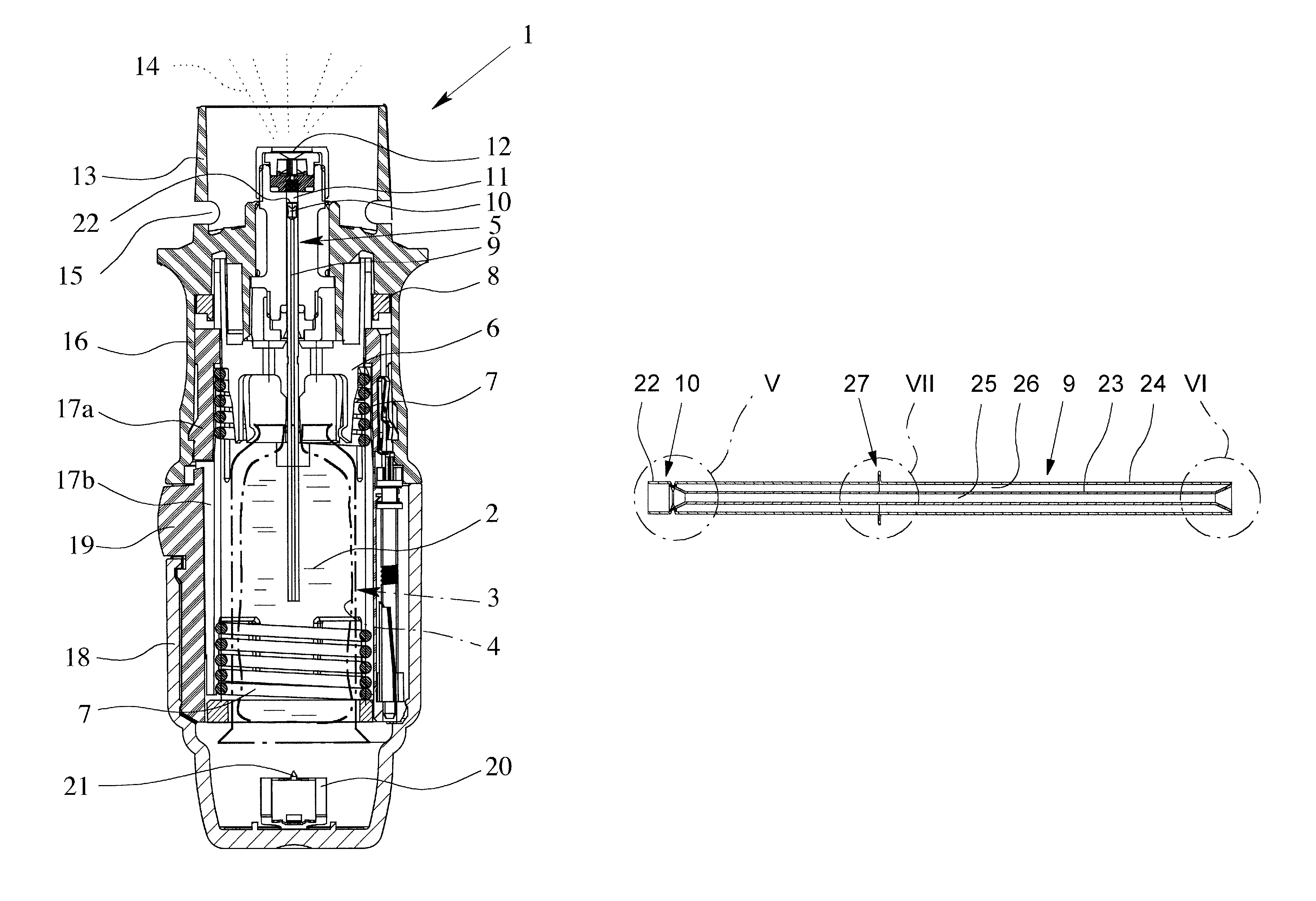

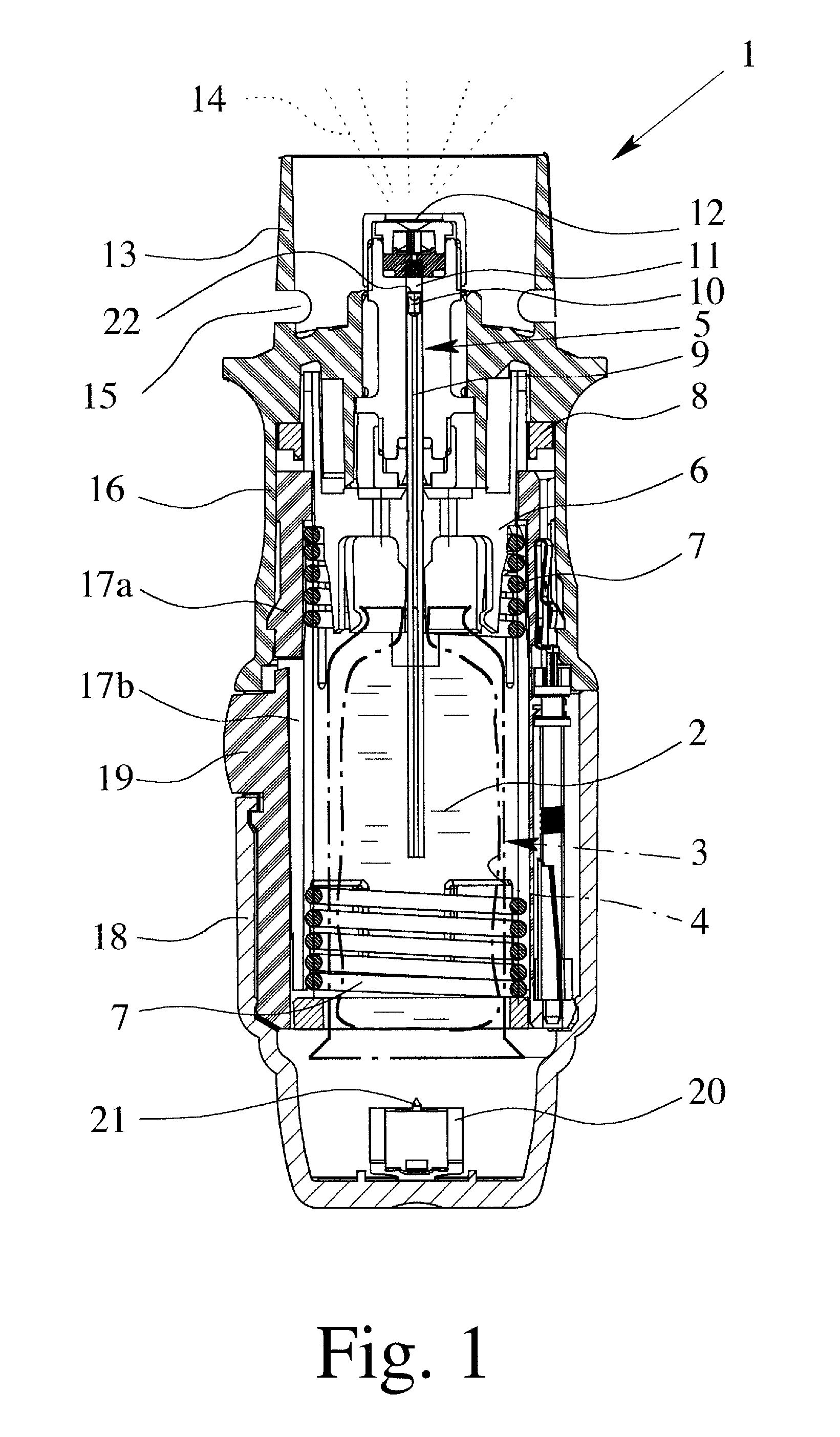

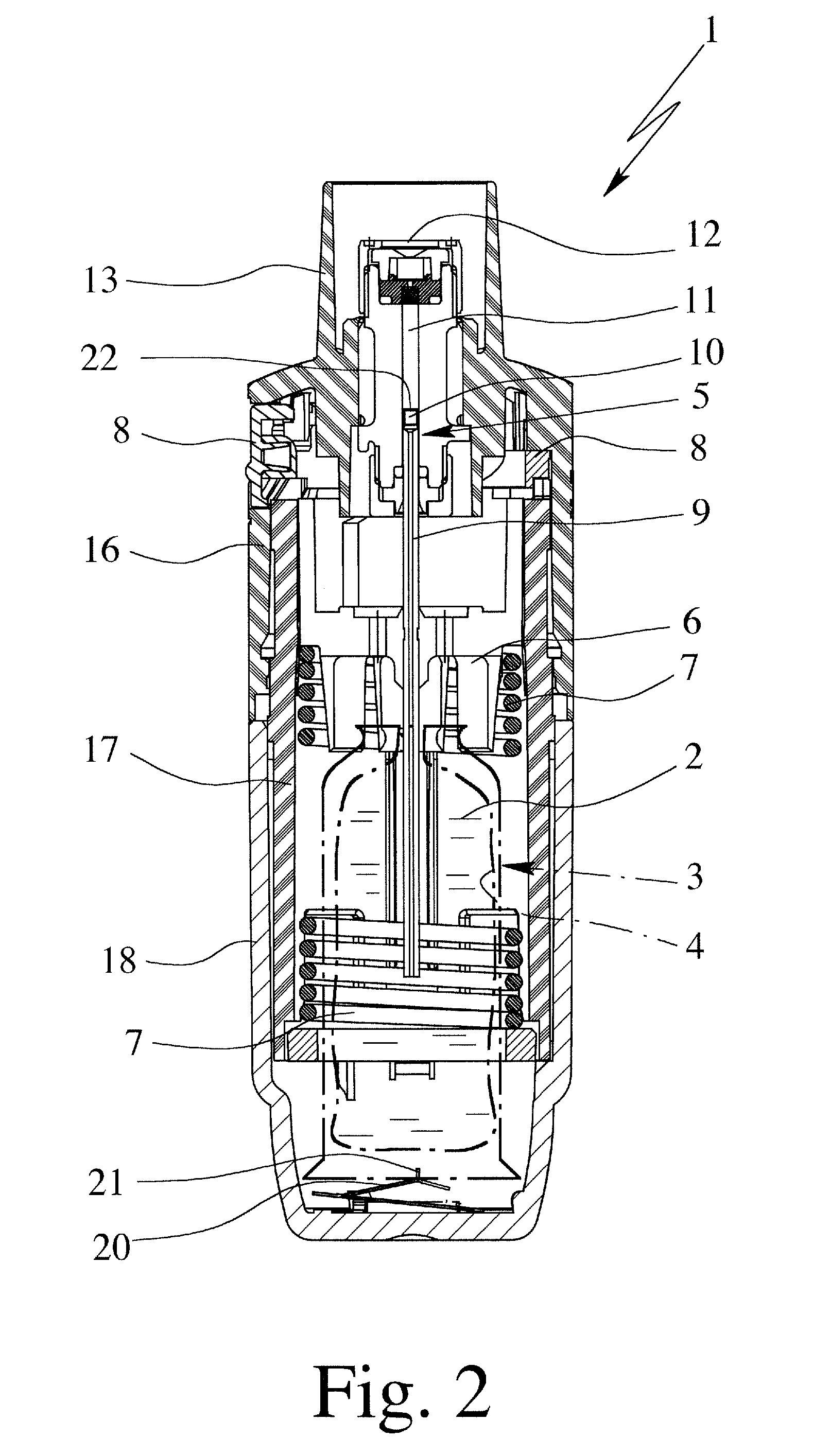

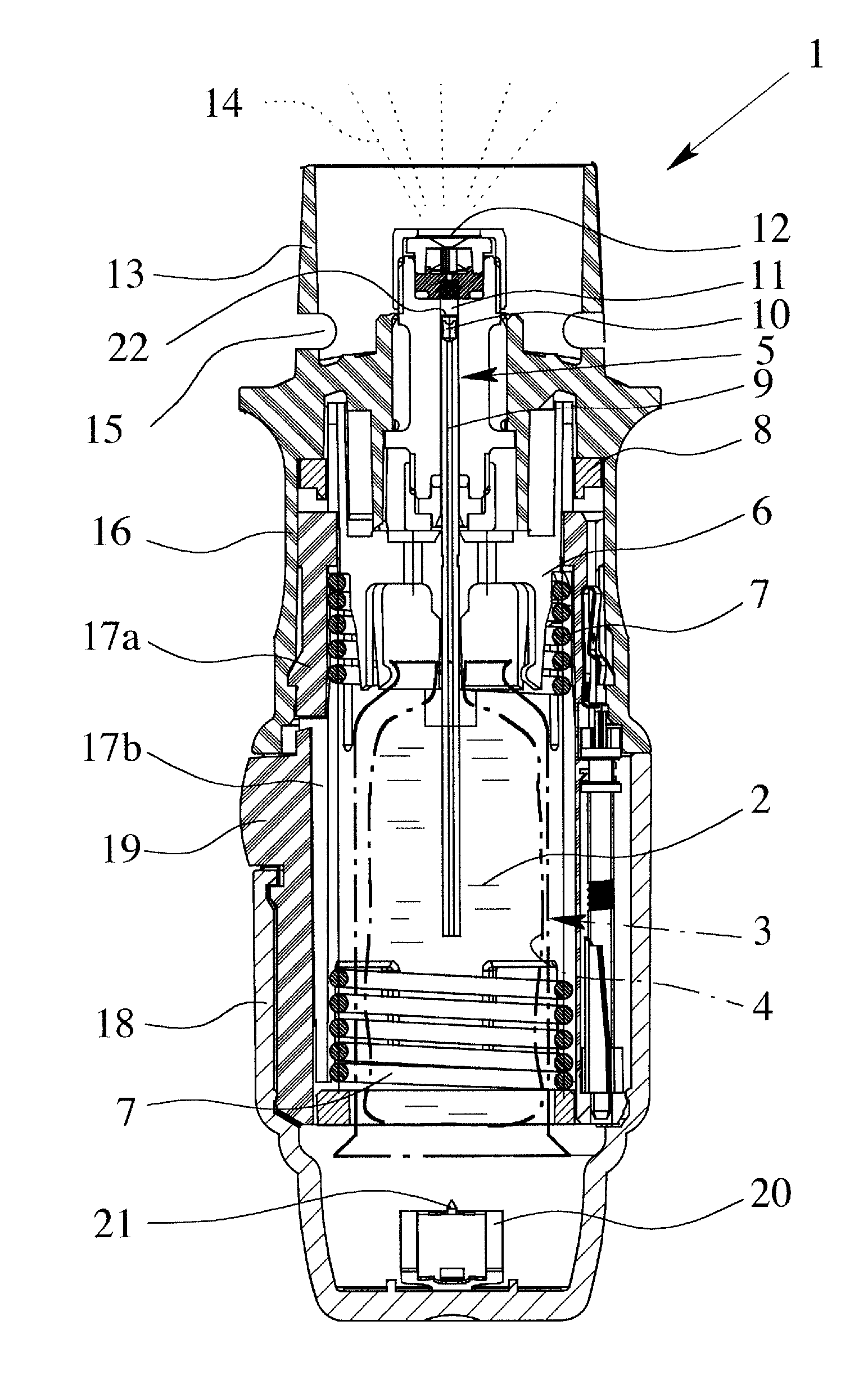

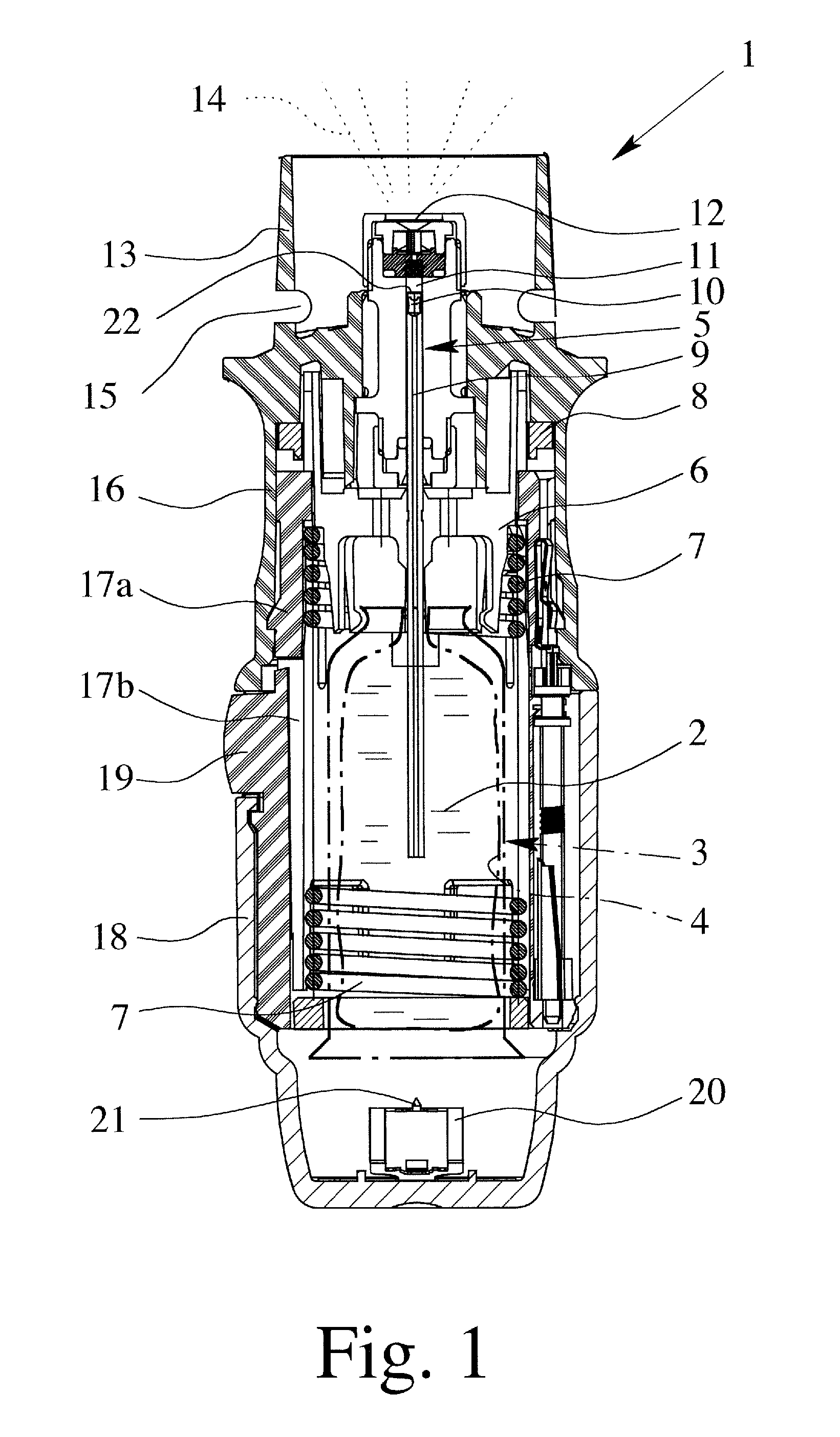

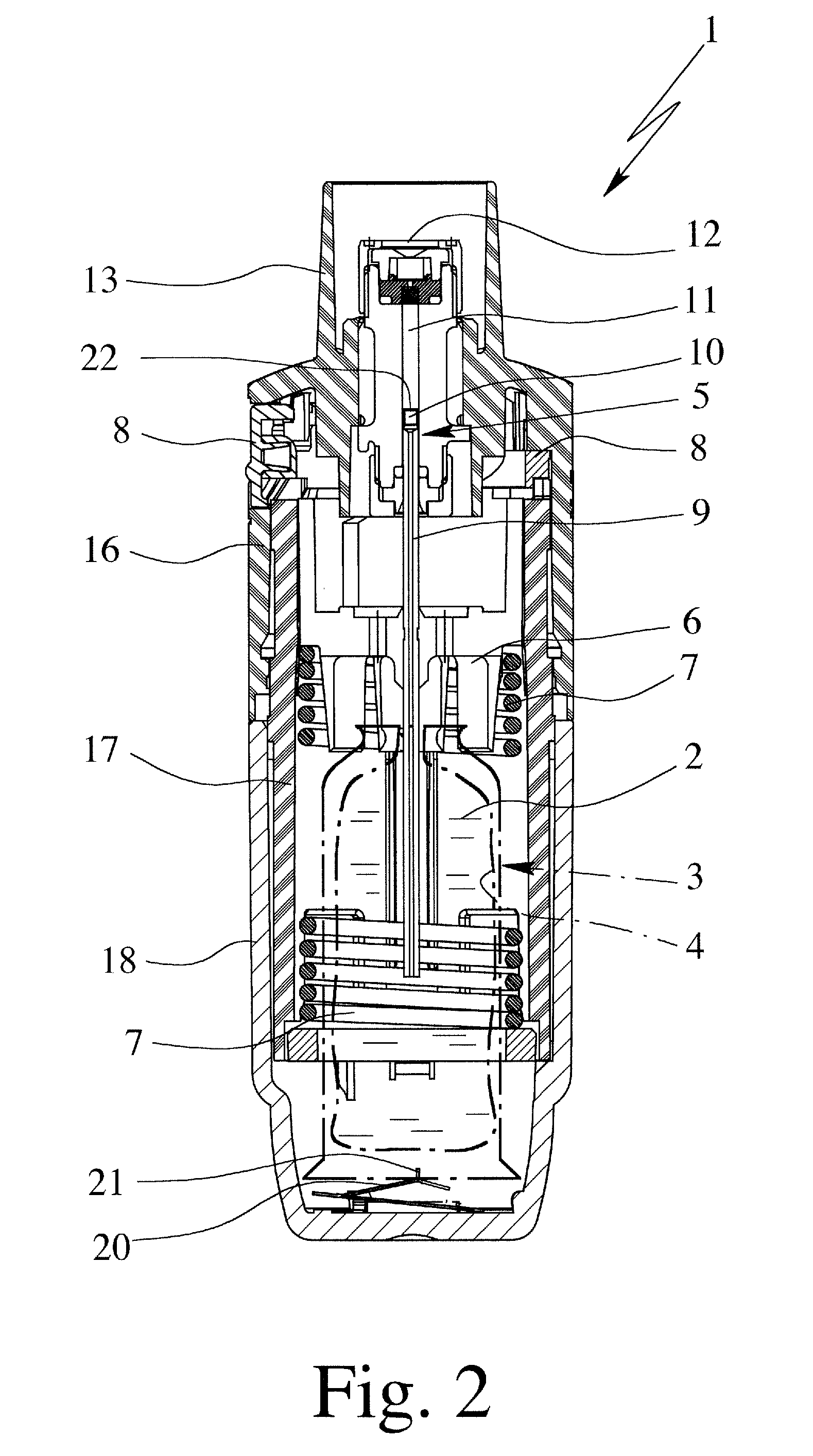

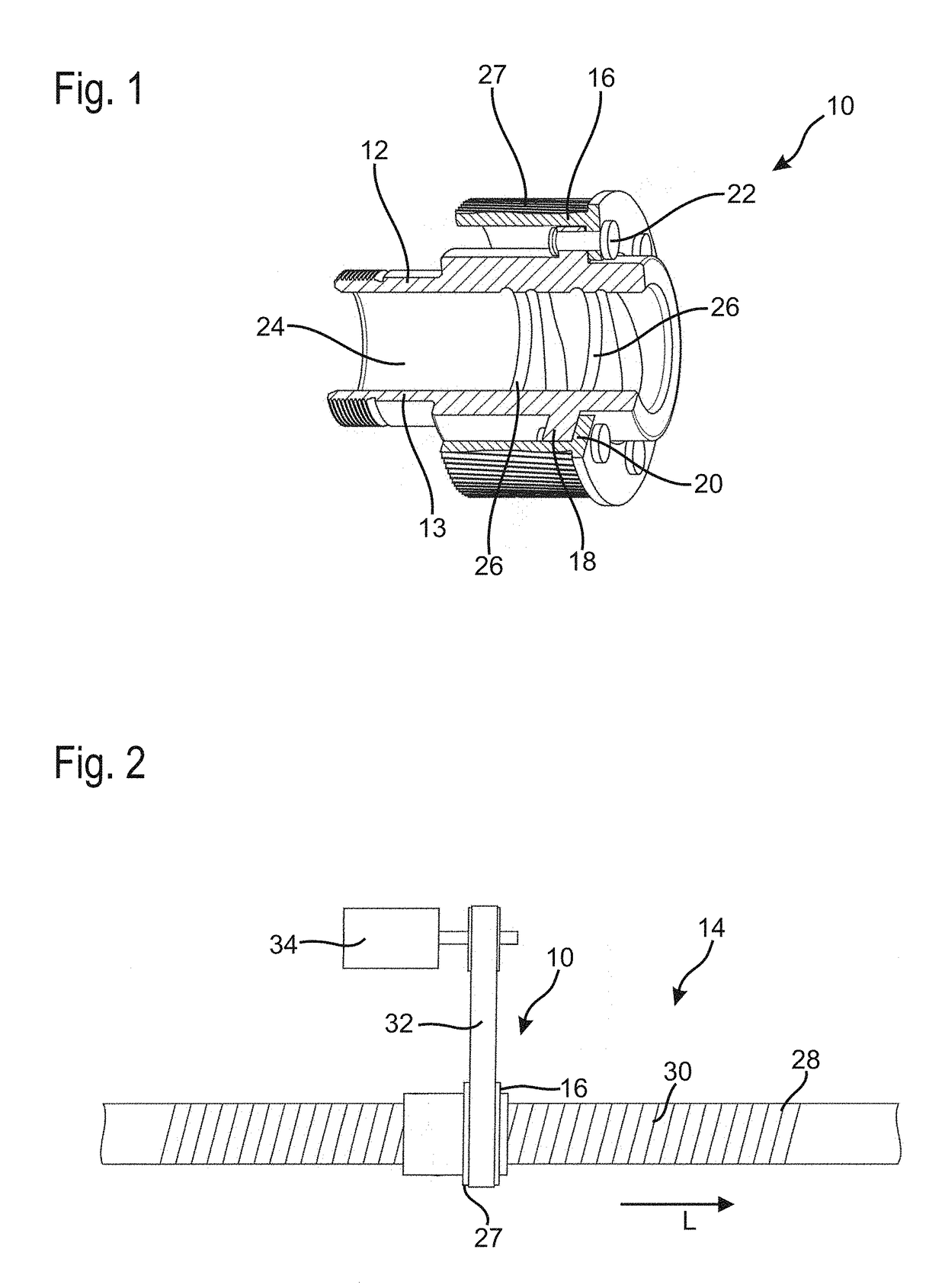

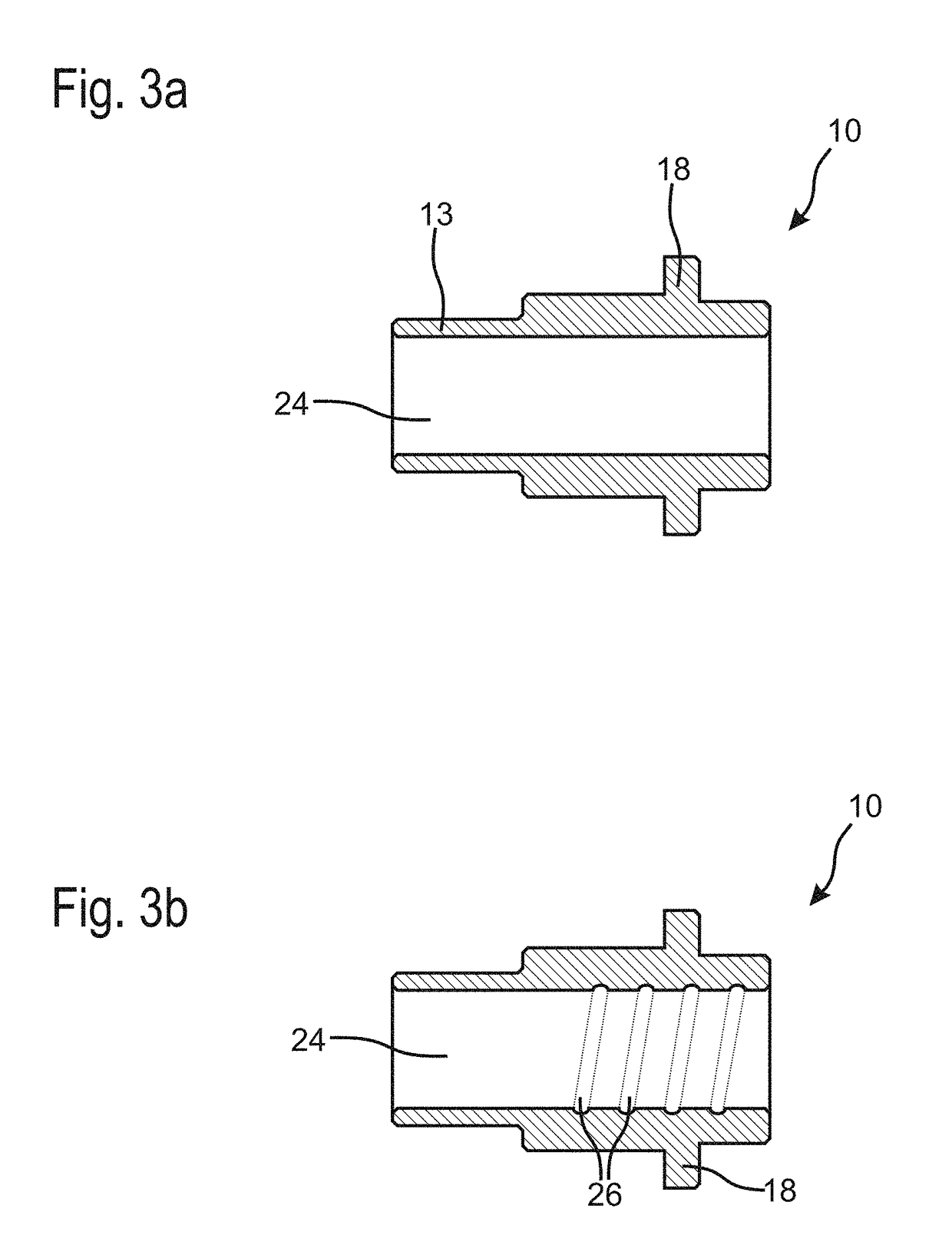

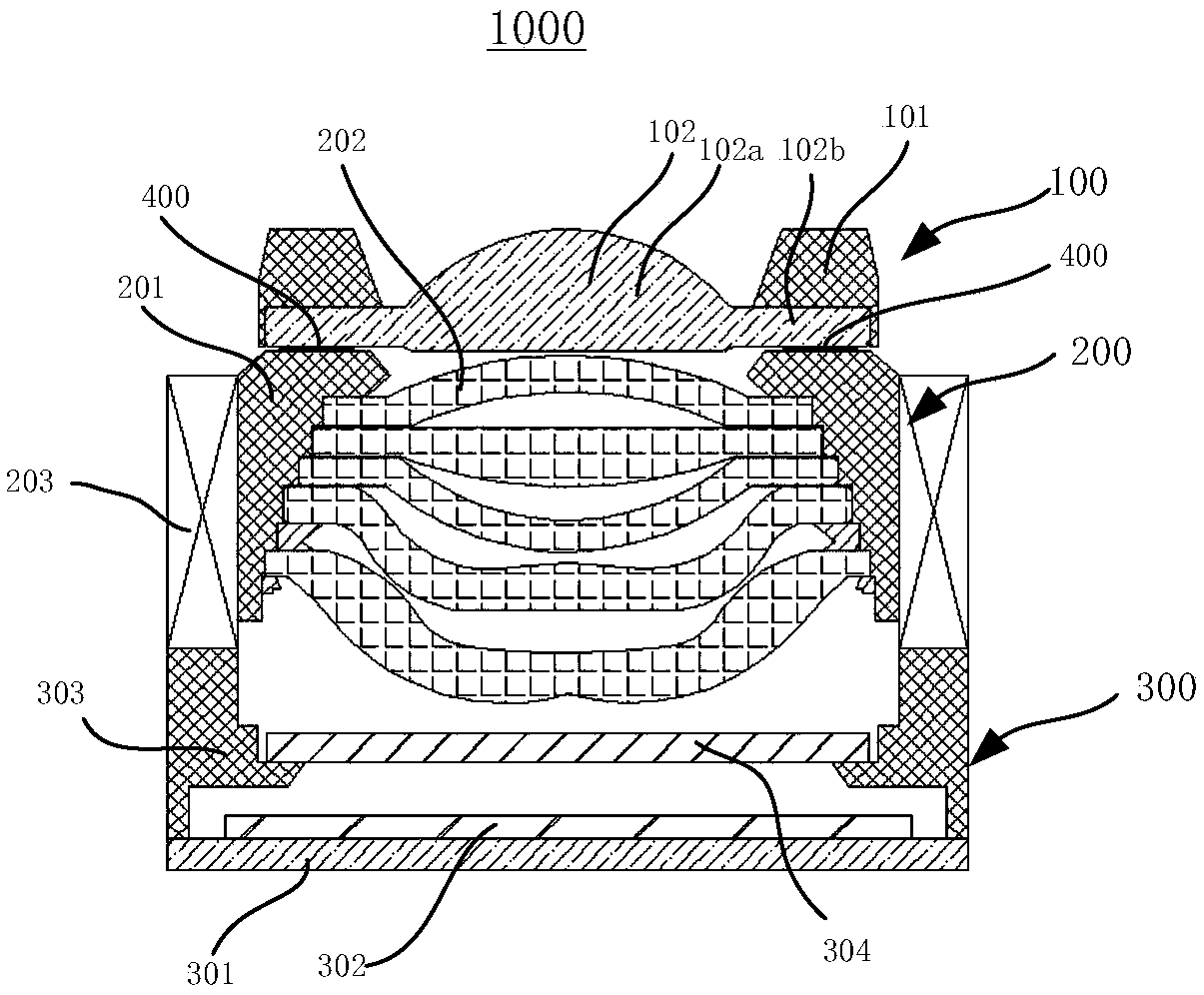

Nebuliser

ActiveUS8479725B2Simple and inexpensive to produceImprove stabilityLiquid surface applicatorsPowdered material dispensingNebulizerCapillary Tubing

A nebulizer for a fluid which has a conveying tube for conveying fluid and a method for producing a thick-walled capillary. The conveying tube or the capillary is of multipart and / or double-walled construction, and in particular, is made up of a number of parts, such as an inner tube and an outer tube. This construction allows the device to be manufactured more easily and cheaply, in particular, when the inner diameters are very small.

Owner:BOEHRINGER INGELHEIM INT GMBH

Turbocharger for an Internal combustion engine of a motor vehicle and internal combustion engine

InactiveUS20110079009A1Improve adaptabilityEasy to changeInternal combustion piston enginesGas turbine plantsImpellerTurbine wheel

In a turbocharger for an internal combustion engine of a motor vehicle, comprising a turbine housing having first and second spiral passages, each of which is connected to at least one exhaust gas line of an exhaust train of the internal combustion engine and a turbine wheel disposed within a rotor chamber of the turbine housing and connected to a compressor impeller via a drive shaft for rotation with the impeller, the exhaust gas of the internal combustion engine can be routed through the spiral passages for admission to the turbine wheel via the first and second spiral passages which have different wrap angles around the turbine wheel.

Owner:DAIMLER AG

Integrated low noise microwave wideband push-push VCO

ActiveUS7088189B2Limited rangeMinimize the phase shiftConveying record carriersPulse automatic controlLow noiseMicrowave

In one aspect, a voltage controlled oscillator is provided that includes circuitry comprising tunable coupled resonator networks, which are coupled to a terminal of a pair of three-terminal devices through a tuning voltage network which supports wide-band tunability. In another aspect, a wide-band tunable resonator is provided that is amenable to integration in the integrated circuit form.

Owner:SYNERGY MICROWAVE CORP

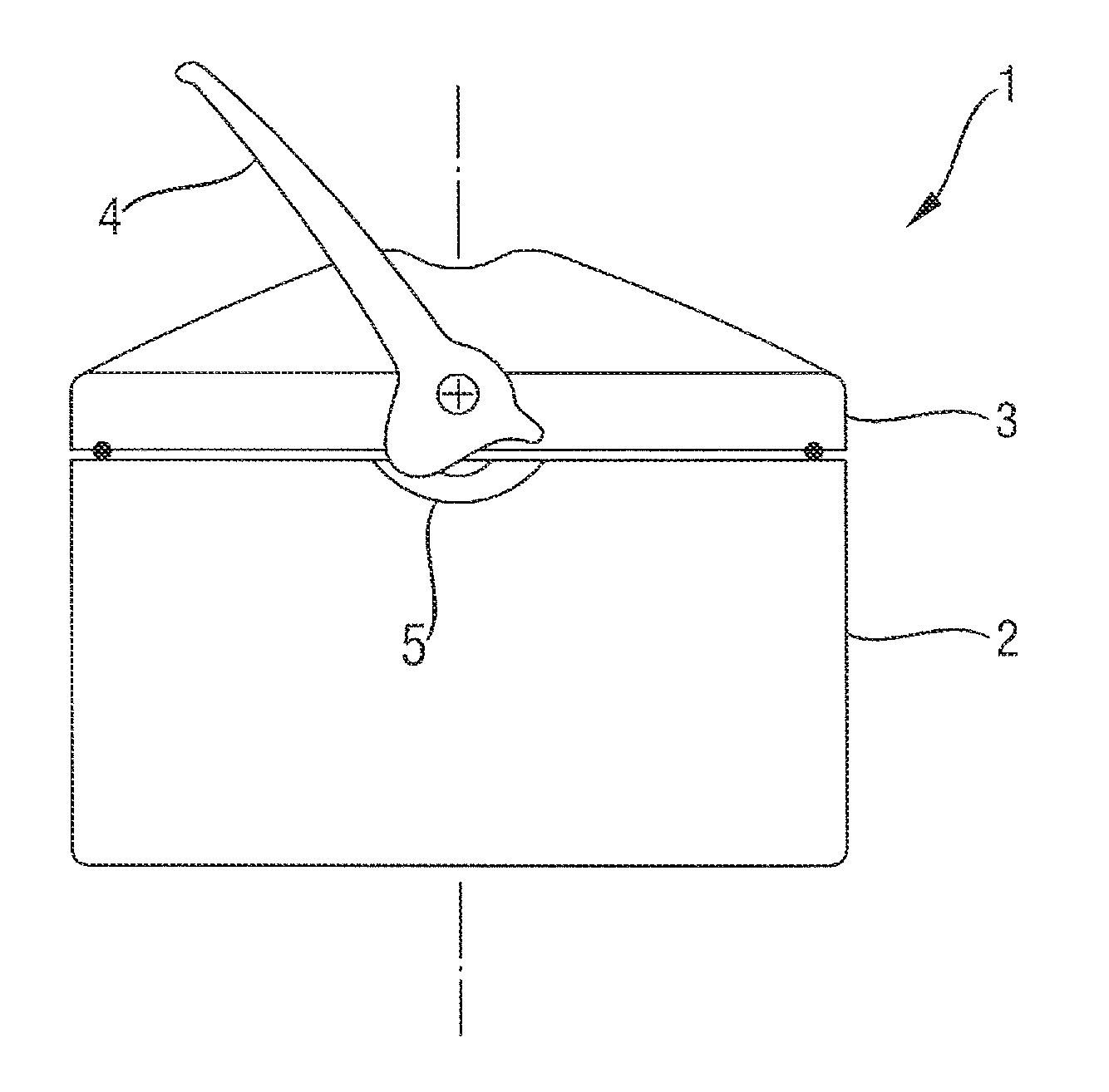

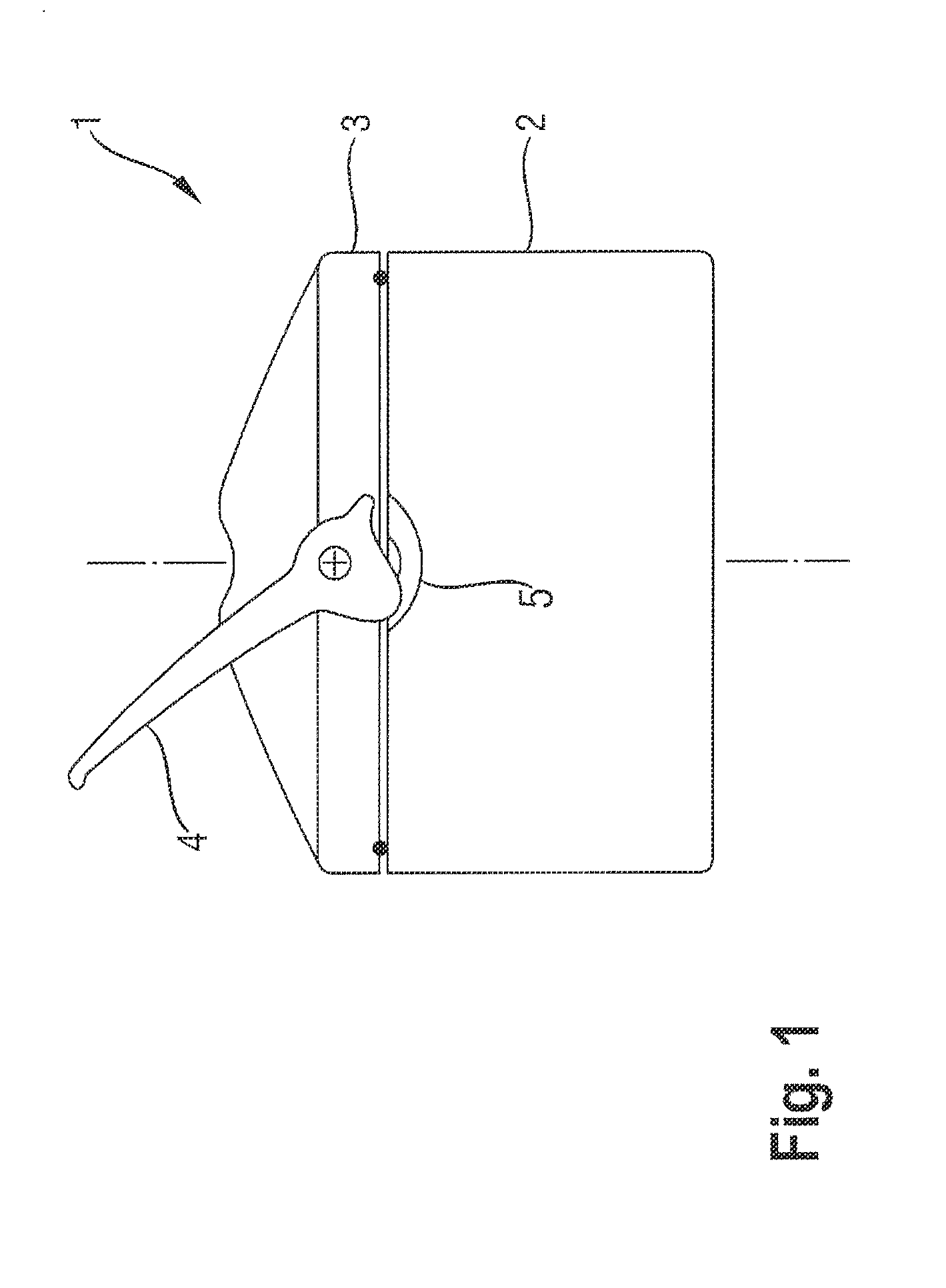

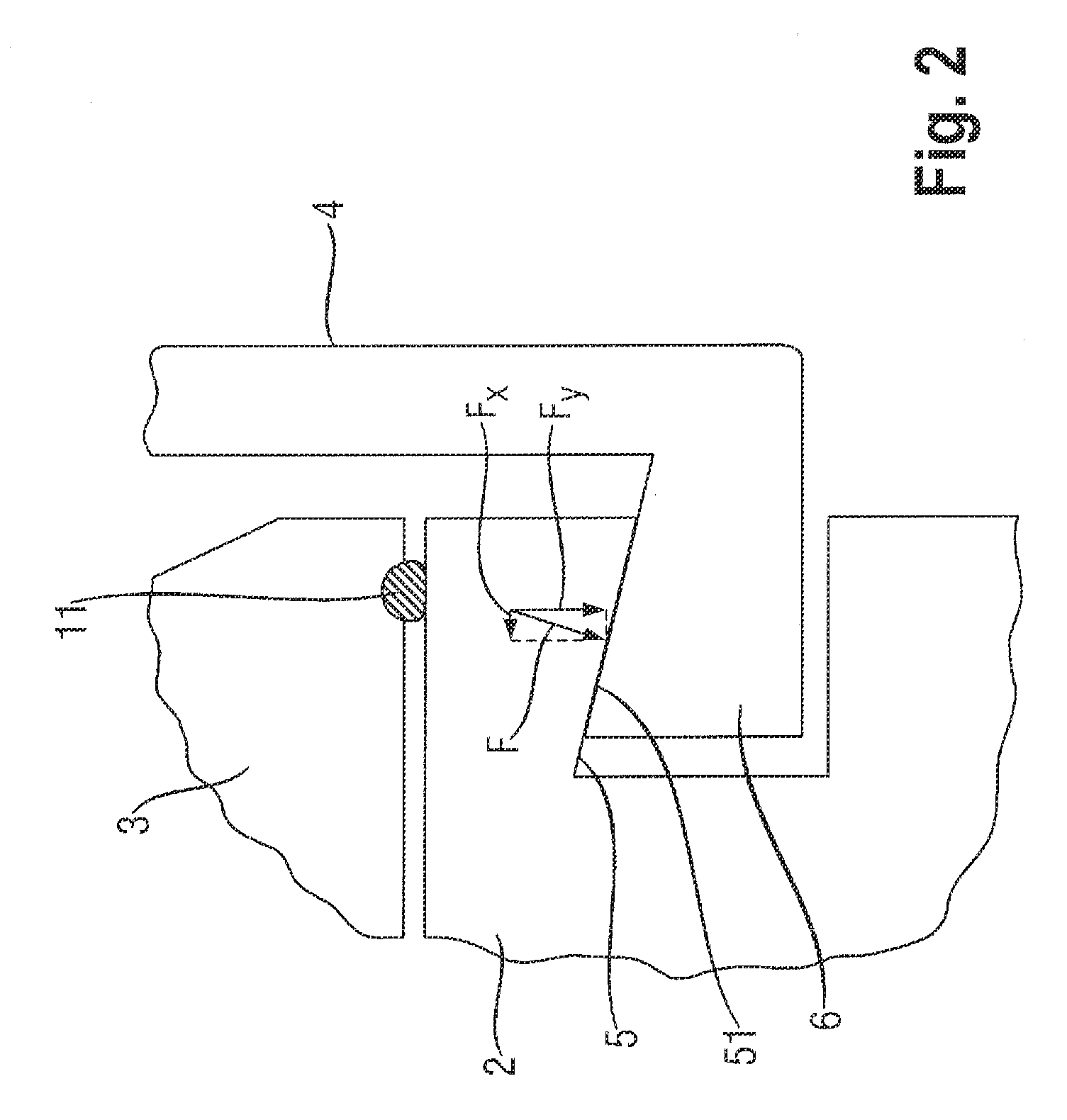

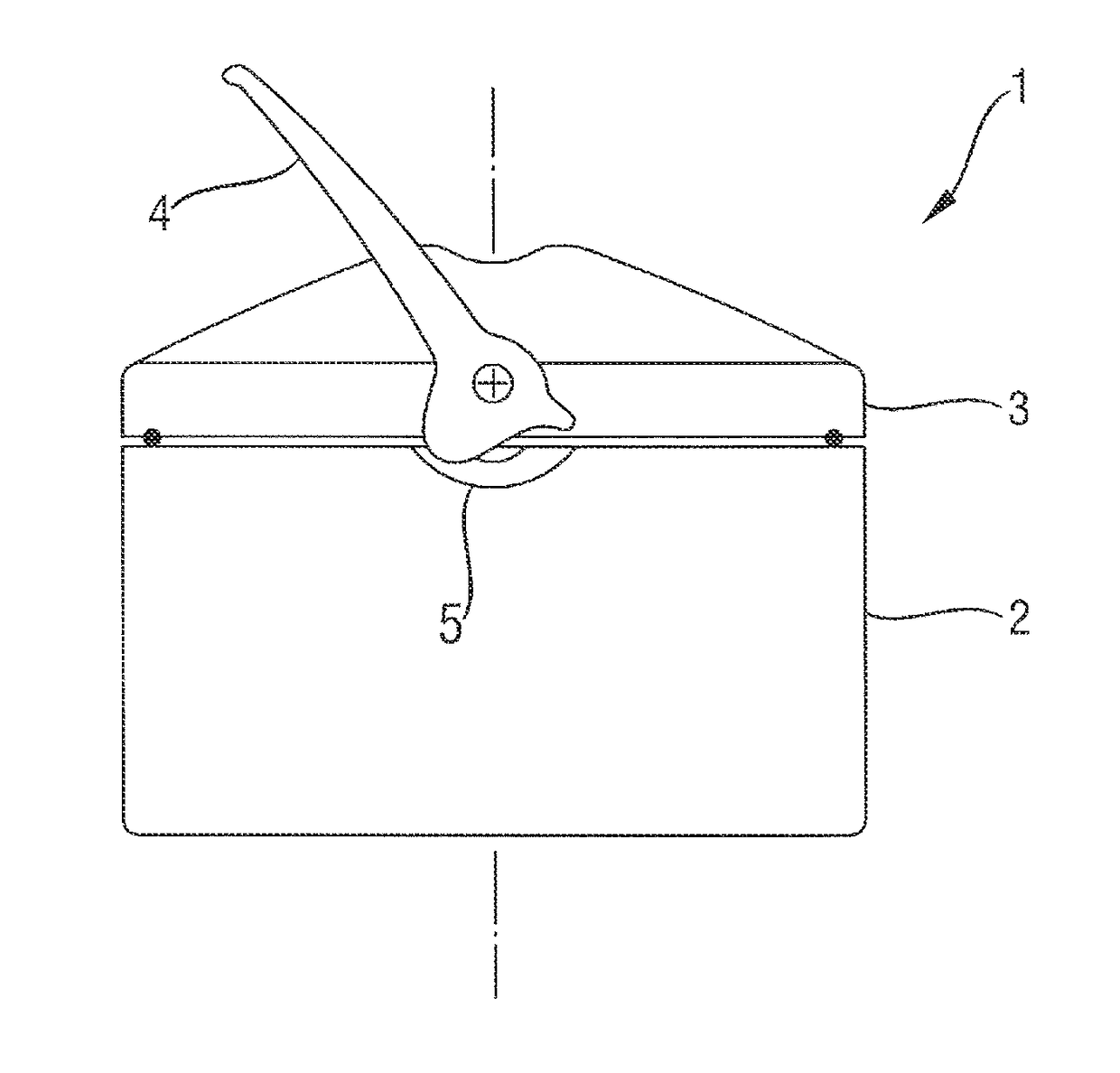

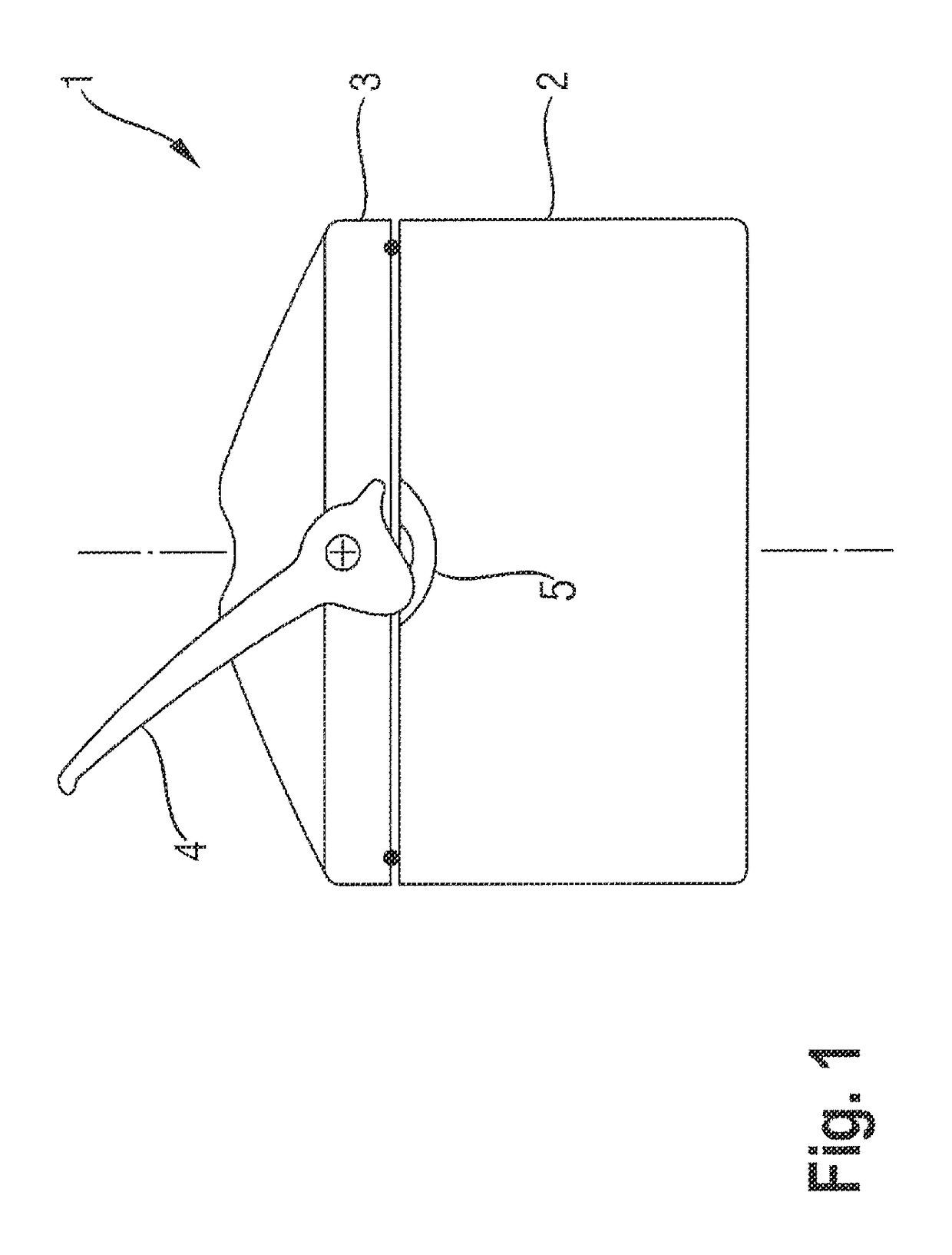

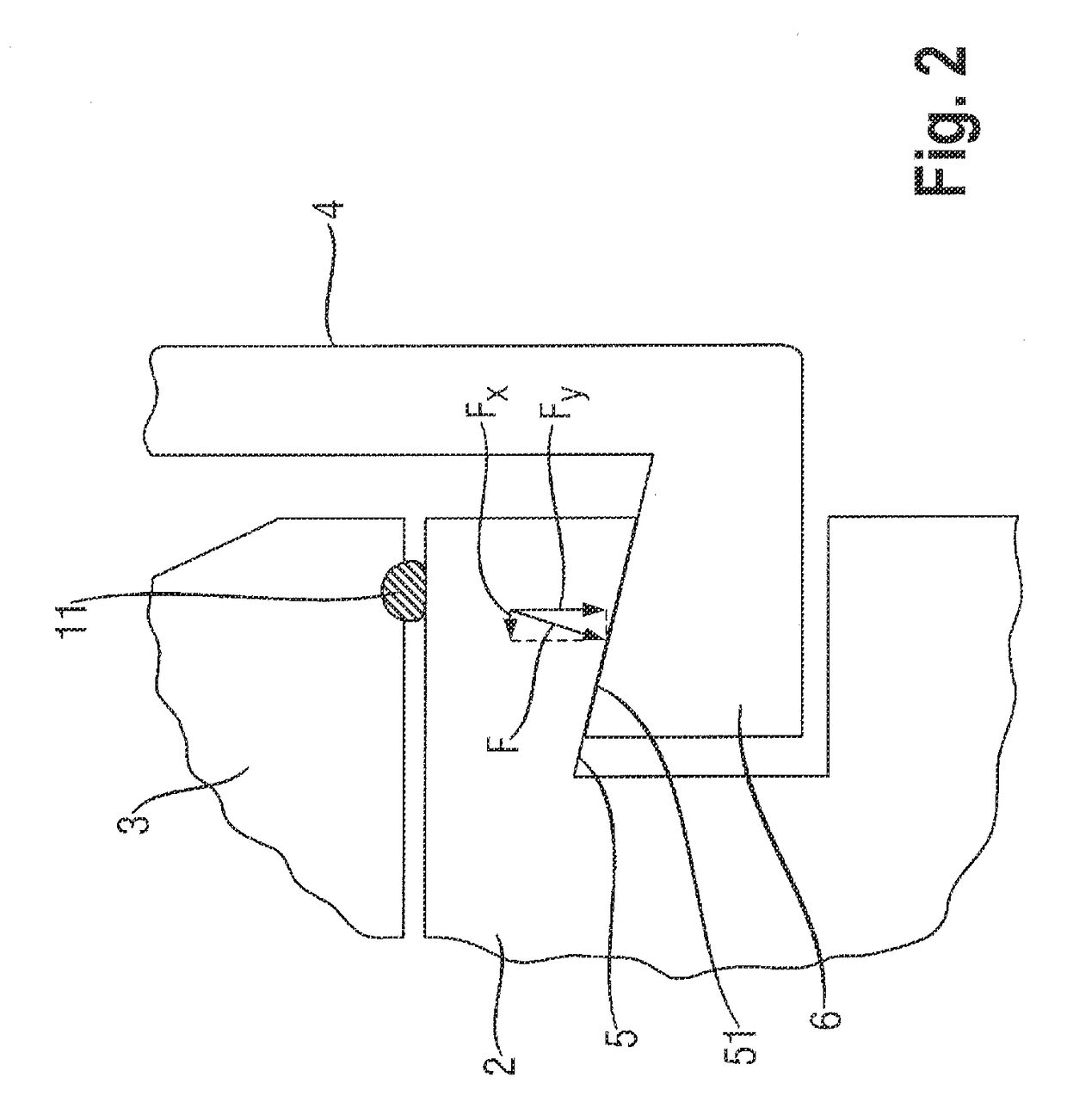

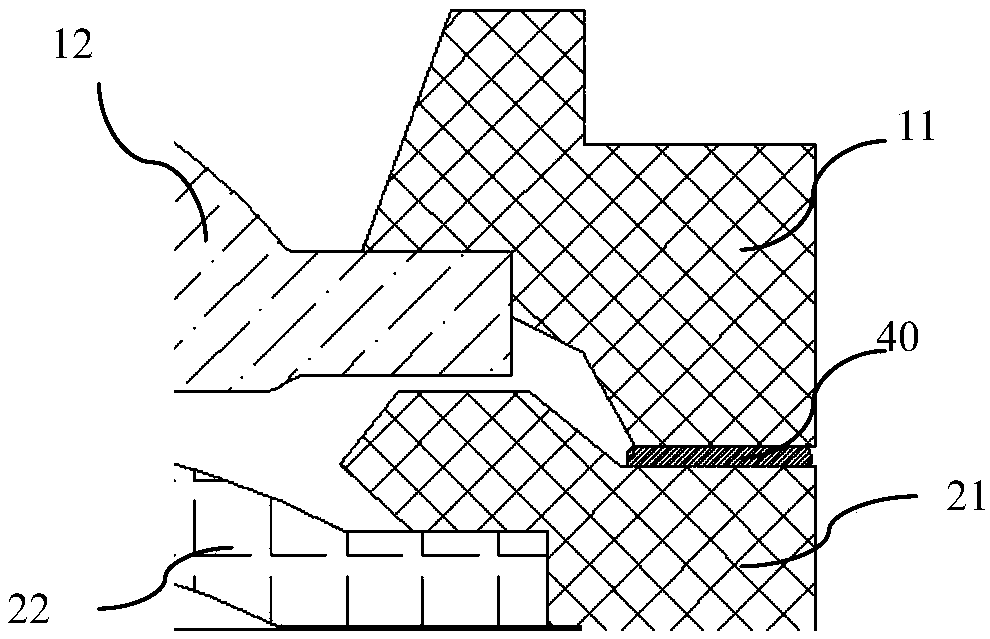

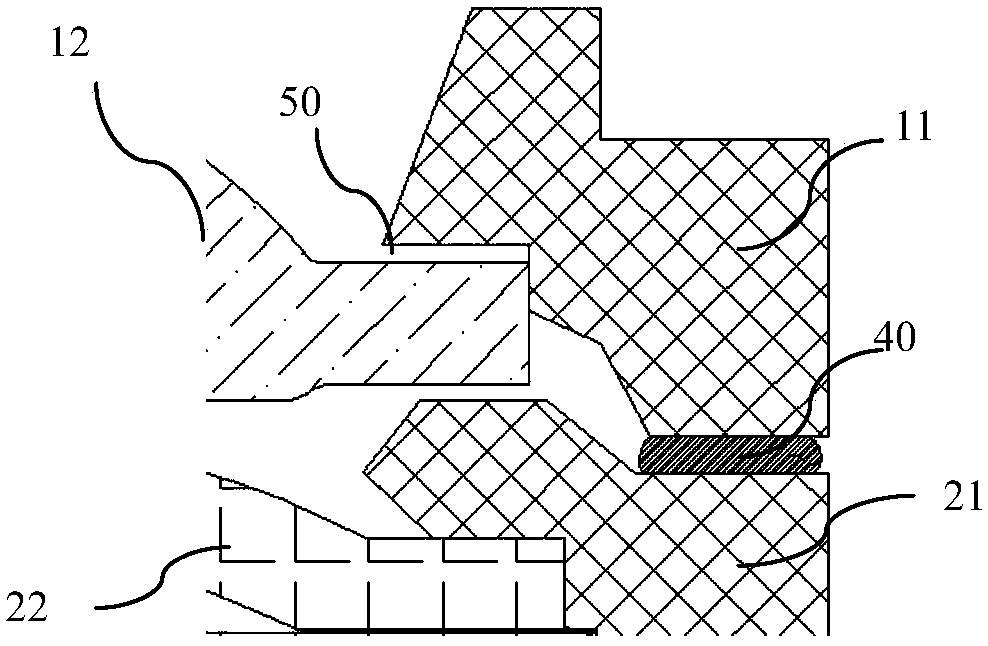

Centrifuge cup

ActiveUS20100004109A1Simple handlingReduce manufacturing tolerancesRotary centrifugesClamping mechanismEngineeringContact line

The invention relates to a centrifuge cup, which has a container and a cover. The cover has a lever including a guide element in each case on opposing edge areas thereof. The guide elements are able to be introduced into an associated guide path of the container by pivoting the lever. The guide elements are implemented in such a way that in a closed state of the cover with the container, a clamping force (F) having vertical force component (Fy) and horizontal force component (Fx) is provided at a contact point or a contact line of the guide elements with the particular associated guide path.

Owner:THERMO ELECTRONICS LED GMBH

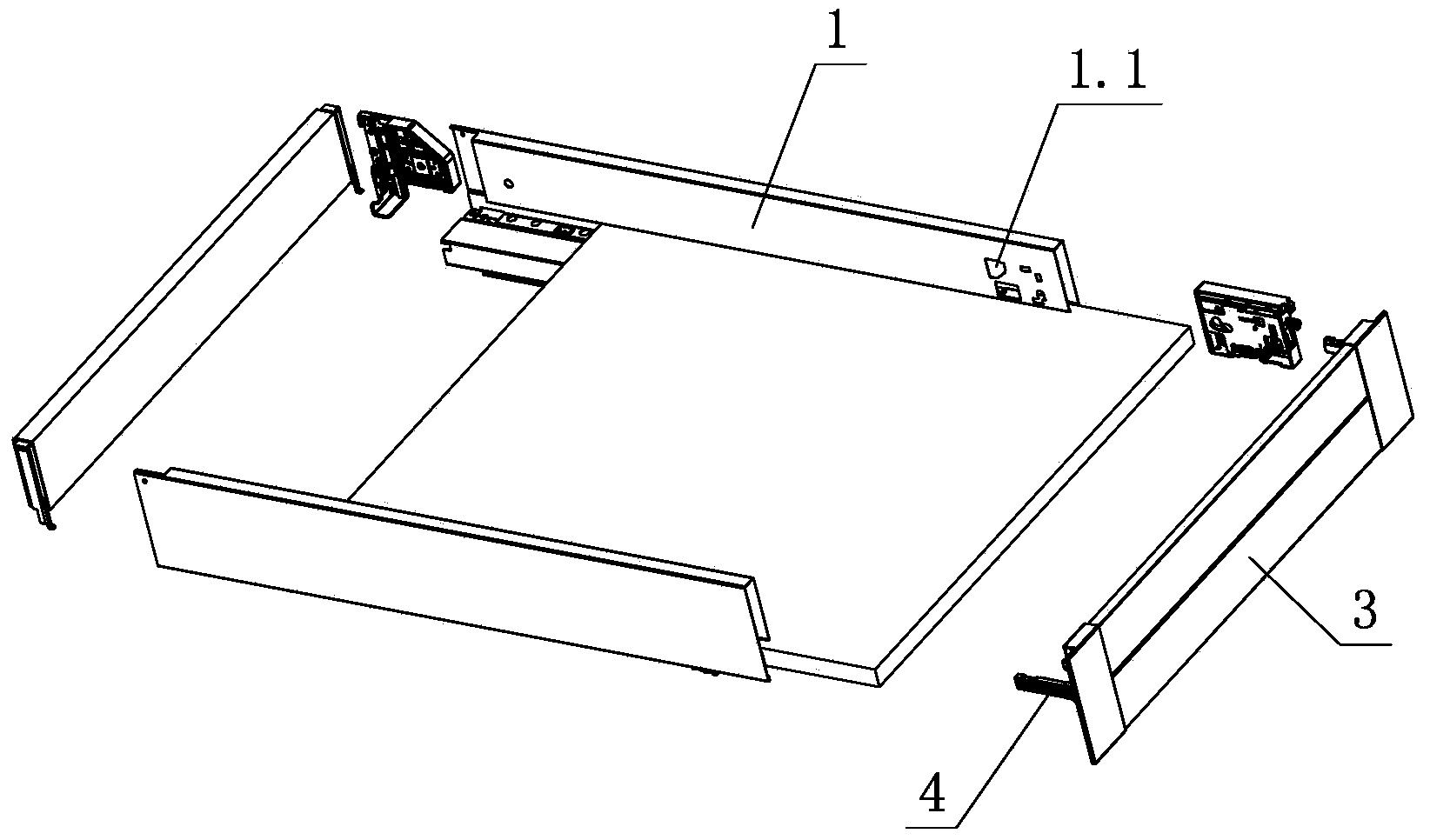

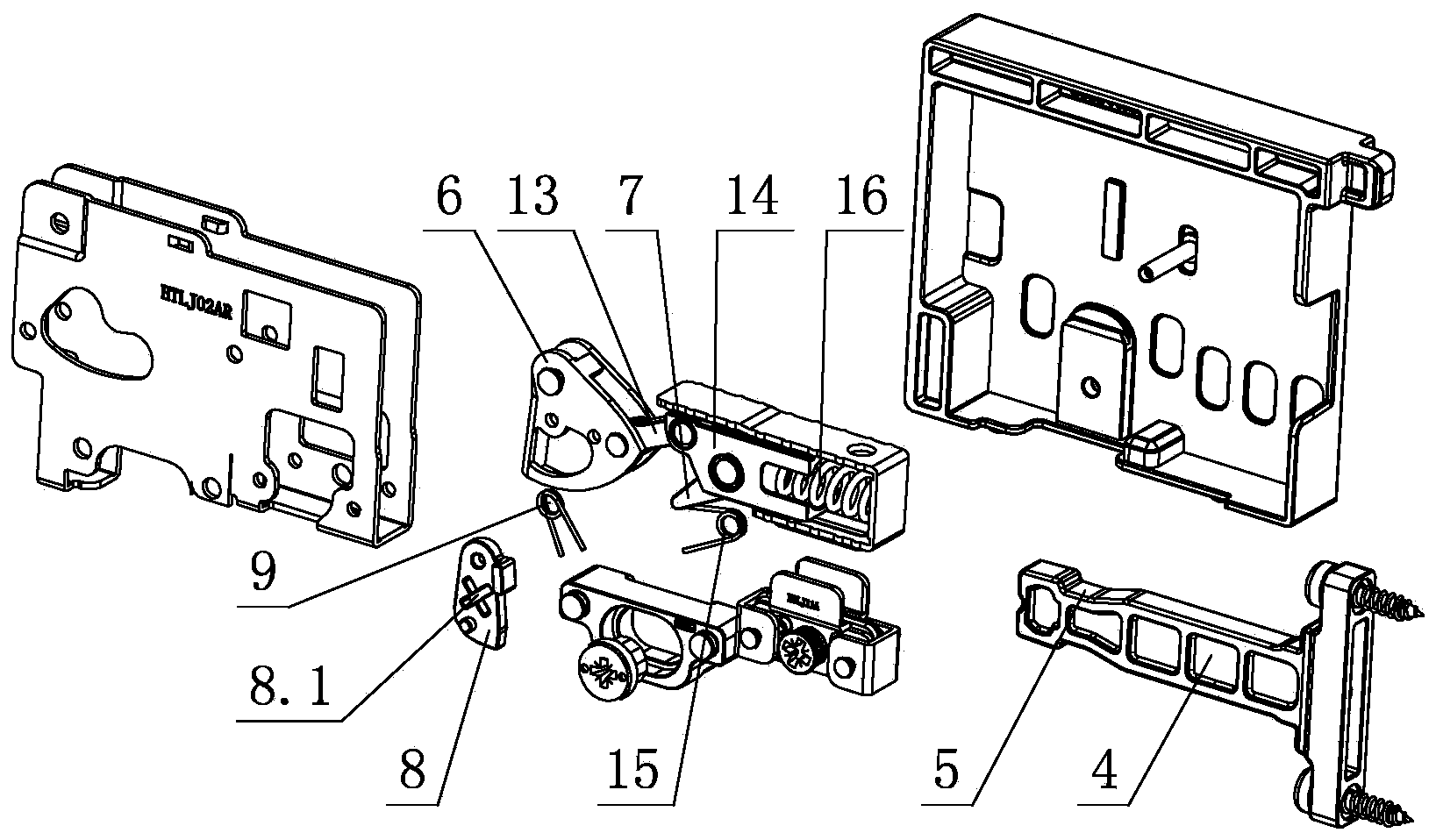

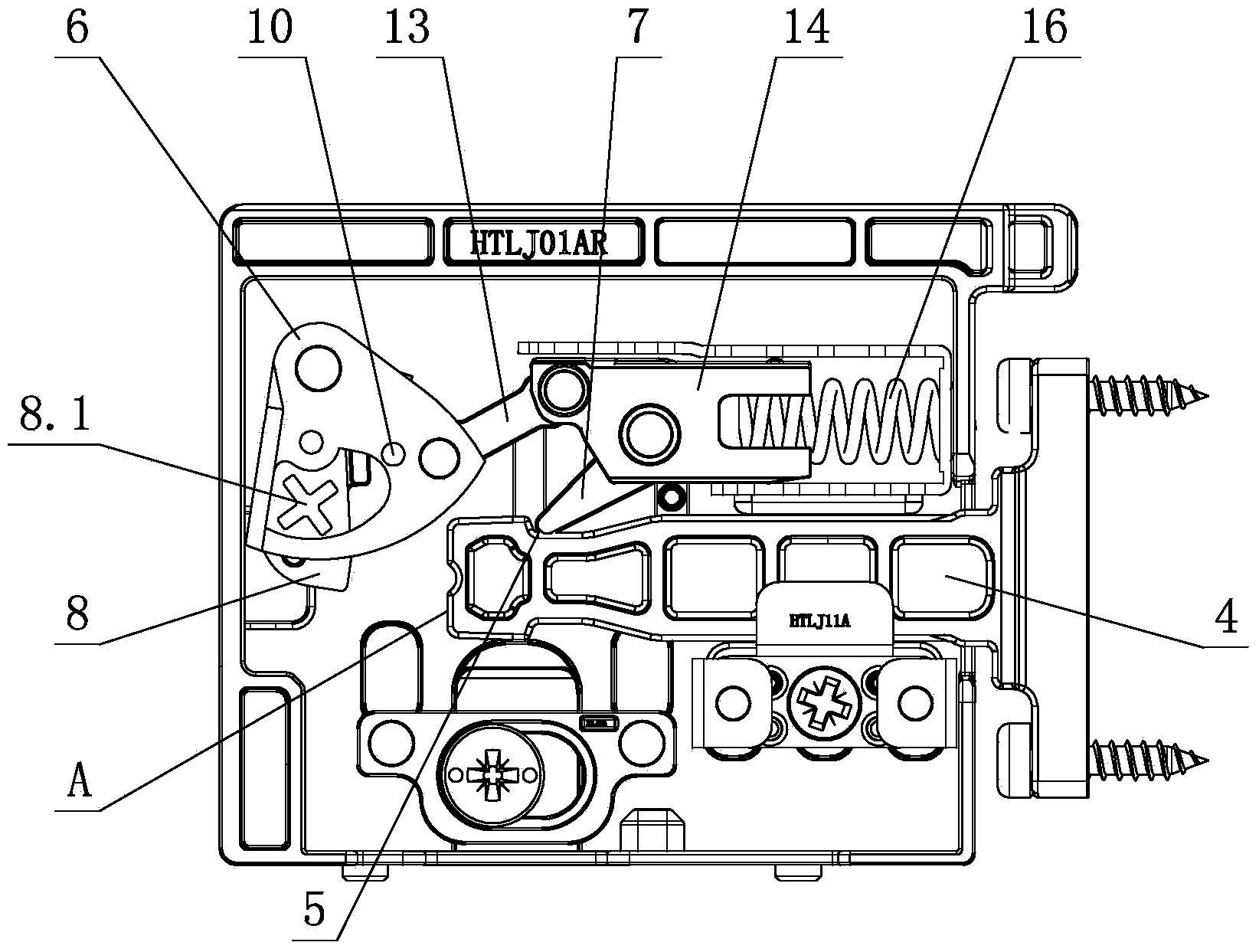

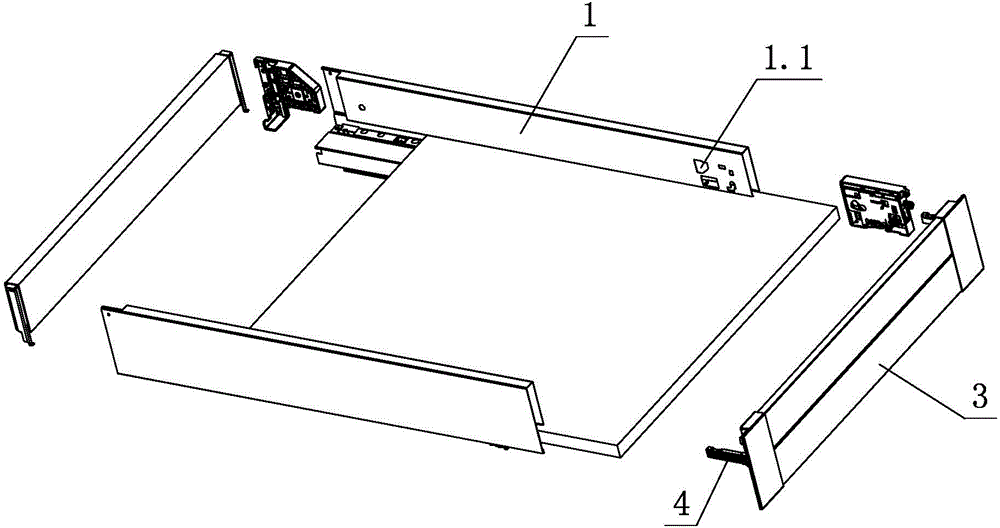

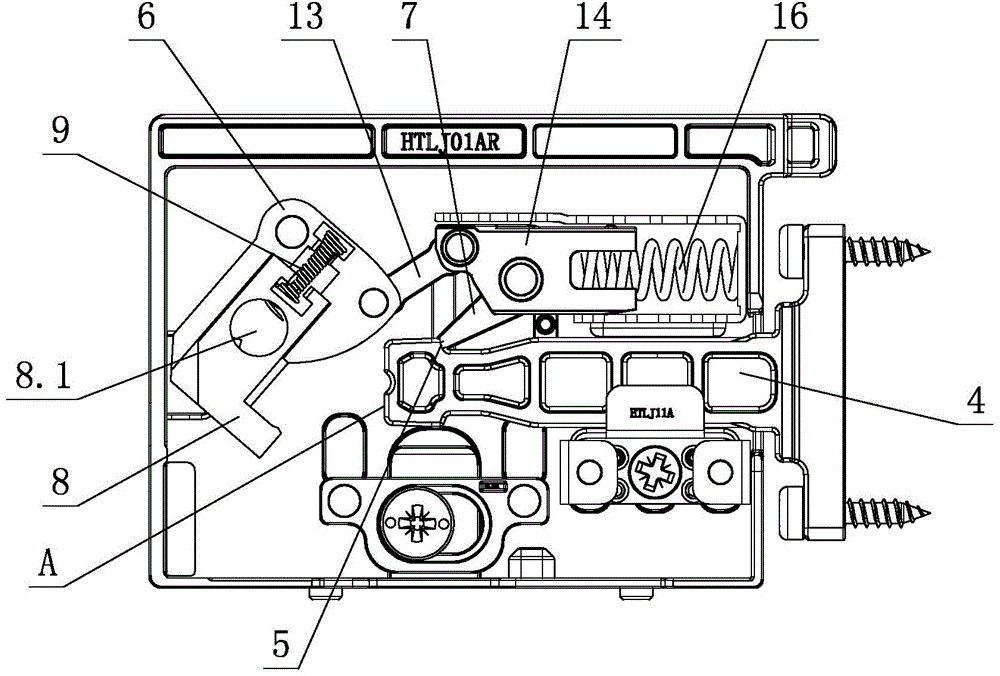

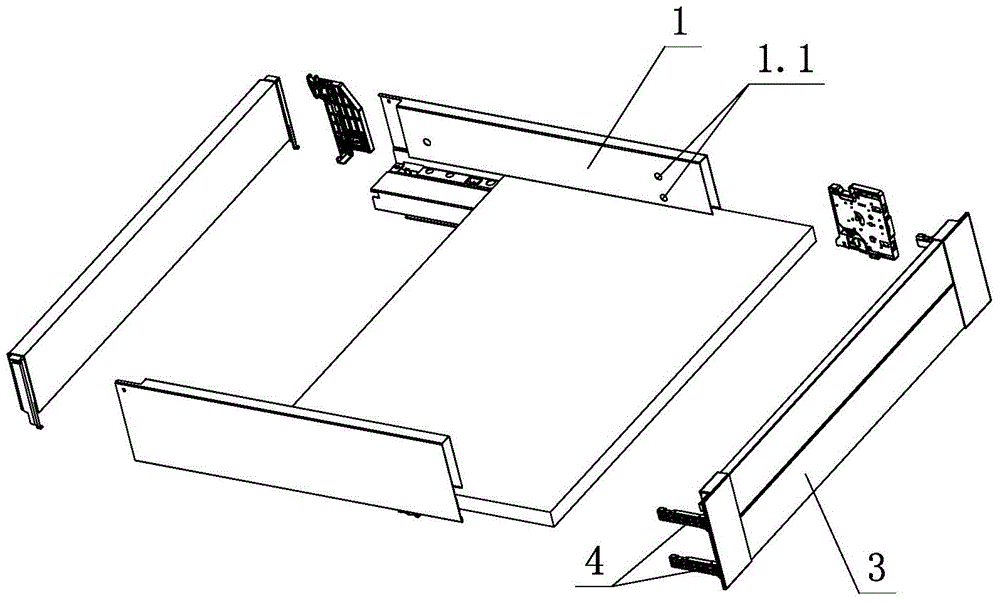

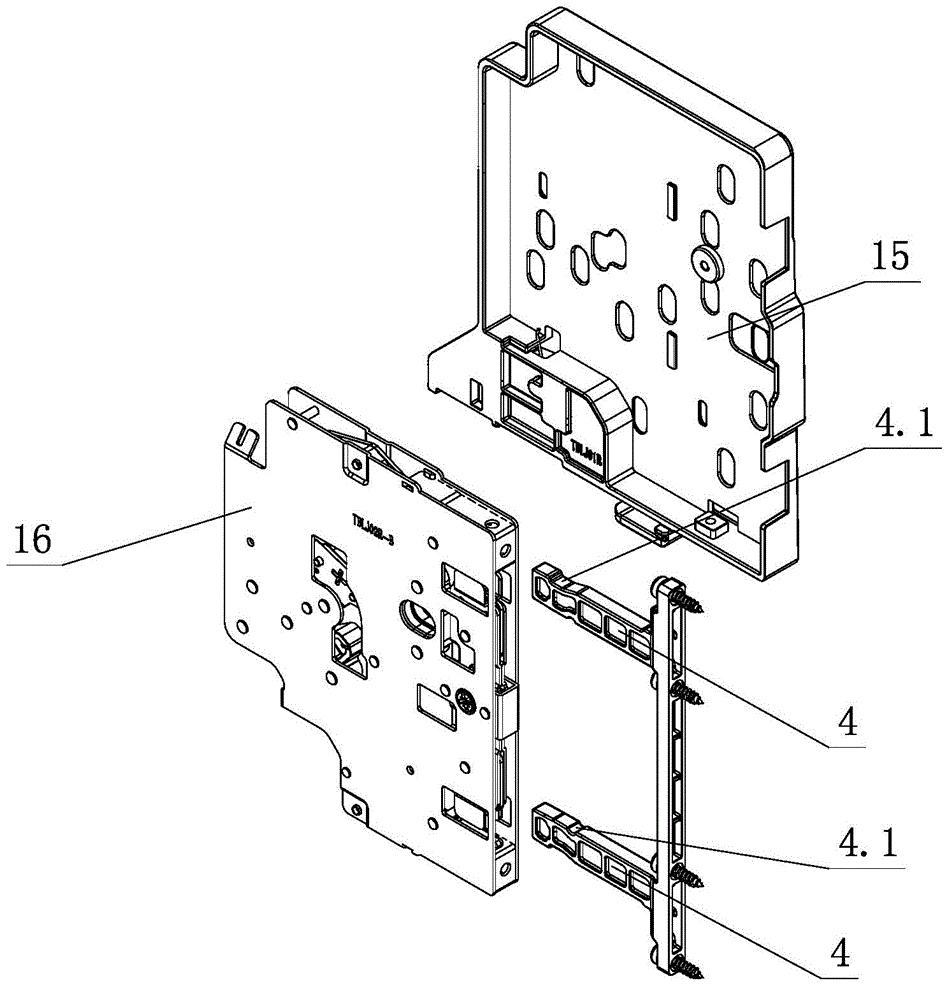

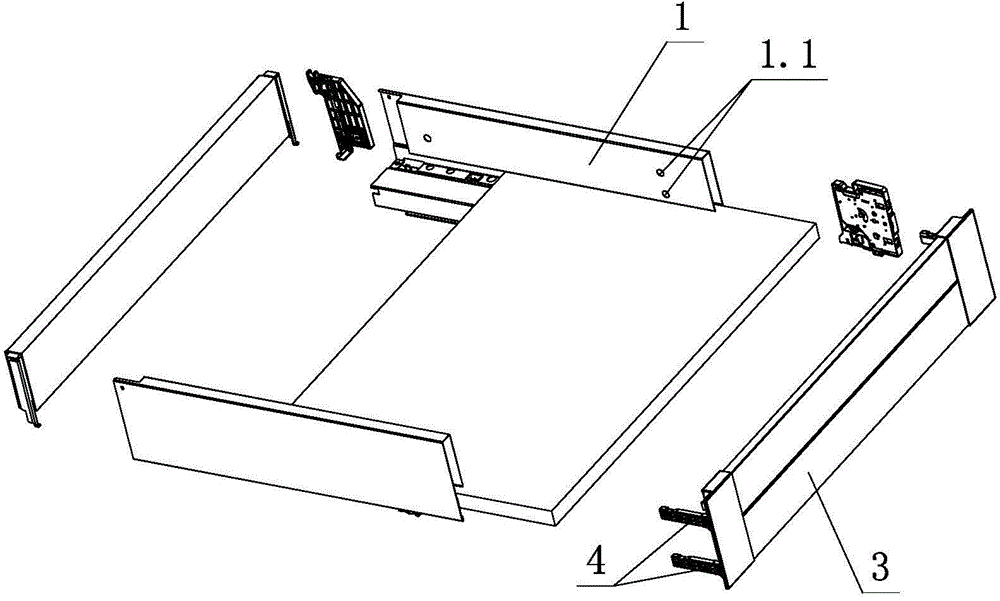

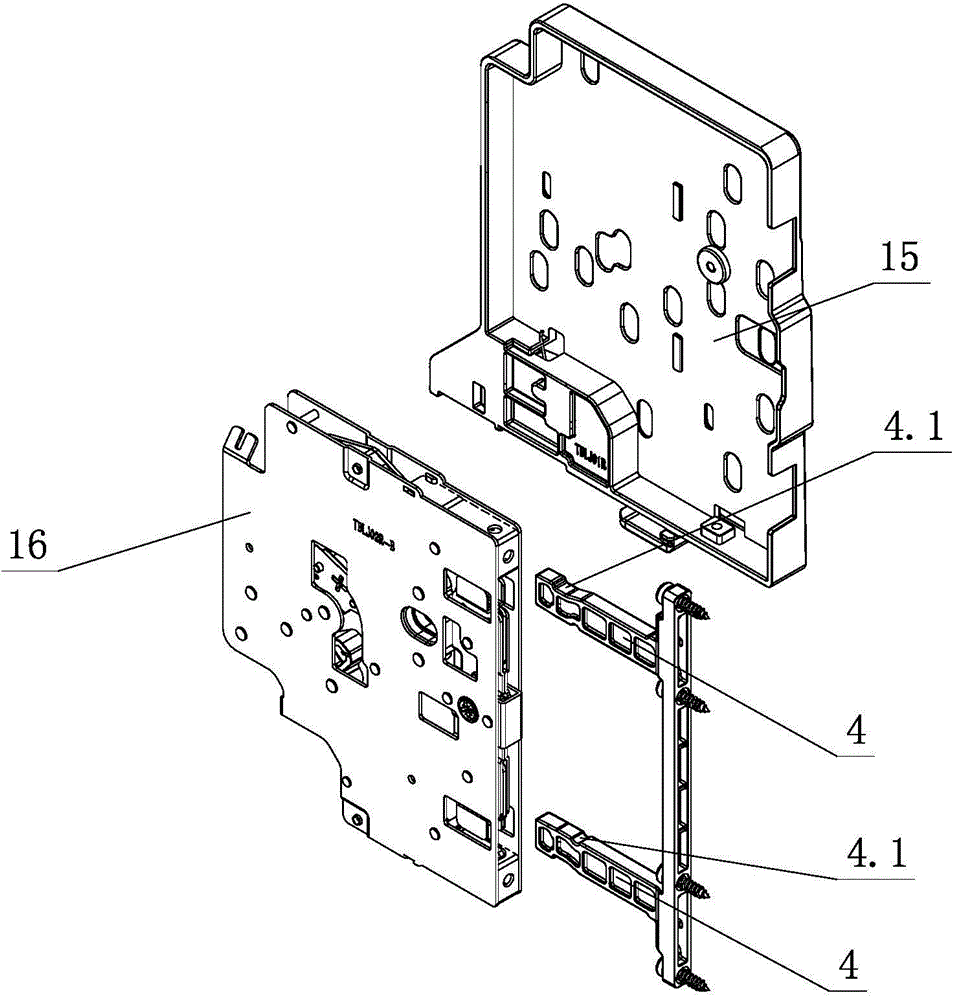

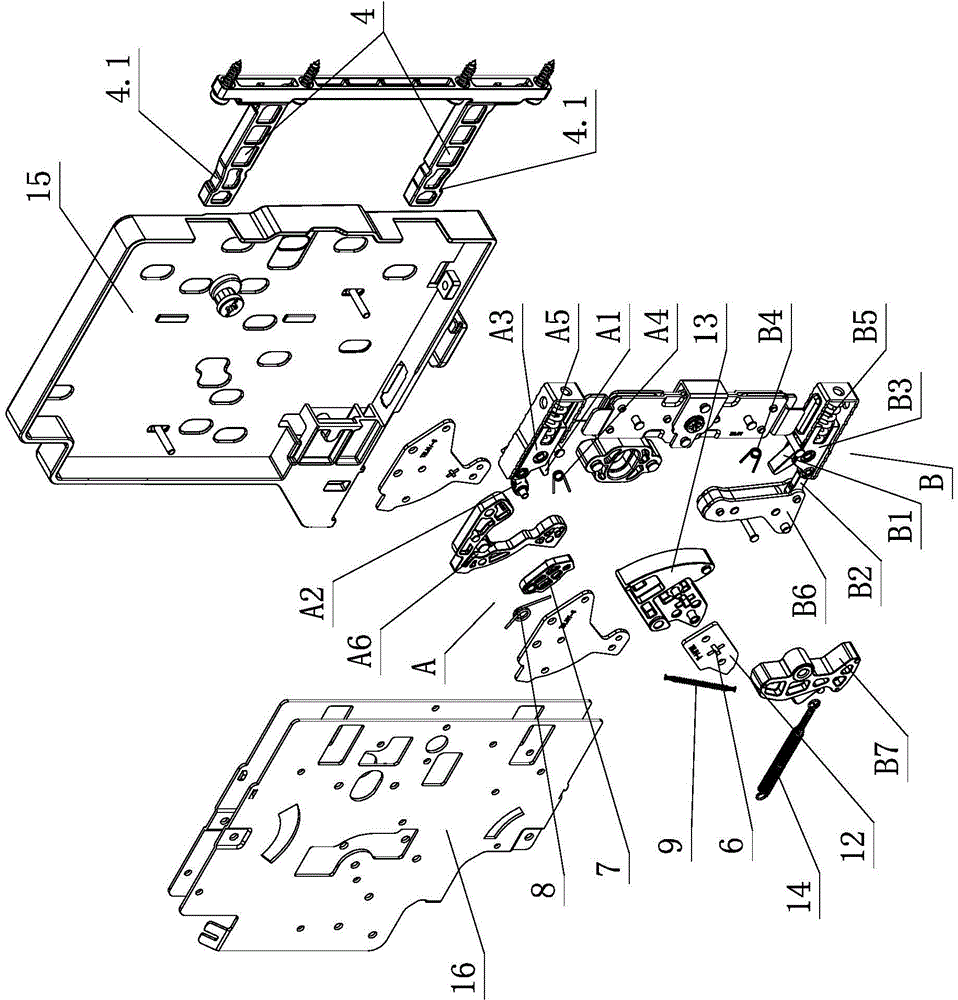

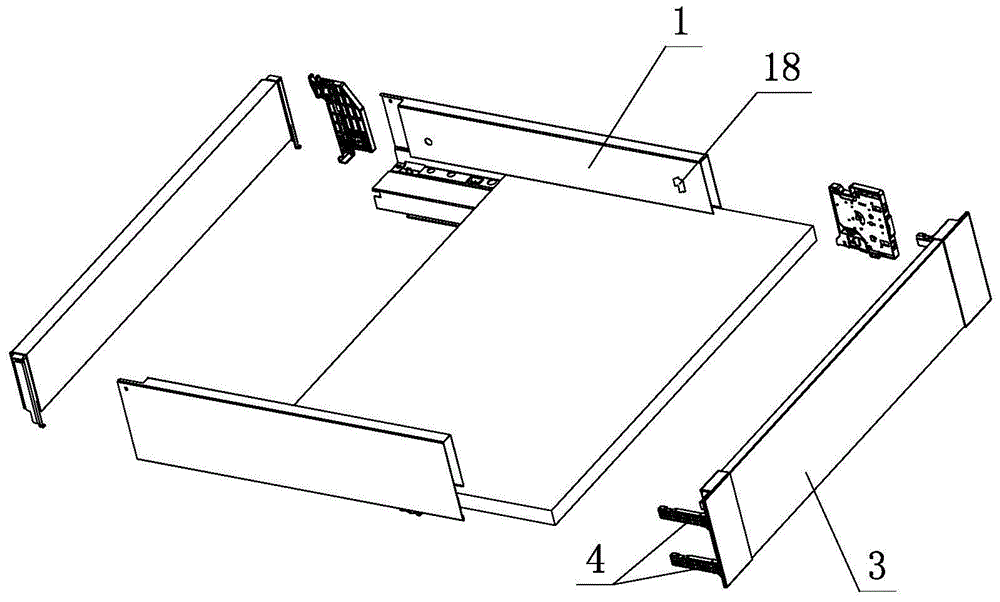

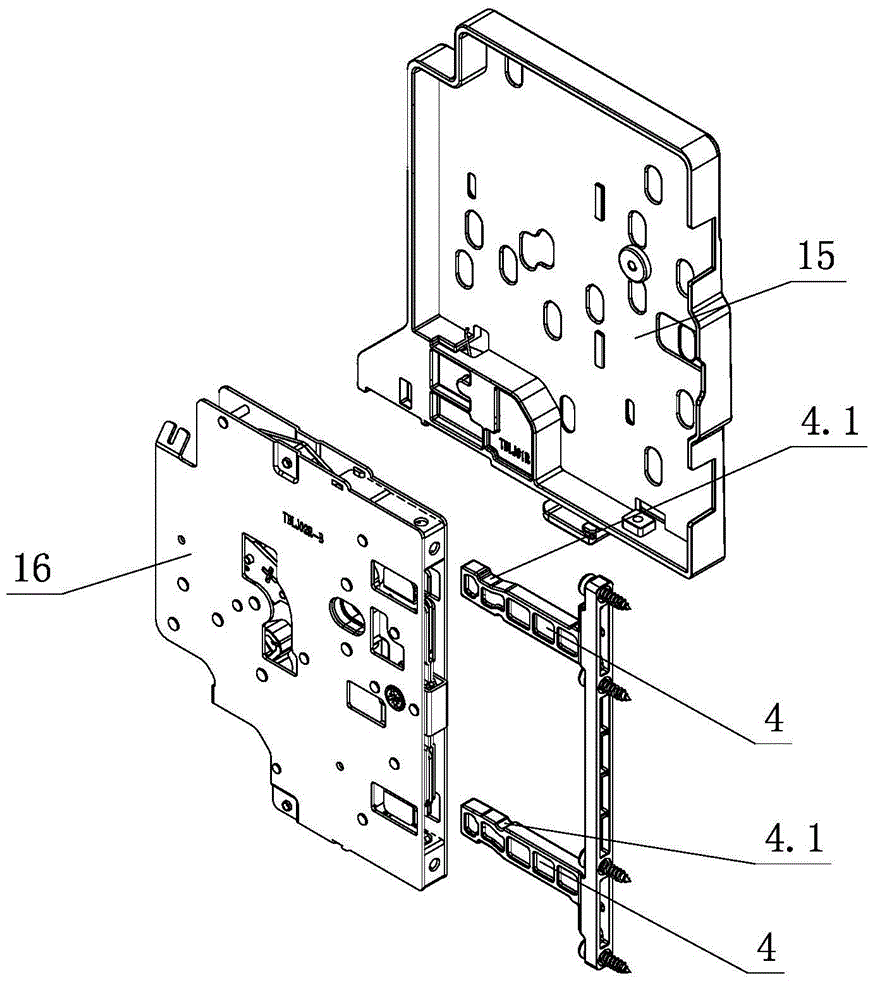

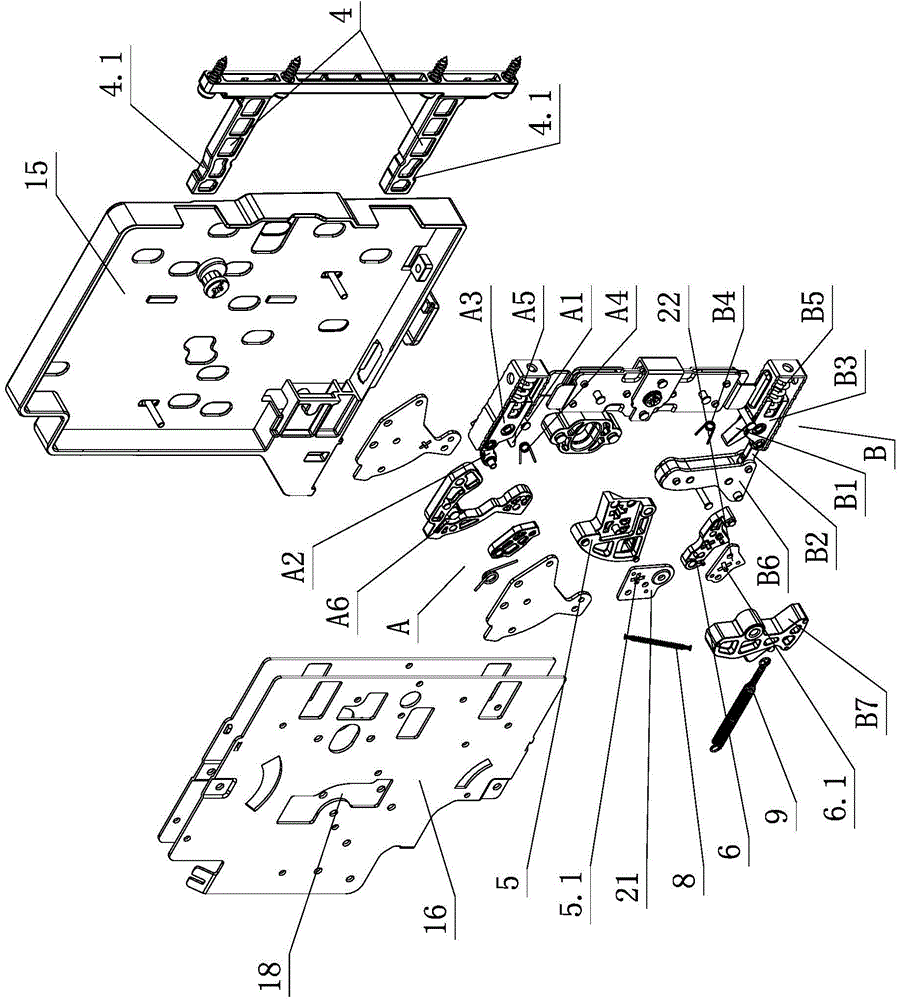

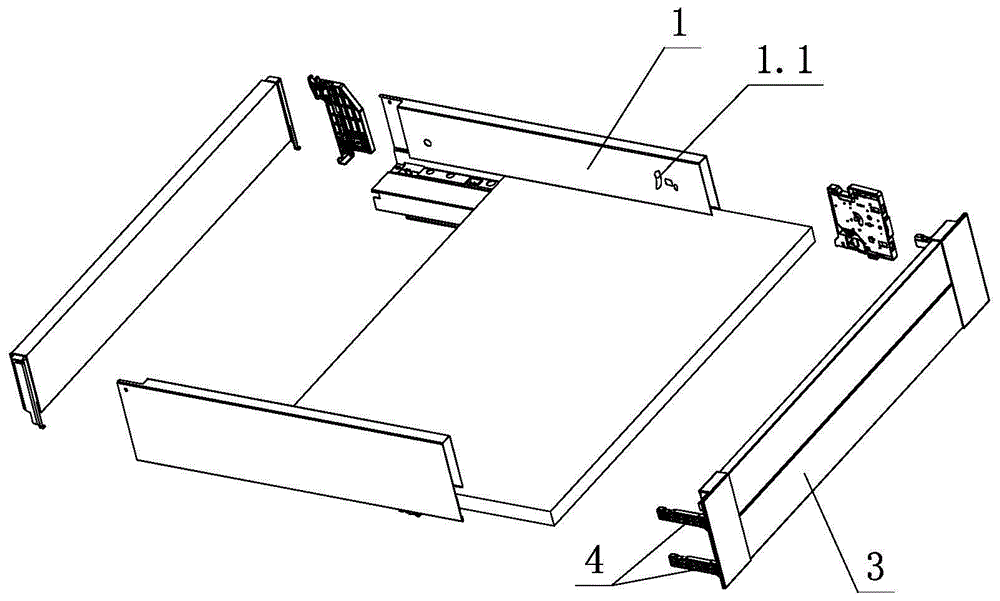

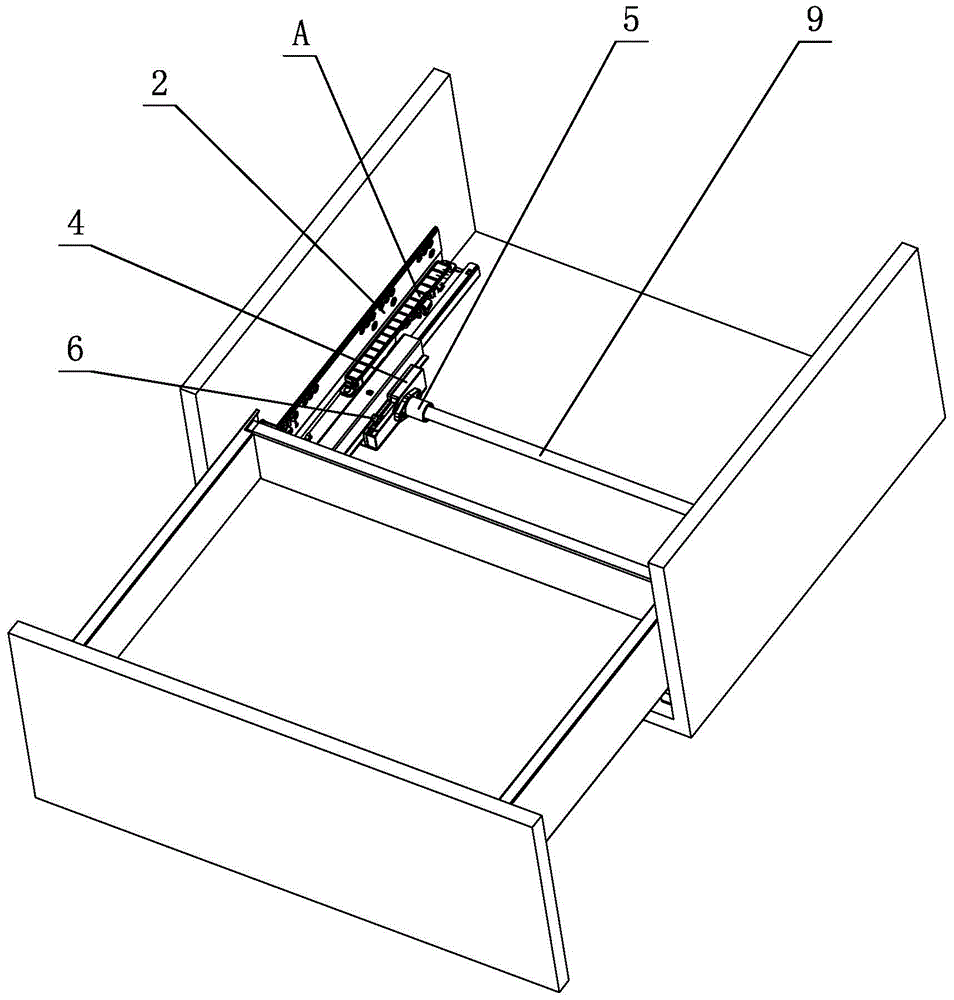

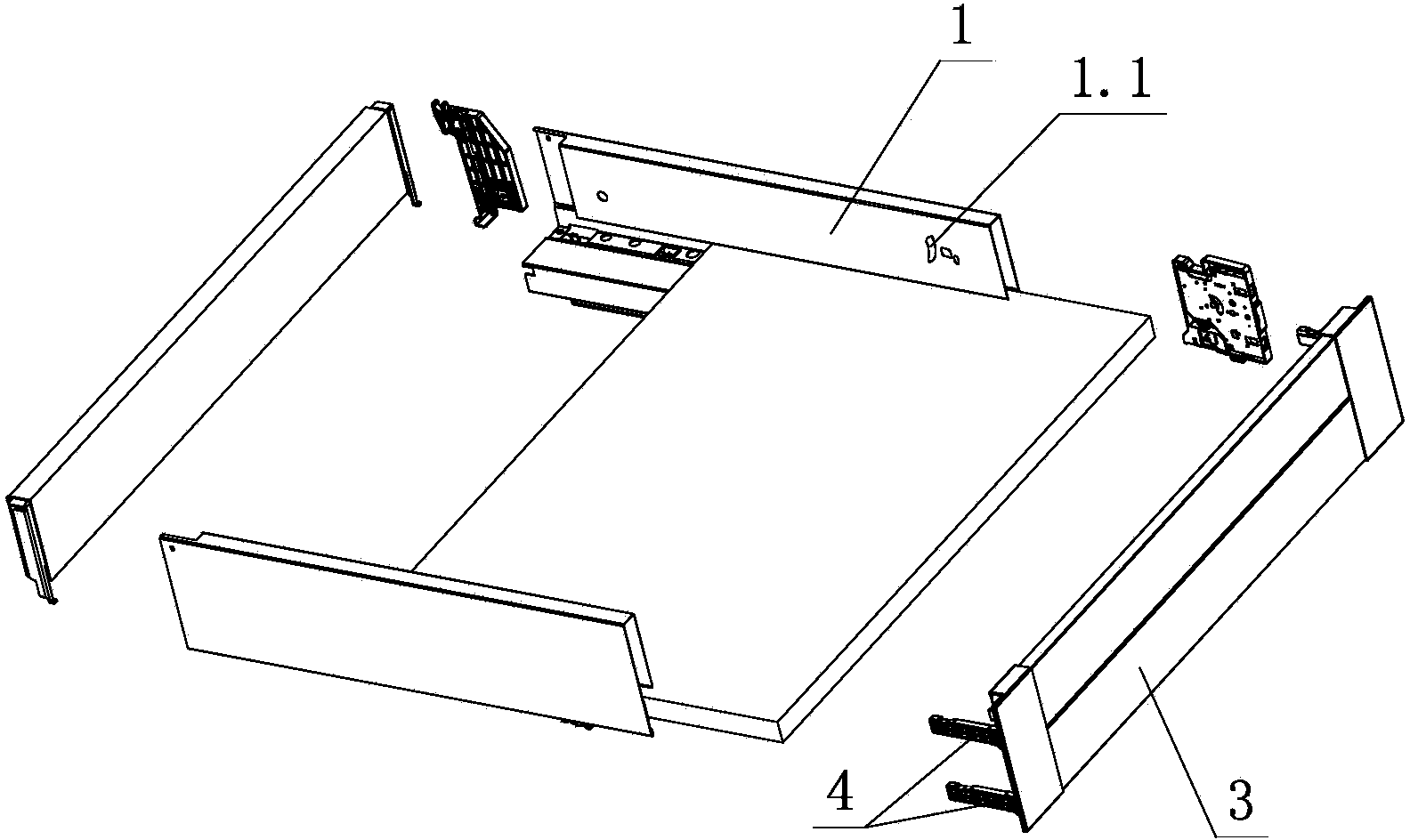

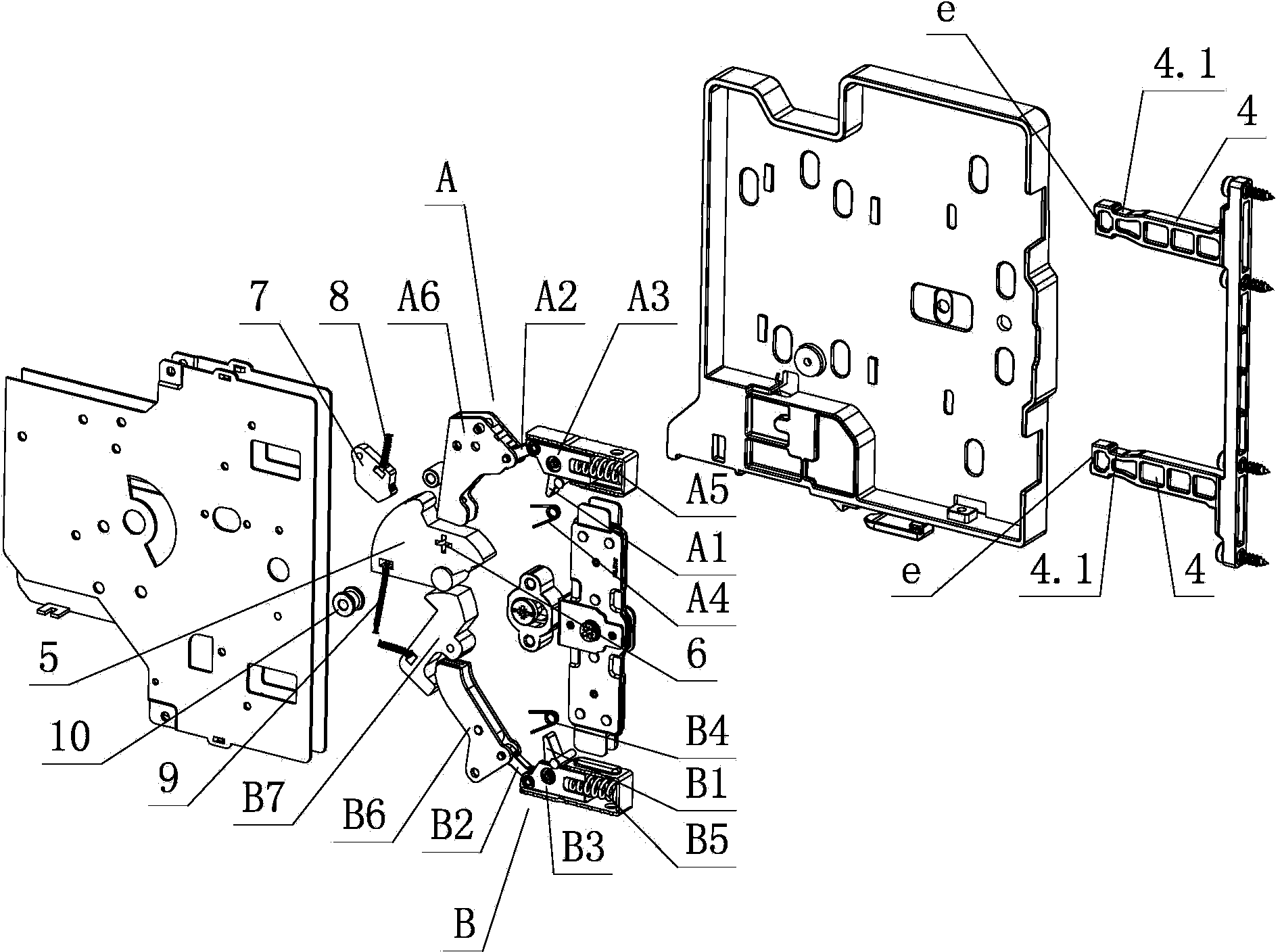

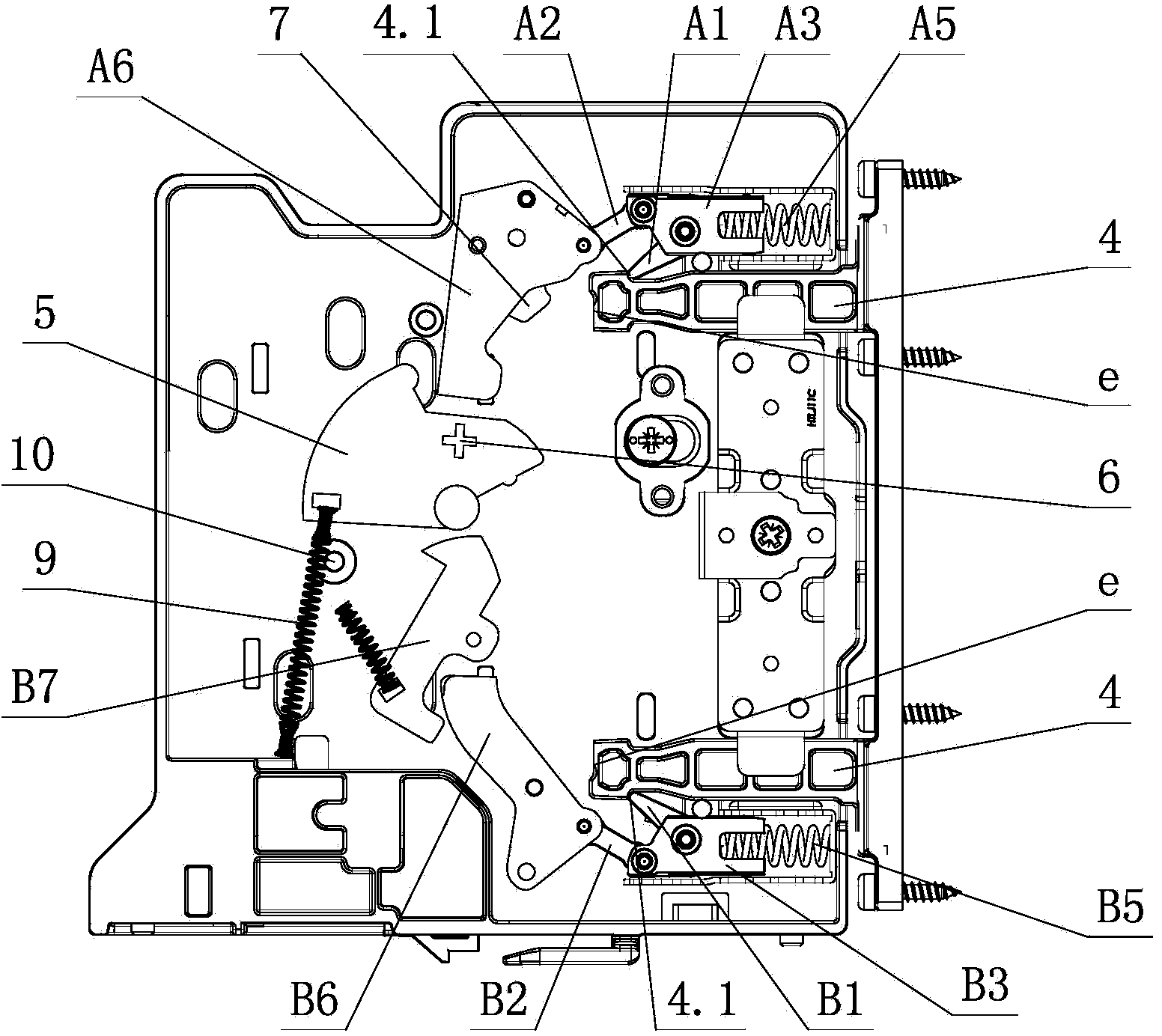

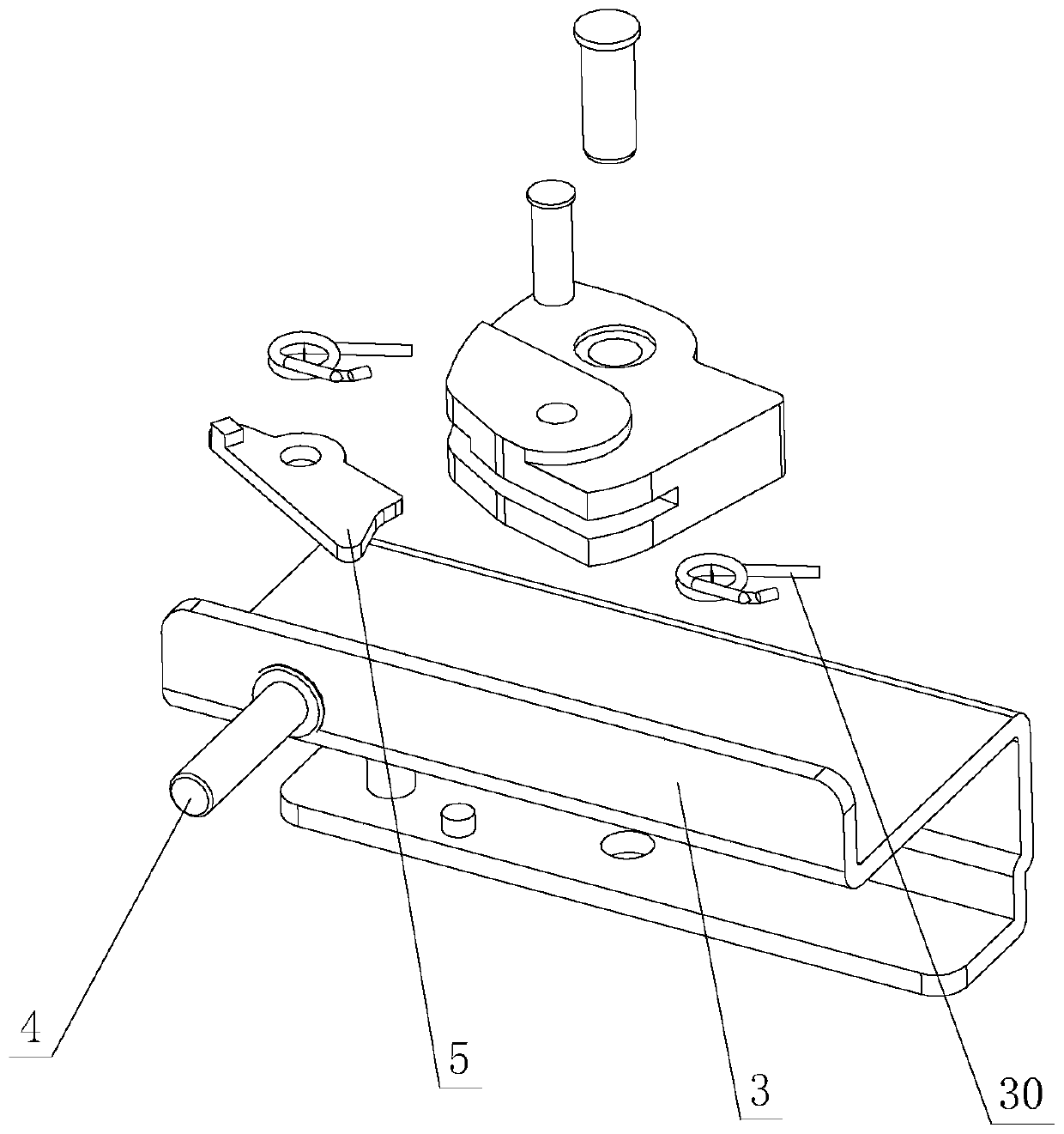

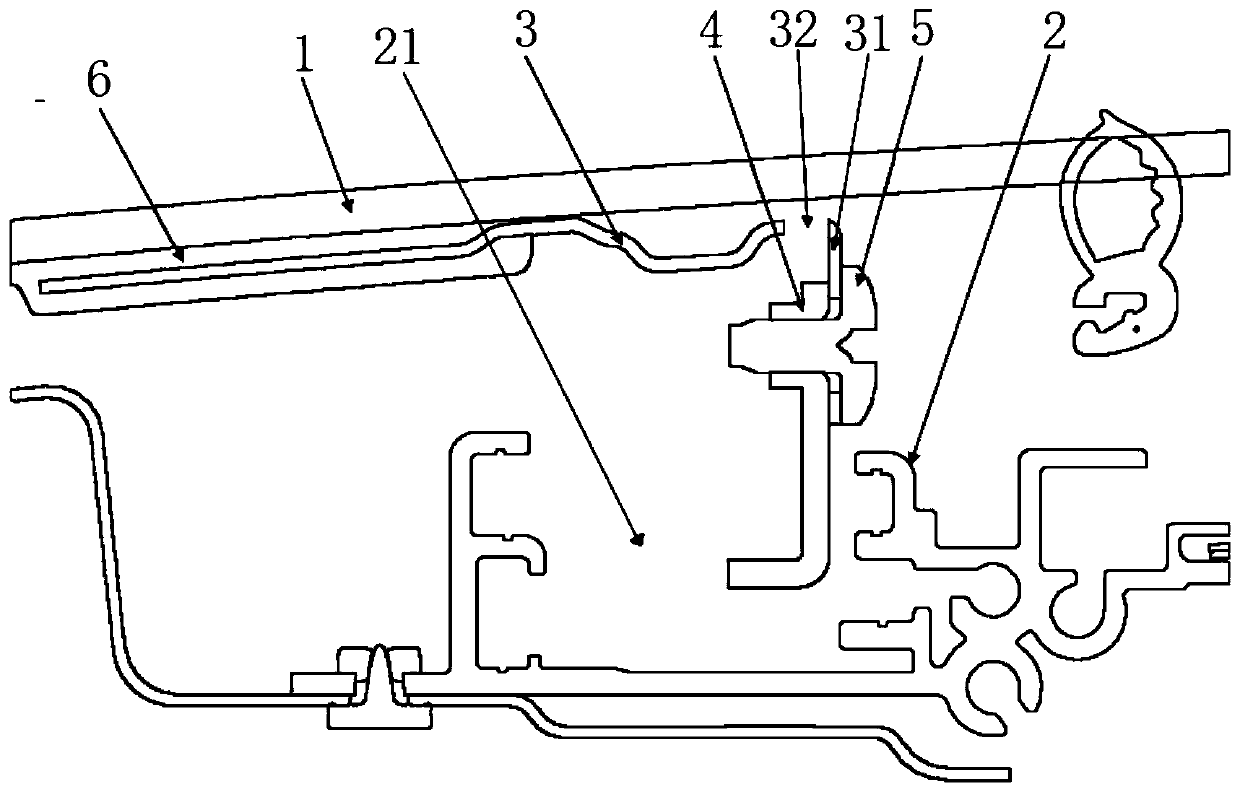

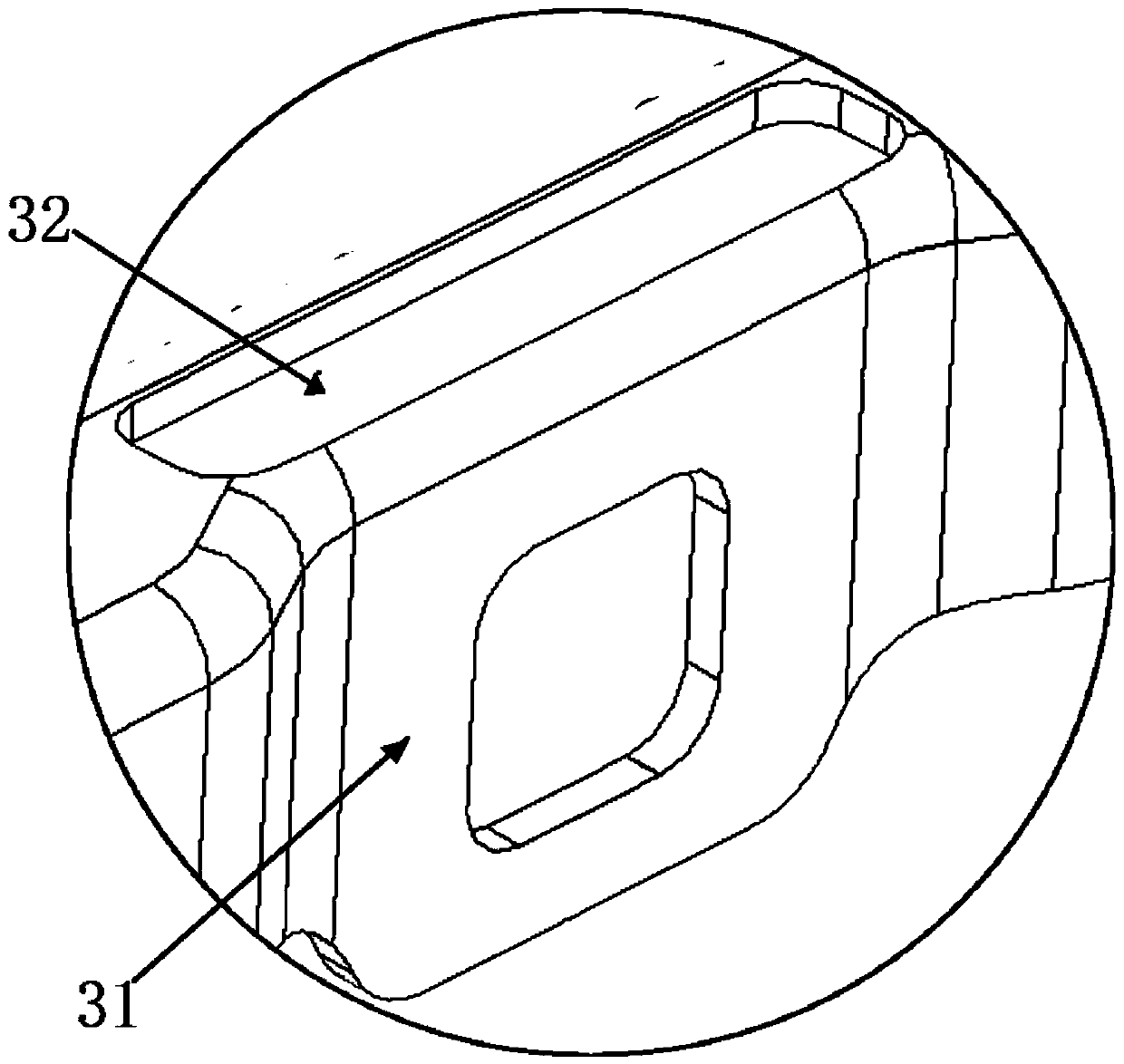

Locking and separating structure used for drawer front face plate

ActiveCN104146509AEasy to disassembleEasy to assemble and disassembleDrawersSurface plateEngineering

Owner:伍志勇

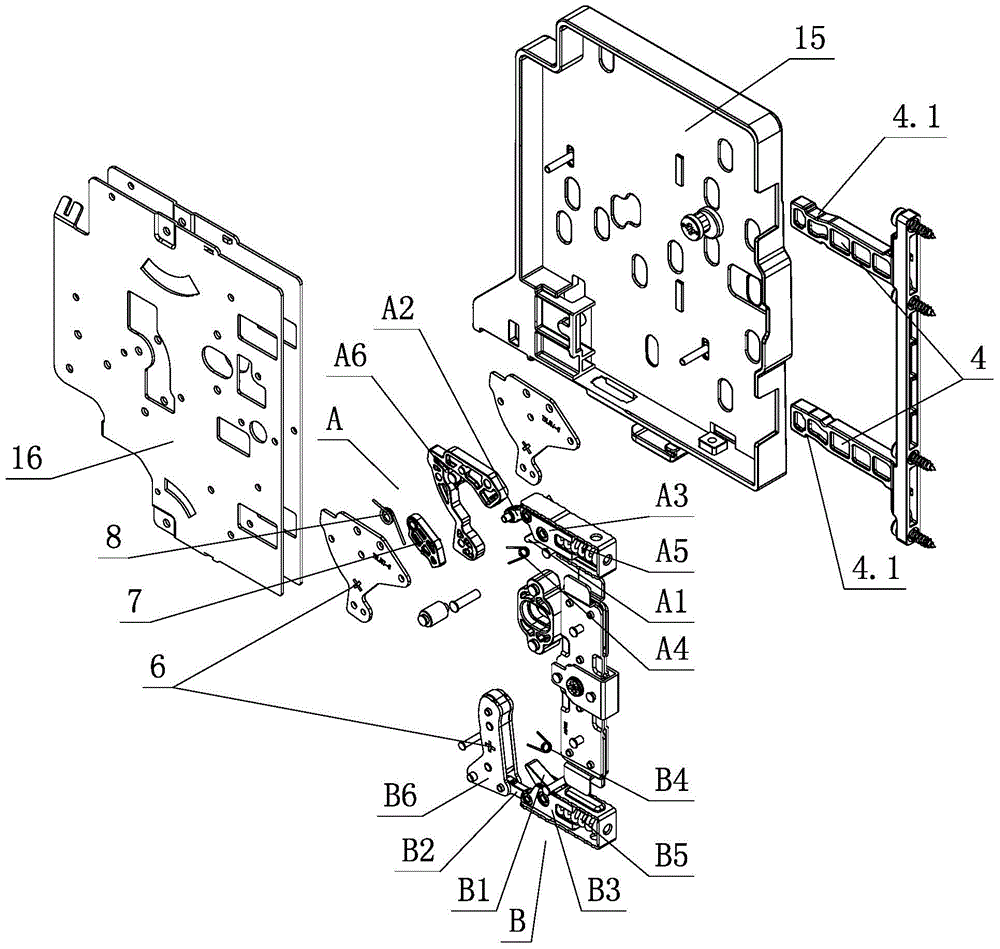

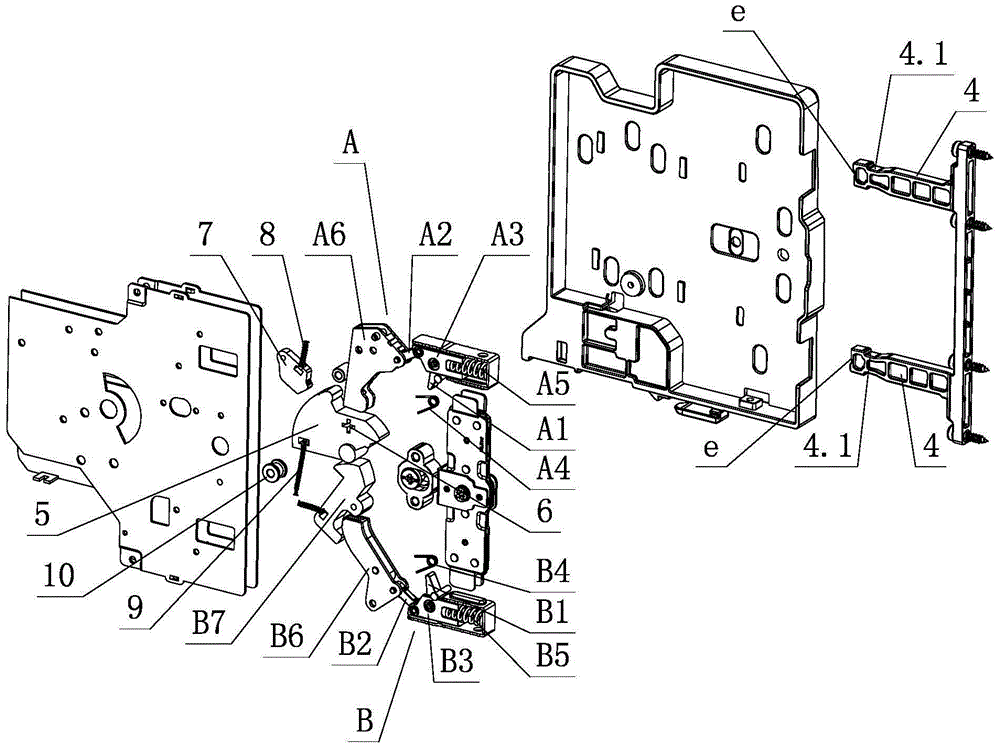

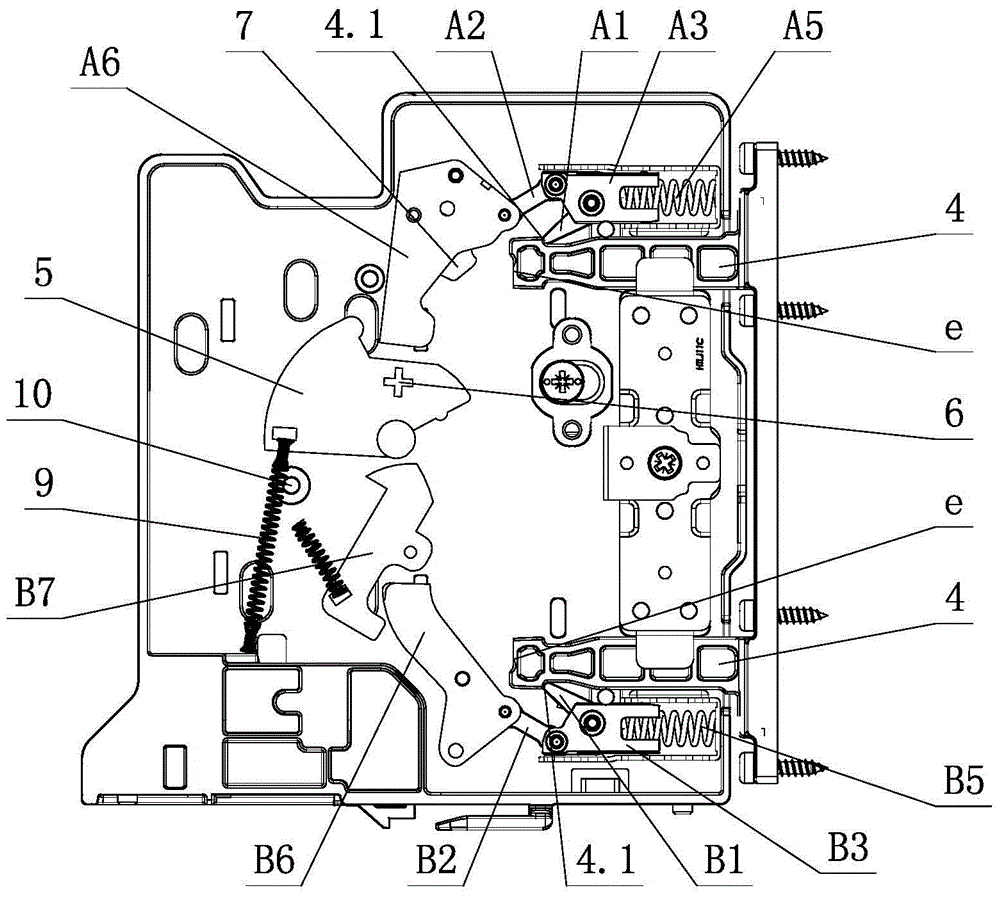

Locking and detaching structure of drawer front panel

ActiveCN104433353AGuaranteed automatic resetAchieve unlockDrawersFront panelElectrical and Electronics engineering

The invention discloses a locking and detaching structure of a drawer front panel. The locking and detaching structure comprises fixing devices arranged on lateral plates, wherein the front panel is connected with the fixing devices through more than two connecting elements; more than two locking and detaching mechanisms for locking and detaching the connecting elements are arranged on the fixing devices; finger-shaped elements and unlocking elements in transmission connection with the finger-shaped elements are arranged on the locking and detaching mechanisms; the finger-shaped elements are locked with and detached from the connecting elements through motion of the unlocking elements; the more than two locking and detaching mechanisms are arranged up and down independently, and not interfered when being locked with and detached from the connecting elements separately; the locking and detaching mechanisms are lever type transmission mechanisms; a holding element and a fourth spring are arranged on at least one of the locking and detaching mechanisms. Through improvement on the structure, the locking and detaching structure disclosed by the invention is simple and reasonable in structure, reliable in performances, firm in connection, low in manufacturing cost, quick and convenient in assembly and disassembly, high in flexibility, wide in application range, and high in practicability.

Owner:伍志勇

Locking and separating structure for front panel of drawer

ActiveCN104398028AIncrease flexibilityEasy to assemble and disassembleDrawersSurface plateElectrical and Electronics engineering

A locking and separating structure for front panel of drawer comprises a fixing device mounted on a lateral plate, the front panel is connected with the fixing device via two connecting elements, the fixing device is provided with two sets of locking-separating mechanisms which are used for locking and separating the connecting elements; the locking-separating mechanisms are provided with finger-type elements and unlocking elements which are in transmission connection with the finger-type elements, the finger-type elements are locked to and separated from the connecting elements through the motion of the unlocking elements; the two sets of locking-separating mechanisms are arranged at relatively independent upper and lower positions, and the connecting element of each set of locking-separating mechanism does not affect the other in the locking-separating cooperation; unlocking components jointly act respectively on the unlocking elements of the two sets of locking-separating mechanisms sequentially in the same movement direction with the help of a tool, so as to separate the finger-type elements from the locking portions of the connecting elements, thereby achieving the separation of the front panel and the lateral plate. By such a structure improvement, the locking and separating structure for front panel of drawer has the advantages of simple and reasonable in structure, credible in performance, firm in connection, low in manufacturing cost, fast and convenient in detaching and assembling, high in flexibility, and the like.

Owner:伍志勇

Nebuliser

ActiveUS20070029475A1Simple and inexpensive to produceImprove stabilityLiquid surface applicatorsPowdered material dispensingCapillary TubingThick wall

Owner:BOEHRINGER INGELHEIM INT GMBH

Front face plate swinging unlocking structure of furniture drawer

A front face plate swinging unlocking structure of a furniture drawer comprises side plates, a front face plate and fixing devices. The front face plates are connected with the fixing devices through two connection elements. The fixing devices are arranged on the side plates and provided with two locking and separating mechanisms used for locking and separating the connection elements. Finger-shaped elements, push elements and springs are arranged on the locking and separating mechanisms. The finger-shaped elements are locked on or disengaged from the connection elements through the cooperation of the push elements and the springs so that the front face plate can be locked on or separated from the side plates. An unlocking assembly is arranged between the two locking and separating mechanisms and comprises a first unlocking element and a second unlocking element. A first unlocking acting part and a second unlocking acting part are arranged on the first unlocking element and the second unlocking element respectively. Tools act on the first unlocking part and the second unlocking part according to the sequence, the first unlocking element and the second unlocking element act on the two push elements respectively, and therefore the two finger-shaped elements are disengaged from the two connection elements according to the sequence respectively, the front face plate and the side plates are separated, and practicality is high.

Owner:伍志勇

Centrifuge cup

ActiveUS9713813B2Reduce manufacturing tolerancesEasy to implementRotary centrifugesClamping mechanismHorizontal forceEngineering

The invention relates to a centrifuge cup, which has a container and a cover. The cover has a lever including a guide element in each case on opposing edge areas thereof. The guide elements are able to be introduced into an associated guide path of the container by pivoting the lever. The guide elements are implemented in such a way that in a closed state of the cover with the container, a clamping force (F) having vertical force component (Fy) and horizontal force component (Fx) is provided at a contact point or a contact line of the guide elements with the particular associated guide path.

Owner:THERMO ELECTRONICS LED GMBH

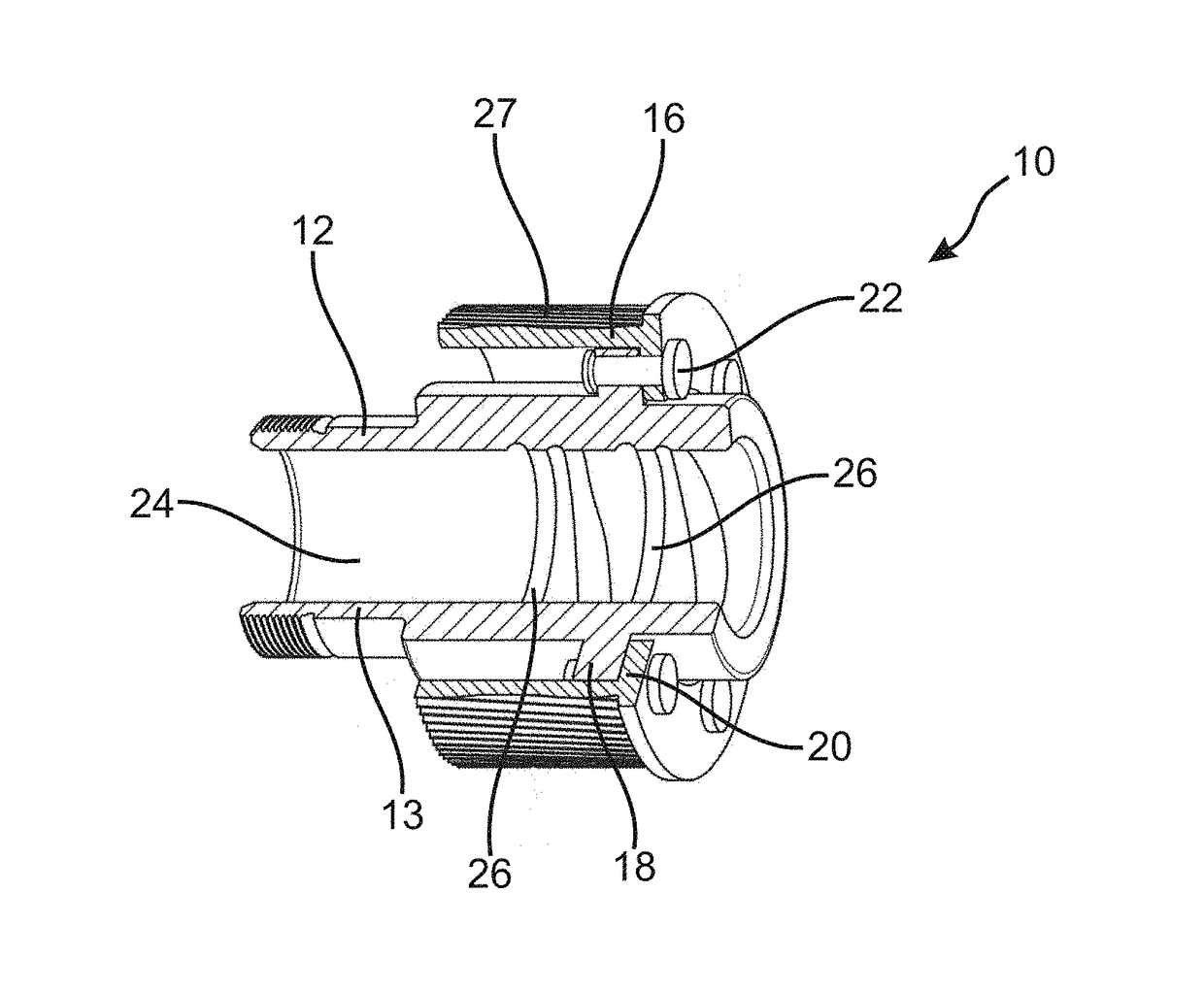

Recirculating ball nut, assembly for a ballscrew drive and method for producing a recirculating ball nut

ActiveUS10119600B2Reduce manufacturing tolerancesSimpler and faster to manufactureToothed gearingsPortable liftingBall screw driveRecirculating ball

Owner:TRW AUTOMOTIVE GMBH

Optical lens, camera module and assembly methods thereof

PendingCN110275263AAvoid position shiftMinus manufacturing toleranceMountingsCamera lensImaging quality

The invention provides an optical lens. The optical lens includes a first lens component including at least one first lens and shielding parts on the top and side surfaces of non-optical regions of the at least one first lens, a second lens component including a second lens barrel and at least one second lens in the second lens barrel, wherein the at least one second lens and the at least one first lens together form an imageable optical system, and a glue material which bonds the first lens component and the second lens component together, wherein the glue material is between the first lenses and the second lens component. The invention also provides a corresponding assembly method of the optical lens, a camera module and an assembly method of the camera module. The optical lens, the camera module and the assembly methods thereof can improve the stability of the optical system and improve the imaging quality of the optical lens and the camera module.

Owner:NINGBO SUNNY OPOTECH CO LTD

Lock-off system for furniture drawer fronts

ActiveCN104367012BEasy to assemble and disassembleQuick disassemblyDrawersEngineeringElectrical and Electronics engineering

A locking and separating system for a furniture drawer front panel comprises a fixing device arranged on a side plate. The front panel is connected with the fixing device through two connecting elements. Two sets of locking and separating mechanisms for locking and separating the connecting elements are arranged on the fixing device. Each locking and separating mechanism is provided with a finger-shaped element and an unlocking element which is in transmission connection with the finger-shaped element, wherein the finger-shaped element and the corresponding connecting element are locked and separated through movement of the unlocking element. The two sets of locking and separating mechanisms are independently and vertically arranged and do not interfere with each other when the locking and separating mechanisms and the corresponding connecting elements are locked and separated in a matched mode. Unlocking components are arranged on the locking and separating mechanisms, and the unlocking components jointly act on the unlocking elements of the two sets of locking and separating mechanisms successively, so that the finger-shaped elements are disengaged from the connecting elements, and the front panel is separated from the side plate. According to the structural improvement, the locking and separating system has the advantages of being simple and reasonable in structure, reliable in performance, firm in connection, low in manufacturing cost, rapid and convenient to disassemble and assemble, high in flexibility and practicability, and the like.

Owner:伍志勇

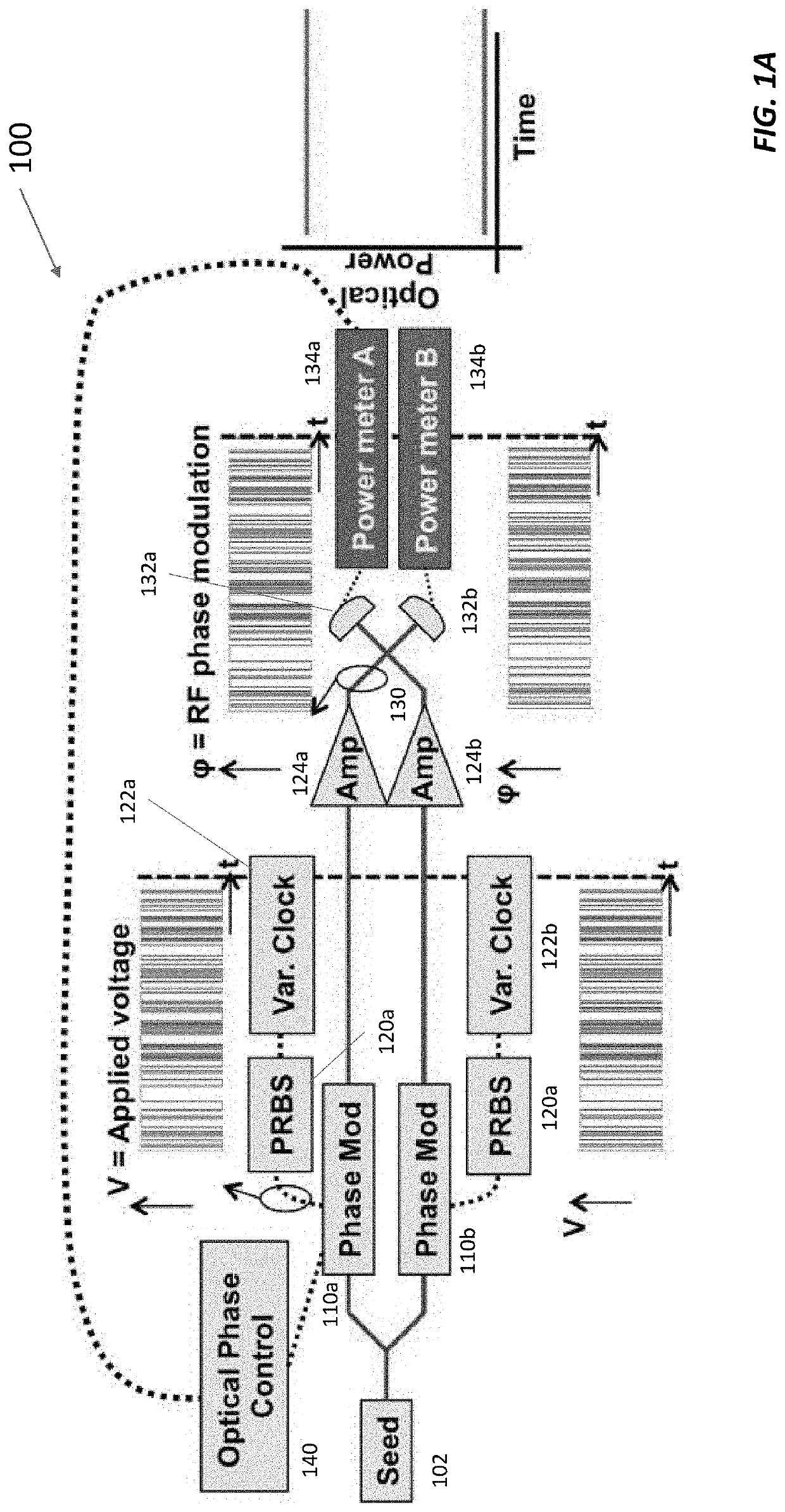

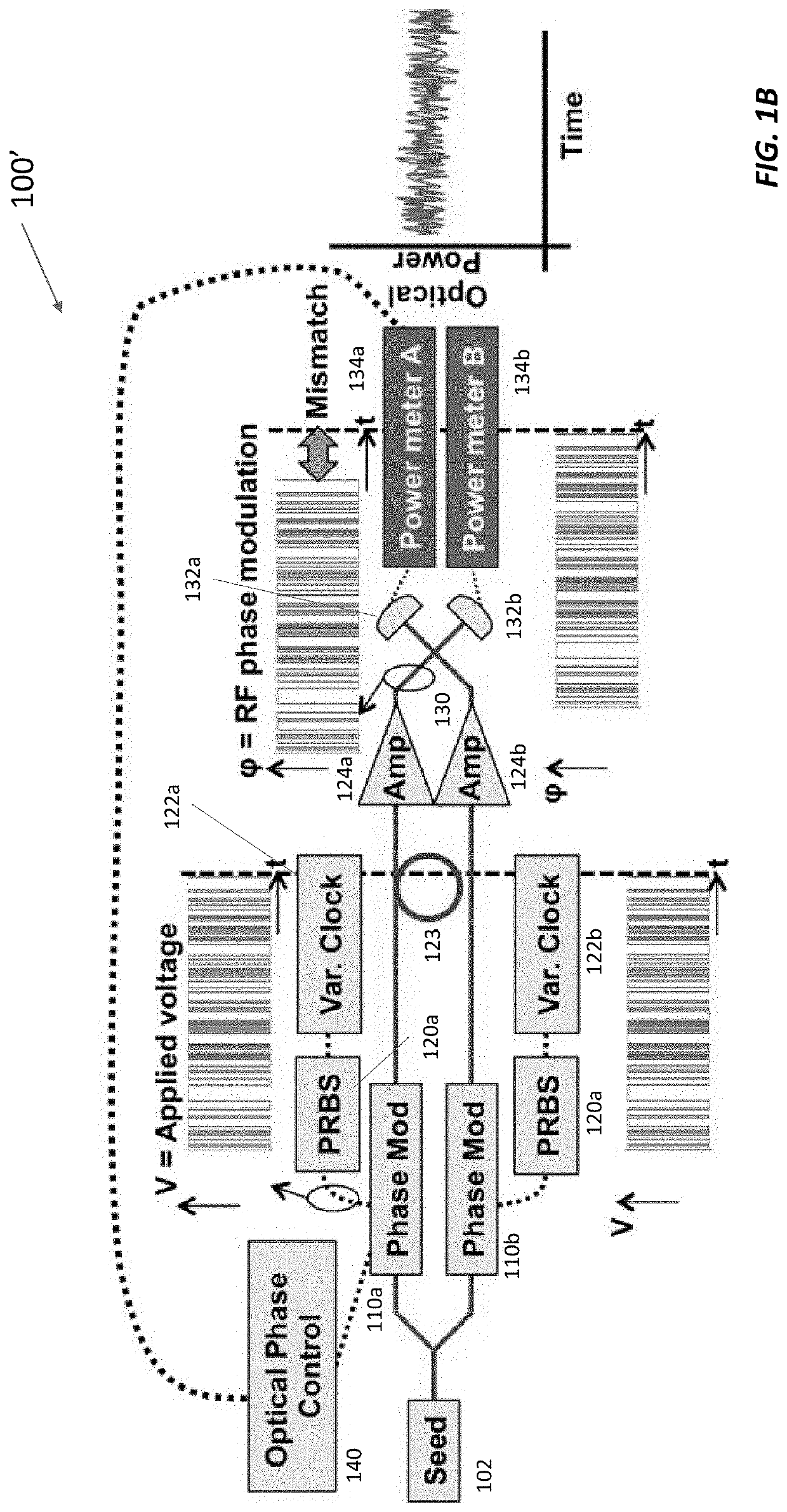

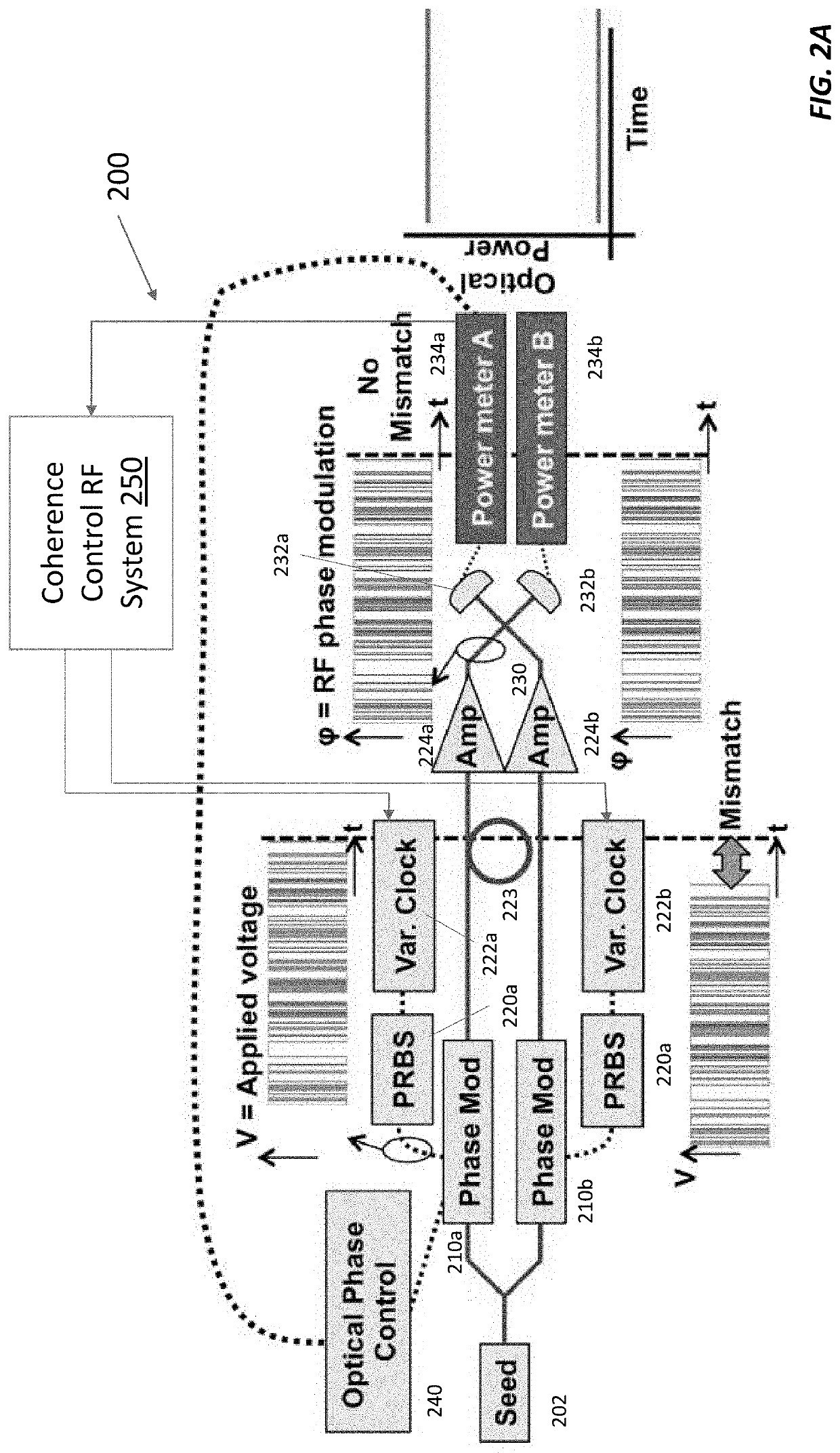

SBS Suppression and Electronic Path Length Matching in Coherent Beam Combining

PendingUS20210351559A1Precise and very time-consumeReduces combine efficiencyLaser arrangementsFiberPhase shifted

In coherent beam combining, the beams can be phase-modulated with a pseudo-random bit sequence (PRBS) to prevent stimulated Brillouin scattering (SBS) downstream. To coherently combine the phase-modulated beams, however, the PRBS waveforms should be true-time-delayed to within a small fraction of the bit duration. Traditionally, this true time delay is achieved by cutting optical fibers to length or with optical trombones. But trimming fibers is hard to do precisely, and optical trombones have large insertion loss. In addition, the path length mismatch varies as the fibers heat up and / or vibrate. Here, the beams are generated from a kilohertz linewidth seed split among N>1 (e.g., N=100) arms. Each arm is phase-modulated with a separate copy of the unique PRBS pattern. The relative phase of the PRBS patterns is stabilized by phase-locking the master oscillators used to read out the PRBS patterns. The PRBS patterns can be phase shifted with respect to one another to compensate for physical path length mismatches of the optical fibers. Scanning the relative phase of the PRBS pattern used to modulate different arms yields a cross-correlation peak in combined power when the phases are matched at the combination plane.

Owner:MASSACHUSETTS INST OF TECH

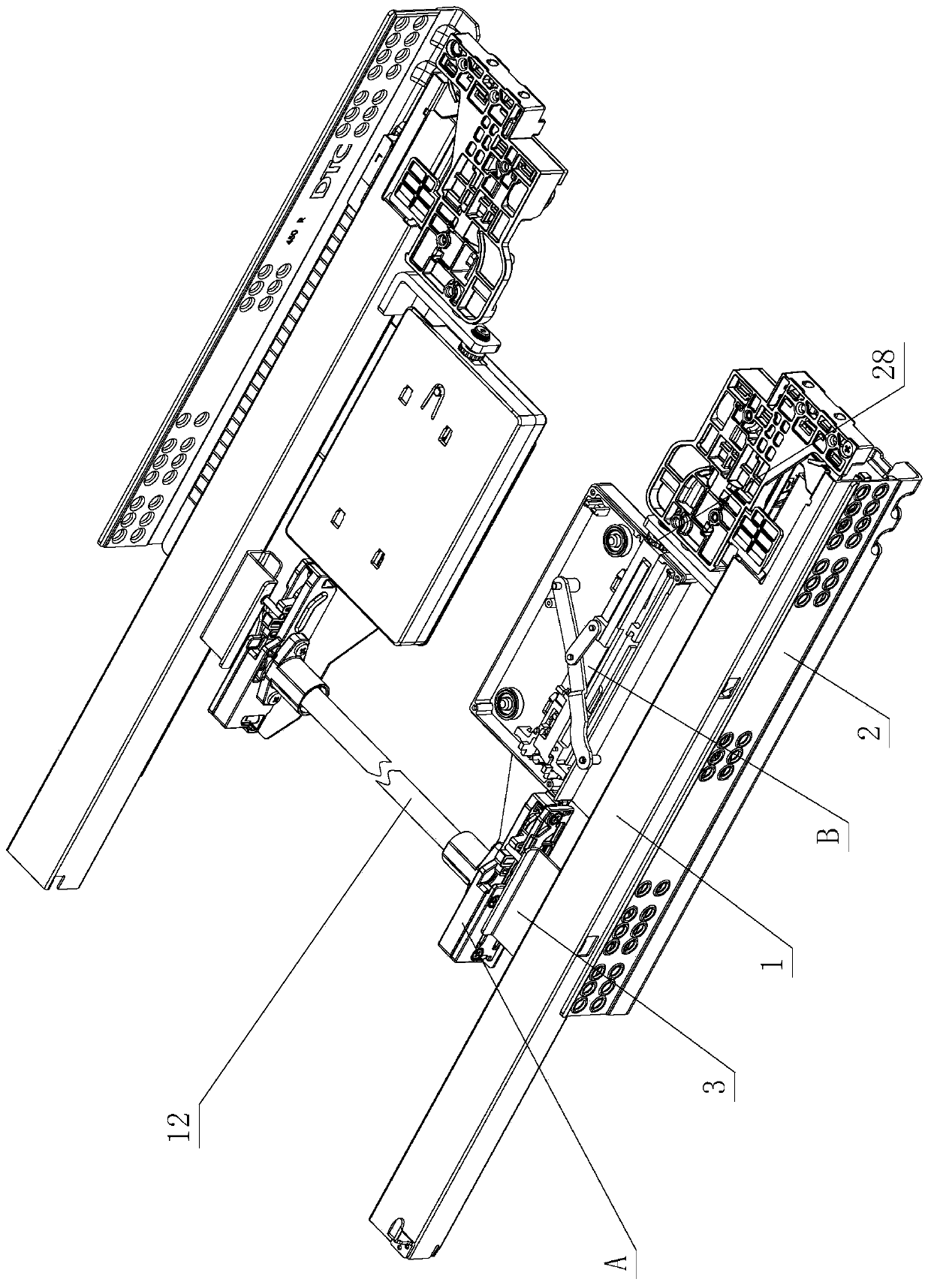

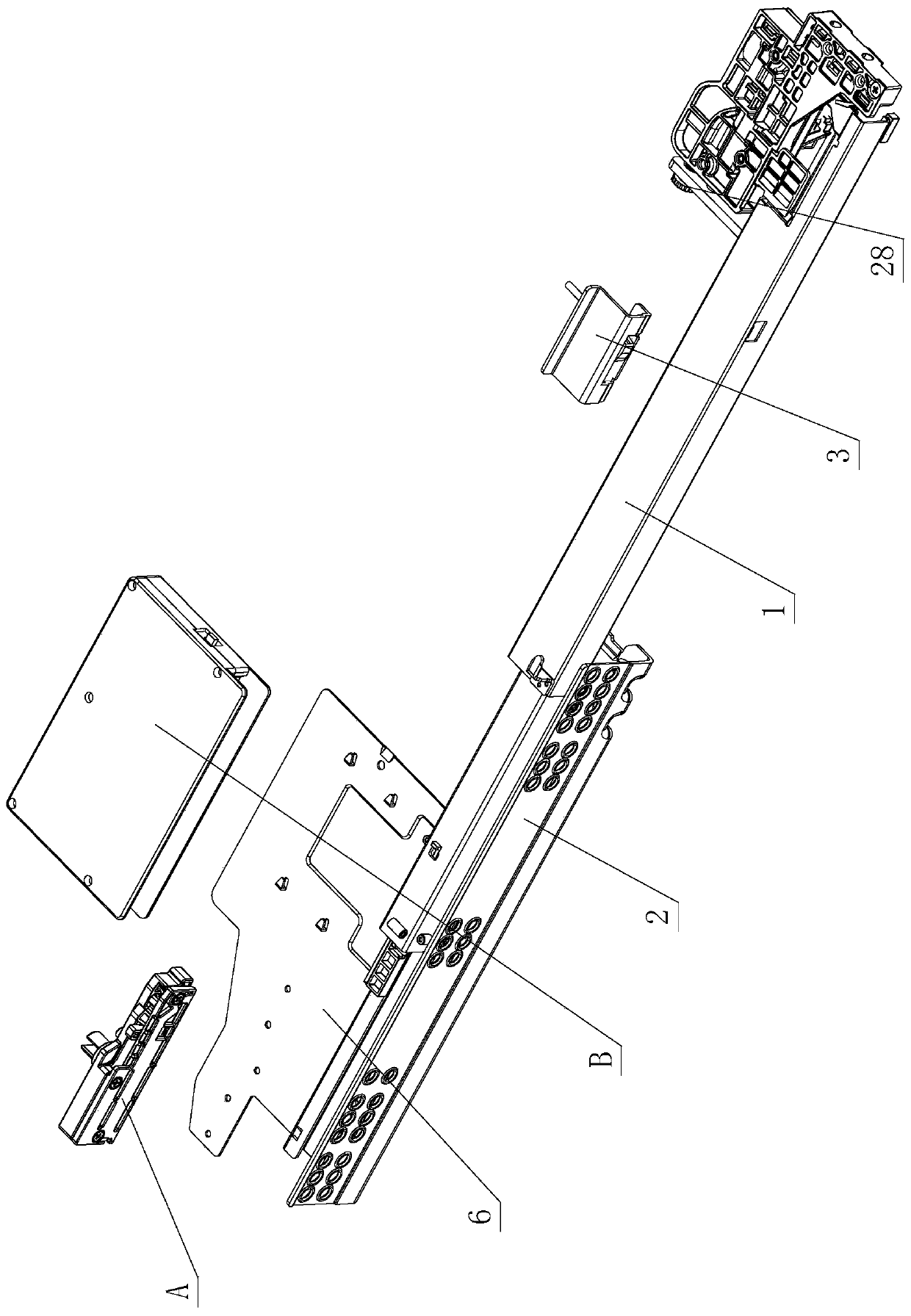

Synchronous adjusting mechanism for furniture

PendingCN110439432AImprove structural rationalityImprove the stability of useHingesWing arrangementsMechanical engineeringEngineering

The invention relates to a synchronous adjusting mechanism for furniture. The synchronous adjusting mechanism includes a furniture door body, a sliding device, and a guide sliding rail, wherein the sliding device is slidably arranged on the guide sliding rail and is rotatably or asway connected with the furniture door body; the furniture door body is rotatably or asway provided with at least two hinge devices; the furniture door body is movably opened and closed on the guide sliding rail through matching of the sliding device and the hinge devices; a synchronous rod is arranged between the atleast two hinge devices, and the hinge devices rotate or swing synchronously on the furniture door body through the synchronous rod; and an adjusting part is arranged on the synchronous rod and / or between the synchronous rod and the hinge devices, and the synchronous rod moves on the hinge devices through adjustment of the adjusting part to adjust the relative position between the synchronous rodand the at least two hinged devices. Through the improved synchronous adjusting mechanism, the synchronous adjusting mechanism has the characteristics of being simple and reasonable in structure, reliable in performance, long in service life, quick and convenient in disassembly and assembly process, smooth and steady, unhindered and labor-saving in opening and closing process, low in manufacturingcost, easy to produce, easy to realize, safe and reliable and the like, and the practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

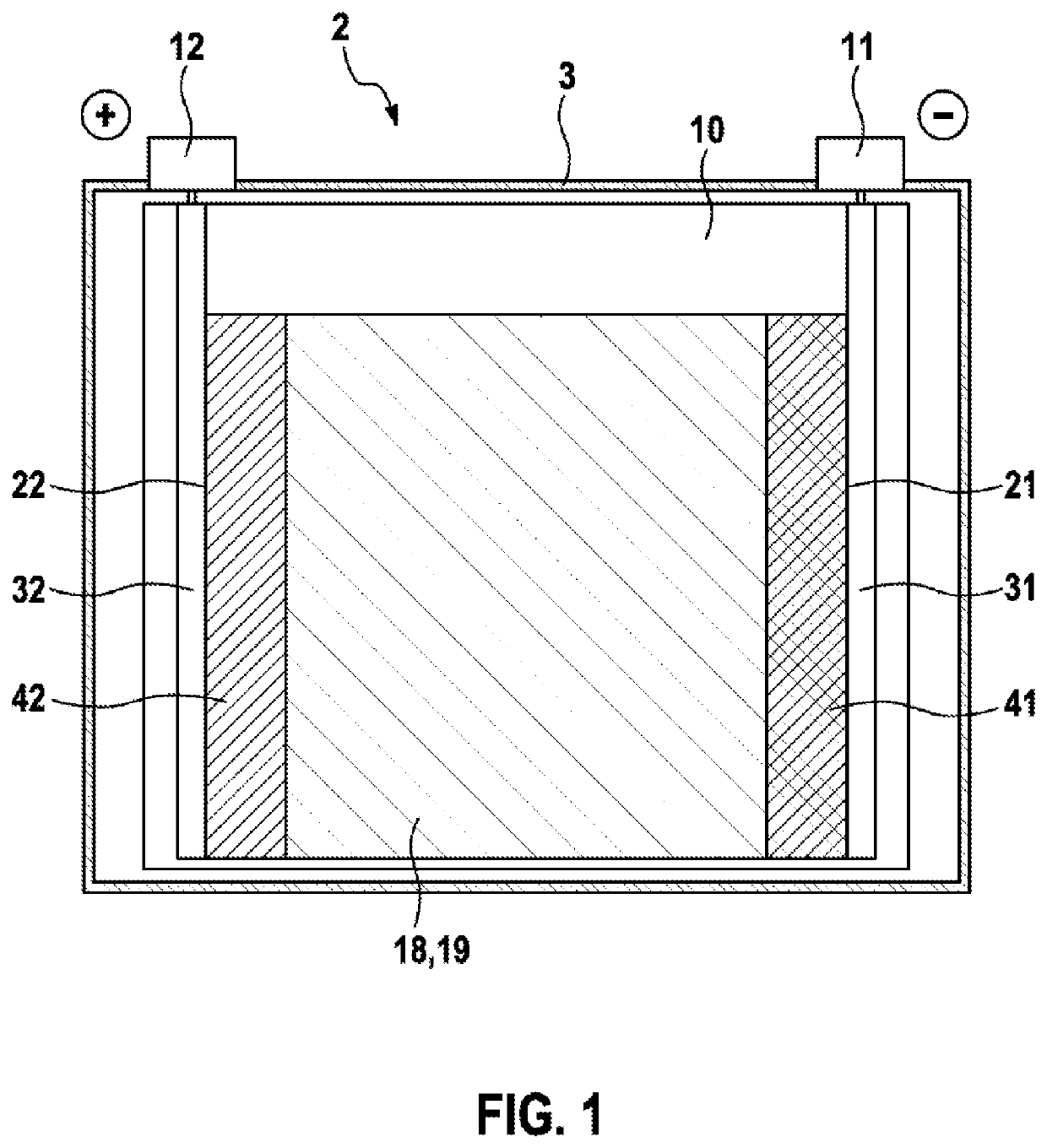

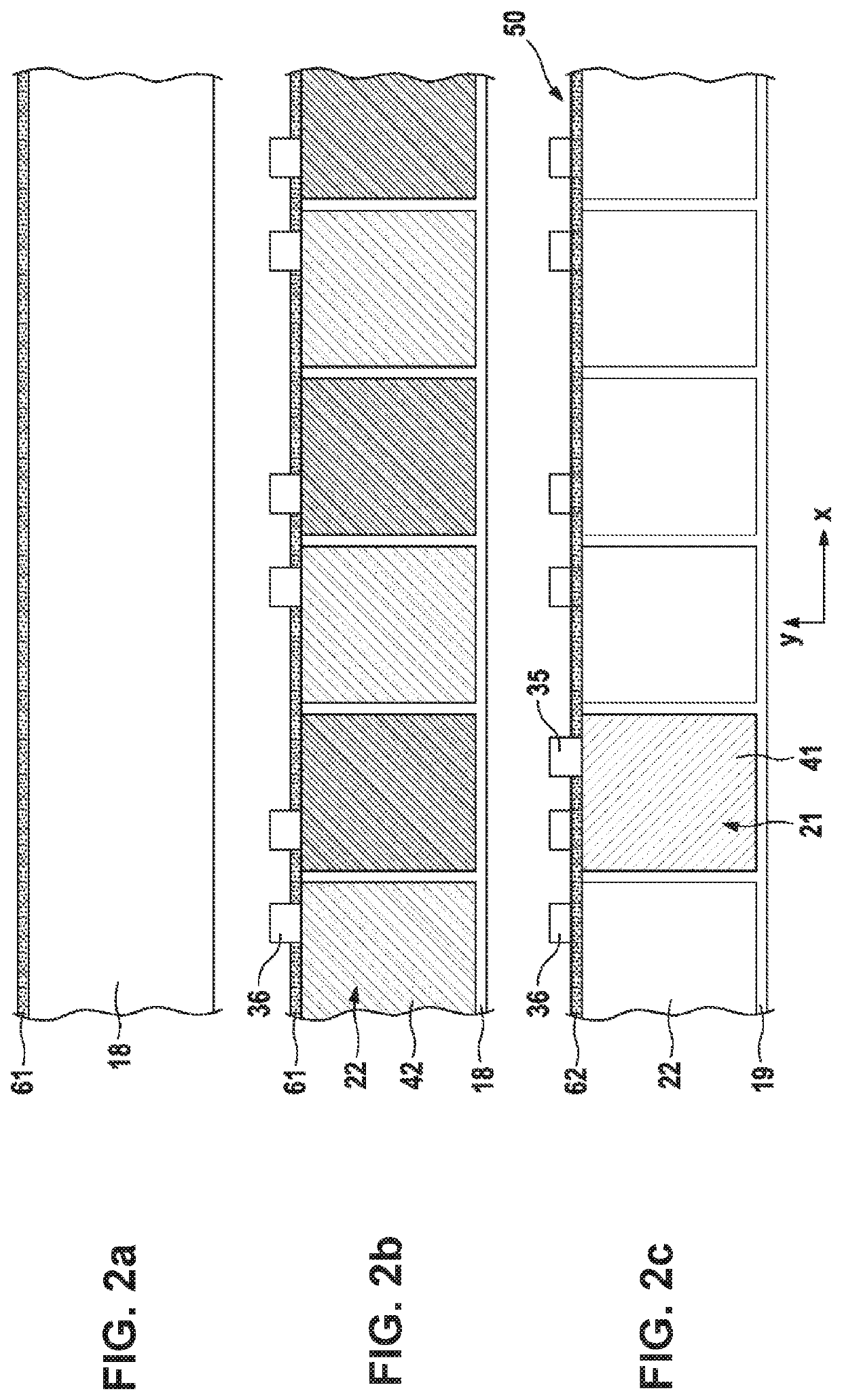

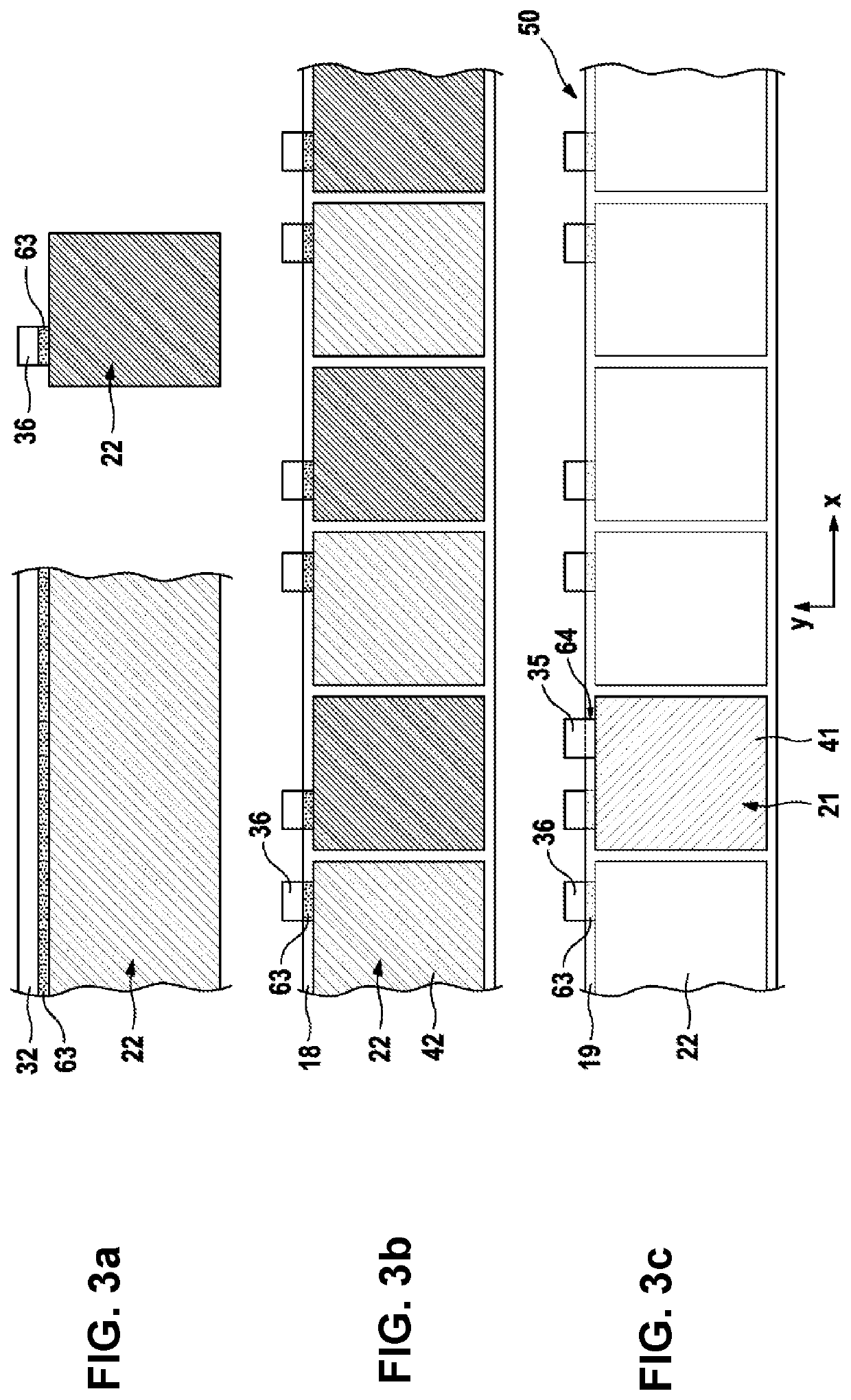

Method for producing an electrode unit for a battery cell and electrode unit

InactiveUS20200028200A1Precise positioningFast processingFinal product manufactureSecondary cells manufactureEngineeringBattery cell

The invention relates to a method for producing an electrode unit for a battery cell comprising the following steps: substance-to-substance bonding of contact lugs (35, 36) of a plurality of plate-shaped segments of a first electrode (21, 22) to a strip-shaped first separator layer (18), substance-to-substance bonding of a strip-shaped second separator layer (19) to the contact lugs (35, 36) of the segments of the first electrode (21, 22) or to the first separator layer (18) such that a strip-shaped composite element (50) is produced, wherein an active material (41, 42) of the segments of the first electrode (21, 22) is surrounded by the first separator layer (18) and by the second separator layer (19), and arranging a plurality of plate-shaped segments of a second electrode (21, 22) on the composite element (50). The invention further relates to an electrode unit for a battery cell, produced by the method according to the invention.

Owner:ROBERT BOSCH GMBH

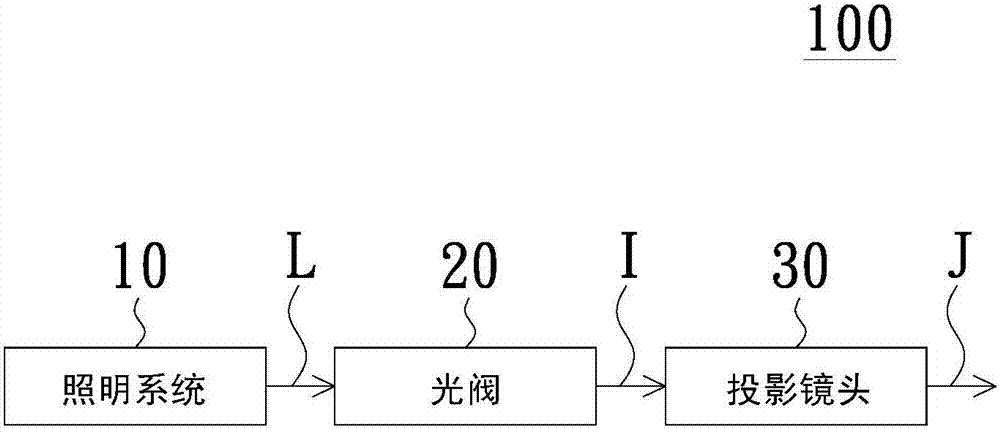

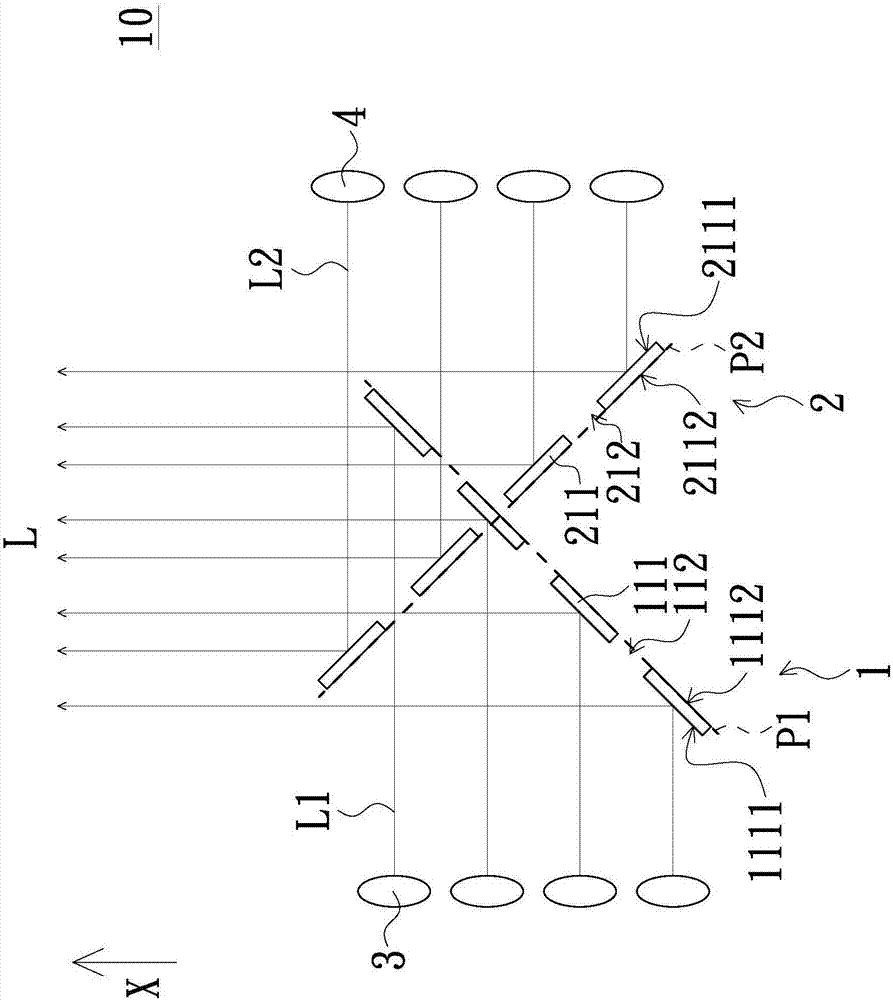

Projection system and illumination system

InactiveCN107463057AImprove optical qualityHigh image qualityProjectorsReflectorsImaging qualityLight reflection

The invention discloses a projection system, and the system comprises a first illumination integration element, a second illumination integration element, a plurality of first light source elements, and a plurality of second light source elements. The first illumination integration element is provided with a plurality of first light reflection regions which are separated from each other and are located on a first plane. The second illumination integration element is provided with a plurality of second light reflection regions which are separated from each other and are located on a second plane. The second plane is not parallel to the first plane. The first light source elements provide first light beams. The first light reflection regions are located on the transmission path of the first light beams, and the first light beams are reflected by the first light reflection regions and then move forwards in an illumination direction. The second light source elements provide second light beams. The second light reflection regions are located on the transmission path of the second light beams, and the second light beams are reflected by the second light reflection regions and then move forwards in an illumination direction. The illumination system is good in optical quality, and the projection system is good in imaging quality.

Owner:CORETRONIC

Radar sensor including waveguide structure

ActiveUS20220029281A1Easy to produceReduce manufacturing tolerancesWave based measurement systemsParticular array feeding systemsPhysicsEngineering

A radar sensor. The radar sensor includes a high-frequency component situated on a circuit board and a waveguide structure, which is connected via a coupling structure to the high-frequency component. The waveguide structure is formed in a mold, which is injection molded to a part of the circuit board supporting the high-frequency component.

Owner:ROBERT BOSCH GMBH

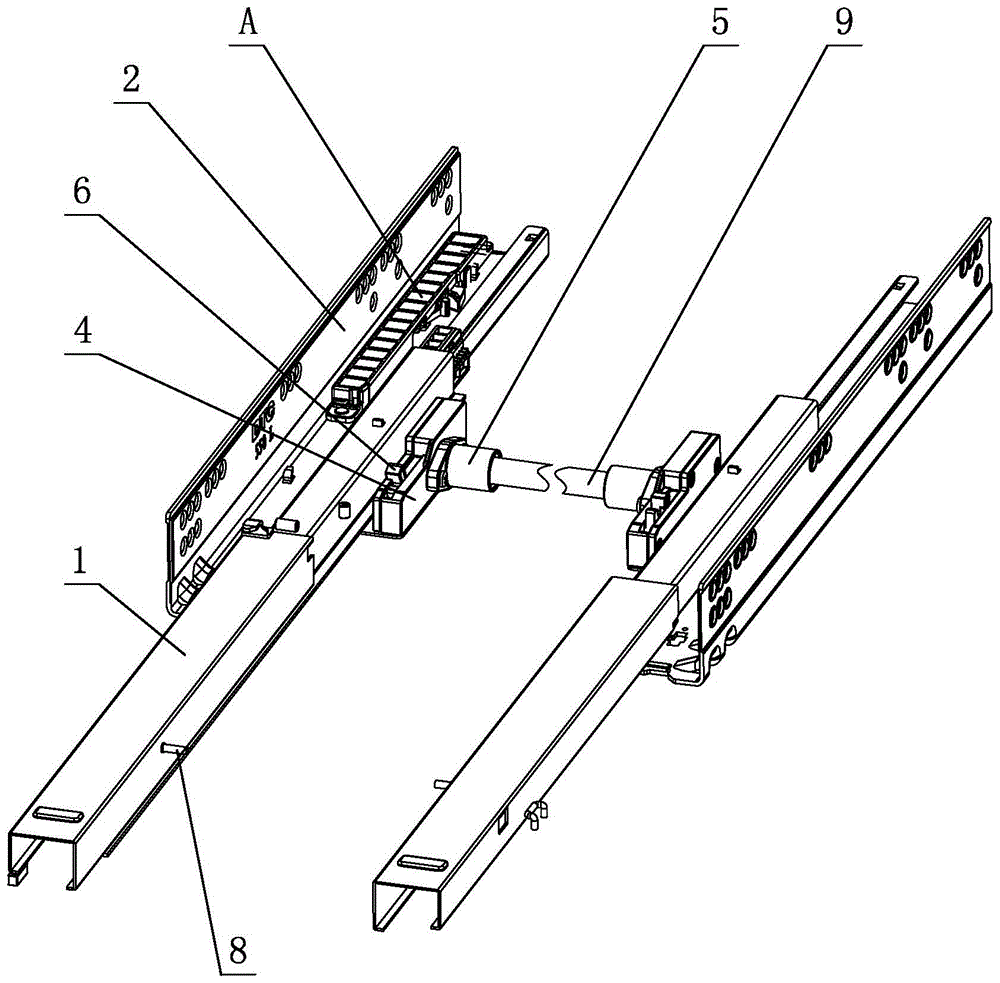

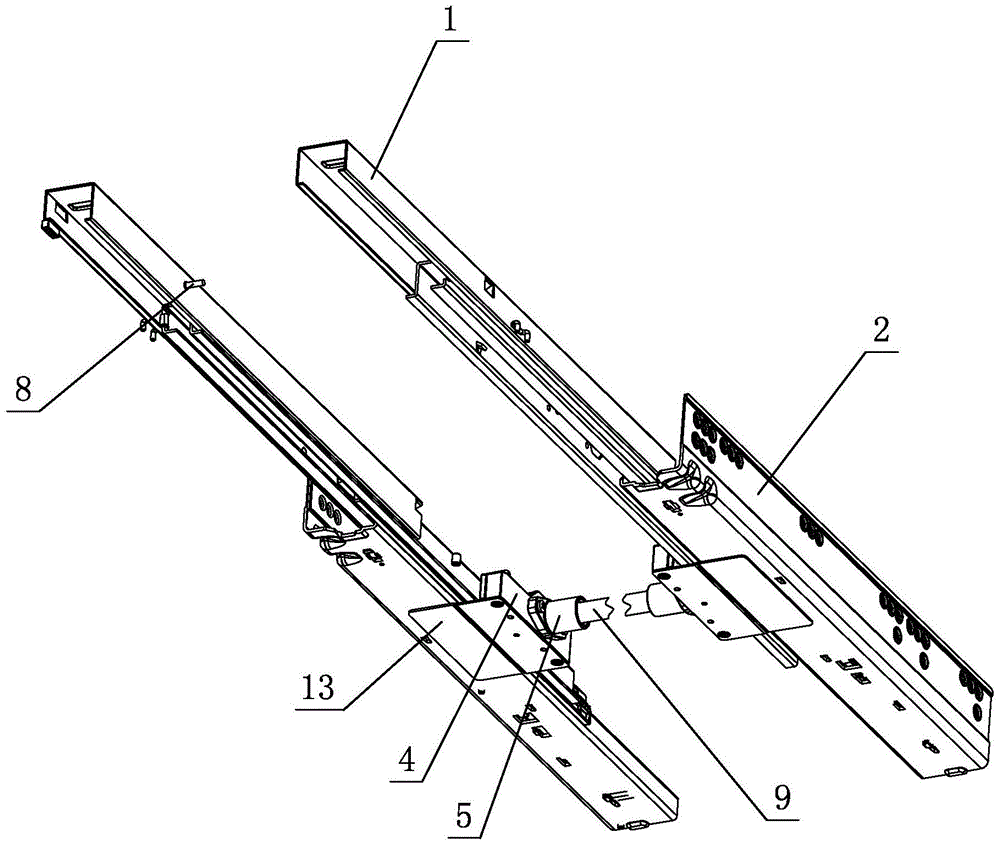

An Auxiliary Stabilizing Mechanism of a Drawer Slide Rail Synchronization Device

An auxiliary stabilization mechanism of drawer sliding rail synchronizers comprises sliding rail assemblies arranged on a left cabinet side board and a right cabinet side board respectively. Each sliding rail assembly comprises a movable sliding rail and a fixed sliding rail. The synchronizers are arranged on the movable sliding rails or the fixed sliding rails on the left side and the right side. Each synchronizer comprises a moving piece, a sliding groove seat and an auxiliary stabilization piece, wherein each moving piece is arranged on the corresponding sliding groove seat and provided with a rack, each sliding groove seat rotates relative to the corresponding rack and is provided with a gear component meshed with the corresponding rack in positioning mode, and each moving piece at least linearly slides on the corresponding sliding groove seat through meshing between the corresponding rack and the corresponding gear component. A shifting piece is arranged on each fixed sliding rail or each moving sliding rail, wherein at least one stroke of each shifting piece acts on the corresponding moving piece when the corresponding sliding rail assembly moves. A rotary connecting rod is arranged between the left gear component and the right gear component, and the left sliding rail assembly and the right sliding rail assembly are opened and closed synchronously through transmission connection between the gear components and the rotary connecting rod. One end of each auxiliary stabilization piece is arranged on a fixed part of a drawer, the other end of each auxiliary stabilization piece is arranged on the rotary connecting rod in a clearance and sleeve joint mode, and the rotary connecting rod is rotated in a positioned mode on the auxiliary stabilization pieces when the drawer is opened or closed.

Owner:伍志勇

Locking and separating system for furniture drawer front panel

ActiveCN104367012AEasy to assemble and disassembleQuick disassemblyDrawersEngineeringElectrical and Electronics engineering

A locking and separating system for a furniture drawer front panel comprises a fixing device arranged on a side plate. The front panel is connected with the fixing device through two connecting elements. Two sets of locking and separating mechanisms for locking and separating the connecting elements are arranged on the fixing device. Each locking and separating mechanism is provided with a finger-shaped element and an unlocking element which is in transmission connection with the finger-shaped element, wherein the finger-shaped element and the corresponding connecting element are locked and separated through movement of the unlocking element. The two sets of locking and separating mechanisms are independently and vertically arranged and do not interfere with each other when the locking and separating mechanisms and the corresponding connecting elements are locked and separated in a matched mode. Unlocking components are arranged on the locking and separating mechanisms, and the unlocking components jointly act on the unlocking elements of the two sets of locking and separating mechanisms successively, so that the finger-shaped elements are disengaged from the connecting elements, and the front panel is separated from the side plate. According to the structural improvement, the locking and separating system has the advantages of being simple and reasonable in structure, reliable in performance, firm in connection, low in manufacturing cost, rapid and convenient to disassemble and assemble, high in flexibility and practicability, and the like.

Owner:伍志勇

Synchronous pressing rebounding opening and closing structure used for furniture

The invention discloses a synchronous pressing rebounding opening and closing structure used for furniture. The structure comprises left and right sliding rail assemblies, each of the left and right sliding rail assemblies comprises a movable sliding rail and a fixed sliding rail in sliding opening and closing match, connectors are arranged on the left and right movable sliding rails, each connector is provided with a synchronous acting part and a pressing movable part which are independent from each other and form a certain gap, assembling parts are arranged on the left and right fixed sliding rails, and each assembling part is provided with a synchronous device and a pressing rebounding device which are independent from each other and form a certain gap; or the connectors are arranged onthe left and right fixed sliding rails, each connector is provided with the synchronous acting part and the pressing movable part which are independent from each other and form a certain gap, the left and right movable sliding rails are provided with the assembling parts, and each assembling part is provided with a synchronous device and a pressing rebounding device which are independent from each other and form a certain gap. The technical scheme has the advantages that the structure is simple and reasonable, the performance is reliable, the connection among the components is compact, the service life is long, the manufacturing cost is low, the assembly and disassembly are rapid and convenient and are high in flexibility, etc., and in addition, the practicability is strong.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Glass skylight framework structure

PendingCN110614906ANo problem of insufficient safety clearanceReduce manufacturing tolerancesRoofsSunroofSurface plate

The invention provides a glass skylight framework structure which comprises a glass panel and a guide rail, wherein the guide rail is located under the glass panel, and a guide rail groove is formed at the top of the guide rail; a glass framework which is located between the glass panel and the guide rail, wherein one end of the glass framework is connected with the glass panel, and the other endof the glass framework is bent downwards to form a connecting part; a supporting arm of which the top end is connected with the connecting part, and the bottom is arranged in the guide rail groove andis in sliding connection with the guide rail. The glass framework is provided with a slotting structure, and the slotting structure is located right above the supporting arm. The slotting structure is formed on the glass framework right above the supporting arm to avoid the supporting arm, so that the problem that a safety gap between the glass framework and the supporting arm is insufficient issolved, and the manufacturing and assembling difficulty of all parts is reduced.

Owner:SHANGHAI MOBITECH AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com